Insulating silicone gasket and preparation method and equipment thereof

A technology of insulating silica gel and gasket, applied in chemical instruments and methods, lamination, coating, etc., can solve the problems of inability to meet the heat dissipation requirements of electronic equipment, structural damage, and inability to form, achieving good thermal conductivity and high production efficiency , The effect of convenient processing and molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

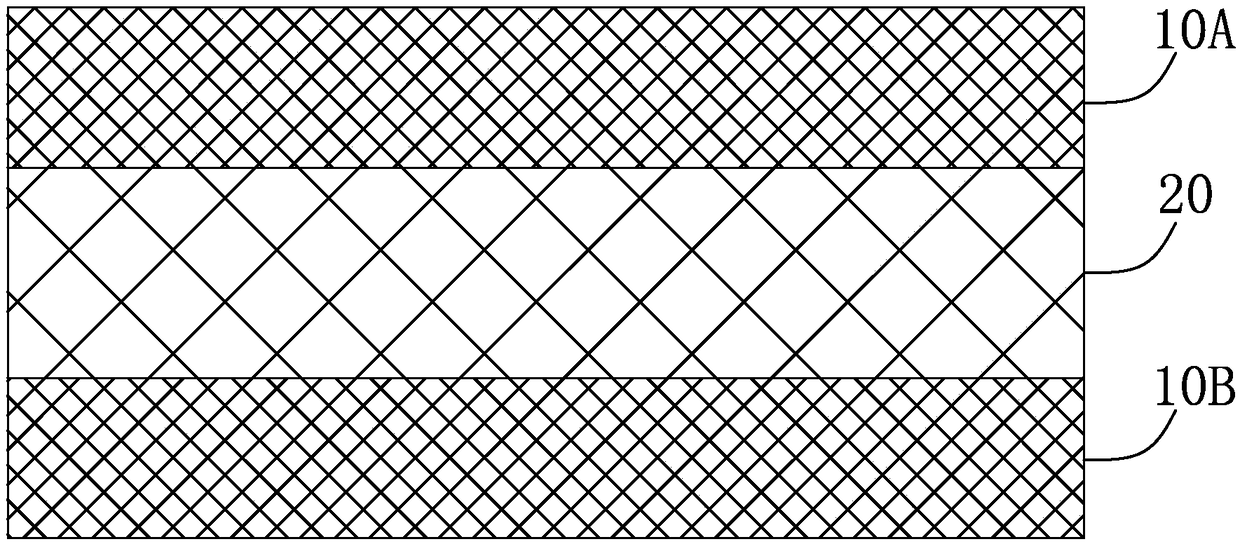

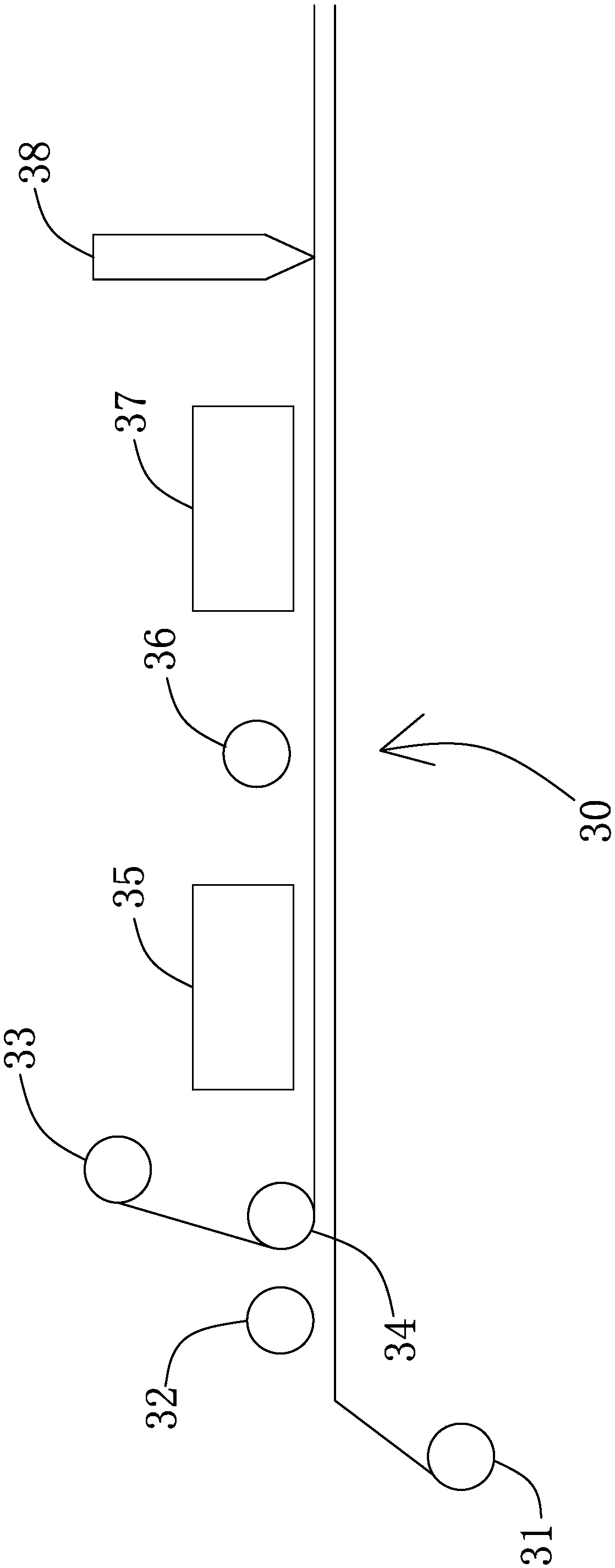

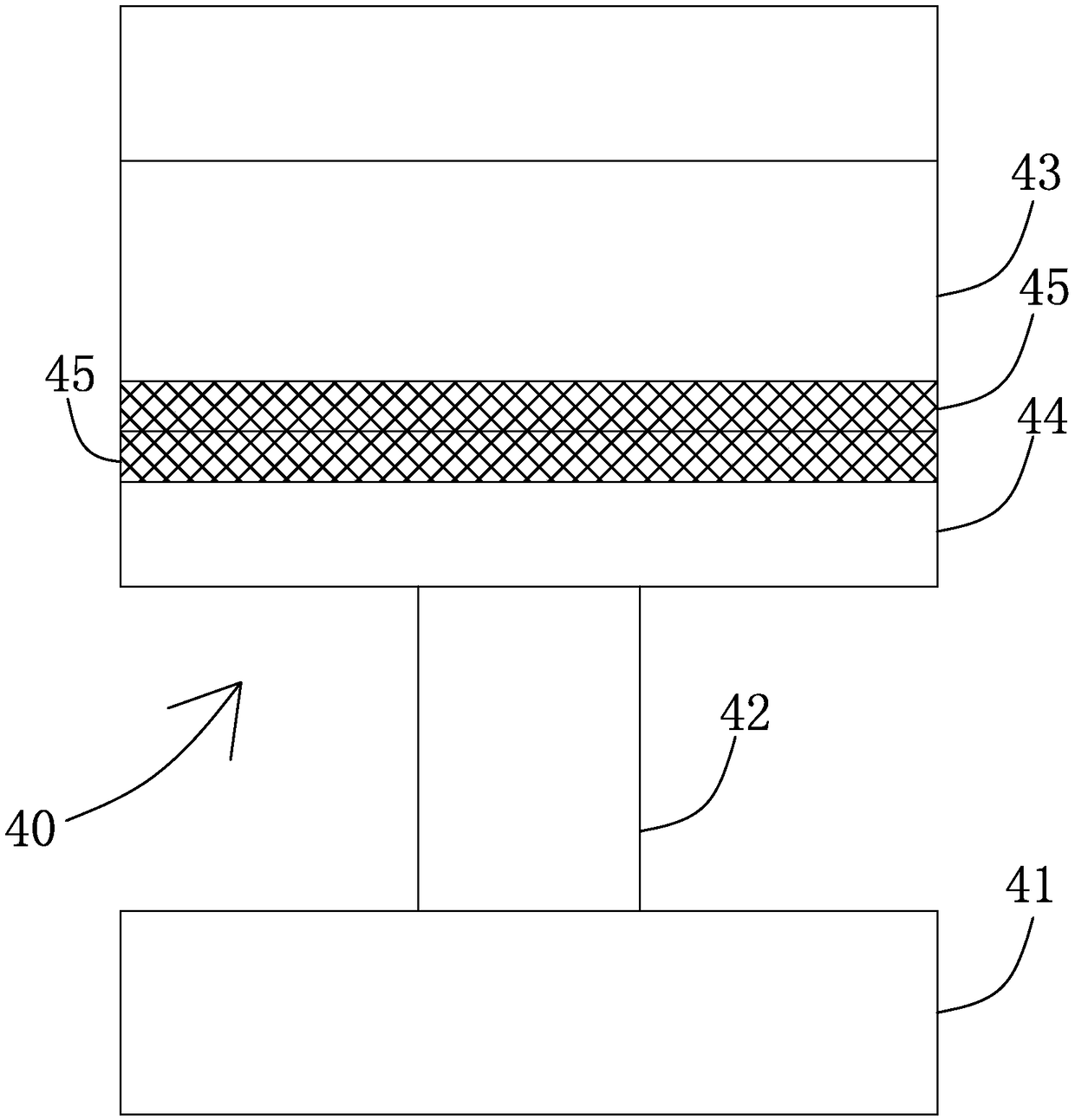

[0025] The preparation method of the insulating silicone rubber gasket is as follows: first dissolve the silicone rubber in a solvent, stir evenly, add boron nitride and other thermally conductive powders, vulcanizing agents and coupling agents, stir evenly and then stand for 1 to 3 hours. Get thermally conductive silica gel. The stirred thermally conductive silica gel is then coated on the release film by the coating device 30, wherein the thickness of the coated thermally conductive silica gel is controlled by a doctor blade. Then the thermal silica gel is combined with the alkali-free glass fiber cloth in the