Patents

Literature

54results about How to "Accurate and stable position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

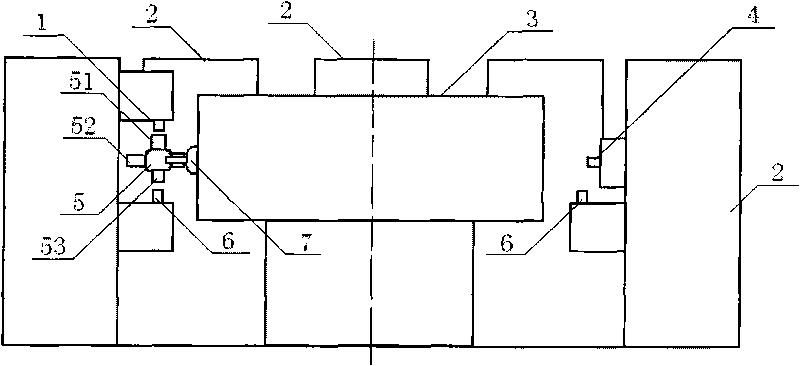

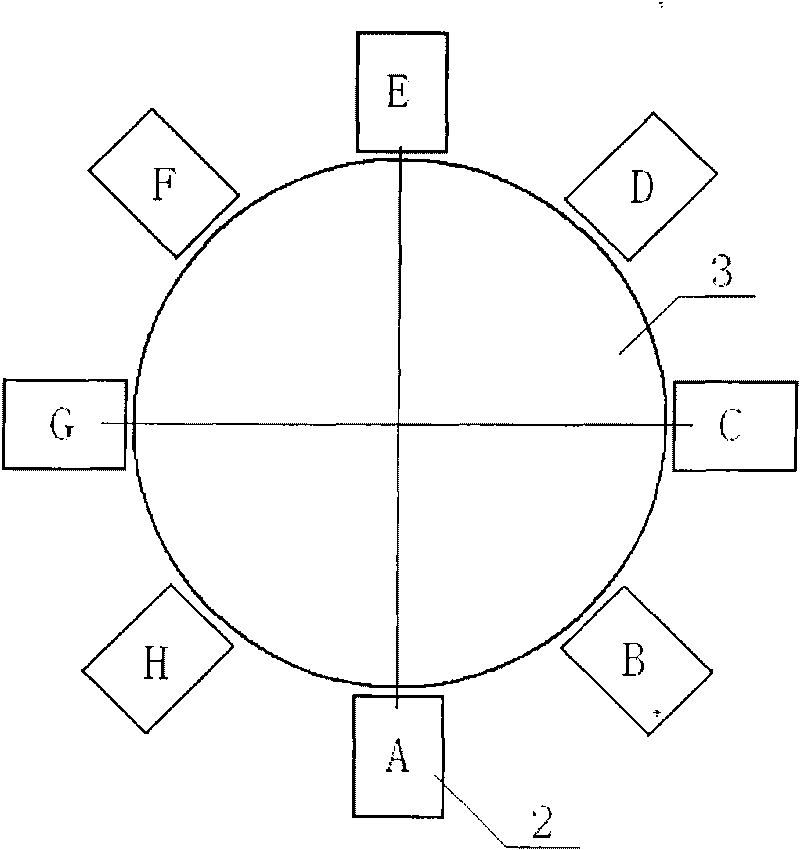

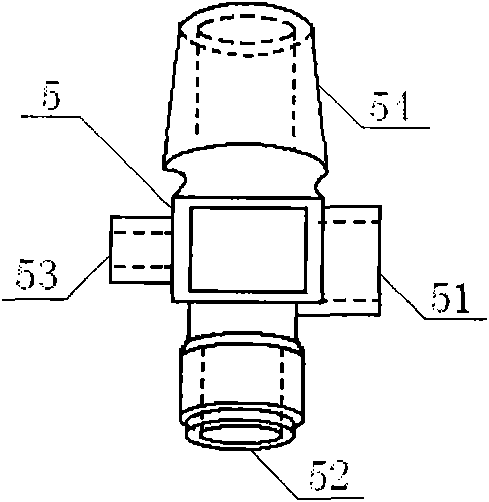

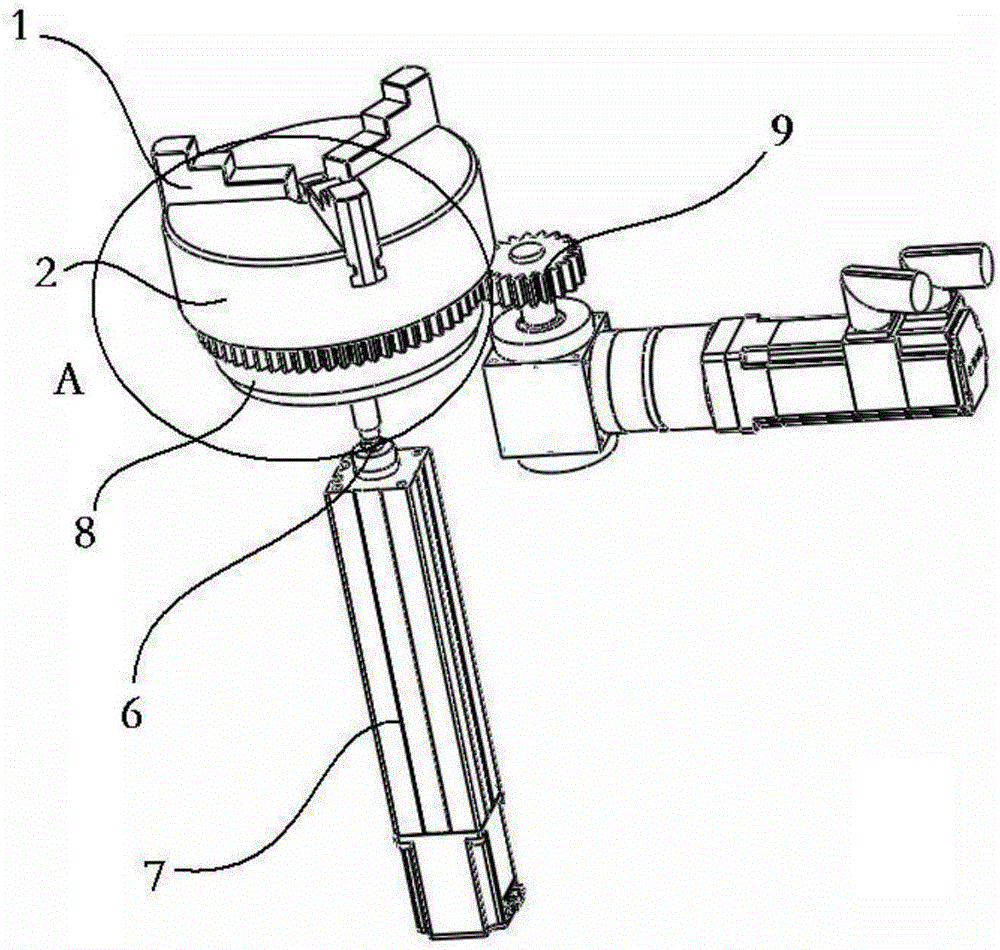

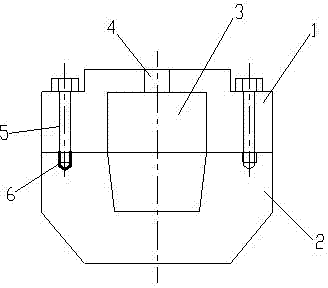

Annular multi-station synthesis valve body machining device

InactiveCN101733636AImprove efficiencyImprove machining accuracyOther manufacturing equipments/toolsDrill holeEngineering

The invention discloses an annular multi-station synthesis valve body machining device and relates to the technical field of machining an air bottle valve. A plurality of stations are positioned at a plurality of positions around a rotating disk; a chuck is arranged on the rotating disk and is used for clamping a workpiece; one station is used for placing or taking down the workpiece; a power head box base is respectively arranged on the other stations; a power head is arranged on the power head box base for machining the workpiece; and each station is provided with 1 to 3 radial or / and upward or / and downward power heads respectively, which are used for processing 1 to 3 procedures of three operations of turning or / and drilling or / and tapping of an external protrusion or / and an upper protrusion or / and a lower protrusion. The annular multi-station synthesis valve body machining device has the advantages that: labor, power and time are saved, the efficiency is about eight times of that of common lathes; the machining error is low and the precision is about eight times of that of the common lathes; the service life of a tool is over ten times of that of the common lathes; the energy is saved, the unit consumption is about 1 / 12 of that of the common lathes; and the total cost can be reduced by about 50 percent.

