High gloss glass fiber reinforced ABS/PC material for extrusion process and preparation method thereof

An extrusion process and ABS resin technology, applied in the field of ABS/PC materials for high-gloss extrusion process and their preparation, can solve the problems affecting the apparent quality of products, glass fiber exposure, etc., and achieve great economic value and social value, Excellent extrusion formability and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

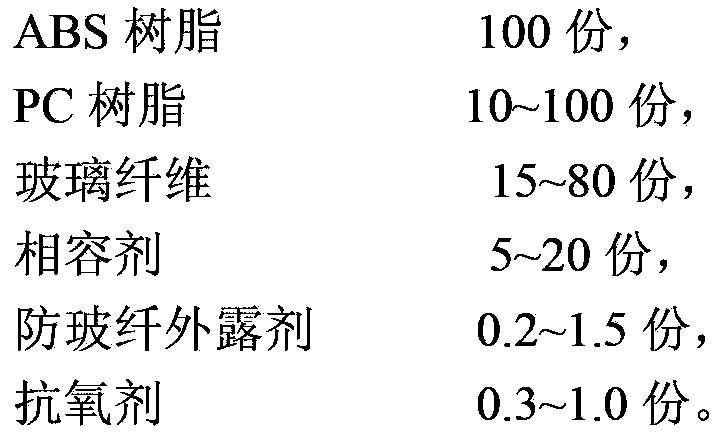

[0027] (1) Weigh the raw materials of each component according to the following parts by weight:

[0028] ABS resin (flow coefficient 6.5) 100 parts,

[0029] PC resin (melt index 40g / 10min) 10 parts,

[0030] Glass fiber (diameter 7μm) 20 parts,

[0031] ABS-g-MAH 5 parts,

[0032] TAF 0.2 parts,

[0033] Antioxidant 1076 0.1 parts,

[0034] Antioxidant 168 0.2 parts;

[0035] Mix the above raw materials at high speed with a high-speed mixer, control the speed of the high-mixer to 700rmp, the mixing temperature to 80°C, and mix for 3 minutes;

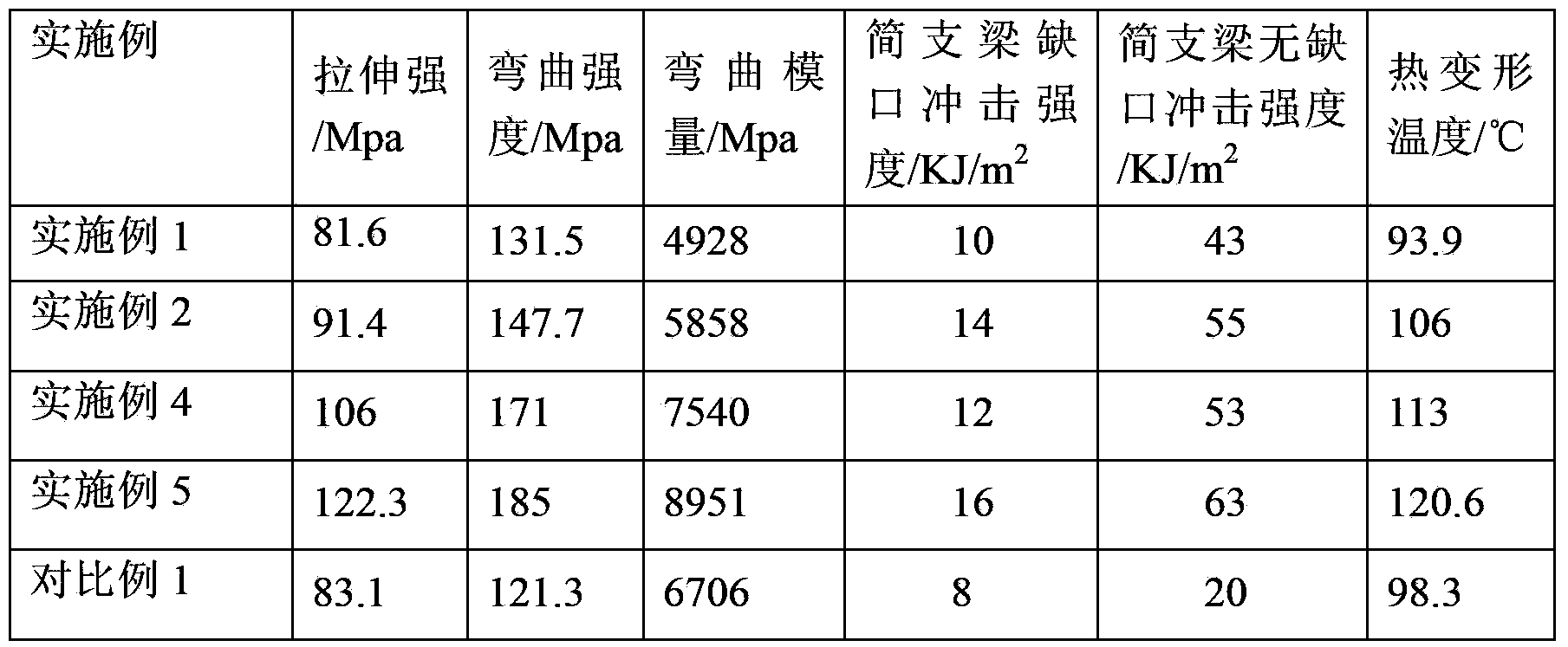

[0036] (2) Pass the mixed material through a twin-screw extruder. The temperature of each zone is controlled at 190-220 ° C. The extruder strands are cut into pellets to obtain ABS / PC materials. The mechanical properties of the test are shown in Table 1.

Embodiment 2

[0038] (1) Weigh the raw materials of each component according to the following parts by weight:

[0039] ABS resin (flow coefficient 4.5) 100 parts,

[0040] PC resin (melt index 30g / 10min) 20 parts,

[0041] Glass fiber (diameter 11μm) 32 parts,

[0042] SMA 8 parts,

[0043] Silicone powder 0.5 part,

[0044] Antioxidant 1010 0.2 parts,

[0045] Antioxidant 168 0.3 parts;

[0046] The above raw materials were mixed at high speed by a high-speed mixer, the speed of the high-mixer was controlled to 700rmp, the mixing temperature was 60°C, and the mixing was carried out for 6 minutes;

[0047] (2) Pass the mixed material through a twin-screw extruder, and control the temperature of each zone at 195-230°C, and pelletize the strands to obtain ABS / PC materials. The mechanical properties of the test are shown in Table 1.

Embodiment 3

[0049] (1) Weigh the raw materials of each component according to the following parts by weight:

[0050] ABS resin (flow coefficient 3.4) 100 parts,

[0051] PC resin (melt index 18g / 10min) 30 parts,

[0052] 20 parts of glass fiber (10μm in diameter),

[0053] ABS-g-MAH 10 parts,

[0054] PE wax 0.3 part,

[0055] Antioxidant 1076 0.2 parts,

[0056] Antioxidant 168 0.4 parts;

[0057] The above raw materials were mixed at a high speed by a high-speed mixer, the speed of the high-mixer was 700rmp, the mixing temperature was 60°C, and the mixture was mixed for 5 minutes;

[0058] (2) Pass the mixed material through a twin-screw extruder, and control the temperature of each zone at 220-235°C, and then pelletize the strands to obtain ABS / PC materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com