Method for preparing polymer micro-filter membrane

A technology of microfiltration membrane and polymer, applied in the field of preparation of polymer microfiltration membrane, can solve the problems of difficult processing, difficult to recycle, unable to satisfy hydrophilicity, chemical solvent resistance and temperature resistance at the same time, and achieve repeatability. Good, simple molding, mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

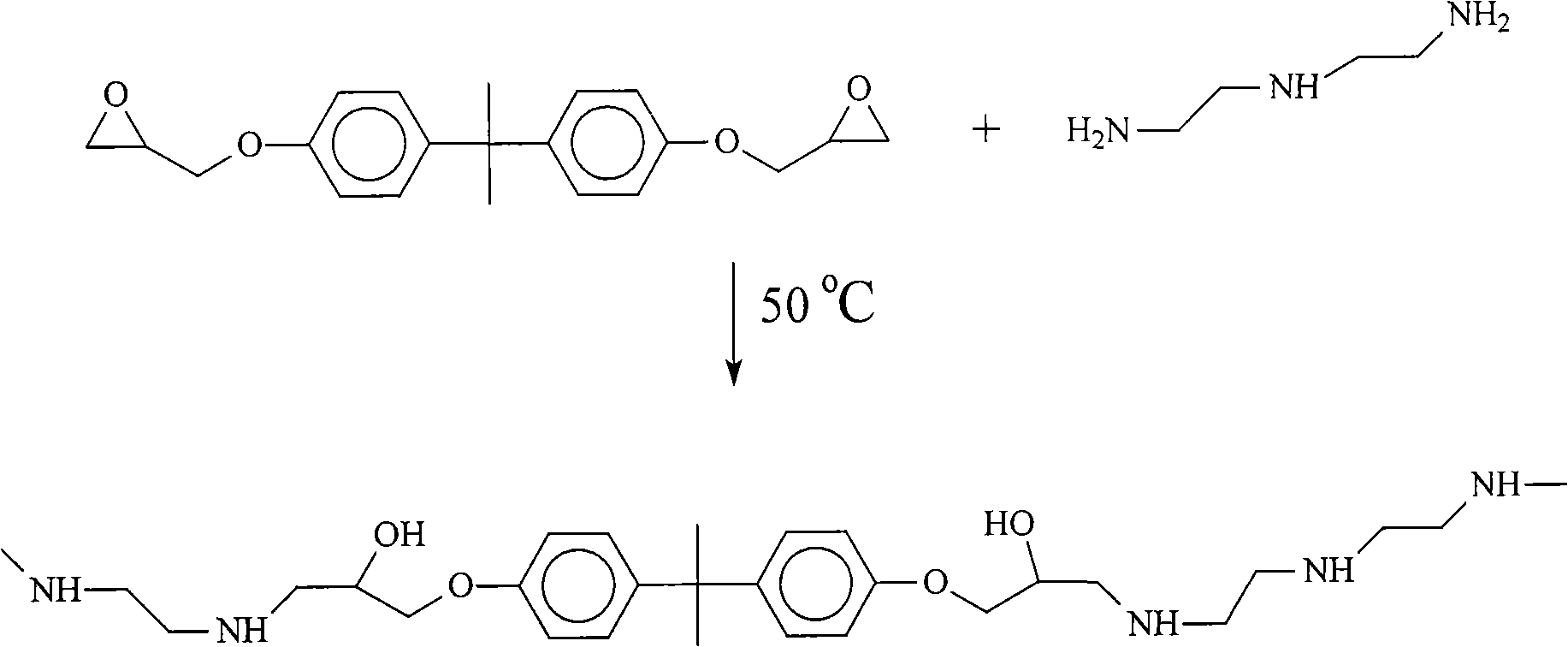

Method used

Image

Examples

Embodiment 1

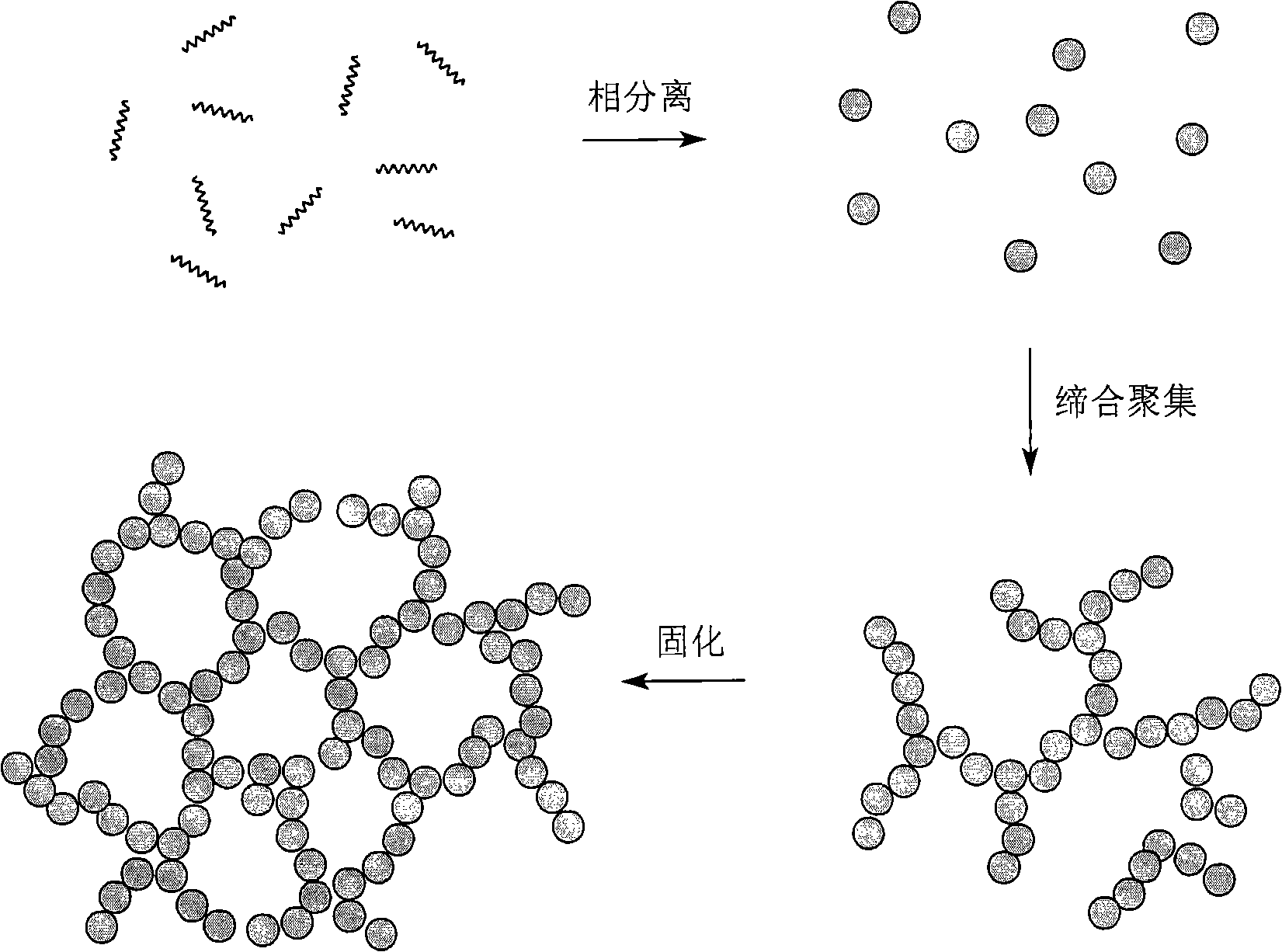

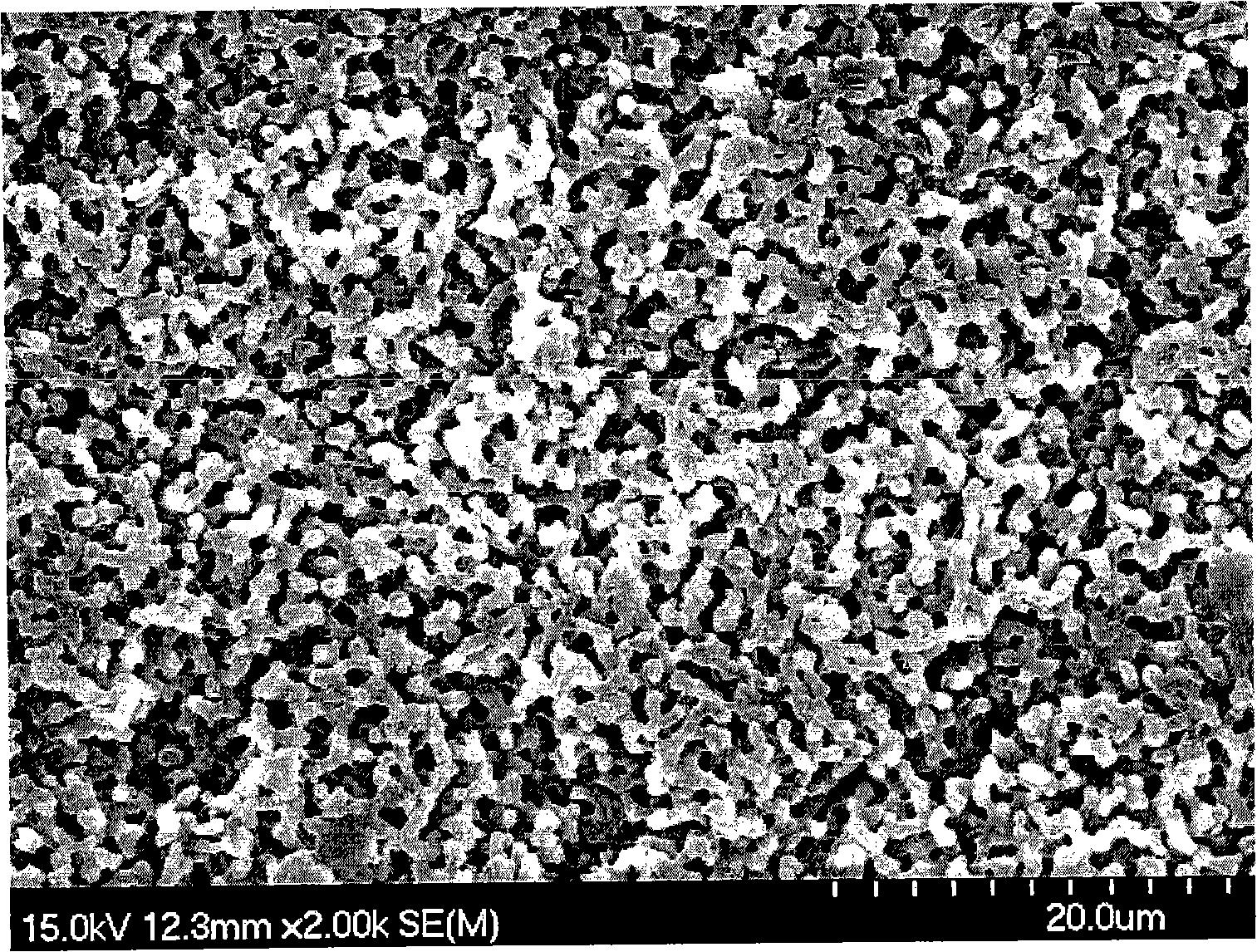

