Polyamide based resin composition having excellent whiteness, thermal conductivity, and extruding moldability, and preparation method and product thereof

A technology of polyamide resin and thermoplastic resin, applied in the field of polyamide-based resin composition and preparation and products with excellent whiteness, thermal conductivity and extrusion formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0075] Example

[0076] The compounds used in Examples and Comparative Examples are as follows.

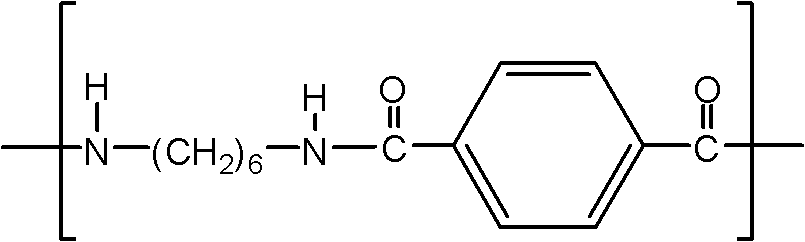

[0077] (A) polyamide resin

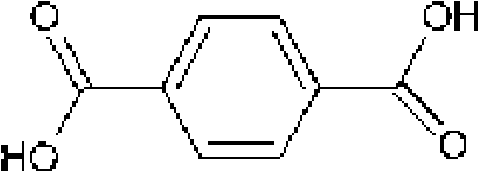

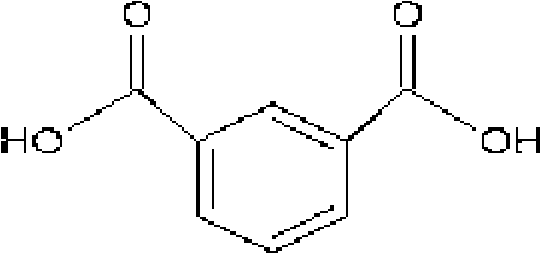

[0078] A polyamide resin containing 100 parts by weight of dicarboxylic acid and 100 parts by weight of 1,6-diaminohexane consisting of 60 wt% of terephthalic acid and 40 wt% of adipic acid was used.

[0079] (B) Boron nitride is used for thermal conductivity and whiteness.

[0080] (C) Using glass fiber as a filler.

[0081] (D) Polymethyl methacrylate having a weight average molecular weight of 1,250,000 is used as a thermoplastic resin having compatibility with polyamide and a weight average molecular weight of 500,000 to 5,000,000.

[0082] (E) Titanium dioxide is used as a white pigment.

[0083] Each polyamide thermoplastic resin (Examples 1-6, Comparative Examples 1-6) was prepared by mixing each compound according to the mixing ratio in Table 1 below, thermal conductivity was measured according to ASTM E 1530, and whiteness was also measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com