Owner:魏松岭

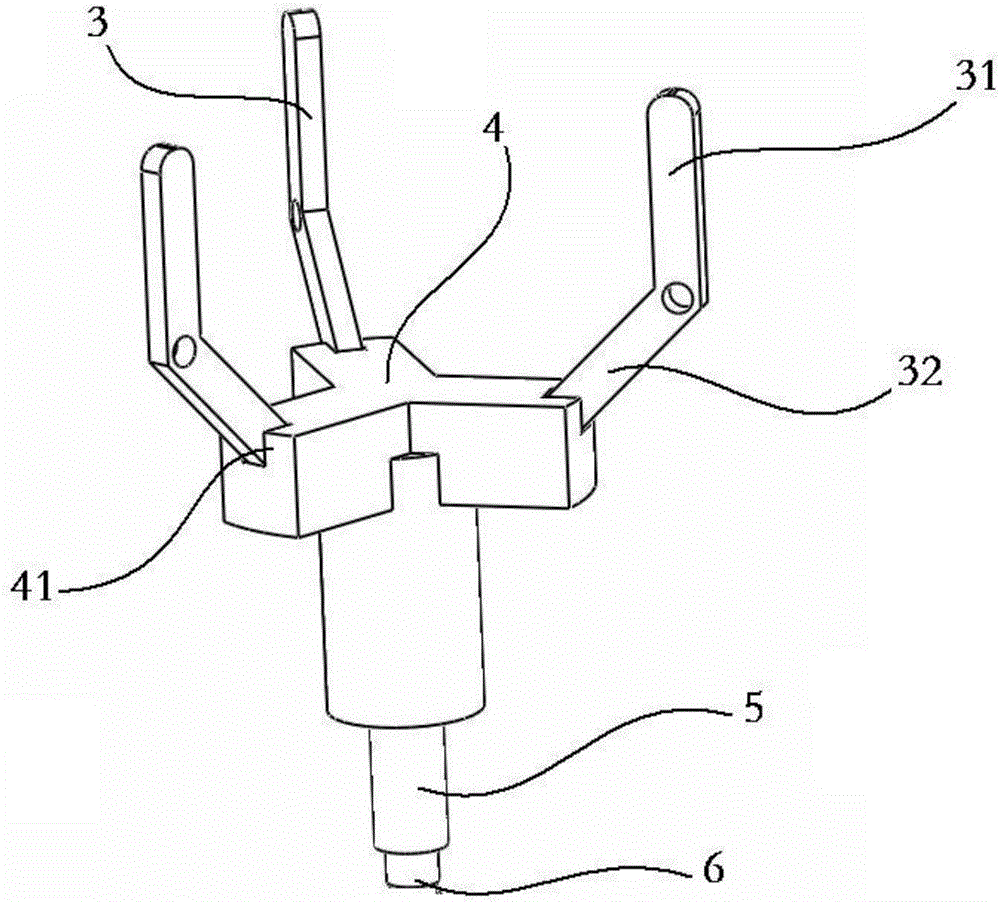

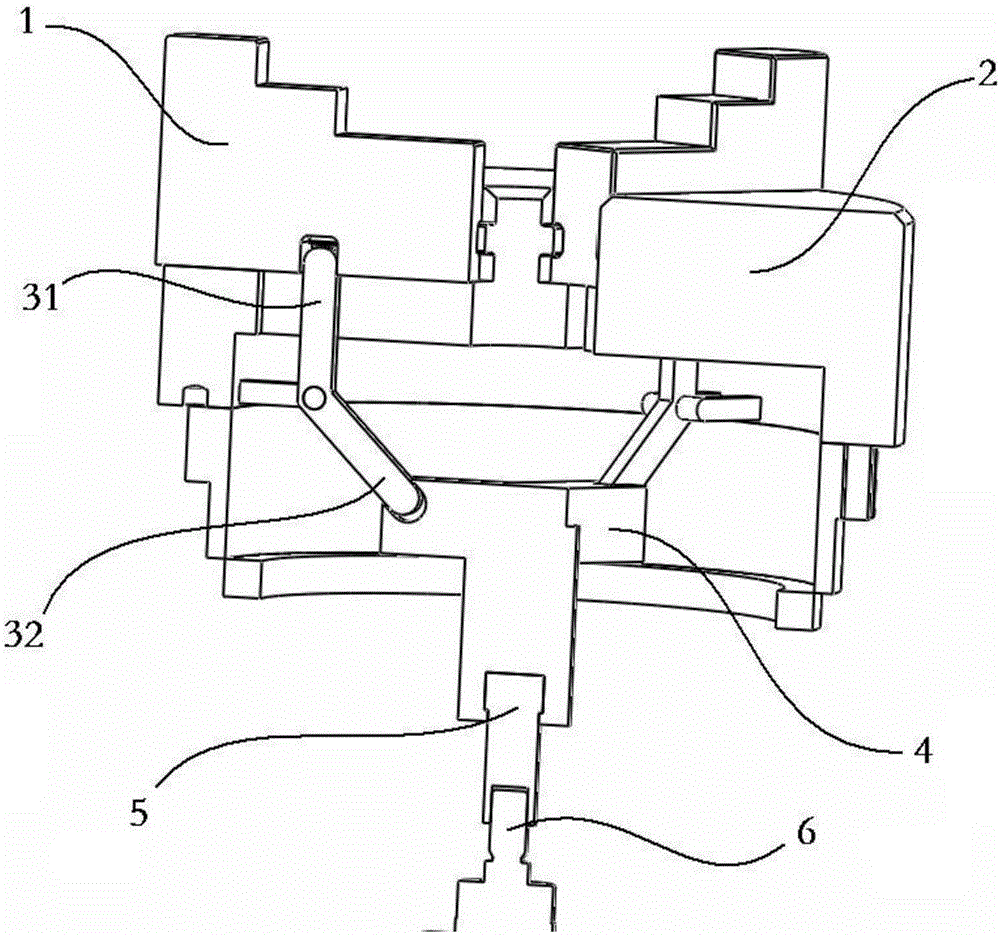

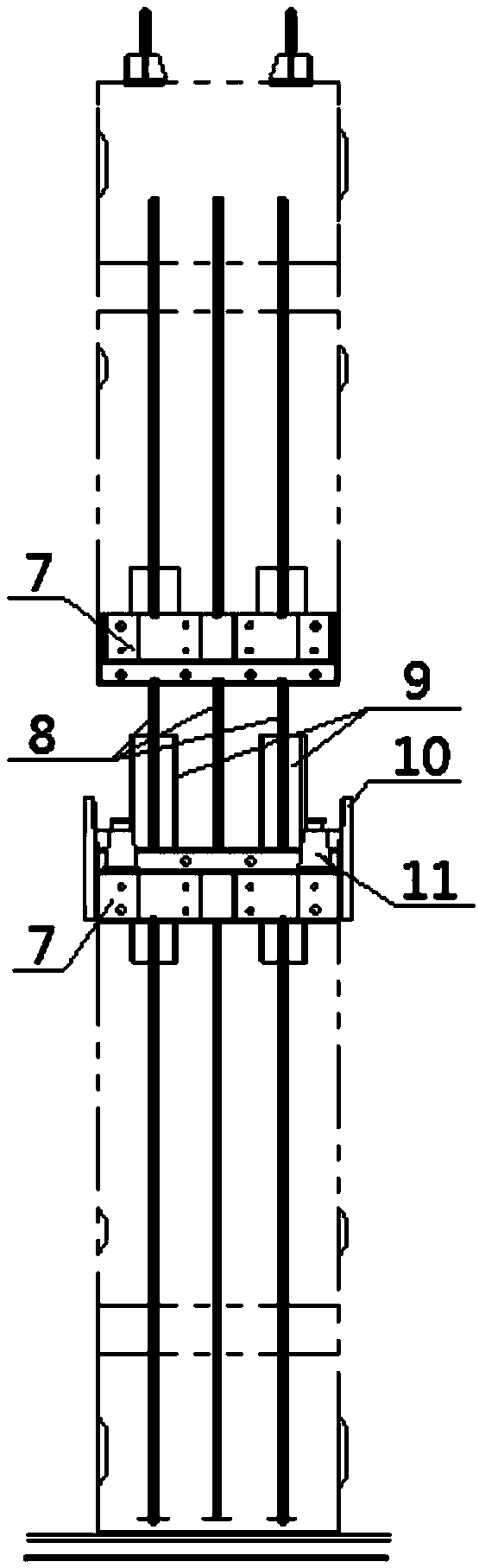

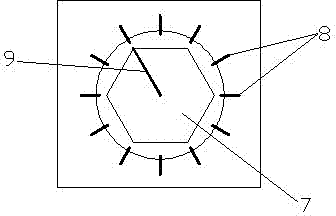

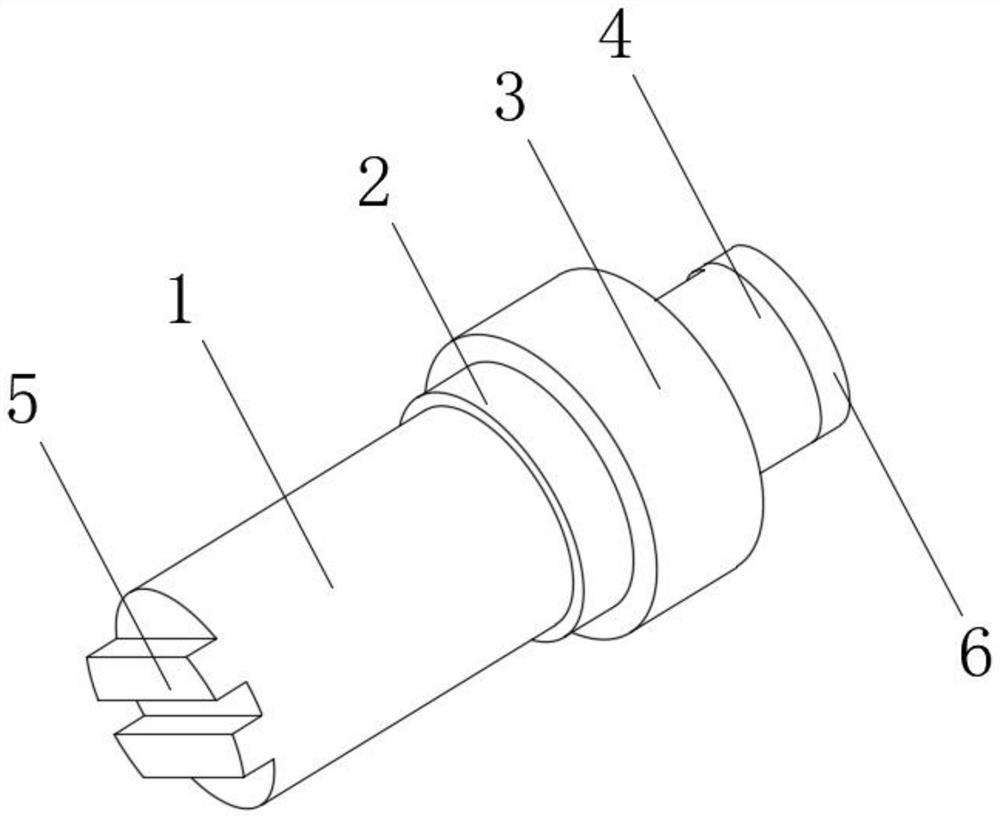

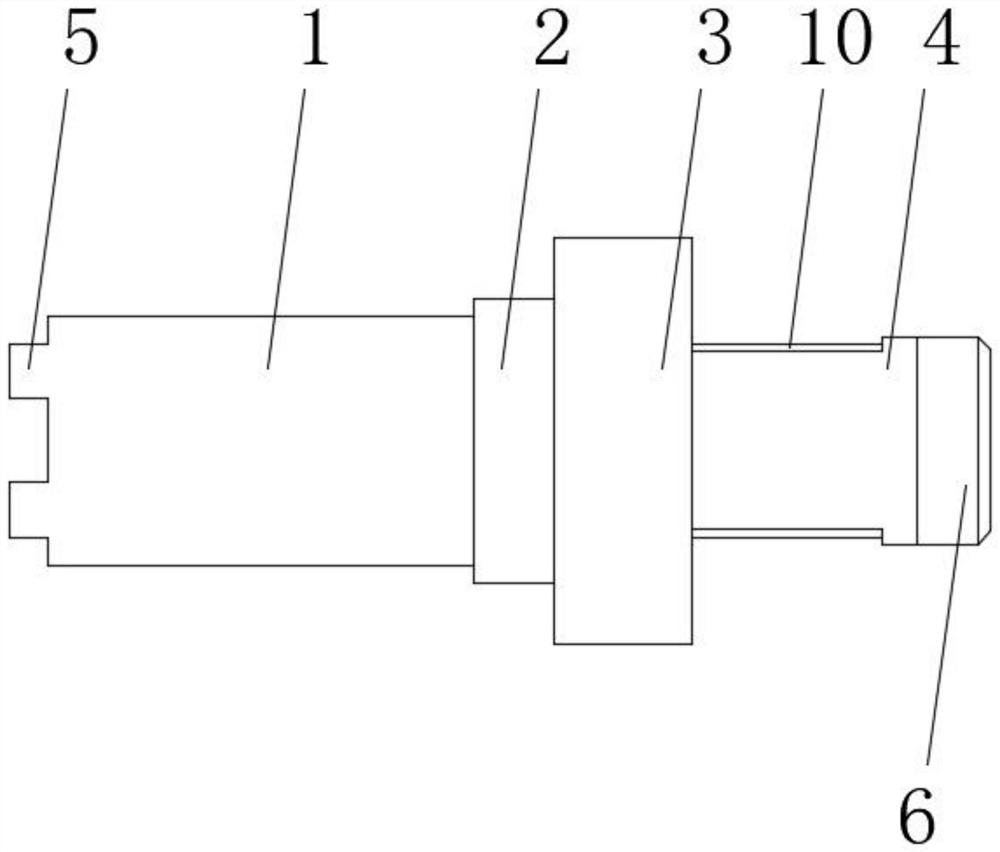

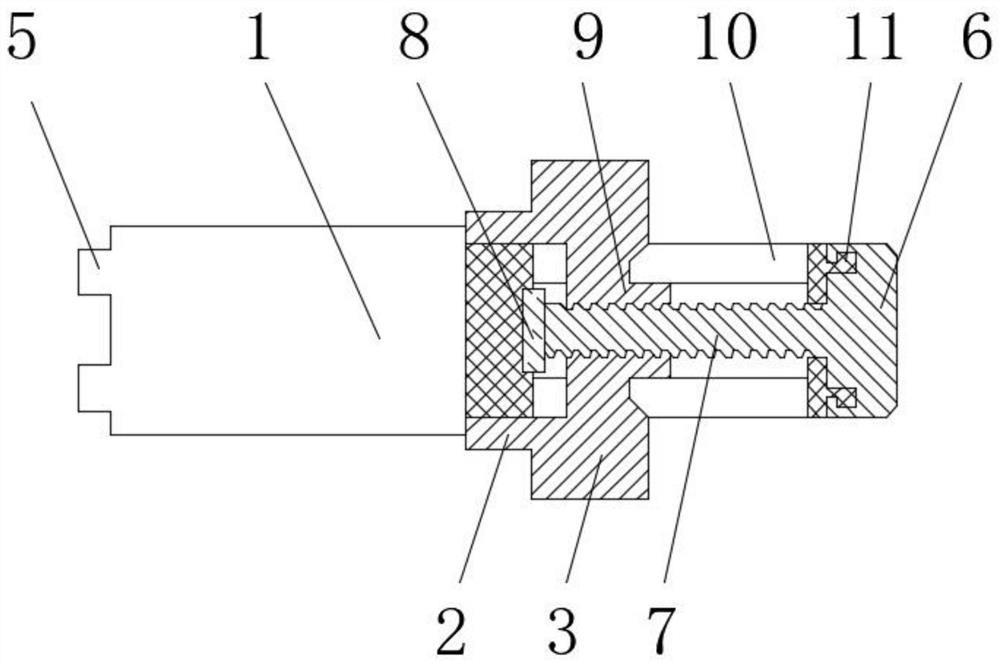

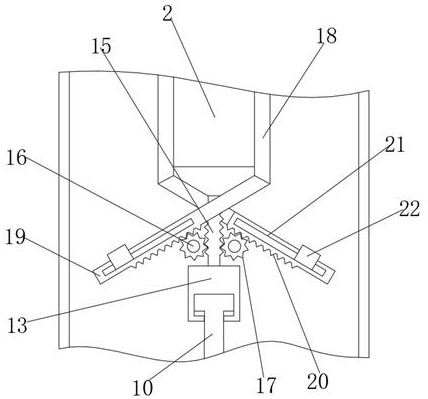

Driving mechanism driving moving pieces to move back and forth on installation base in radial direction and chuck

ActiveCN106112038ARealize radial push and pullThe mechanical transmission process is simple and reliableChucksMechanical transmissionEngineering

The invention discloses a driving mechanism driving moving pieces to move back and forth on an installation base in the radial direction and a chuck. The driving mechanism comprises stirring pieces and a driving assembly. The stirring piece can rotate relative to the installation base and rotate in the plane determined by the radial direction of the moving pieces corresponding to the stirring pieces and the axial direction of the installation base, and the stirring pieces are connected with the corresponding moving pieces. The driving assembly is provided with stirring piece connecting parts, wherein distribution of the stirring piece connecting parts is consistent with that of the stirring pieces. The stirring pieces are hinged to the corresponding stirring piece connecting parts. When the driving assembly moves back and forth in the axial direction of the installation base, the stirring pieces are driven to rotate to drive the moving pieces to move back and forth in the radial direction of the installation base. According to the driving mechanism driving the moving pieces to move back and forth on the installation base in the radial direction and the chuck, a mechanical transmission assembly is simple in structure, stable and reliable, and non-interference rotation of the chuck can be achieved.

