EVA (ethylene-vinyl acetate) wear-resistant nonflammable elastomer material and preparation method thereof

An elastomer material and flame-retardant technology, which is applied in the field of new wear-resistant and flame-retardant elastomer materials and its preparation, can solve the problems of flammability, poor wear resistance, and poor comfort, and achieves the advantages of less equipment investment and improved yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

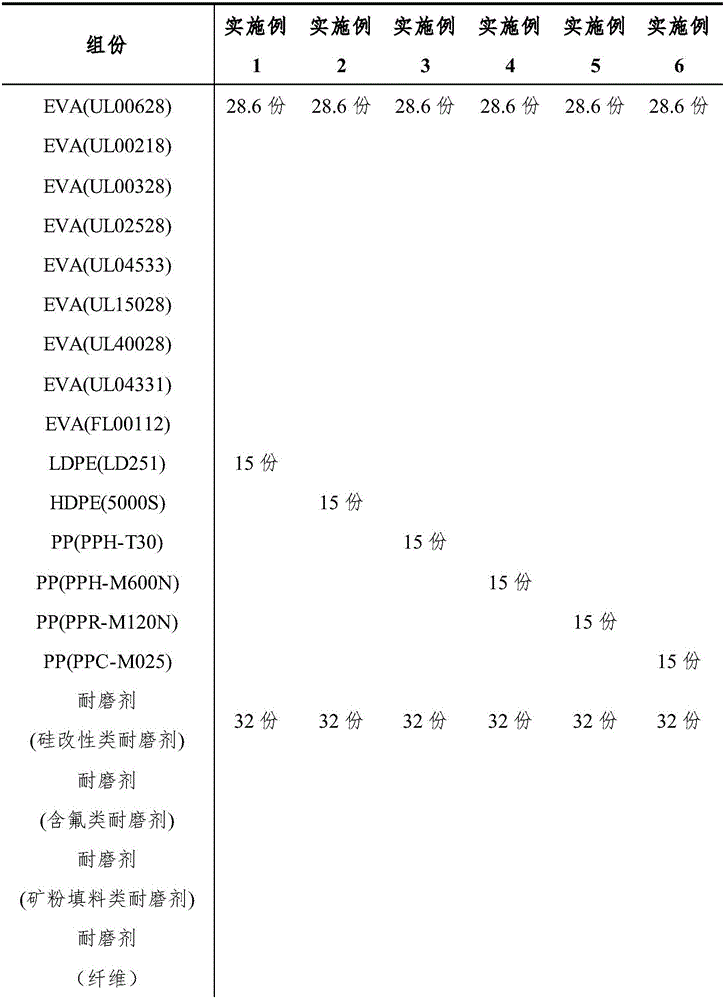

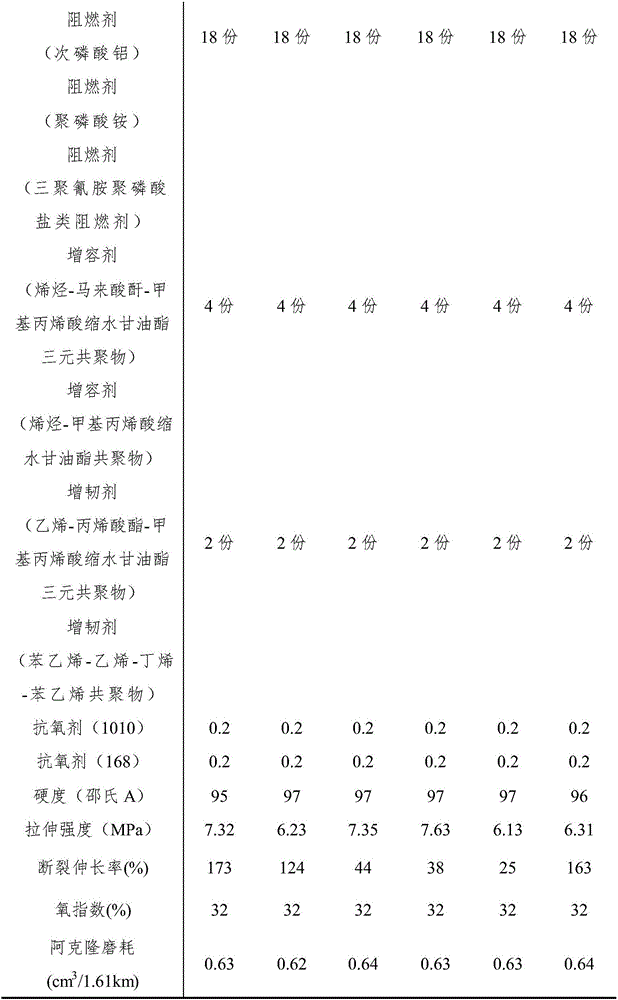

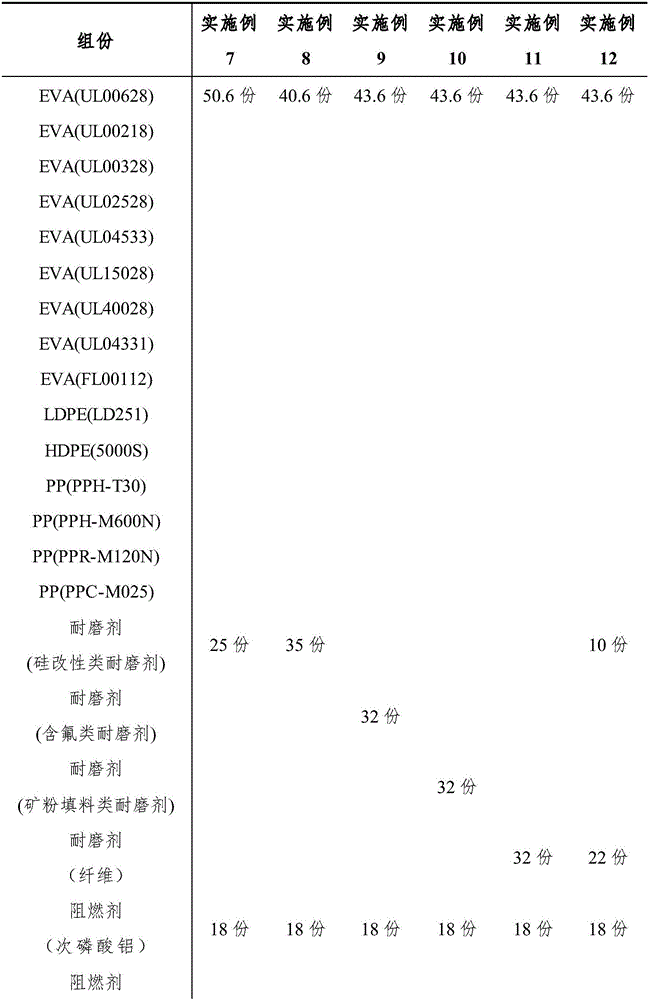

Embodiment 1

[0027] Mix EVA UL00628, LDPE LD251, anti-wear agent, flame retardant, compatibilizer, toughening agent and antioxidant according to the proportion, then add it to the internal mixer at 170°C, 120 rpm, and melt blend for 30 minutes , the obtained EVA wear-resistant and flame-retardant elastomer material was molded into blocks and then cut into national standard splines to measure its performance. The test results are shown in Table 1.

Embodiment 2

[0029] Mix EVA UL00628, HDPE 5000S, anti-wear agent, flame retardant, compatibilizer, toughening agent and antioxidant according to the proportion, then add it to the internal mixer at 170°C, 120 rpm, and melt blend for 30 minutes , the obtained EVA wear-resistant and flame-retardant elastomer material was molded into blocks and then cut into national standard splines to measure its performance. The test results are shown in Table 1.

Embodiment 3

[0031] Mix EVA UL00628, PP PPH-T30, wear-resisting agent, flame retardant, toughening agent and antioxidant according to the proportion, then add it to the internal mixer at 170°C, 120 rpm, and melt blend for 30 minutes to obtain The EVA wear-resistant and flame-resistant elastomer material was molded into blocks and then cut into national standard splines to measure its performance. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com