Honeycomb nest hydrogenation protecting agent

A hydrogenation protective agent and honeycomb technology, which is applied in the field of honeycomb bird's nest hydrogenation protective agent, can solve the problems of unstable center of gravity, large porosity, reduced efficiency of capturing impurities, etc., and achieves improved strength and service life, high fever The effect of improving the qualified rate and improving the catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]The strengthening protective agent formula of the present invention: 40% of alumina powder, 40% of kaolin, 5% of talcum powder, 10% of clay, 4% of alkaline solvent material, and 1% of auxiliary material.

[0037] The alkaline solvent material in the present invention is a mixture of albite, potassium feldspar, calcium carbonate and magnesium carbonate; the auxiliary material in the present invention is cellulose.

[0038] The present invention also provides a method for preparing the above-mentioned bird's nest proppant, the preparation steps comprising:

[0039] (1) Mud formula: weigh each raw material according to the formula ratio;

[0040] (2) Mixing: Put the powder formed by mixing the raw materials in step (1) into a kneader or a mixer, add water (15% of the weight of the powder) and oil (such as waste oil and rapeseed oil, which can be used as a powder) 5% of material weight) carry out mud kneading, obtain the evenly mixed mud;

[0041] (3) extruding the process...

Embodiment 2

[0044] The raw materials for the preparation of hydrogenation protective agent: 30% of alumina powder, 40% of kaolin, 10% of talcum powder, 15% of clay, 3% of alkaline solvent material, and 2% of auxiliary materials. The preparation steps are the same as in Example 1.

Embodiment 3

[0046] The raw materials for the preparation of the hydrogenation protecting agent mainly include: 50% of alumina powder, 30% of kaolin, 5% of talcum powder, 10% of clay, 4% of alkaline solvent material and 1% of auxiliary material. The preparation steps are the same as in Example 1.

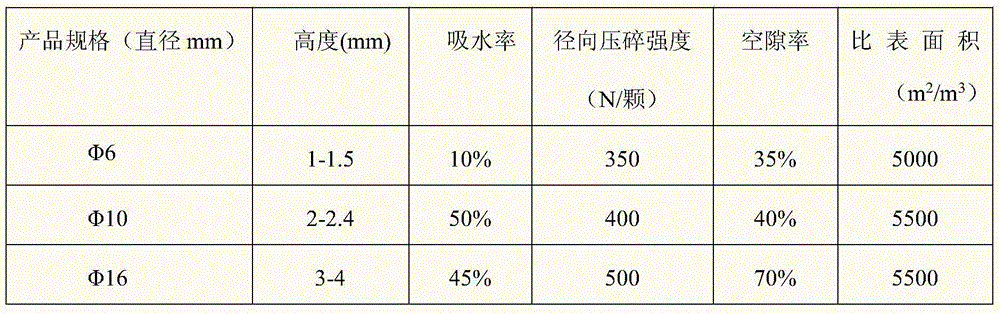

[0047] Table 1 Performance and specifications of the sample of the embodiment of the present invention

[0048]

[0049] Note: The radial crushing strength in the above table 1 is a hydrogenated protective agent with a certain diameter and height, and the length is the strength that can be withstood by the pressure applied at both ends of the axial direction.

[0050] It can be seen from the above examples that the product of the present invention will have more and denser through holes in its unit cross-sectional area, which can greatly increase the external specific surface area of the product, reaching 5000m 2 / m 3 Above, make the reaction raw material and protective agent have larger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com