Owner:BEIJING XUANYU INTELLIGENT TECH CO LTD

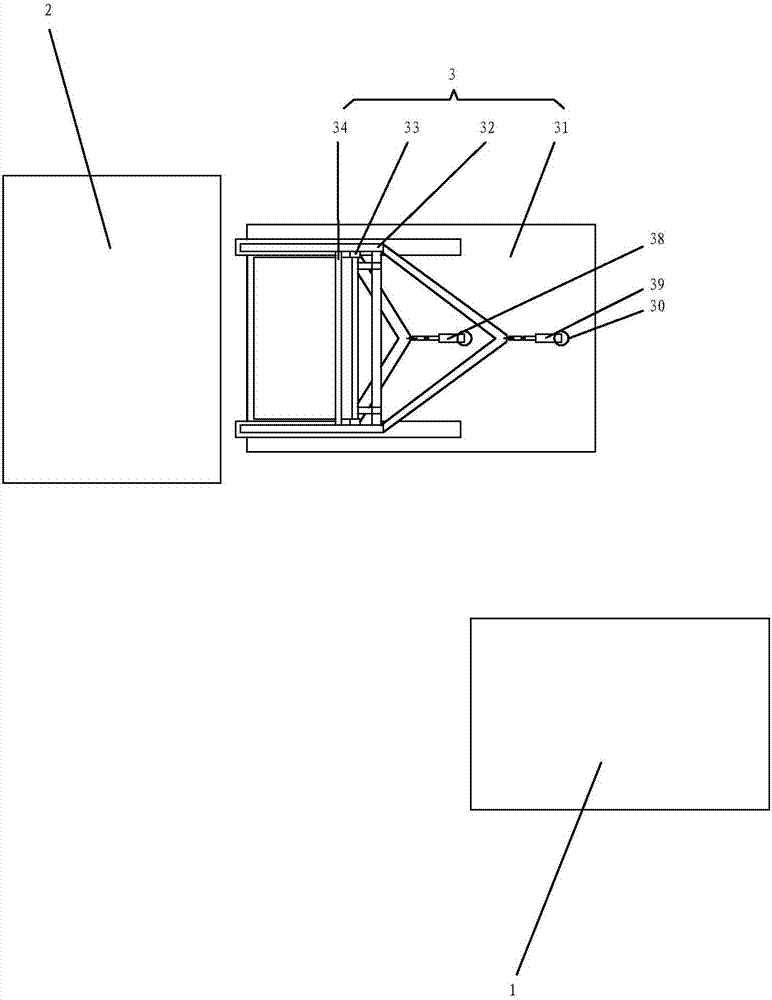

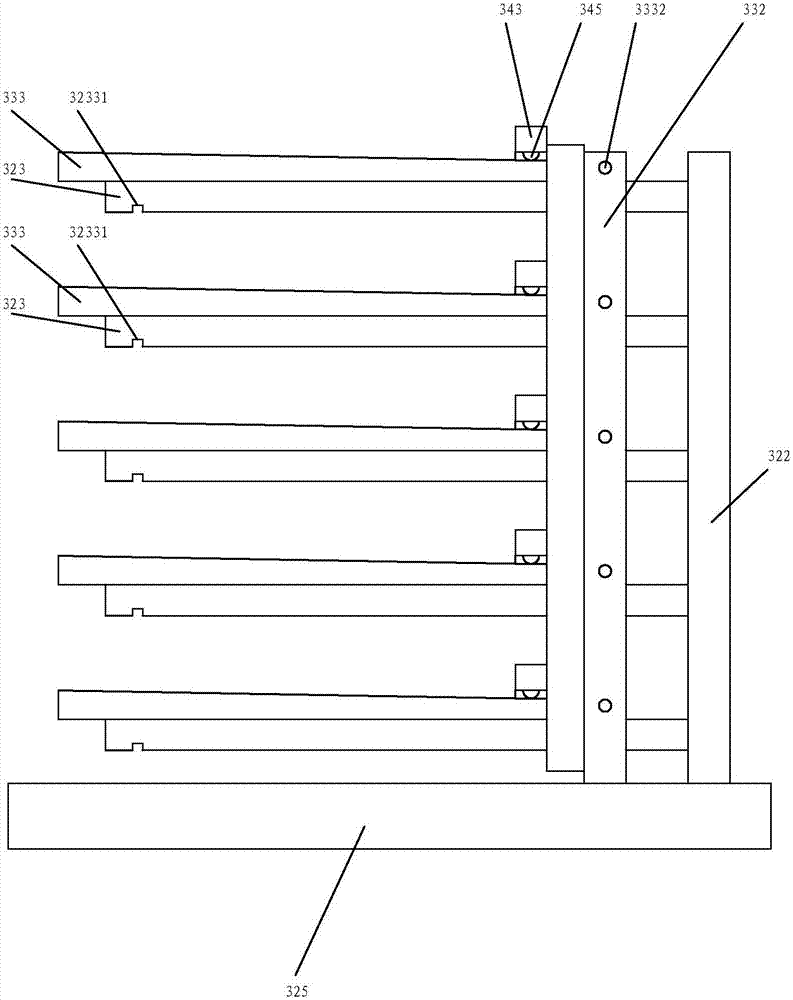

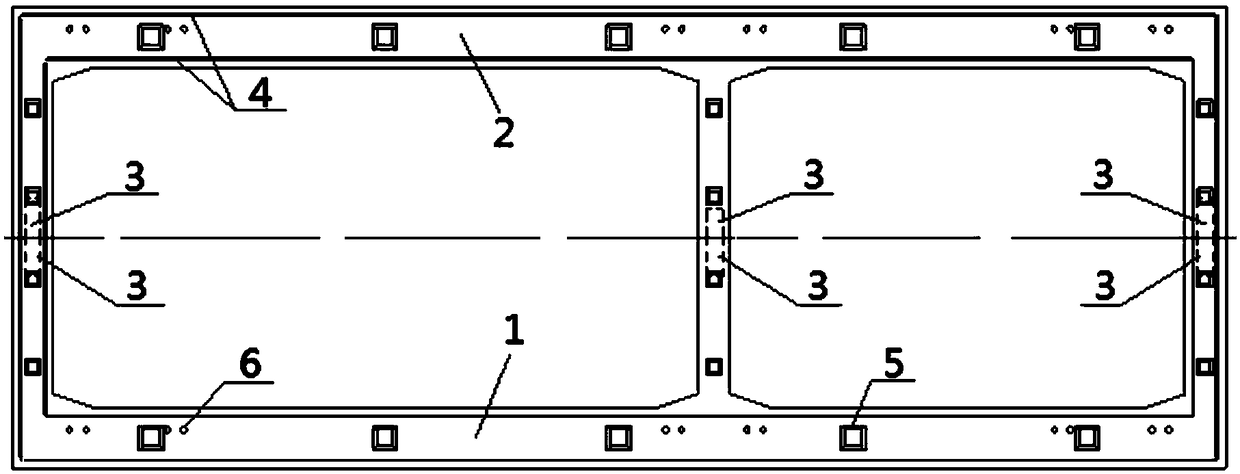

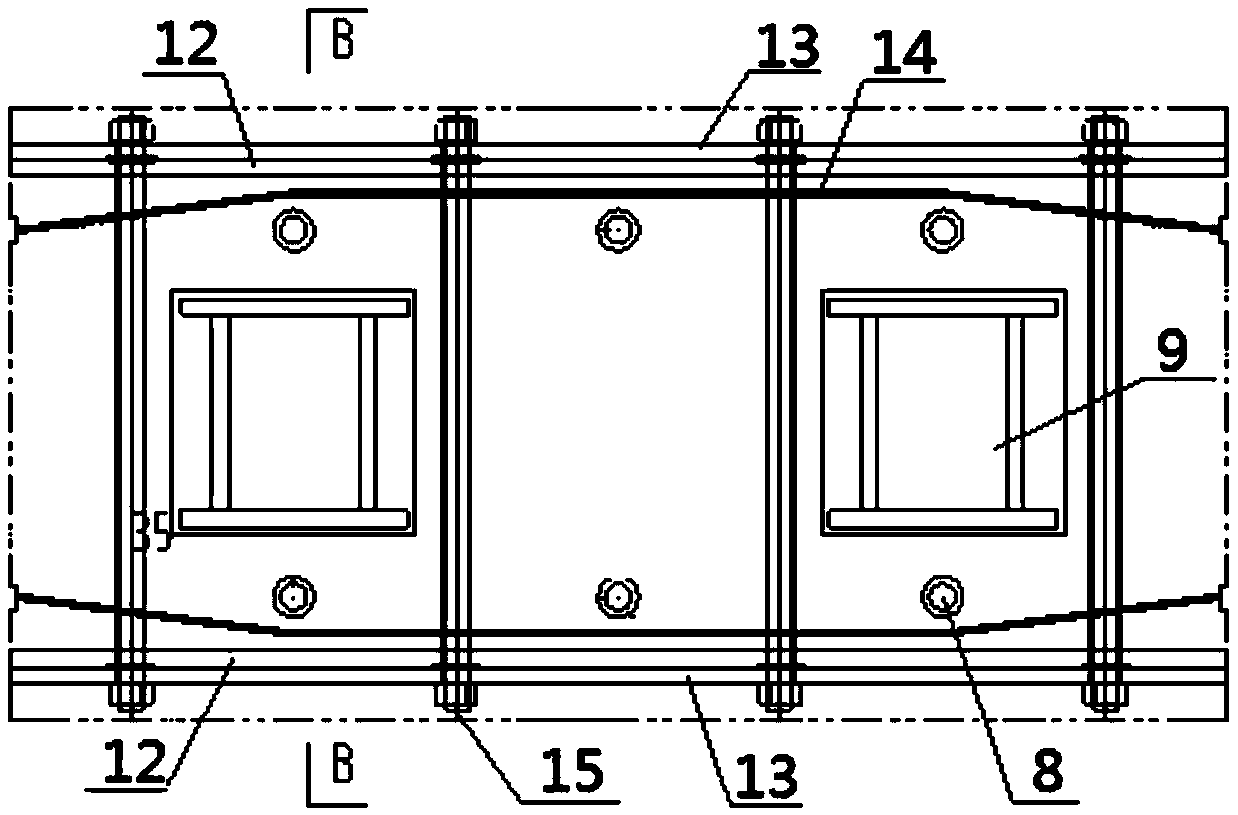

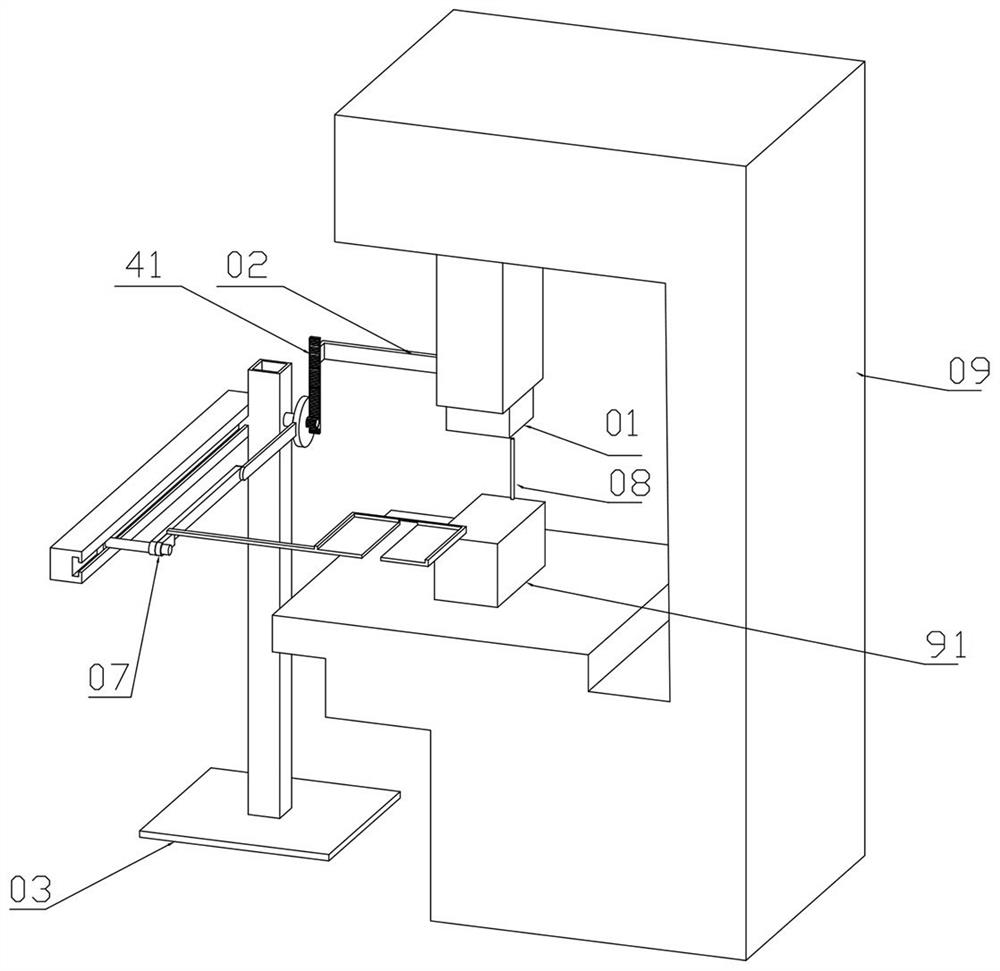

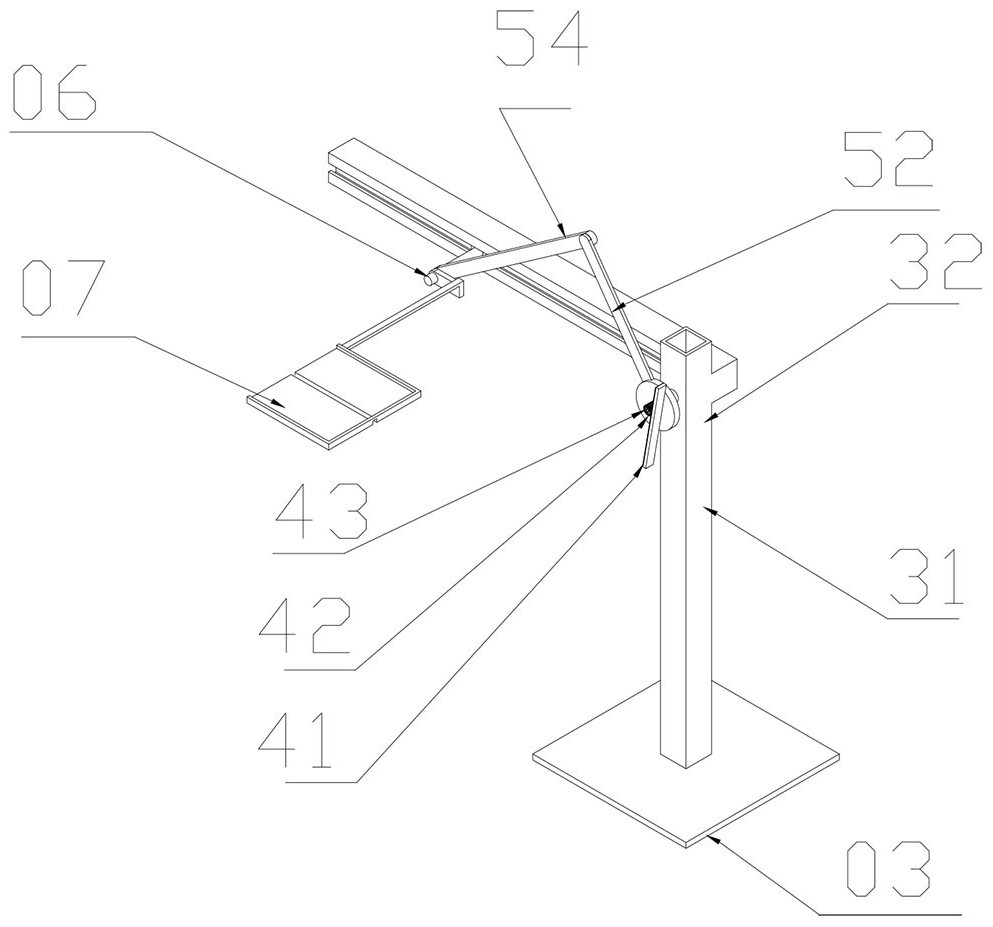

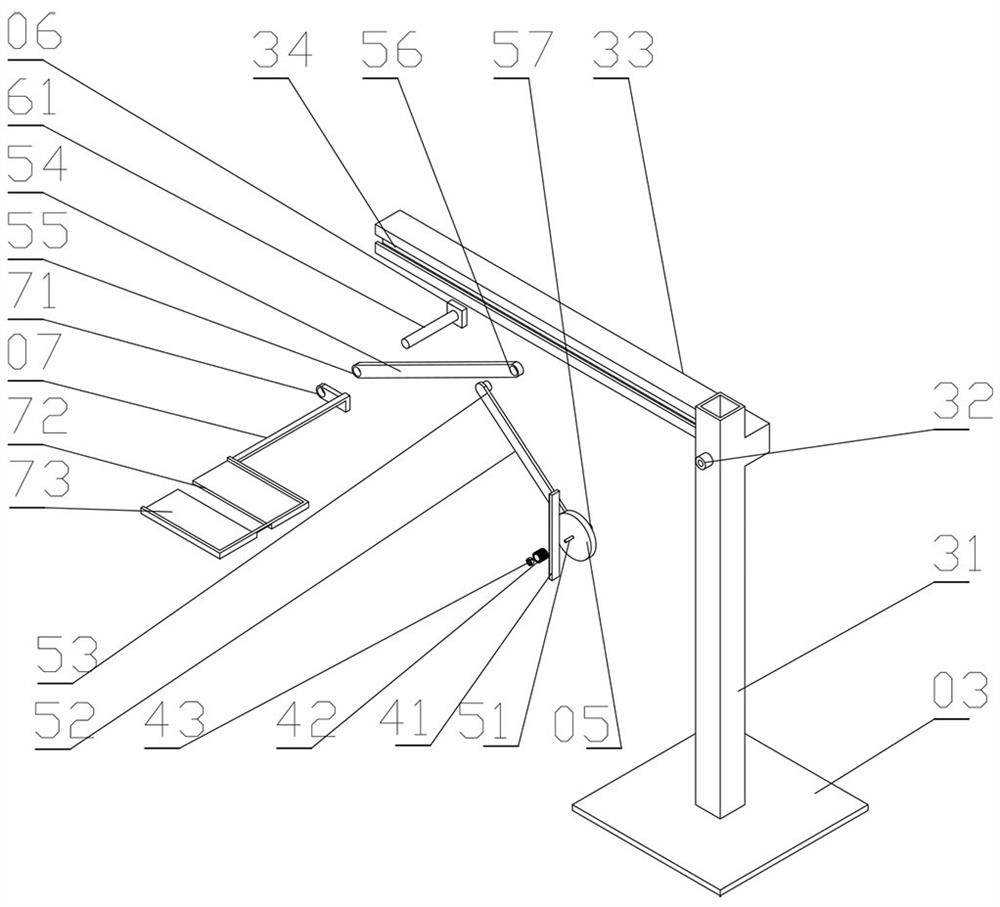

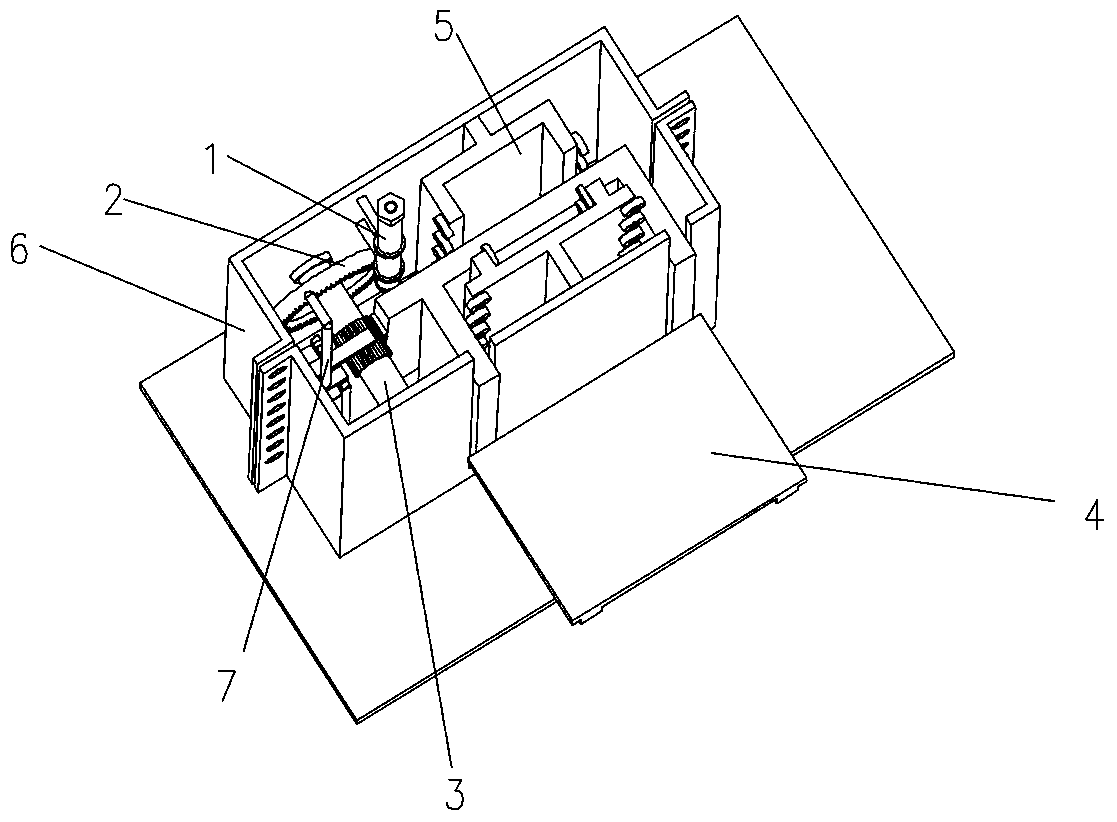

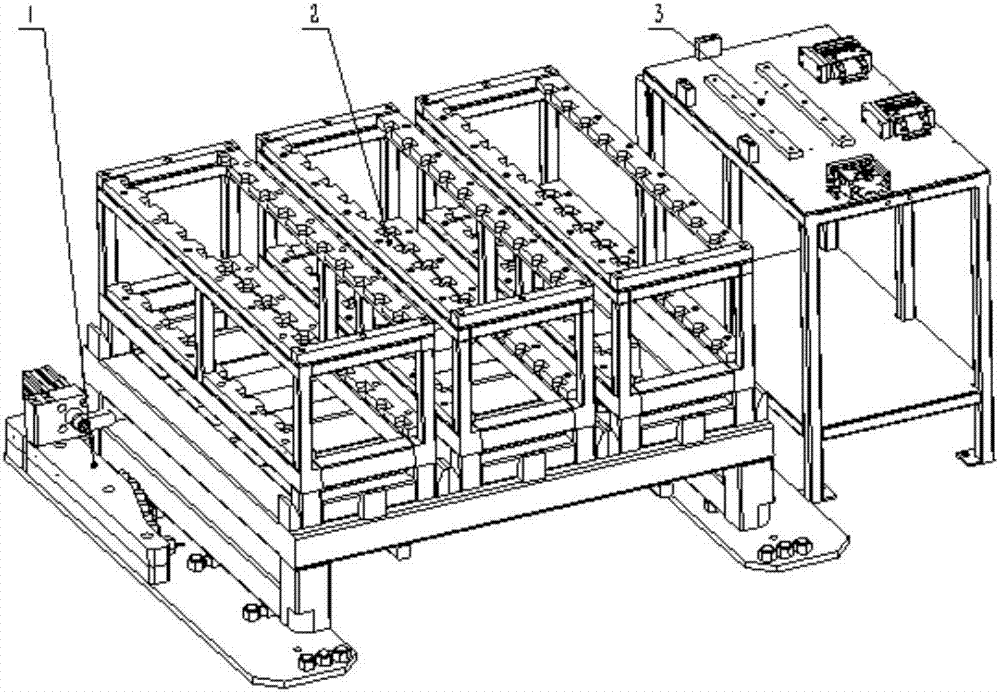

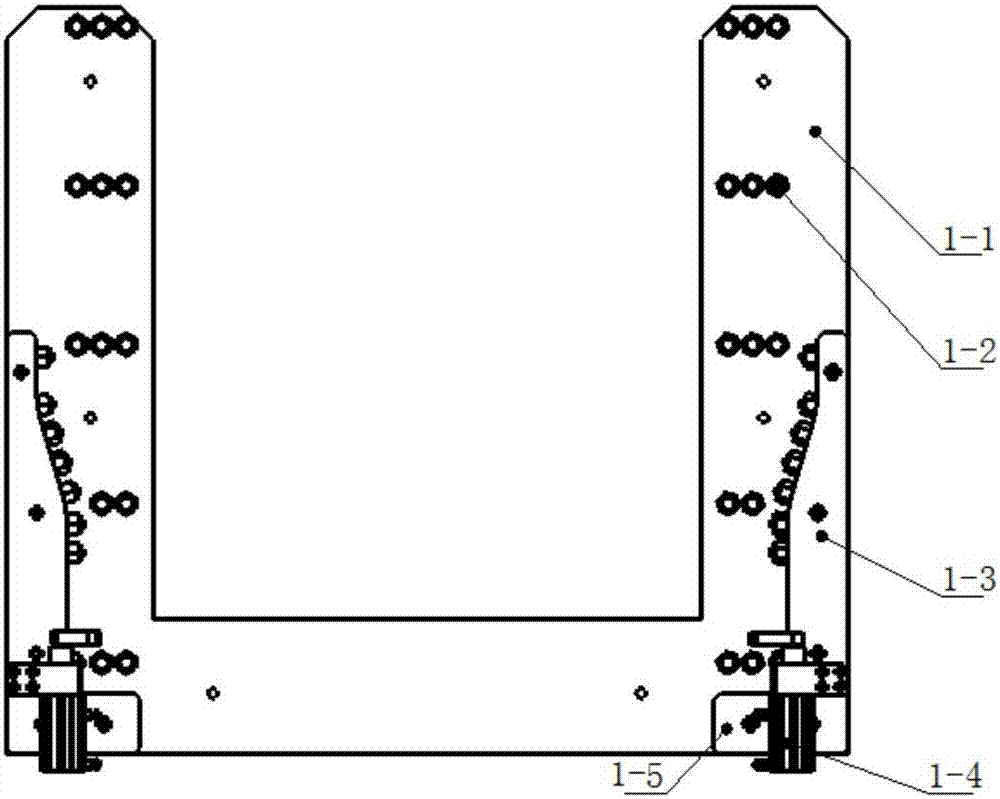

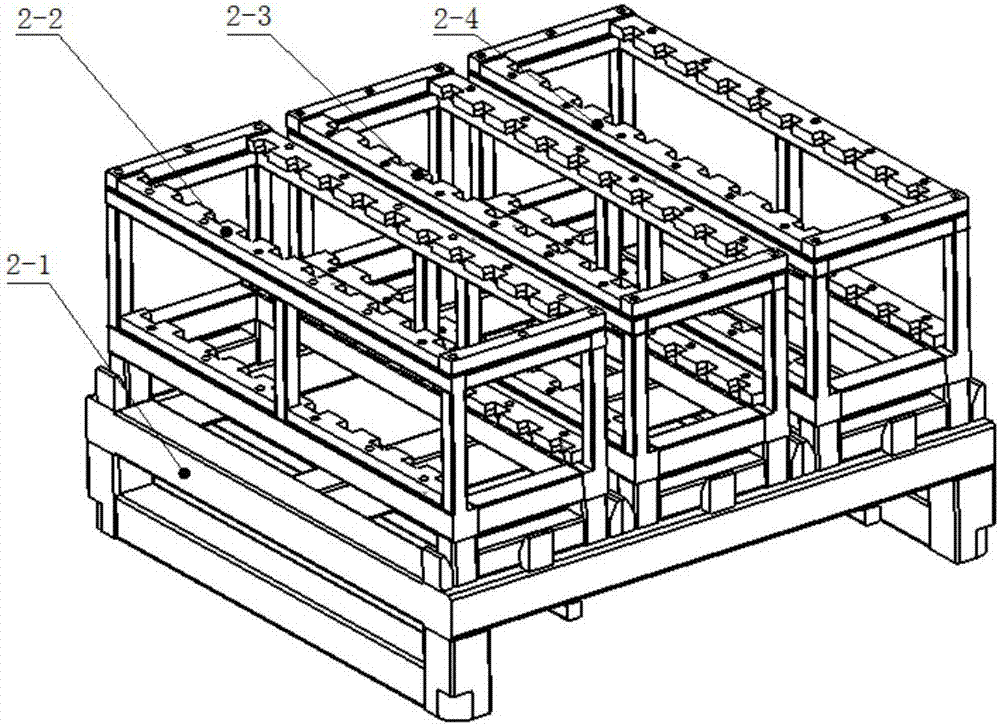

Low-carbon plywood machining assembly line

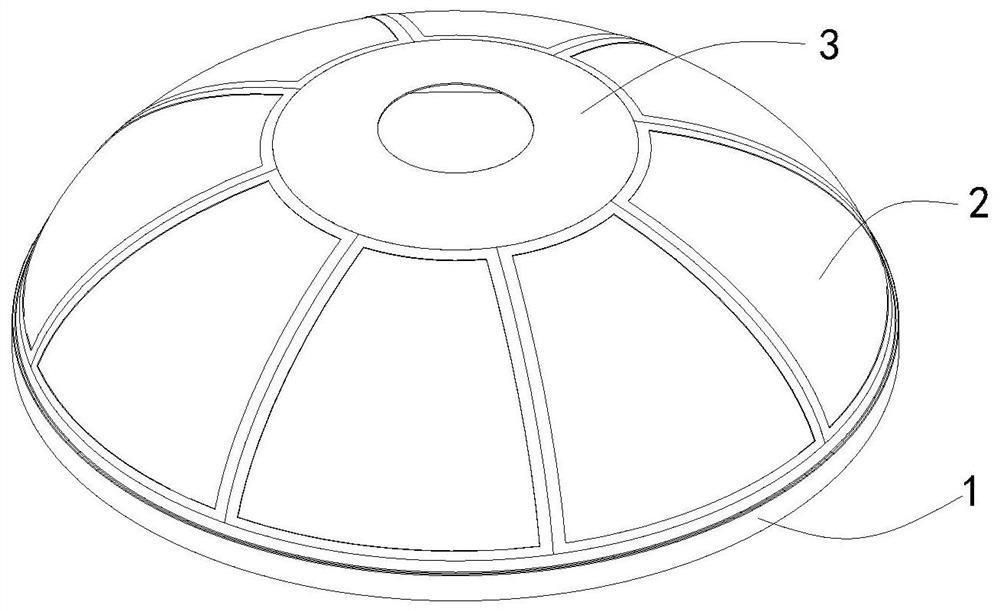

ActiveCN107053371AWill not cause torsion deviation, etc.Accurate and stable positionPlywood pressesVeneer pressesEngineeringAssembly line

The invention provides a low-carbon plywood machining assembly line. The low-carbon plywood machining assembly line comprises a prepressing device located on the upstream portion and used for carrying out prepressing on template blanks, a hot pressing device located on the downstream portion and used for carrying out hot pressing forming on the template blanks, a feeding device located on the upstream portion of the prepressing device and used for feeding, and a transfer device located between the prepressing device and the hot pressing device and used for transferring the template blanks on the prepressing device onto the hot pressing device. According to the low-carbon plywood machining assembly line, the structure form of traditional plywood machining equipment is broken through; and in the actual working process, the feeding device carries out feeding on the prepressing device, the prepressing device carries out prepressing on the template blanks, the pre-pressed template blanks are put on a movable bearing rack of the transfer device, and the multiple layers of template blanks are put into all layers of heating press plates of the hot pressing device one by one through the movable bearing rack. Therefore, by means of the low-carbon plywood machining assembly line, the template blanks can be conveyed to the hot pressing device efficiently, stably and accurately, the forming quality and efficiency of plywood are improved, high efficiency and low carbon are achieved, and practicality is high.

