Improved ceramic core firing method

A ceramic core and firing technology, applied in the field of investment precision casting, can solve problems such as long time, save energy, expand the scope of application, and shorten the firing cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

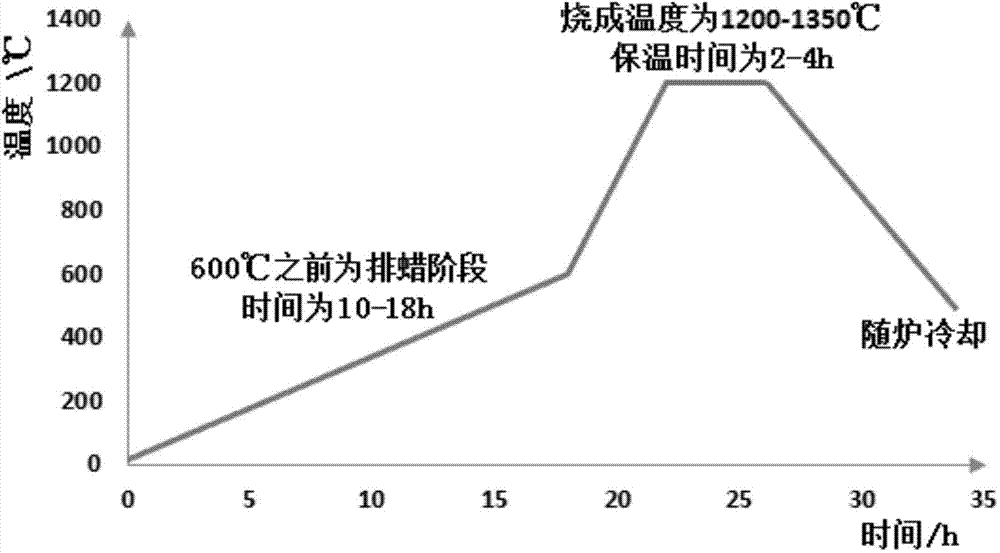

Embodiment 1

[0013] Take and attach image 3 The green ceramic core body shown, put it in the drain basket, and then place the drain basket in the container containing n-heptane until the green ceramic core body is completely immersed in n-heptane, soak it at room temperature for 90 minutes Then take it out and dry the remaining liquid on the surface in a cool and ventilated place, then put it in a crucible and fill it with alumina powder around it, and then place the crucible on a shaking platform to shake it. Next, put the crucible into the ceramic core baking furnace and press figure 2 In the system shown for roasting, the heating rate in the wax removal stage is 3°C / min, the firing temperature is 1200°C, and the holding time is 2h. After the firing is completed, the furnace is cooled to 200°C, the furnace door is opened, and the furnace is cooled to below 60°C before leaving the kiln.

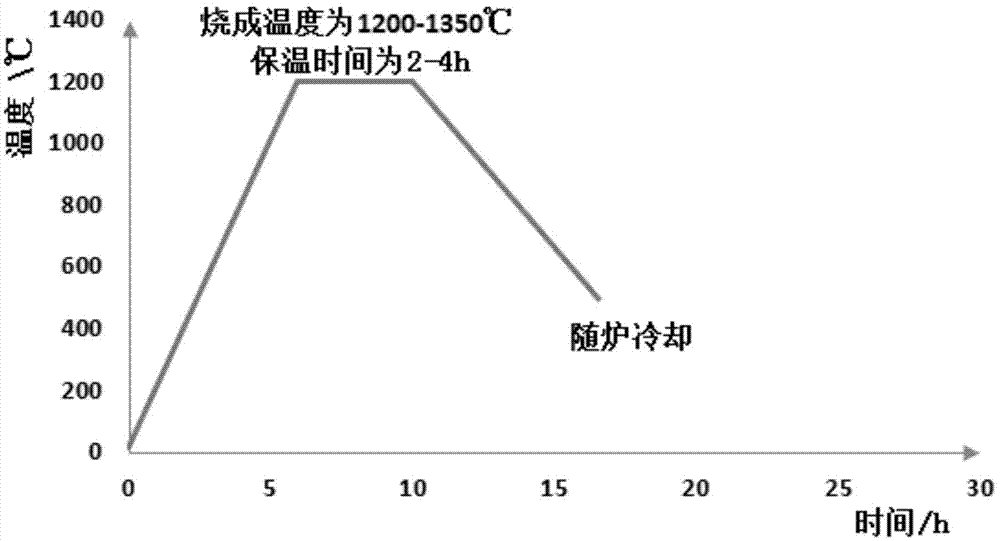

Embodiment 2

[0015] Take and attach Figure 4 The green ceramic core body shown, put it in the drain basket, and then place the drain basket in the container containing n-heptane until the green ceramic core body is completely immersed in n-heptane, refer to figure 2 After soaking at room temperature for 15 minutes, take it out, and dry the residual liquid on the surface in a cool and ventilated place, then put it in a crucible and fill it with alumina powder around it, and then place the crucible on a shaking platform to shake it. Next, put the crucible into the ceramic core baking furnace and press figure 2 In the shown system of roasting, the heating rate in the waxing stage is 3.3°C / min, the firing temperature is 1350°C, and the holding time is 3h. After the firing is completed, the furnace is cooled to 200°C, the furnace door is opened, and the furnace is cooled to below 60°C before leaving the kiln.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com