Basalt reinforced LCP composite material and preparation process thereof

A composite material and preparation process technology, which is applied in the field of new plastic materials to achieve the effects of increasing tensile strength, high tensile strength, and easy recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

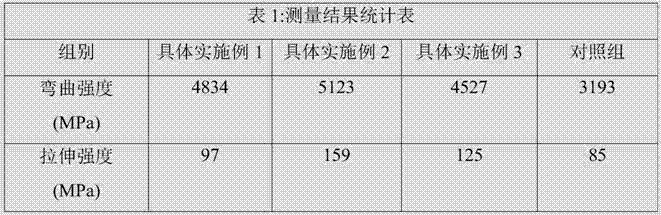

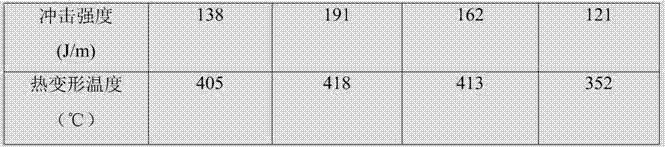

specific Embodiment 1

[0026] Basalt reinforced LCP composite material, including the following components in parts by weight, 70 parts of LCP, 12 parts of basalt fiber, 0.7 parts of heat-resistant agent, 3 parts of coupling agent, 4 parts of main antioxidant, 2 parts of auxiliary antioxidant, 1.5 parts of compatibilizer, 0.8 parts of lubricant, 4 parts of flame retardant, 2 parts of flame retardant synergist.

specific Embodiment 2

[0028] Basalt reinforced LCP composite material, including the following components in parts by weight, 59 parts of LCP, 20 parts of basalt fiber, 0.7 parts of heat-resistant agent, 6 parts of coupling agent, 4 parts of main antioxidant, 2 parts of auxiliary antioxidant, 1.5 parts of compatibilizer, 0.8 parts of lubricant, 4 parts of flame retardant, 2 parts of flame retardant synergist.

specific Embodiment 3

[0030] Basalt reinforced LCP composite material, including the following components in parts by weight, 48 parts of LCP, 28 parts of basalt fiber, 0.7 parts of heat-resistant agent, 9 parts of coupling agent, 4 parts of main antioxidant, 2 parts of auxiliary antioxidant, 1.5 parts of compatibilizer, 0.8 parts of lubricant, 4 parts of flame retardant, 2 parts of flame retardant synergist.

[0031] Control group 1: LCP without basalt fiber reinforcement

[0032] LCP composite material, including the following components in parts by weight, 85 parts of LCP, 4 parts of primary antioxidant, 2 parts of auxiliary antioxidant, 1.5 parts of compatibilizer, 0.8 part of lubricant, 4 parts of flame retardant, flame retardant Synergist 2 parts.

[0033] In the above examples and the control group, the basalt fiber is a continuous fiber with an aspect ratio of 1500; the heat-resistant agent is N,N'-4,4'-diphenylmethane bismaleimide; the coupling agent is silane coupling agent; the main an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com