Owner:漳州鑫华成机械制造有限公司

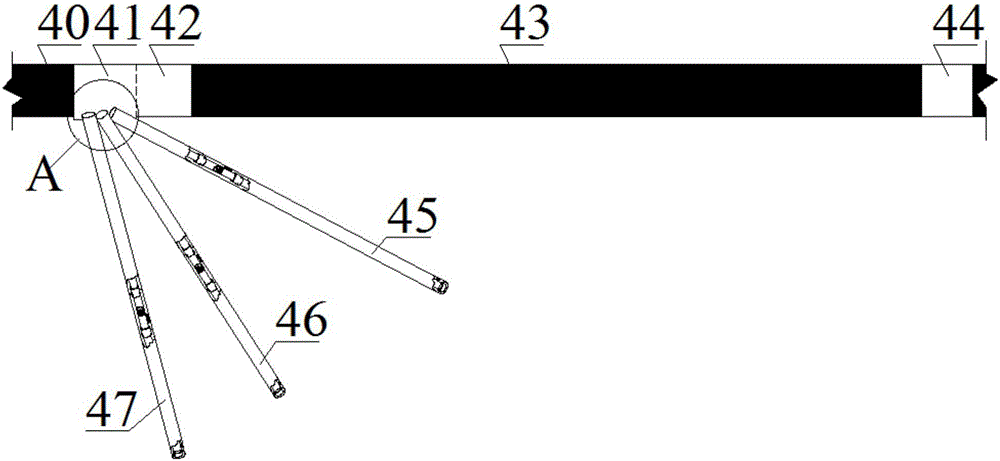

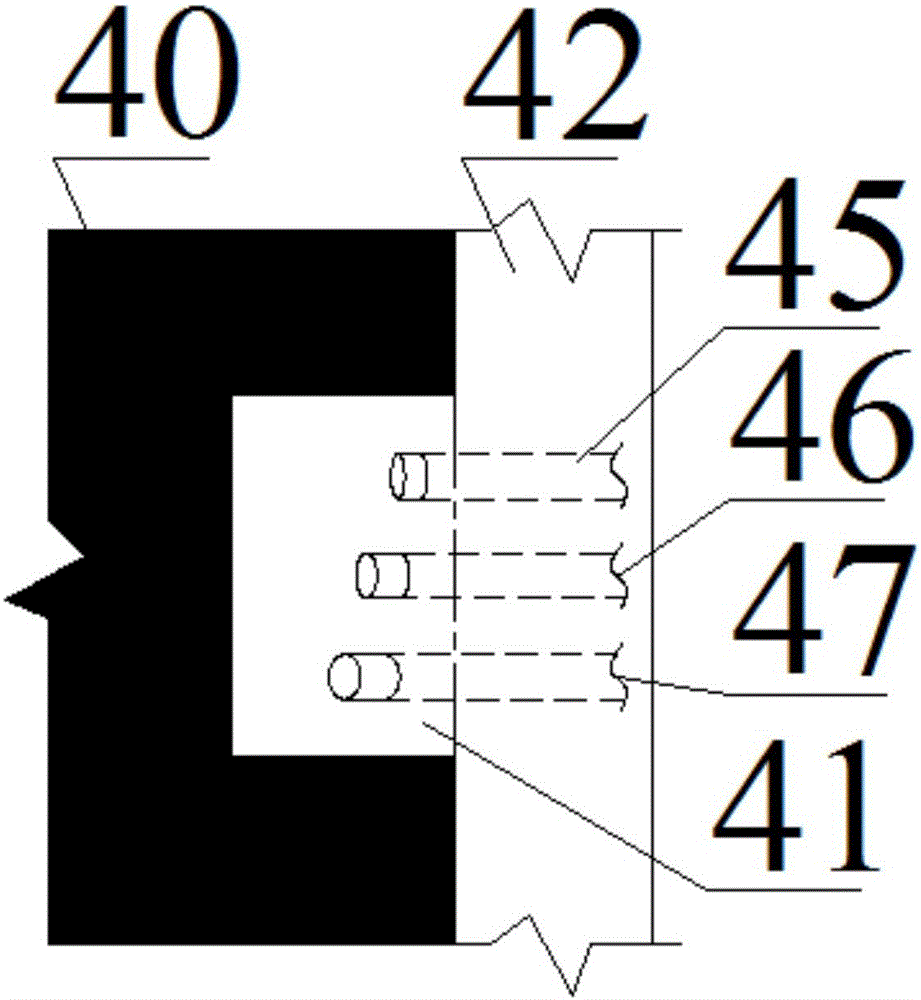

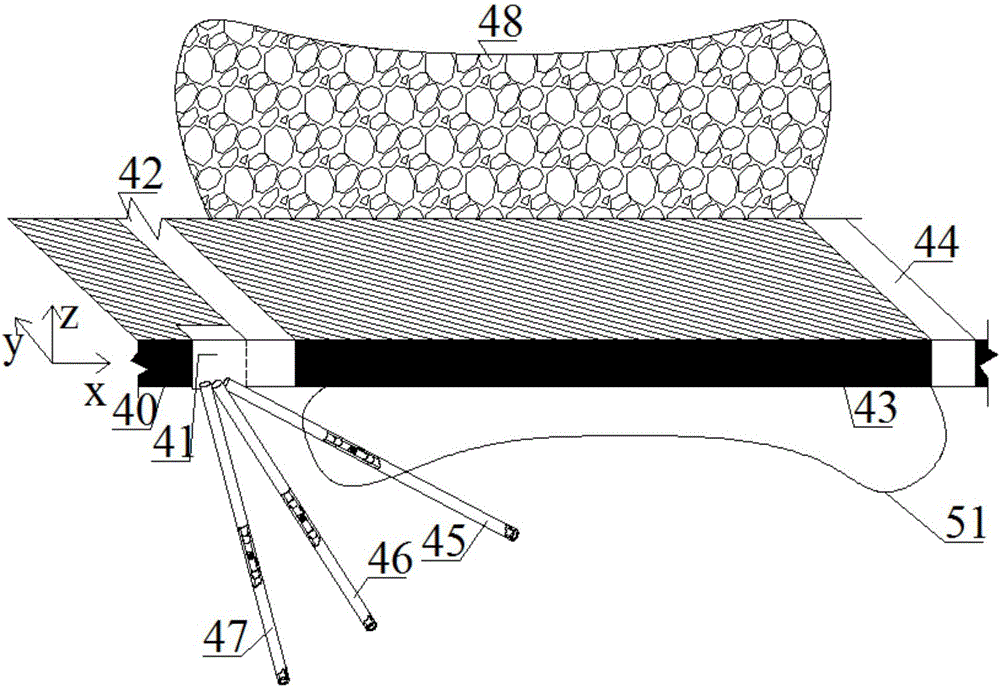

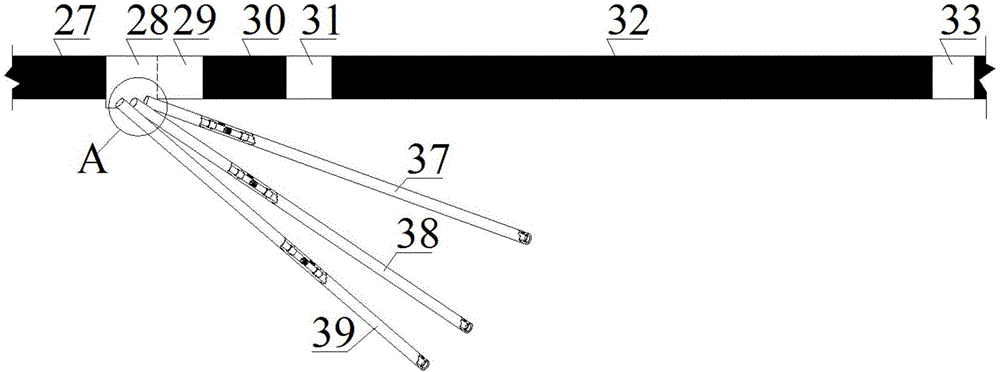

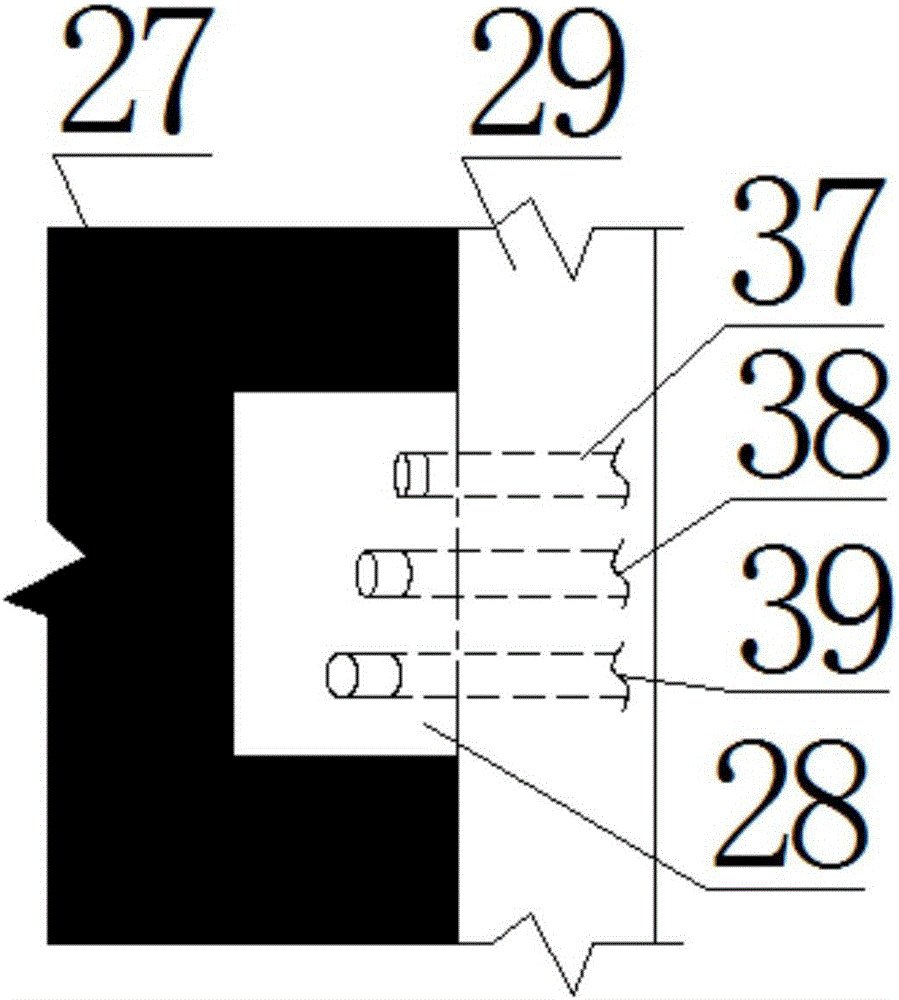

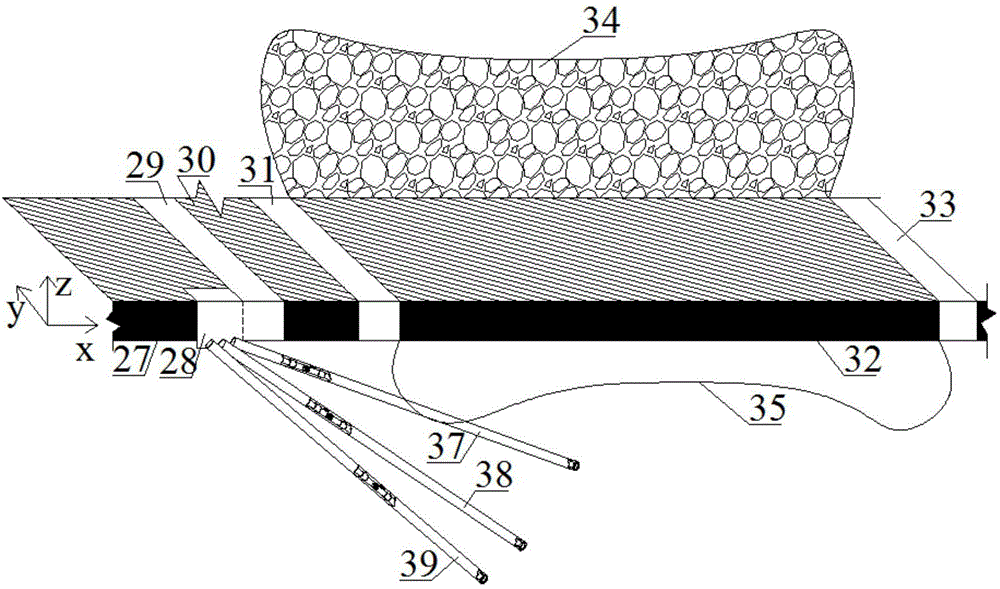

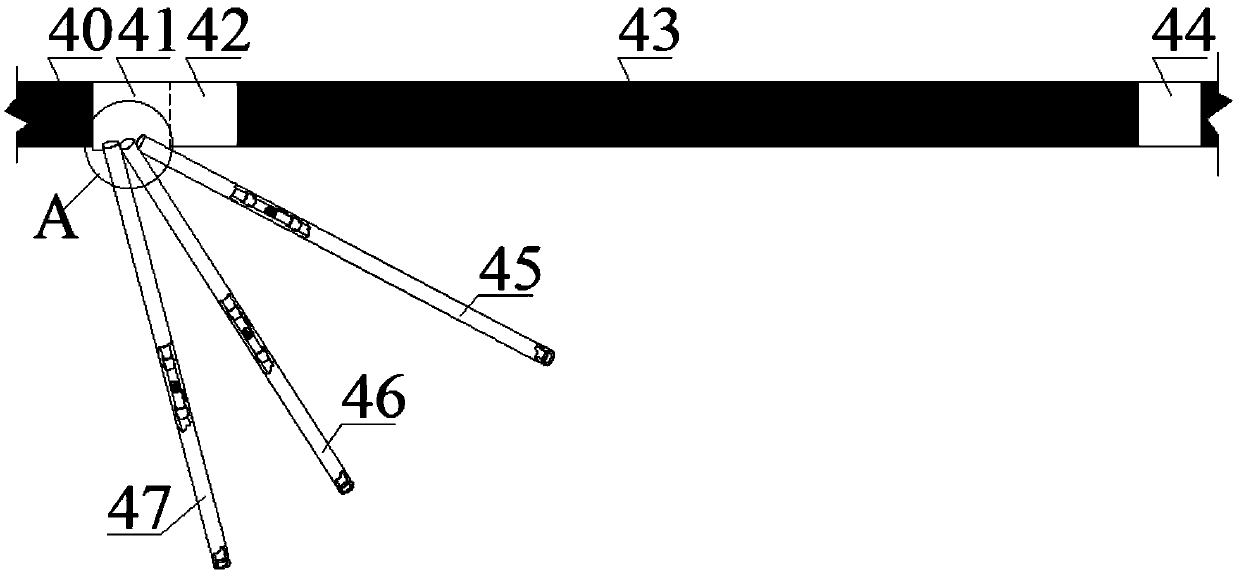

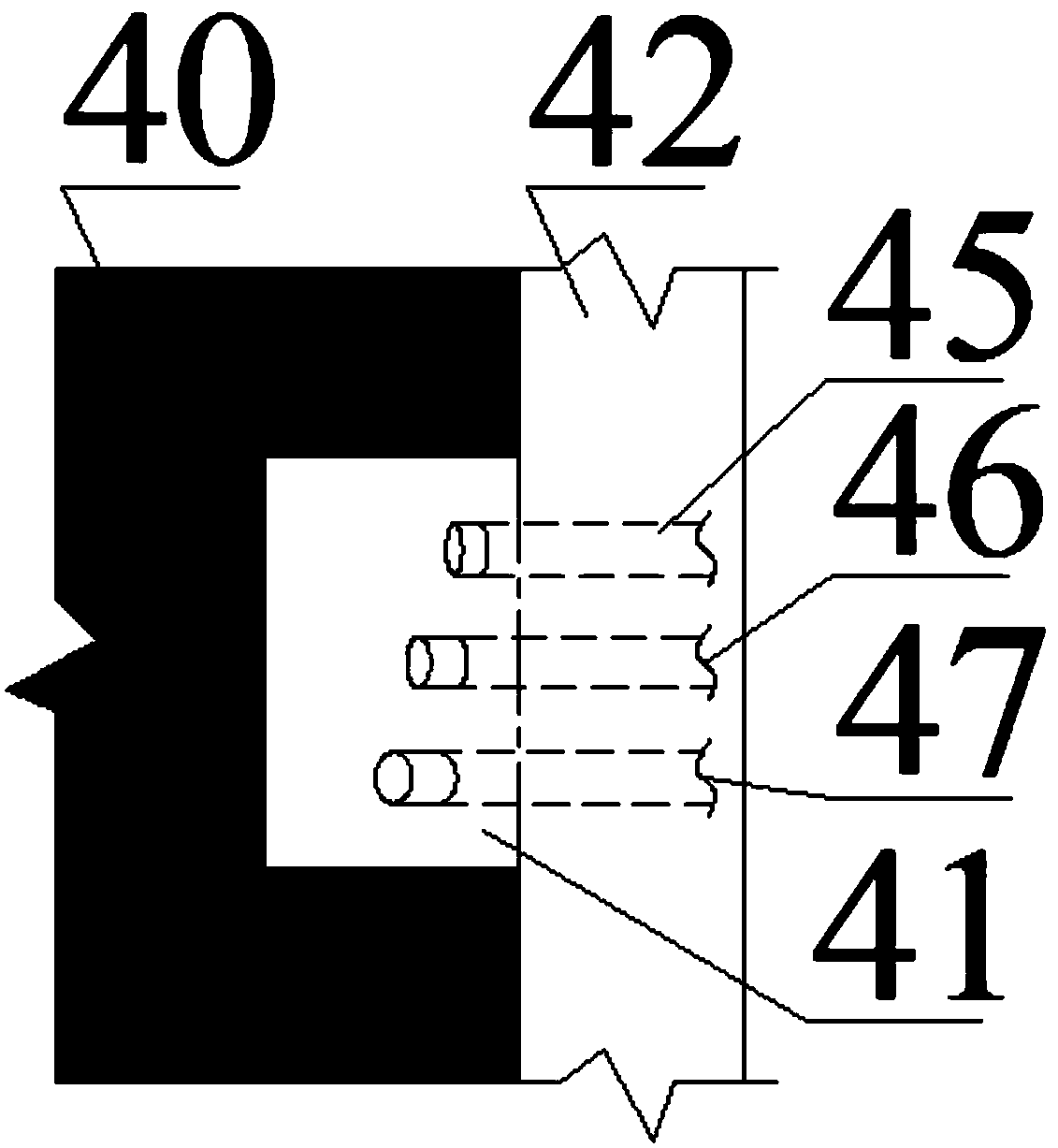

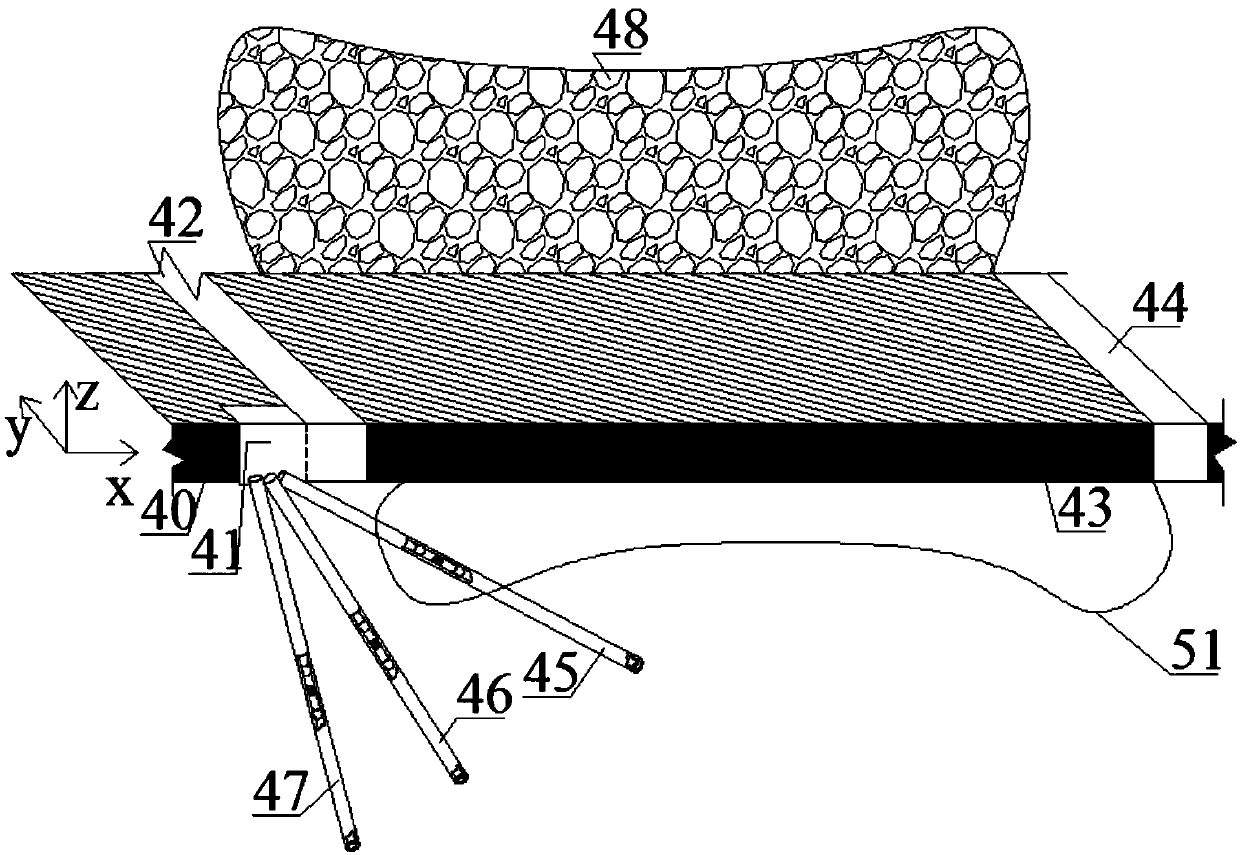

Detection system and method for monitoring fracture development of coal pillar-free gob-side entry retaining floor

ActiveCN106285628AReasonable structural designSafe and stable drillingSurveyConstructionsEngineeringCoal pillar

The invention relates to a detection system and a method for monitoring fracture development of a coal pillar-free gob-side entry retaining floor. The method comprises the following steps of chiseling a floor drilling field at one side of the coal pillar-free gob-side entry retaining, drilling in a floor rock layer according to different angles, gradually butting transparent hollow pipe sections by a butting sealing system, and sending into each drilling hole; grouting and anchoring a gap between each drilling hole and the corresponding transparent hollow pipe, enabling a detection positioning assembly to record the fracture of the drilling surrounding rock according to different scales of a measuring tape, performing monitoring tasks on evolution of floor mining failure rule for multiple times in different mining phases until the data is stable, and then finishing the observation. The method has the advantages that the floor small-angle drilling hole, the floor medium-angle drilling hole, and the floor large-angle drilling hole extend from the drilling field to the floor of a to-be-mined coal layer and are distributed in parallel in a stereo way; by observing the fracture condition of adjacent drilling holes in the same time and the fracture condition of the same drilling hole in different coal mining phases, the development state of the plastic failure area of the floor and the development state of the failure area of the floor after the coal bed is mined are determined, so as to provide reliable data reference for safety construction.

