Polyfluortetraethylene water-based emulsion, polyfluortetraethylene fine powder and preparation method

A polytetrafluoroethylene, water-based emulsion technology, applied in the field of chemical production, can solve the problem that the molecular weight of fluoropolymer is not high enough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

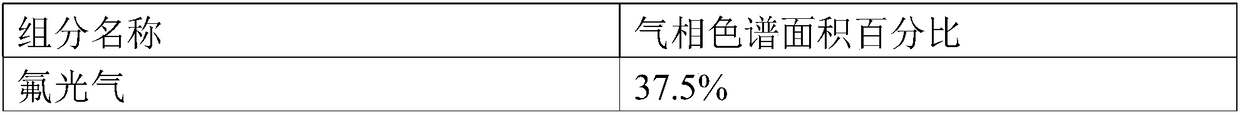

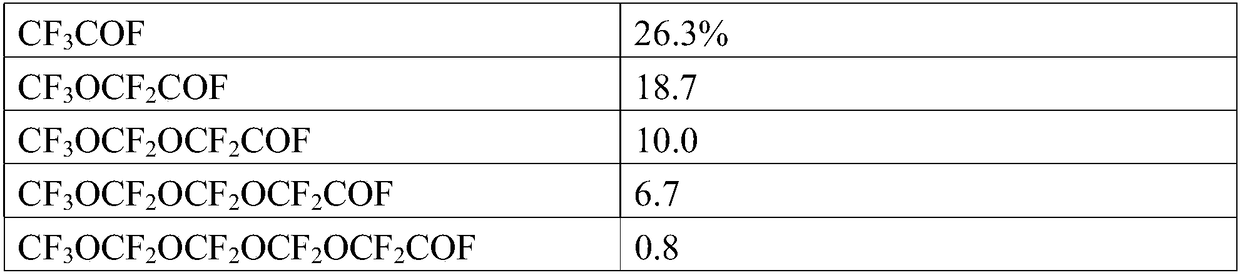

Method used

Image

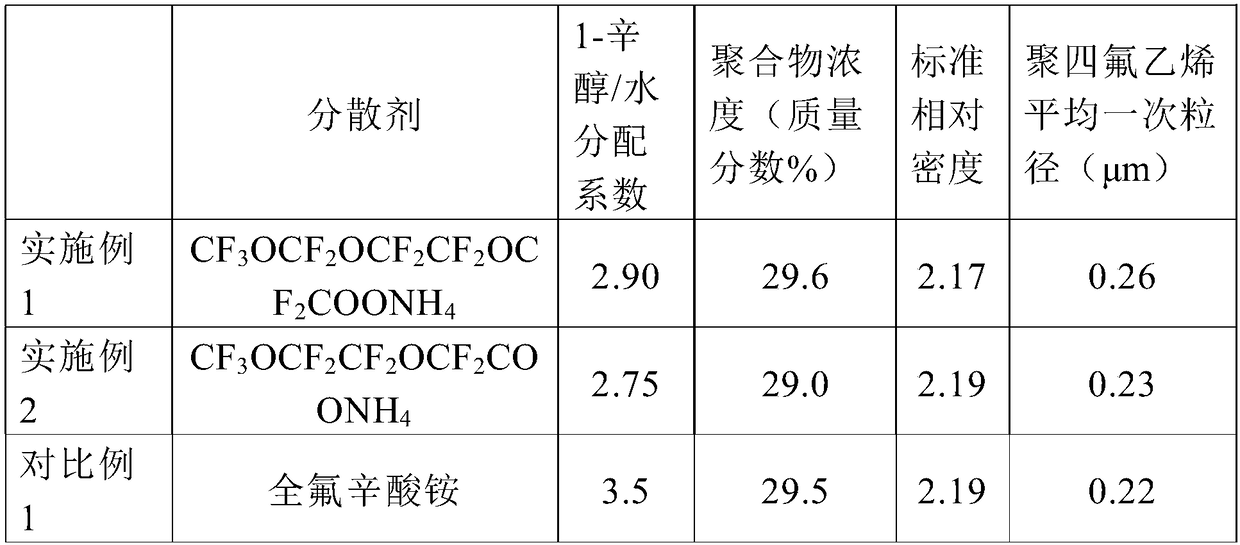

Examples

Embodiment 1

[0081] A preparation method of polytetrafluoroethylene aqueous emulsion, comprising the following steps:

[0082] (1) Add 20g of fluorine-containing emulsifier, 60g stabilizer, and 15L deionized water to a polymerization tank with a volume of 30L, then repeatedly press in nitrogen and remove under reduced pressure, so that the oxygen content in the polymerization tank is less than 30ppm;

[0083] (2) Stir the polymerization tank in step (1) and heat up to 70°C with 80 rpm, then press tetrafluoroethylene monomer until the internal pressure reaches 0.8MPa, then add 500g of ammonium persulfate aqueous solution with a mass fraction of 0.06%, Tetrafluoroethylene was added during the reaction to maintain the internal pressure at 0.8MPa;

[0084] (3) Supply tetrafluoroethylene monomer so that the solid mass fraction of the obtained aqueous dispersion is 30%, stop stirring, and empty the tetrafluoroethylene in the polymerization tank to obtain a polytetrafluoroethylene aqueous emulsio...

Embodiment 2

[0101] A preparation method of polytetrafluoroethylene aqueous emulsion, comprising the following steps:

[0102] (1) Add 20g of fluorine-containing emulsifier, 60g stabilizer, and 15L deionized water to a polymerization tank with a volume of 30L, then repeatedly press in nitrogen and remove under reduced pressure, so that the oxygen content in the polymerization tank is less than 30ppm;

[0103] (2) Stir the polymerization tank in step (1) at 80 rpm and heat up to 70°C, then press tetrafluoroethylene monomer until the internal pressure reaches 0.8MPa, then add 500g of ammonium persulfate aqueous solution with a mass fraction of 0.06%, Tetrafluoroethylene was added during the reaction to maintain the internal pressure at 0.8MPa;

[0104] (3) Supply tetrafluoroethylene monomer so that the solid mass fraction of the obtained aqueous dispersion is 30%, stop stirring, and empty the tetrafluoroethylene in the polymerization tank to obtain a polytetrafluoroethylene aqueous emulsion....

Embodiment 3

[0138] A preparation method of polytetrafluoroethylene aqueous emulsion, comprising the following steps:

[0139] (1) Add 20g of fluorine-containing emulsifier, 60g stabilizer, and 15L deionized water to a polymerization tank with a volume of 30L, then repeatedly press in nitrogen and remove under reduced pressure, so that the oxygen content in the polymerization tank is less than 30ppm;

[0140] (2) Stir the polymerization tank in step (1) and heat up to 70°C with 80 rpm, then press tetrafluoroethylene monomer until the internal pressure reaches 0.8MPa, then add 500g of ammonium persulfate aqueous solution with a mass fraction of 0.06%, Tetrafluoroethylene was added during the reaction to maintain the internal pressure at 0.8MPa;

[0141] (3) Supply tetrafluoroethylene monomer so that the solid mass fraction of the obtained aqueous dispersion is 30%, stop stirring, and empty the tetrafluoroethylene in the polymerization tank to obtain a polytetrafluoroethylene aqueous emulsion....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com