Preparation method of novel cardanol modified epoxy resin

A technology of epoxy resin and cardanol, which is applied in the direction of organic chemistry, can solve the problems of insufficient heat resistance and poor weather resistance, and achieve the effects of improved solvent resistance, strong reactivity, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

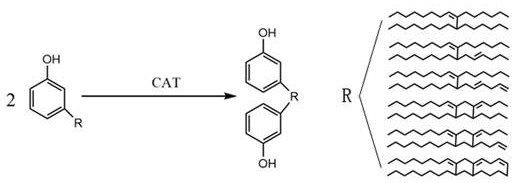

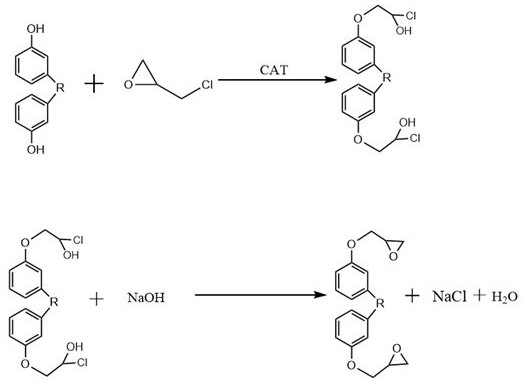

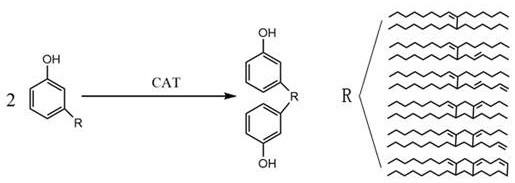

Method used

Image

Examples

Embodiment 1

[0028] 1) Add 70g of refined cardanol and 0.5g of azobisisobutyronitrile into the reactor, stir and mix evenly, and pre-pass N 2 To protect the entire reaction system, raise the temperature to 110°C and keep it warm for 2 hours;

[0029] 2) Add diethyl sulfate-phosphoric acid system (DES-H 3 PO 4 ) 4g, continue to pass N 2 Protection, heating up to 170°C, keeping warm for 4 hours, removing N after the reaction 2 , and then cooled down to room temperature to obtain cardanol low self-polymer;

[0030] 3) Add 40g of epichlorohydrin and 0.8g of tetraethylammonium bromide to the cardanol low self-polymer prepared by step 2), raise the temperature to 65°C, stir for 60min, and slowly add 48% NaOH solution dropwise 32g, control the dripping in 1.5 hours, after the dripping, raise the temperature to 70°C, keep the temperature for 1h;

[0031] 4) Control the temperature at 70°C and the pressure at 5Kpa, and distill the product prepared by step 3) under reduced pressure, and remove ...

Embodiment 2

[0034] 1) Add 150g of refined cardanol and 3.0g of azobisisoheptanonitrile into the reactor, stir and mix evenly, pass N in advance 2 To protect the entire reaction system, raise the temperature to 115°C and keep it warm for 1.5h;

[0035] 2) Add diethyl sulfate-sulfuric acid system (DES-H 2 SO 4 ) 10g, continue to pass N 2 Protect and heat up to 190°C, keep warm for 2 hours, remove N after the reaction is over 2 , and then cooled down to room temperature to obtain cardanol low self-polymer;

[0036] 3) Add 100g of epichlorohydrin and 2g of tetraethylammonium bromide to the cardanol low self-polymer prepared in step 2), raise the temperature to 75°C, stir for 60min, and slowly add 80g of 48% NaOH solution dropwise , control the dripping in 3 hours, after the dripping, the temperature is raised to 70°C, and the temperature is kept for 2 hours;

[0037] 4) Control the temperature at 75°C and the pressure at 8Kpa, and distill the product prepared by step 3) under reduced pre...

Embodiment 3

[0040] 1) Add 100g of refined cardanol and 1.0g of azobisisobutyronitrile into the reactor, stir and mix evenly, pass N in advance 2 To protect the entire reaction system, raise the temperature to 120°C and keep it warm for 1 hour;

[0041] 2) Add diethyl sulfate-phosphoric acid system (DES-H 3 PO 4 ) 6g, continue to pass N 2 Protect and heat up to 200°C, keep warm for 3 hours, remove N after the reaction is over 2, and then cooled down to room temperature to obtain cardanol low self-polymer;

[0042] 3) Add 60g of epichlorohydrin and 1.2g of tetraethylammonium bromide to the cardanol low self-polymer prepared by step 2), raise the temperature to 75°C, stir for 60min, and slowly add 48% NaOH solution dropwise 48g, control the dripping in 2 hours, after the dripping, raise the temperature to 75°C, keep the temperature for 1.5h;

[0043] 4) Control the temperature at 75°C and the pressure at 8Kpa, and distill the product prepared by step 3) under reduced pressure, and remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com