Owner:XIAN UNIV OF SCI & TECH

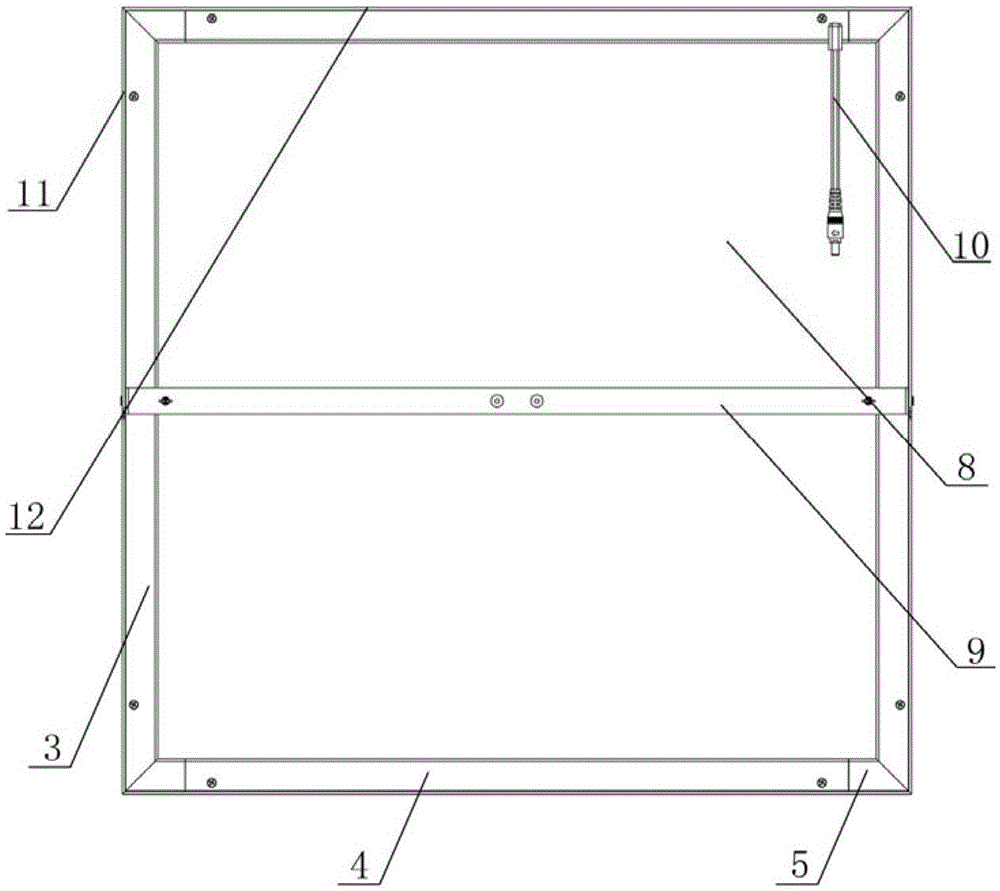

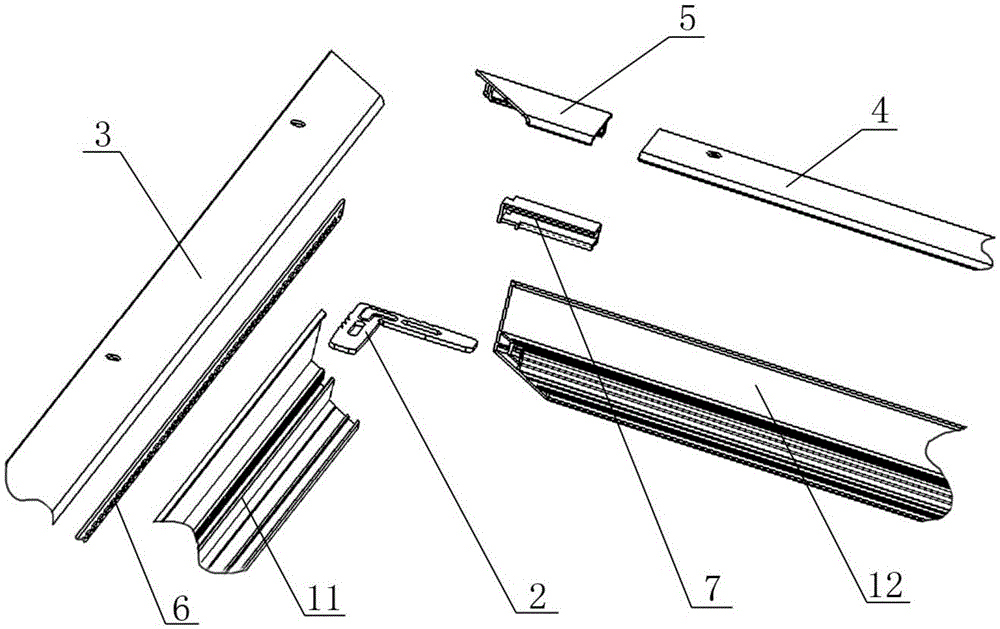

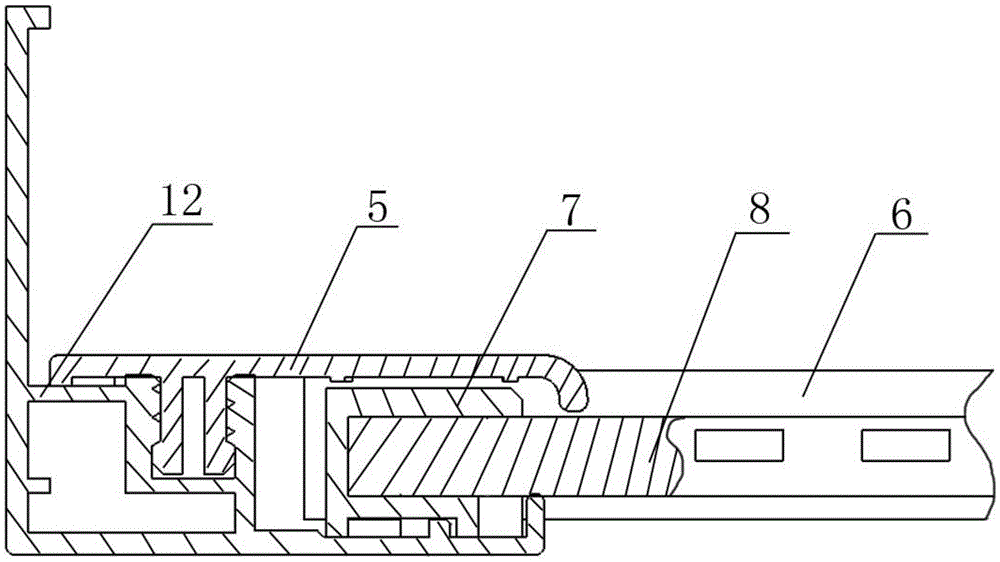

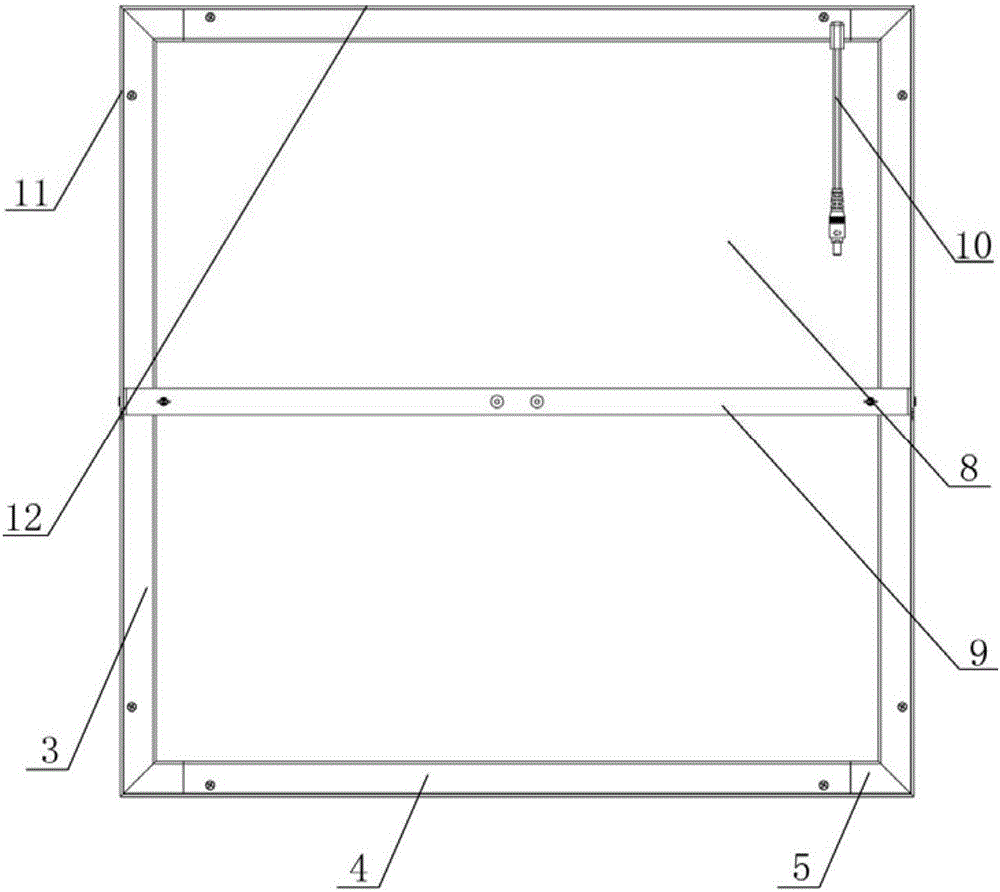

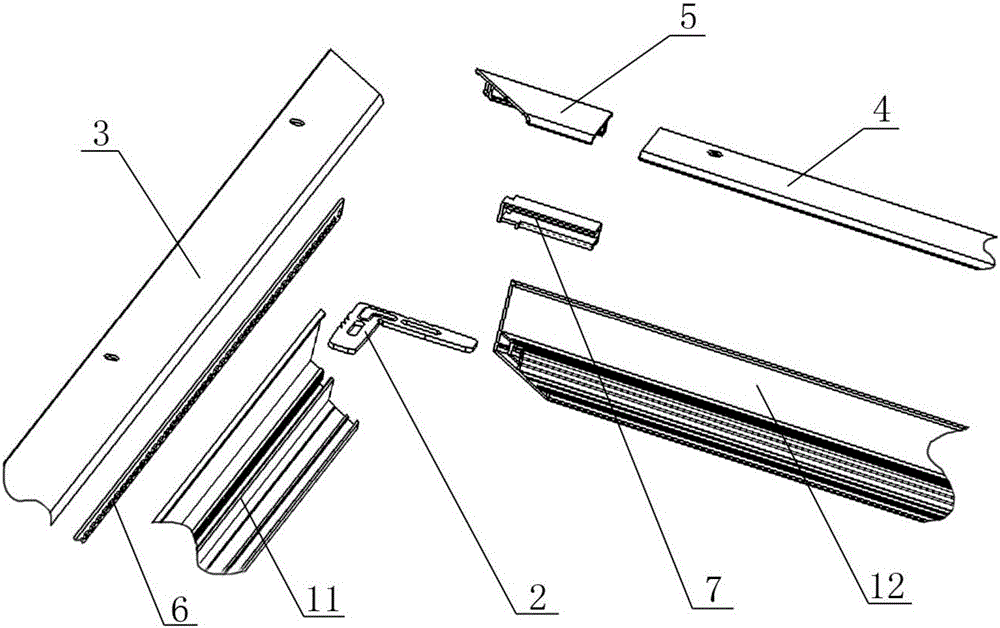

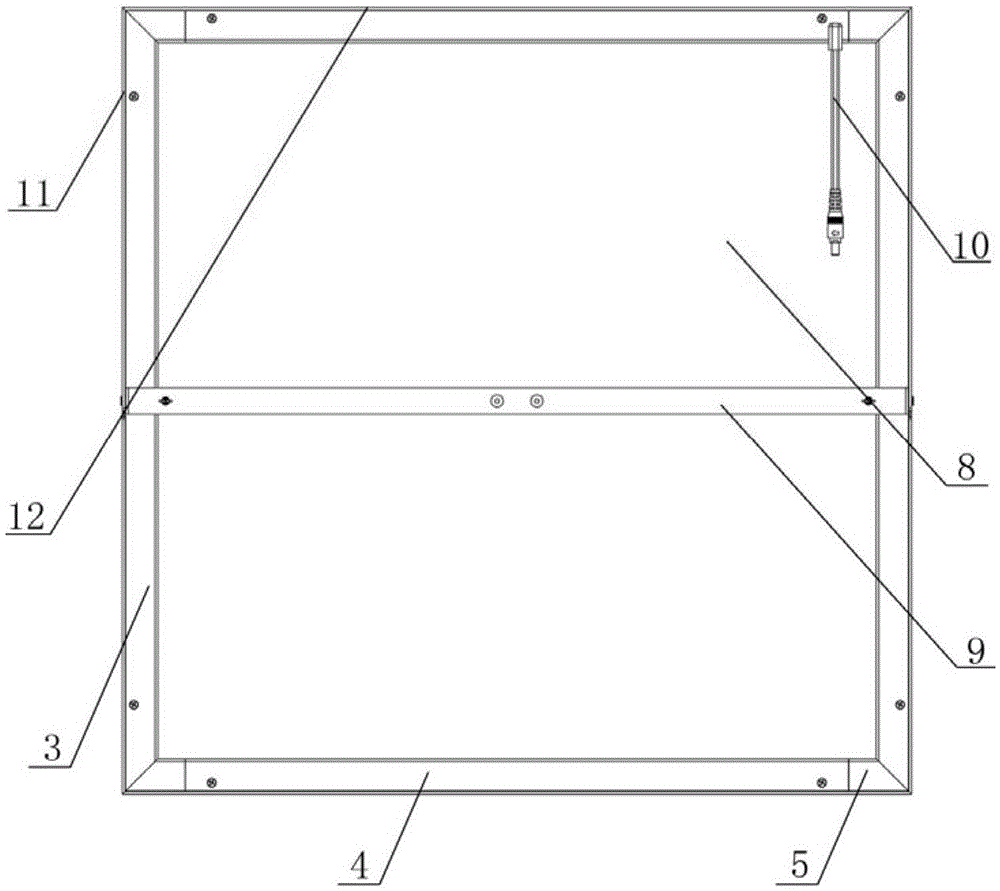

LED panel lamp

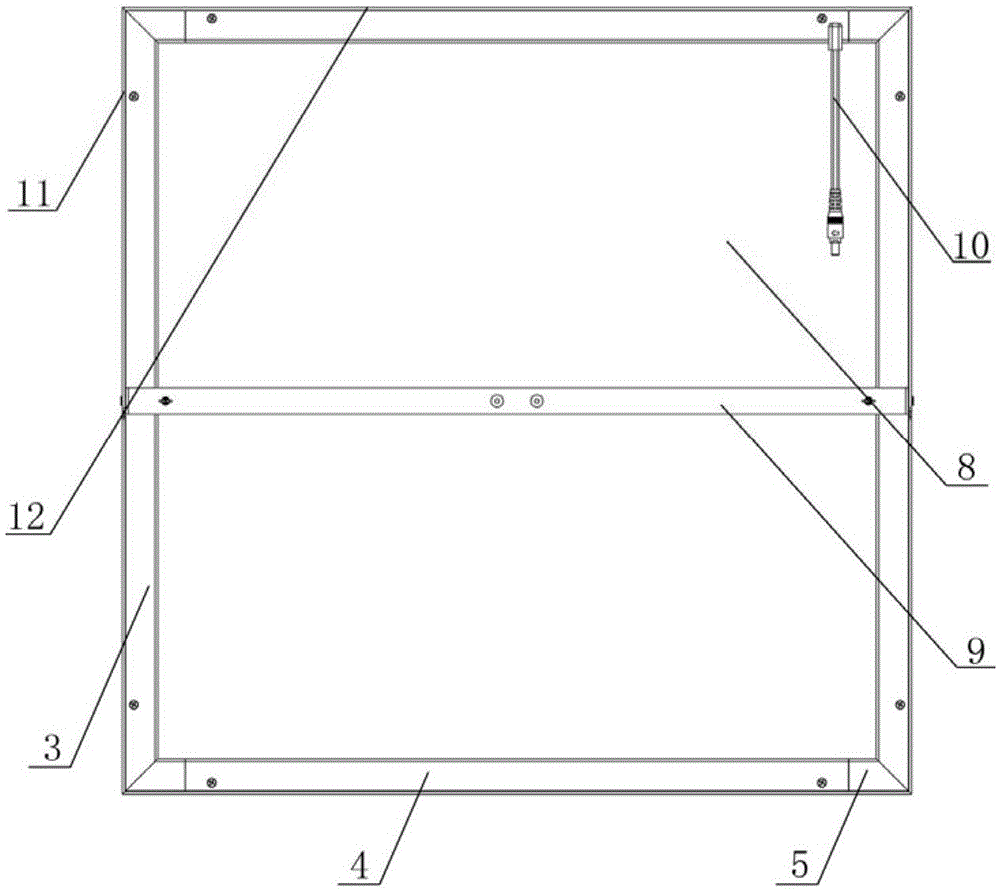

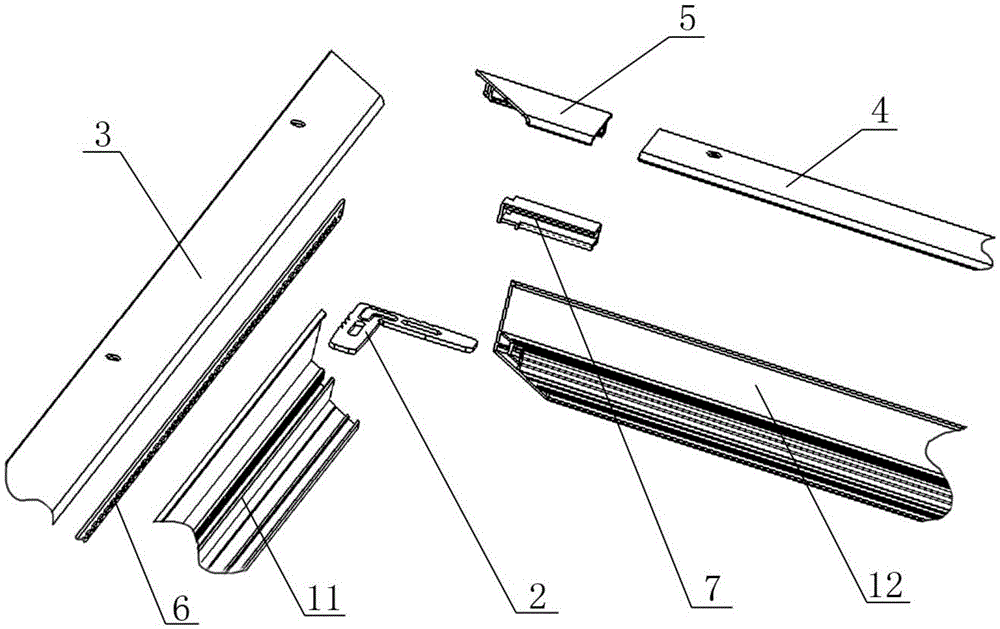

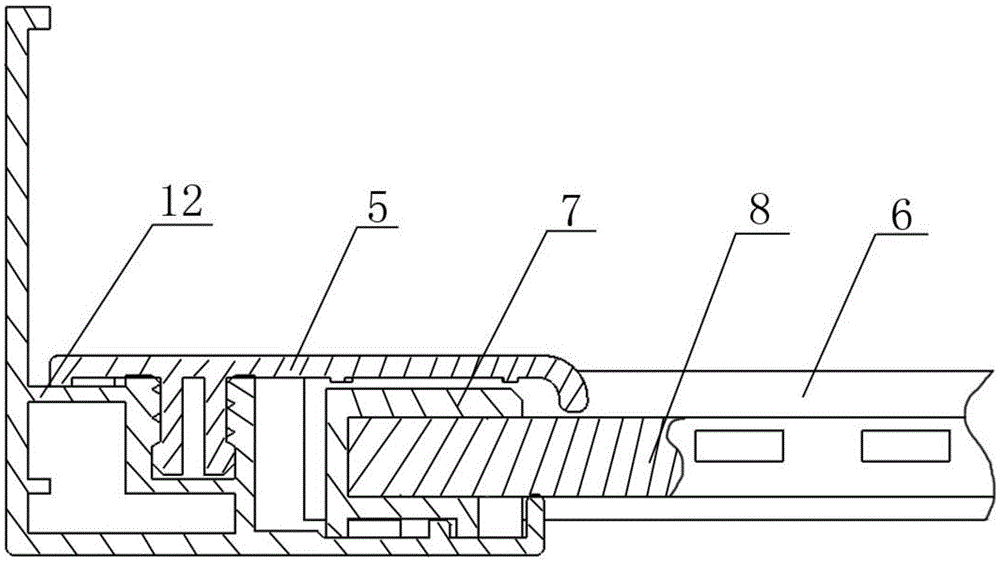

ActiveCN105650549AImprove structural strengthFirmly connectedPlanar light sourcesMechanical apparatusLight guideLED lamp

The invention relates to an LED panel lamp which comprises a frame, an LED lamp bar, positioning blocks and a light guide plate assembly, wherein the frame is formed by connection of two first frame profile bars and two second frame profile bars through four corner connection pieces, the two first frame profile bars are arranged oppositely, four corners of the light guide plate assembly are limited in clamping spaces of the four positioning blocks respectively, the four positioning blocks are fixed at the four corners of the frame, first profile bar cover plates are arranged on the first frame profile bars and mounted on the first frame profile bars in a detachable connection manner, the middles of the first profile bar cover plates extend downwards to form positioning bars, and the LED lamp bar is limited among the positioning bars and the positioning blocks; second profile bar cover plates are arranged on the second frame profile bars. The LED lamp bar is easy and convenient to replace, maintain and operate and is time-saving and labor-saving.

Owner:ANHUI ZERUN OPTOELECTRONICS

System and method for monitoring reserved coal pillaralong-goaf remained gateway floor crack development

ActiveCN106223931AReasonable structural designSafe and stable drillingSurveyConstructionsButt jointDrill site

The invention discloses a system and method for monitoring reserved coal pillaralong-goaf remained gateway floor crack development. A floor drill site is dug in one side of a reserved coal pillaralong-goaf remained gateway, different depths of drilling is conducted on a floor, and a butt joint sealing system is adopted to deliver transparent hollow pipes to drill holes in a section-by-section butt joint mode; after casting is conducted in gaps between the drill holes and the transparent hollow pipes for anchorage, a detecting