middle, and it is dried at a temperature of 60~80℃ for 3-8 minutes, and then the thermal silica gel is coated on the alkali-free glass fiber cloth and placed at a temperature of 60~80℃ After drying for 3-8 minutes, it is shaped to obtain a semi-finished product. The semi-finished product is cut into sheets, and then the surface is covered with a release film, and then ...

Embodiment 1

[0031] Put 5 kg of methyl vinyl silicone rubber in 10 kg of xylene solvent and stir for 2 hours to fully dissolve the silicone rubber, then add 0.1 kg of silane coupling agent A-151, 12 kg of boron nitride, 2 One kilogram of alumina and 0.1 kilogram of bis-tetradichlorobenzoyl peroxide (trade name bis-two-four) were stirred for 1 hour to make them uniform, and then stirred for 15 minutes to obtain thermally conductive silica gel. Let the thermally conductive silica gel stand for 1 hour, and apply the thermally conductive silica gel on the coating device 30 at the first coating head 32 on the PTFE fiberglass cloth with a width of 300 mm, and control the coating width to 200 mm , The thickness is 0.2 mm, and then the alkali-free glass fiber cloth with a thickness of 0.1 mm (commodity model 1080) is composited through the composite roller 34, and the composite alkali-free glass fiber is placed in the first drying equipment 35 at a temperature of 70 ℃ Dry in medium for 5 minutes. ...

Embodiment 2

[0034] Put 5 kg of methyl vinyl silicone rubber in 10 kg of xylene solvent and stir for 2 hours to fully dissolve the silicone rubber, then add 0.1 kg of silane coupling agent A-151, 15 kg of boron nitride, 2 One kilogram of magnesium oxide and 0.1 kilogram of bis-tetradichlorobenzoyl peroxide (trade name bis-two-four) were stirred for 1 hour to make them uniform, and then stirred for 15 minutes to obtain thermally conductive silica gel. Let the thermal silica gel stand for 1 hour, and coat the thermal silica gel on the PTFE glass cloth with a width of 400 mm at the first coating head 32 on the coating device 30, and control the coating width to 300 mm , The thickness is 0.3 mm, and then the alkali-free glass fiber cloth with a thickness of 0.05 mm (commodity model 104) is composited by the composite roller 34, and the composite alkali-free glass fiber is placed in the first drying equipment 35 at a temperature of 70 ℃ Dry in medium for 5 minutes. Then through the second coati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Breakdown voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com