Sleeve type flushing reduction flow equalization disc

A sleeve-type, flow-disc technology, applied in chemical/physical processes, chemical instruments and methods, etc., can solve the problems that affect the effect of the hydrogenation reactor distributor, the uneven depth of the liquid layer on the distribution plate, and the ability to resist the inclination of the tray. Weak and other problems, to achieve the effect of saving reactor space, optimizing material distribution, and smoothing the liquid layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

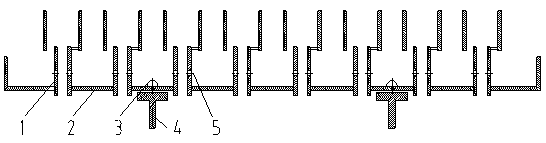

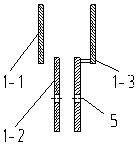

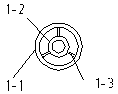

[0064] After the transformation, the sleeve-type shock-reducing equalizing plate of the present invention is added in the upper head, using such as figure 1 The sleeve-type shock-reducing equalizer shown is used in combination with a common ERI-type bubble-cap gas-liquid distributor. The main parameters of the sleeve-type flow equalizer: the height of the impact reduction cylinder is preferably 300mm; the diameter of the impact reduction cylinder is preferably 150mm; the upper edge of the impact reduction cylinder is provided with triangular slots, and the height of the tooth grooves is 10% of the height of the impact reduction cylinder. The horizontal gap between the impact reduction cylinder and the chimney distributor is preferably 30mm; the cross-sectional area of the impact reduction cylinder is 5 times the cross-sectional area of the chimney distributor; the bottom edge of the impact reduction cylinder overlaps with the chimney distributor; the overlapping position is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com