[0028] Dissolve 6 grams of epoxy resin and 1.5 grams of diethylenetriamine in 15 grams of polyethylene glycol 1000 medium to obtain a clear solution, remove air bubbles, then cast the solution on a stainless steel plate, let it stand, and keep it warm at 50 ° C for 5 hours , the initial solution undergoes phase separation, and the gel solidifies into a white epoxy resin nascent membrane. Finally, the nascent membrane is immersed in water to remove the medium polyethylene glycol to obtain a microfiltration membrane. The membrane thickness is 120 μm, and the average pore size and water flux are shown in Table 1.

Embodiment 2~5

[0030] Fix the weight of epoxy resin and diethylenetriamine constant, change the weight ratio of polyethylene glycol 1000 and epoxy resin, the rest of the conditions and operations are the same as in Example 1, and the corresponding microfiltration membranes are prepared, the average pore size and water flow rate are the same. The amount is shown in Table 1.

[0031] Table 1:

[0032]

Embodiment 6

[0034] The weight of fixed epoxy resin is 6 grams, the weight of Polyethylene Glycol 1000 is 18 grams, uses triethylenetetramine instead, and the weight of amine is 2 grams, all the other conditions and operation are identical with embodiment 1, obtain microfiltration membrane, The average pore size and water flux are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com