Method for grading catalyst for hydrogenation treatment

A hydroprocessing and catalyst technology, which is applied in the treatment of hydrocarbon oil, hydrocarbon oil cracking, petroleum industry, etc., can solve the problems of increasing radial temperature difference, affecting the service life of the catalyst, and exacerbating the bias flow of heavy raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

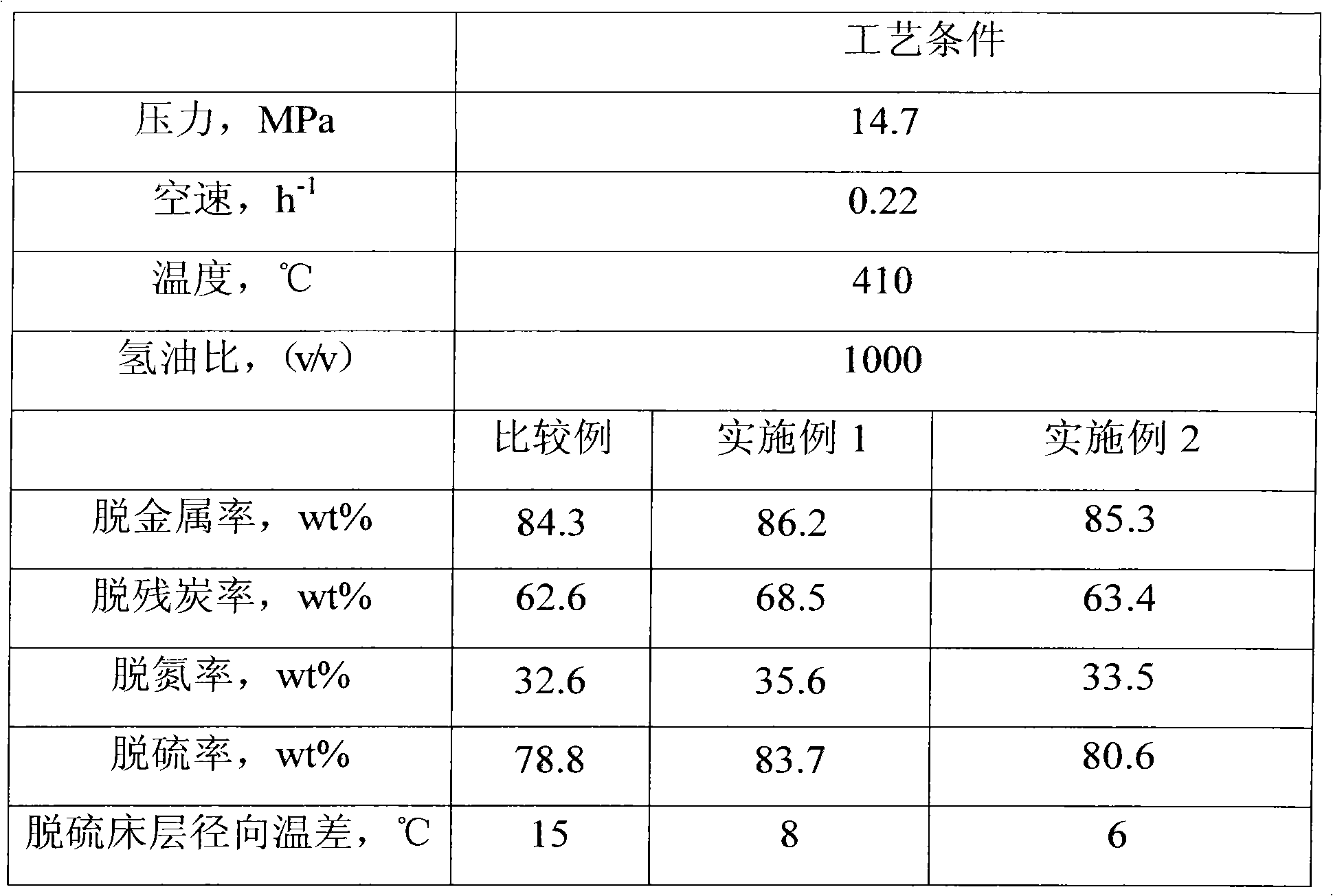

[0017] In the 3-meter-high hydrogenation reactor, the residual oil raw material is in contact with the protective agent, demetallization catalyst, and desulfurization catalyst in sequence, and a spherical catalyst layer is added in the demetallization catalyst layer. The diameter of the spherical catalyst is 19mm, and the bulk density is 600kg m -3 , the spherical catalyst carrier is Al2O3, the active component and its content are MoO 3 8.0wt%, NiO 2.0wt%, the specific filling method is shown in Table 1, and the process conditions and test results are shown in Table 3.

