Energy-saving supporting piece for domestic ceramic firing and preparation method of supporting piece

An energy-saving and support technology, which is applied in the field of kiln furniture, can solve the problems of large ceramic glaze bonding damage, inconvenient and quick loading and unloading of workers, and large consumables for shed boards and pillars, so as to achieve convenient and quick loading and unloading and improve the overall appearance performance, uniform heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The above-mentioned method for preparing an energy-saving support for firing daily-use ceramics is characterized in that it comprises the following steps:

[0036] a Raw material equipment

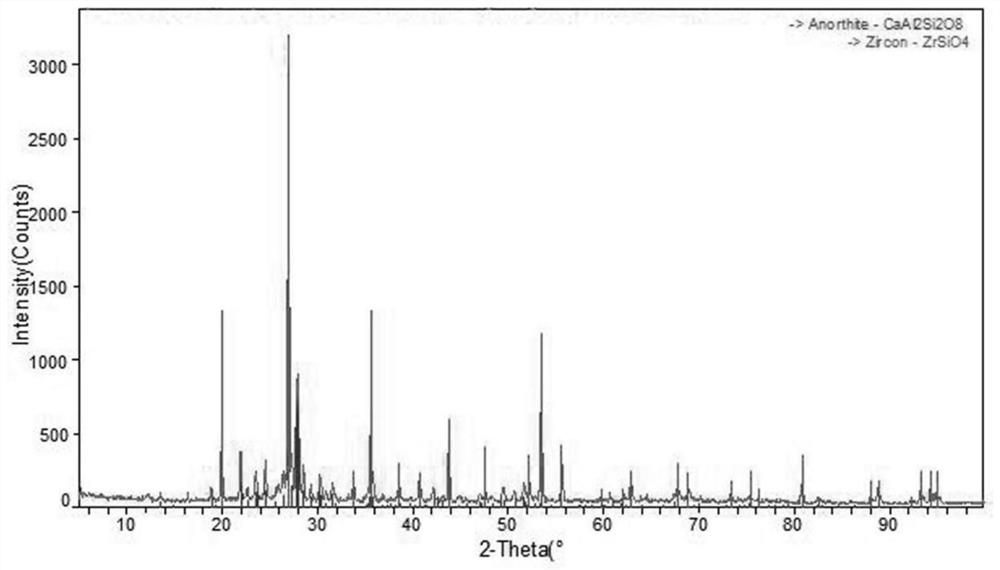

[0037] The raw materials are composed of the following components by weight percentage: 15-25% of mullite material; 5-10% of bauxite; 10-20% of calcium carbonate; 10-20% of zircon sand; 30-45% of clay; yellow paste Fine 0.1-0.4%;

[0038] b mixed rolling

[0039] Put all the raw materials prepared in step a in a high-speed mixer, dry-mix for 3-5 minutes first, then add water to the dry-blended raw materials and mix for 2-3 minutes, and then put them in the mixer for rolling and mixing Sufficient; high-speed dry mixing makes the raw materials mix more evenly, rolling wet mixing, so that the powder in the raw materials can fully wrap the aggregate, and rolling compactly;

[0040] c sleepy material

[0041] Place the mixed and rolled raw materials in step b in a container, close th...