and positioning assembly is utilized to record surrounding rock gaps of the drill holes at different positions on a measuring ruler, and floor's mining fracture law evolution monitoring tasks are carried out at different mining stages for multiple times till data trends to stable observation finishing. According to the method, floor shallow part drill holes, floor middle deep drill holes and floor deep part drill holes extending from the floor drill site to the mining coal floor and arranged side by side are arranged in a stereo mode, the middle floor plastic failure zone developmental morphology during mining and floor failure zone developmental morphology can be delineated by observing the adjacent drill holes and the gap situations of the same drill holes at different coal mining stages at the same time, and reliable data reference can be provided for safe construction.

Owner:中国平煤神马控股集团有限公司 +2

Construction method of fabricated under-crossing tunnel

InactiveCN109208642AStable supportOrderly supportArtificial islandsUnderwater structuresLine segmentBuilding construction

The invention discloses a construction method of a fabricated under-crossing tunnel, comprising the following steps of: a, constructing a concrete foundation at the bottom of the foundation pit, and setting a steel rail thereon; b, lifting a bottom plate over the steel rail in place, lifting and aligning a top plate over the bottom plate and dropping the bottom plate down, and connecting and assembling the bottom plate and the top plate into a ring to form a single tunnel segment; c, assembling subsequent segments into a ring and then pushing the subsequent segment to attach the previous segment, and performing longitudinal permanent prestress compression on the plurality of segments to form a hole segment; d, repeating steps b and c to form a plurality of hole segments, and setting a settlement joint between the adjacent hole segments; e, grouting the gap between the segment bottom plate and the concrete foundation after the assembly is completed. According to the construction method,the under-crossing tunnel can be ensured to be assembled in order, the engineering quality of the entire under-crossing tunnel is ensured, the assembly progress of the under-crossing tunnel is also accelerated, the construction efficiency is improved, and the engineering cost is largely saved.

