Wire, cable, and composition

A composition and wire technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of decreased mechanical strength such as tensile strength, difficulty in extrusion molding, increase in compound viscosity, etc., and achieves good appearance and excellent wear resistance. The effect of high-performance, low-friction tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

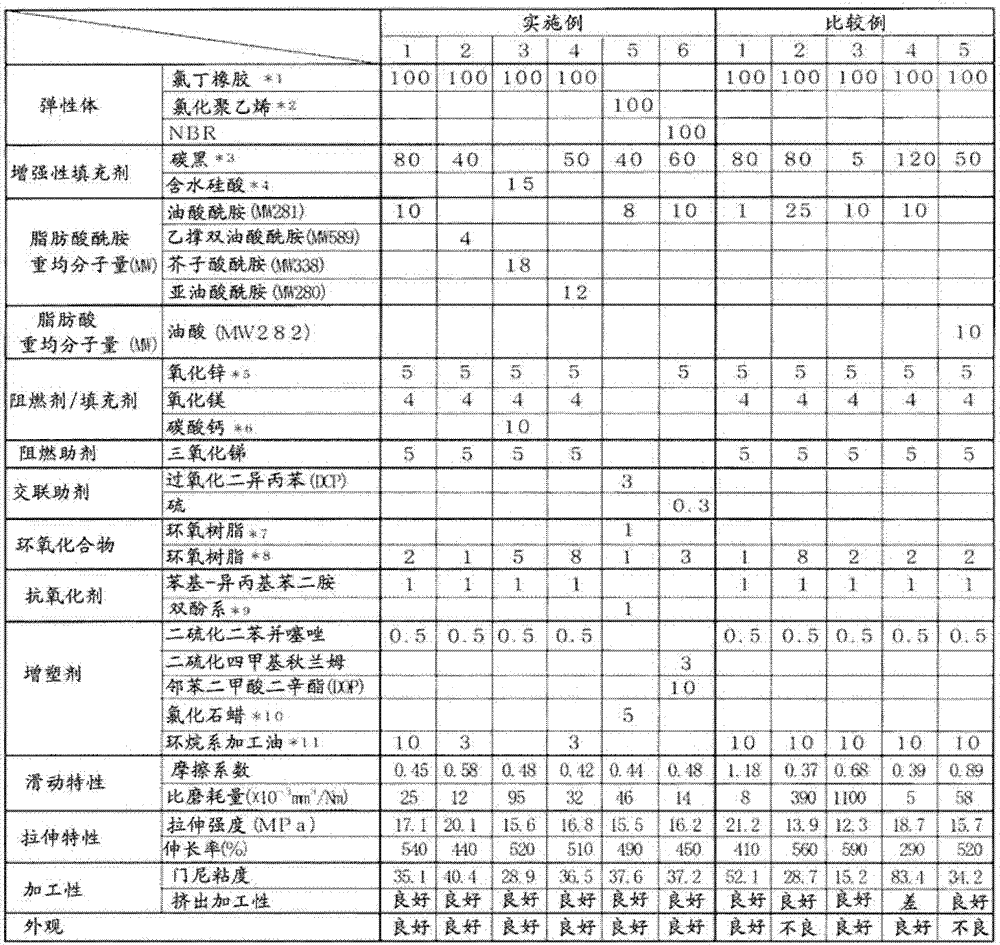

[0049] Hereinafter, it demonstrates combining the Example of this invention and a comparative example.

[0050] Table 1

[0051] (combination: parts by mass)

[0052]

[0053] *1 Shoprene W (シヨウプレンW) (manufactured by Showa Denko) *2 Elastollan 410A (エラストラン410A) (manufactured by Showa Denko)

[0054] *3 Asahi Carbon #80 (manufactured by Asahi Carbon Co., Ltd.) *4 Carplex# 100 (カ一プレツクス#100) (manufactured by Shionogi Pharmaceutical Co., Ltd.)

[0055] *5 Zinc oxide (manufactured by Sakai Chemical Industry Co., Ltd.) *6 LIGHTON BS-O (Rayton BS-O) (manufactured by Bihoku Powder Chemical Industry Co., Ltd.)

[0056] *7 EPON 828 (manufactured by SHELL Chemical Co., Ltd.) *8 Epikote 828 (manufactured by Yuhua Shell Epoxy Co., Ltd.)

[0057] *9 Nocrac NS-30 (ノクラツクNS-30) (manufactured by Ouchi Shinko Chemical Industry Co., Ltd.) *10 Chlorinated paraffin 40 (塩para40) (manufactured by Ajinomoto Co., Ltd.)

[0058] *11 371JY (manufactured...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com