High-strength steel sheets and processes for production of the same

A high-strength steel plate and a manufacturing method technology, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of insufficient elongation, poor ductility, insufficient tensile flanging, etc., and achieve excellent elongation and tensile flanging. Excellent edge properties, elongation and stretch flanging properties, and excellent extrusion formability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

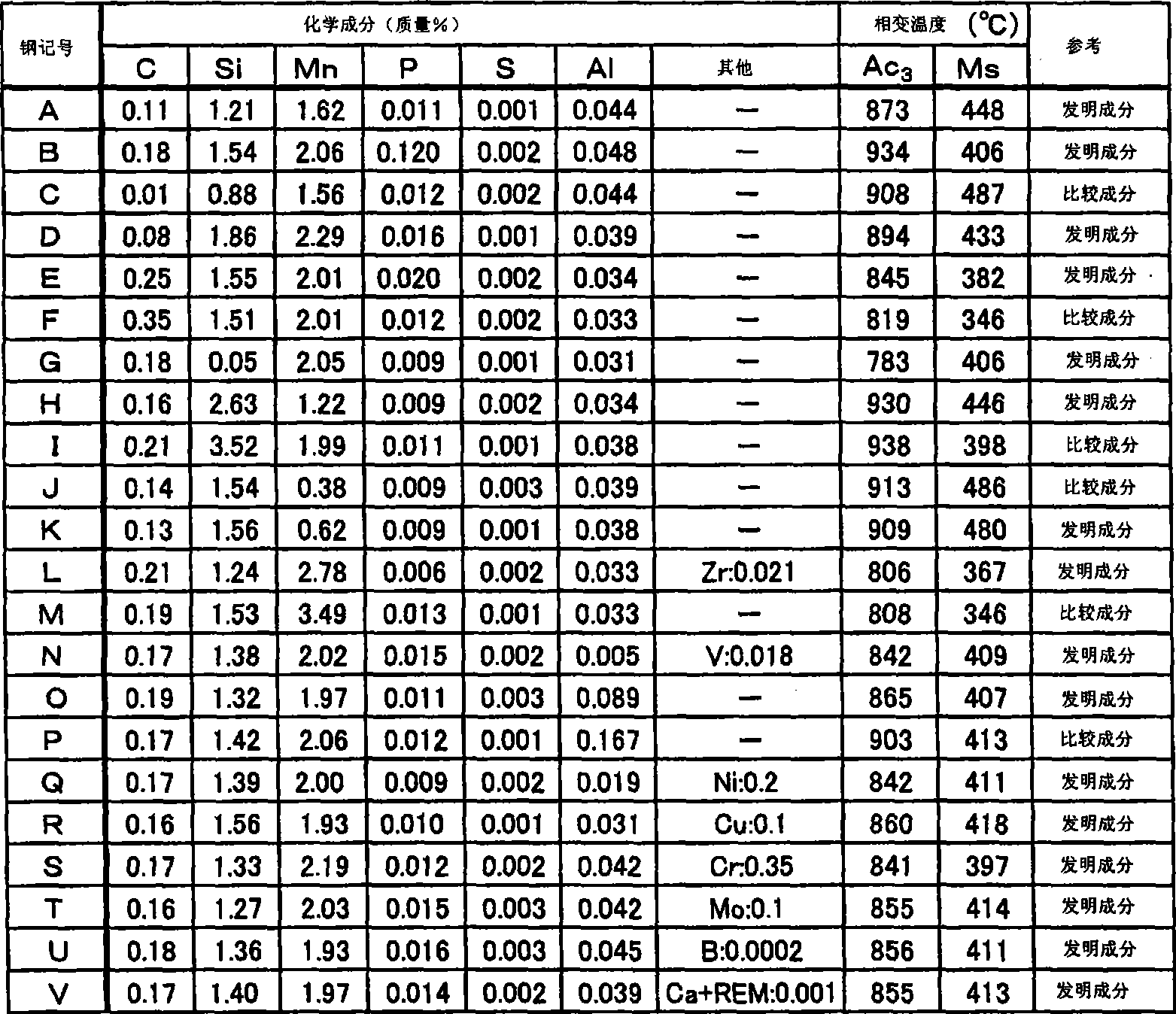

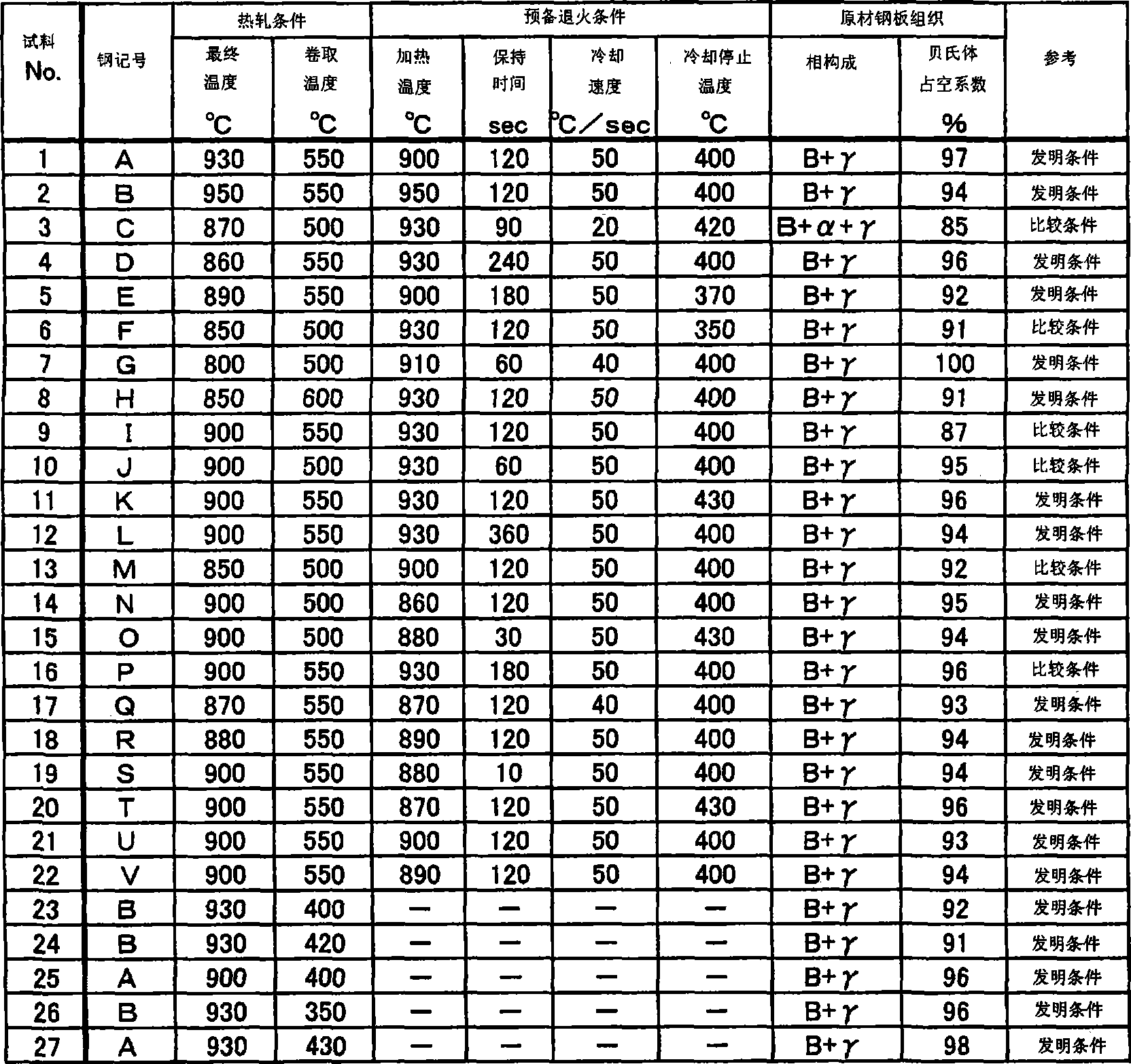

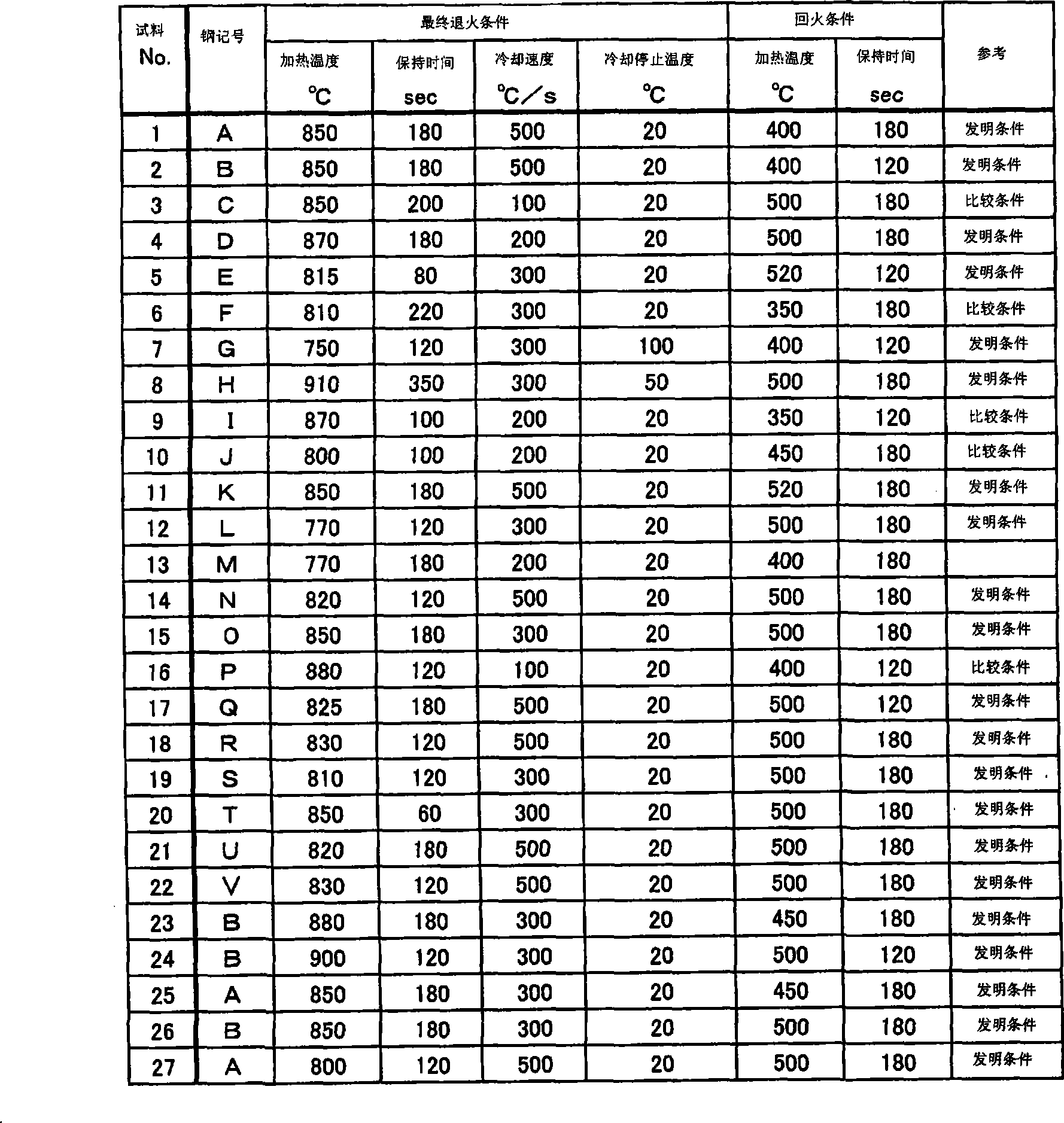

[0083] Steel slabs having chemical compositions shown in the following Table 1 were melted, and each steel slab was heated to about 1000-1100° C., hot rolled under the conditions of the following Table 2, or further subjected to preliminary annealing to produce raw steel sheets. The