Embodiment 2

[0019] In the 3-meter-high hydrogenation reactor, the residual oil raw material is in contact with the protective agent, demetallization catalyst, and desulfurization catalyst in sequence. A spherical catalyst layer is added in the demetallization catalyst bed. The composition of the spherical catalyst is the same as that of the demetallization catalyst. The diameter of the spherical catalyst is 20mm, bulk density 700kg m -3 , the spherical catalyst carrier is Al2O3, the active component and its content are MoO 3 8.0wt%, NiO 2.0wt%, the specific filling method is shown in Table 1, and the process conditions and test results are shown in Table 3.

[0020] Table 1 Properties of Raw Materials

[0021] Analysis Project

Sulfur, wt%

2.73

Carbon residue, wt%

13.50

21.29

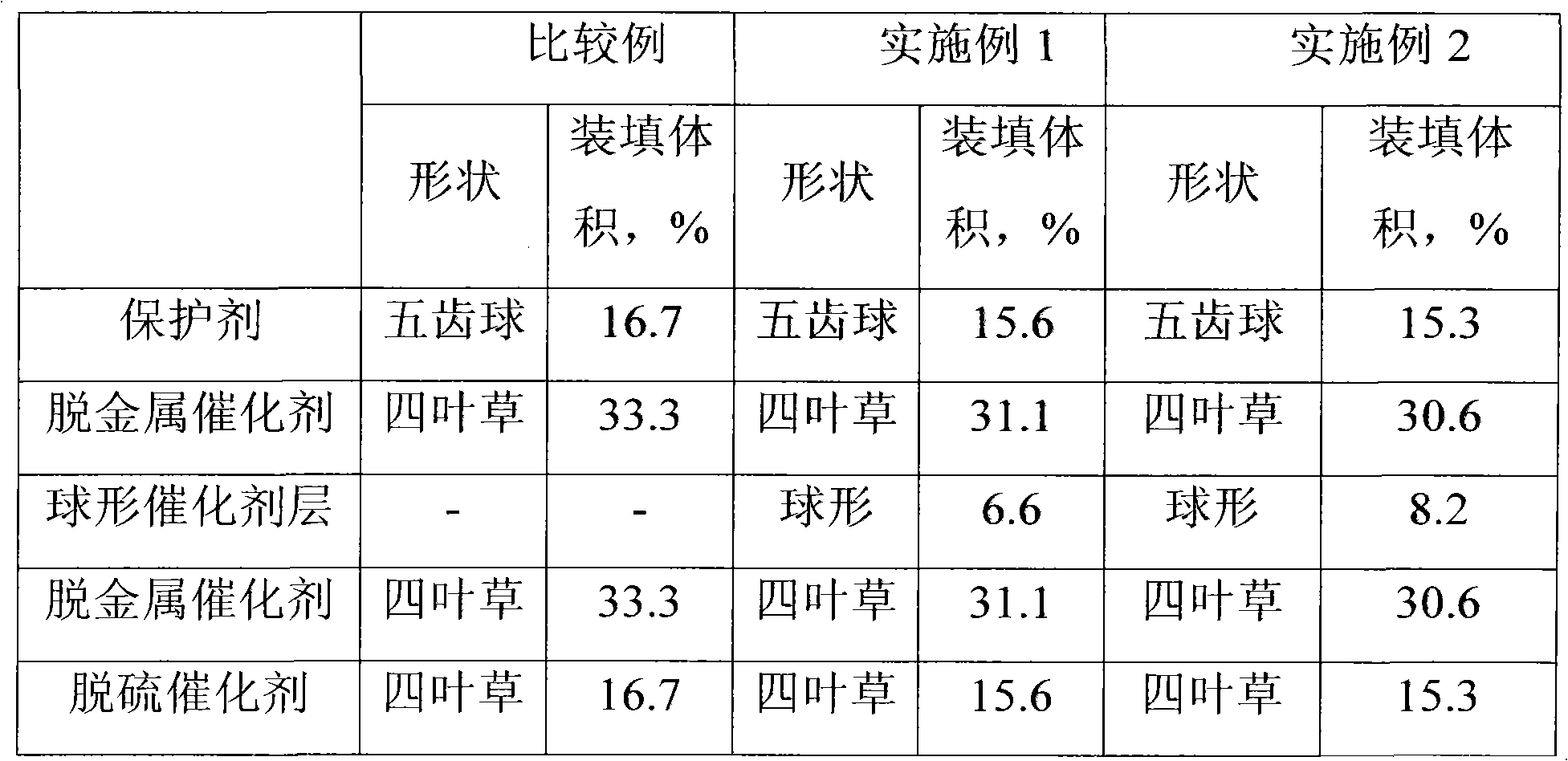

[0022] Table 2 Bed packing method

[0023]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com