Embodiment 1

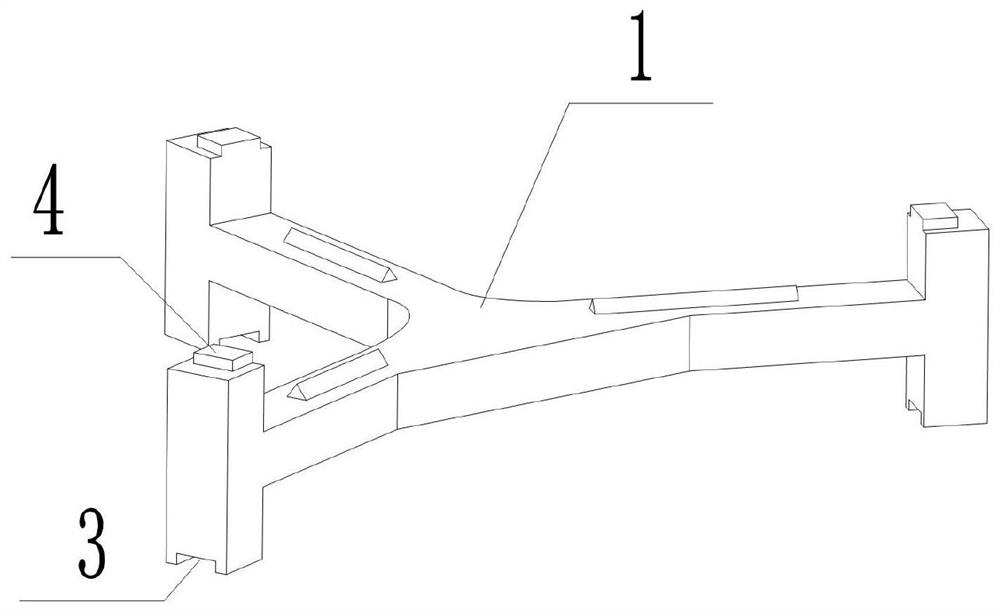

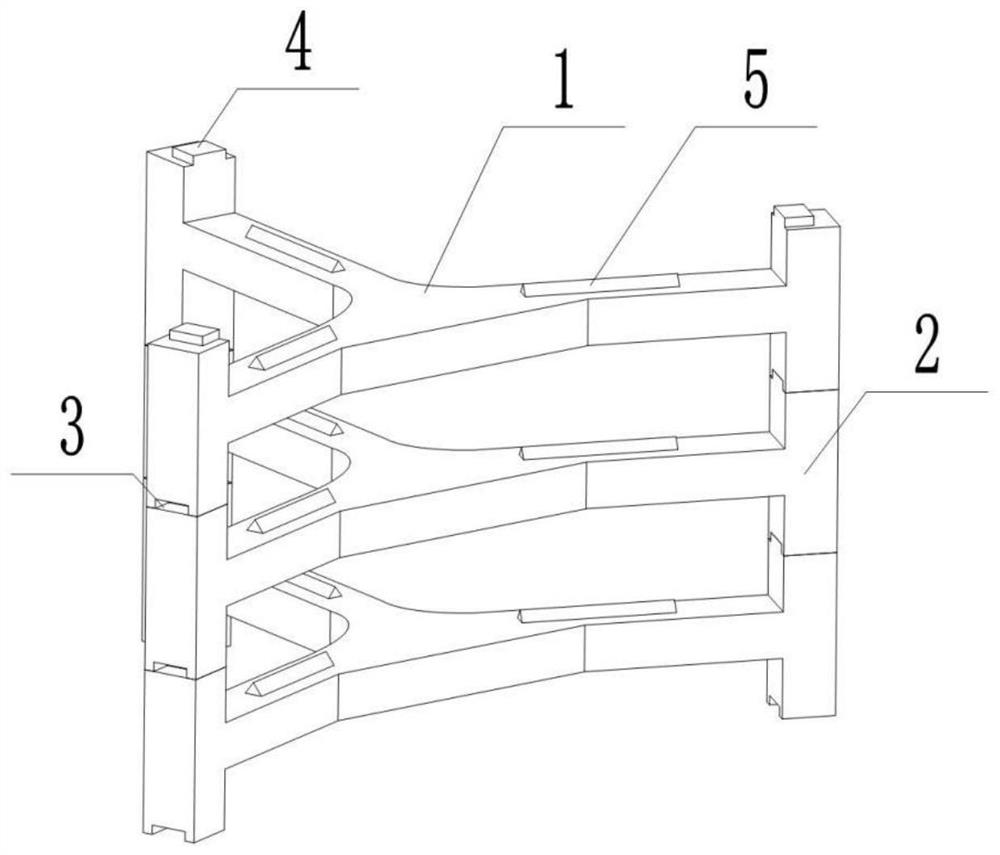

[0059] Such as Figure 1 to Figure 3 As shown in the figure, an energy-saving supporting member for firing ceramics for daily use includes a number of Y-shaped brackets 1 stacked up and down. The three ends of the Y-shaped bracket 1 are connected with vertical legs 2. The Y-shaped bracket 1 The top surface is connected with three protruding ribs 5 distributed in a Y shape, and the ceramic to be fired is attached to the upper end of the protruding ribs 5 on the Y-shaped support 1 .

[0060] The top surface of the leg 2 is provided with a card block 4, the bottom surface of the leg 2 is provided with a card slot 3, and the card slot 3 of the upper Y-shaped bracket 1 of the two adjacent Y-shaped brackets 1 is snapped into the lower Y-shaped bracket. 1 in the card block 4.

[0061] The above-mentioned method for preparing an energy-saving support for firing daily-use ceramics is characterized in that it comprises the following steps:

[0062] a Raw material equipment

[0063] T...

Embodiment 2

[0082] Such as Figure 1 to Figure 3 As shown in the figure, an energy-saving supporting member for firing ceramics for daily use includes a number of Y-shaped brackets 1 stacked up and down. The three ends of the Y-shaped bracket 1 are connected with vertical legs 2. The Y-shaped bracket 1 The top surface is connected with three protruding ribs 5 distributed in a Y shape, and the ceramic to be fired is attached to the upper end of the protruding ribs 5 on the Y-shaped support 1 .

[0083] The top surface of the leg 2 is provided with a card block 4, the bottom surface of the leg 2 is provided with a card slot 3, and the card slot 3 of the upper Y-shaped bracket 1 of the two adjacent Y-shaped brackets 1 is snapped into the lower Y-shaped bracket. 1 in the card block 4.

[0084] The above-mentioned method for preparing an energy-saving support for firing daily-use ceramics is characterized in that it comprises the following steps:

[0085] a Raw material equipment

[0086] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com