average cooling rate after hot rolling was 50° C. / sec. A microstructure observation test piece was extracted from each raw material steel plate, the microstructure was observed with a microscope, and the microscopic microstructure photograph after etchant corrosion was image-analyzed to measure the space factor of bainite. Table 1 shows the values of the Ac3 point and the Ms point calculated from the components using a known calculation formula and is also used as a reference. In addition, the organizational observation results are shown in combination with Table 2. Then, the final annealing (two-phase domain annealing) and tempering were performed on each of the obtained original steel sheets u...

Embodiment 2

[0130] Hereinafter, the operation and effect of the high-strength steel sheet and its manufacturing method according to the present embodiment will be described using examples.

[0131] First, a method for producing a test steel plate tested in this example will be described. In this example, tests were carried out on steel slabs having component compositions represented by steel symbols A to Y having the component compositions shown in Table 5. As shown in Tables 6 and 7, steel slabs composed of these components A to Y were made into 56 test steel plates in which the hot rolling conditions, pre-annealing conditions, annealing process and tempering process were changed, and the tensile strength of these test steel plates was measured. Strength, ductility, tensile flanging and other properties. B, C, E, F, I, J, L, and N to Y in the steel slabs of the component compositions of A to Y are steel slabs of the component compositions corresponding to the examples of the embodiment....

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com