Owner:CHINA RAILWAY 23RD CONSTR BUREAU LTD +1

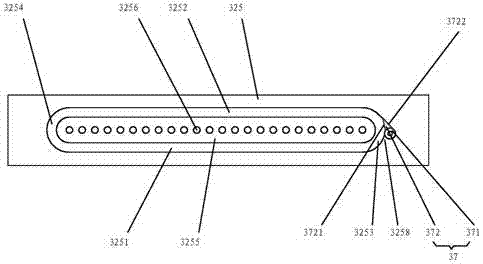

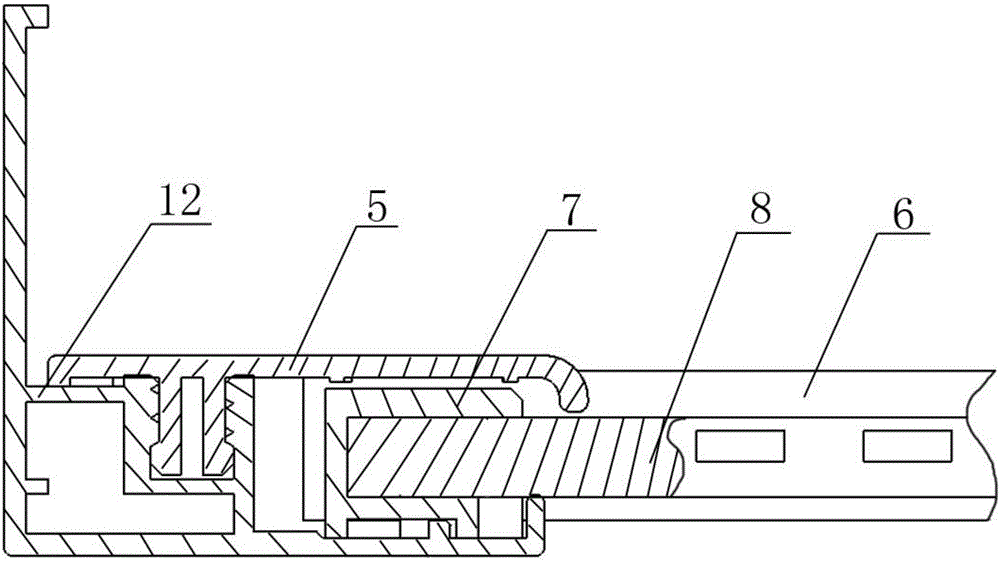

LED panel lamp and lamp bar installation structure thereof

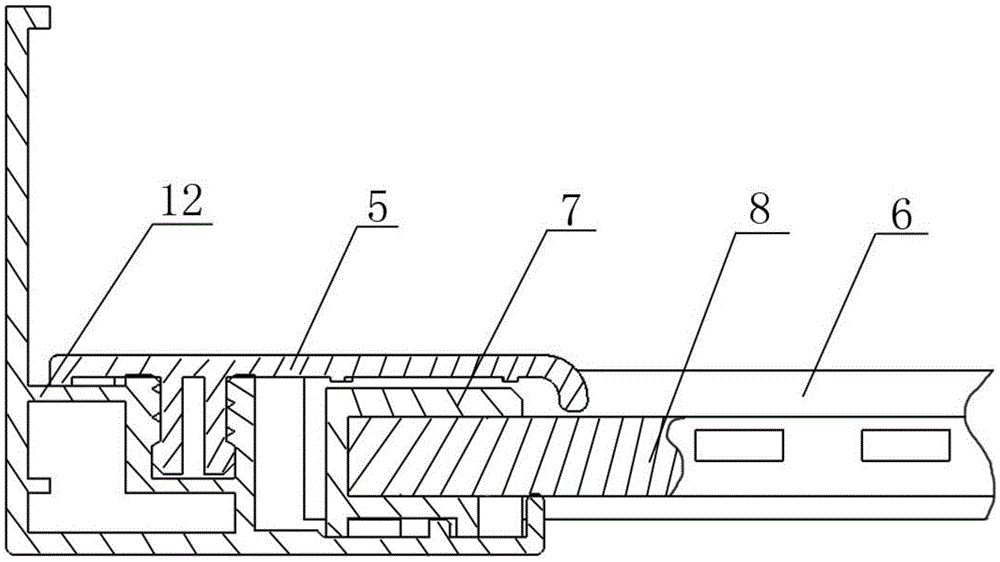

ActiveCN105650554AImprove structural strengthAccurate and stable positionMechanical apparatusLight guides detailsLight guideEngineering

The invention belongs to the field of lighting lamps and particularly relates to a detachable LED panel lamp and a lamp bar installation structure thereof. The lamp bar installation structure comprises a frame, an LED lamp bar, positioning blocks and a light guide plate assembly, wherein the frame is formed by connection of two first frame profile bars and two second frame profile bars through four corner connection pieces, first profile bar cover plates are mounted on the first frame profile bars in a detachable connection manner, the middles of the first profile bar cover plates extend downwards to form positioning bars, the cross sections of the positioning bars of the first profile bar cover plates are in L shapes, the tail ends of the L shapes are folded to form second limit flanges, first limit flanges are further arranged in the positions, corresponding to the second limit flanges, of the first profile bar cover plates, the positioning bars of the first profile bar cover plates, the first limit flanges and the second limit flanges form an accommodating space, and the LED lamp bar is located in the accommodating space. The LED lamp bar is easy and convenient to replace and is time-saving and labor-saving.

Owner:ANHUI ZERUN OPTOELECTRONICS

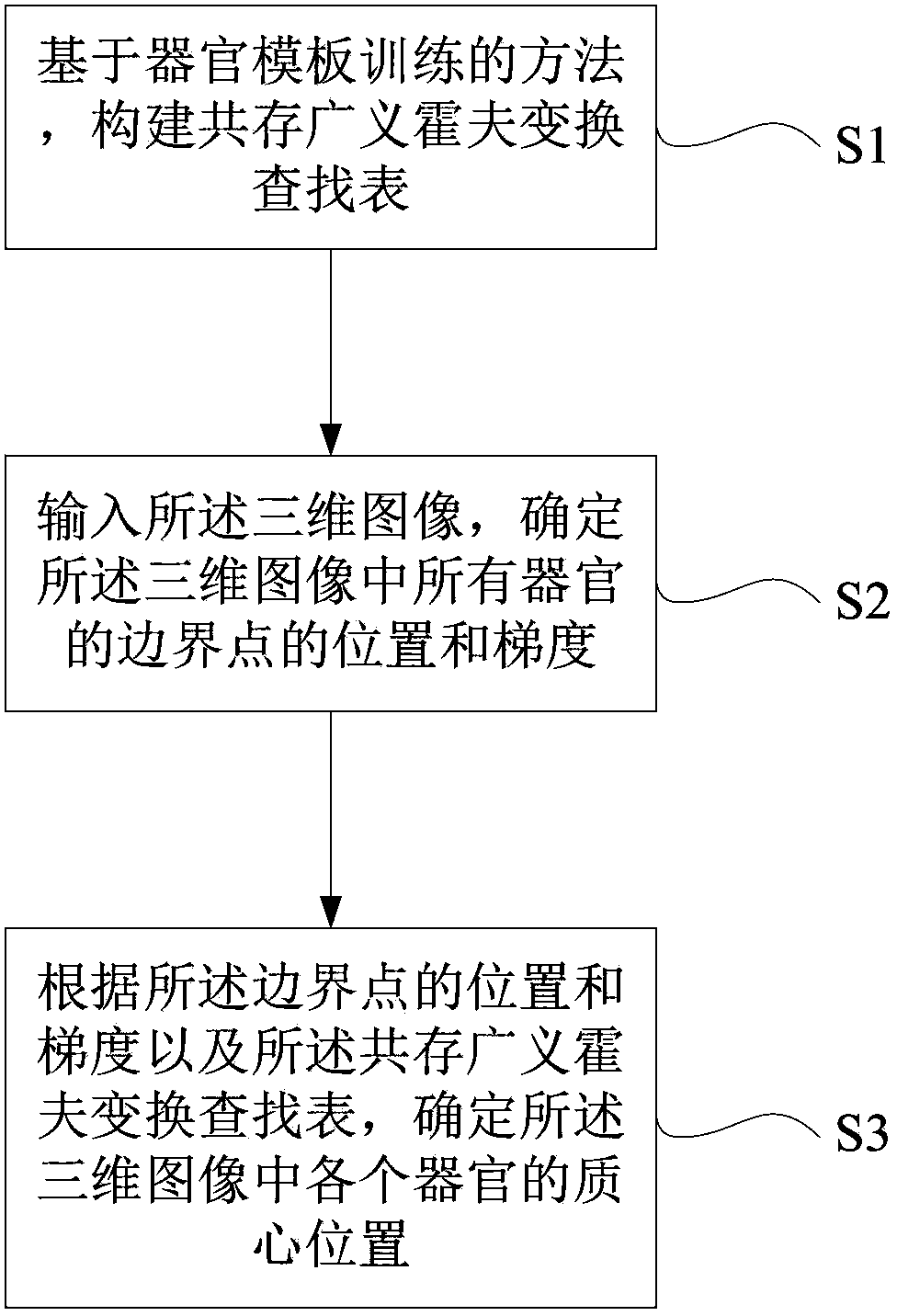

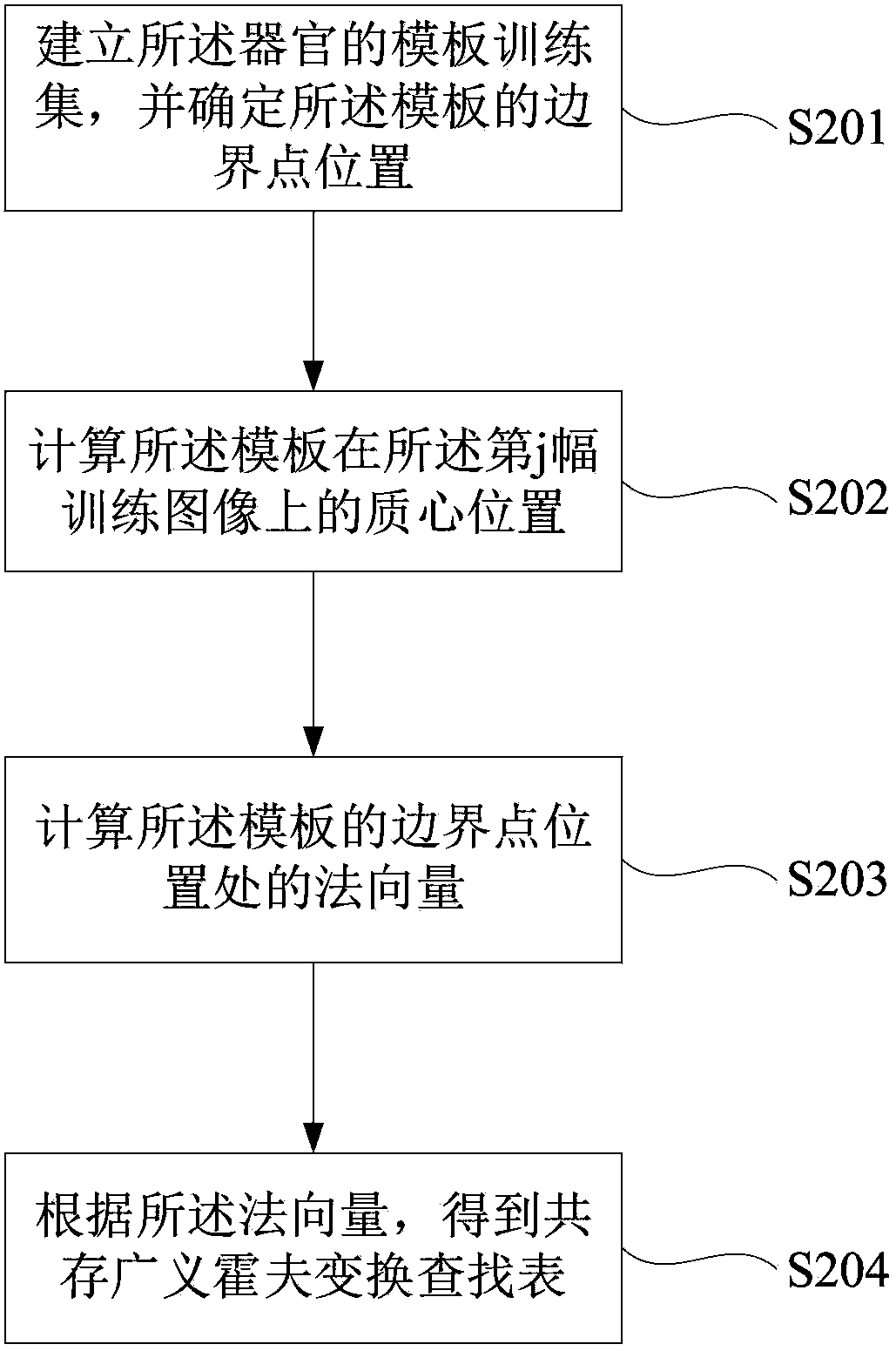

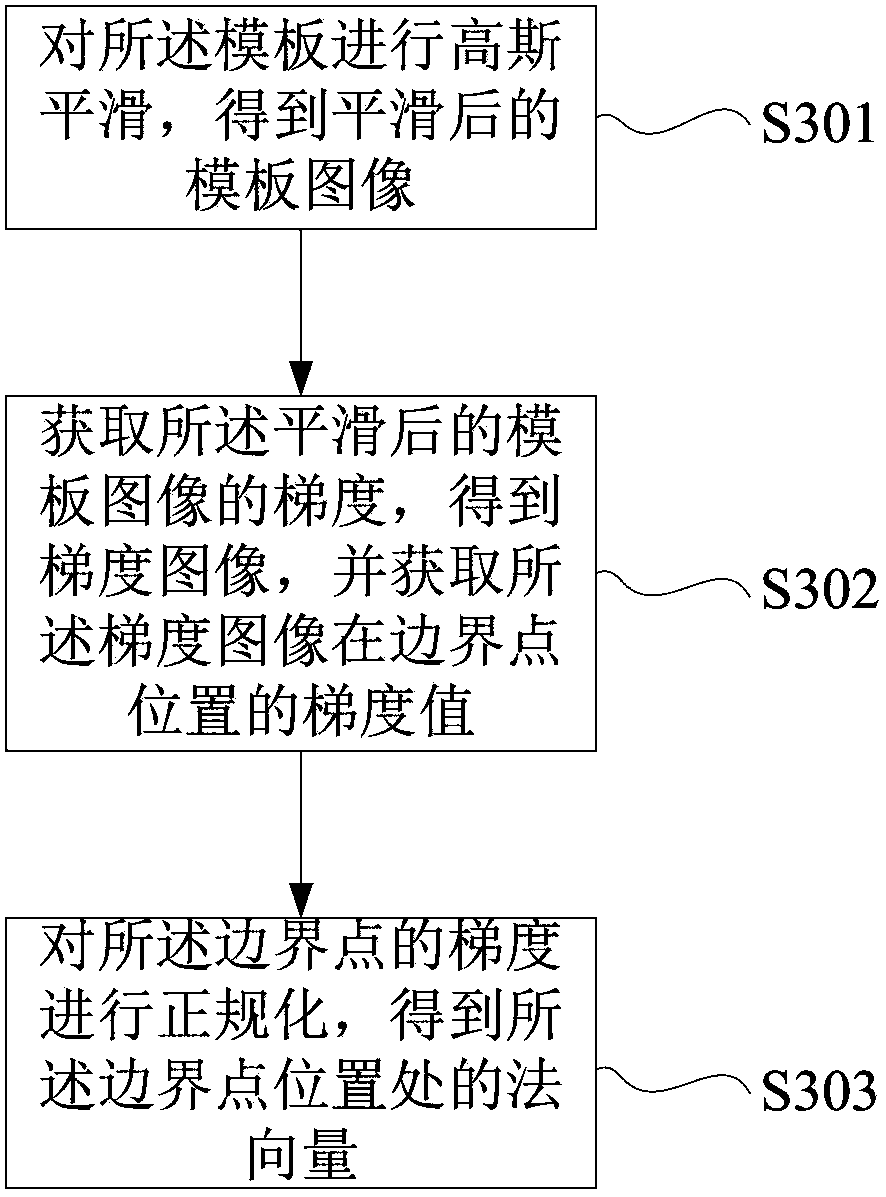

Positioning method of multiple organs in three-dimensional image

ActiveCN104123711ASimilar space orientationReduce complexityImage analysisHough transformLookup table

The invention provides a positioning method of multiple organs in a three-dimensional image. The positioning method comprises constructing a coexistence generalized Hough transform lookup table of the offset of a boundary point of any one organ relative to the positions of the center of mass of all the organs based on an organ template training method; inputting a three-dimensional image, and determining positions and gradients of the boundary points of all the organs in the three-dimensional image; and based on the positions and gradients of the boundary points and the lookup table, determining the position of the center of mass of each organ in the three-dimensional image, that is determining the position of each organ in the three-dimensional image. According to the invention, by use of the form information on an organ in need of position and relative position relation information with other organs, the position of the organ in the image can be quickly, accurately and stably positioned.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

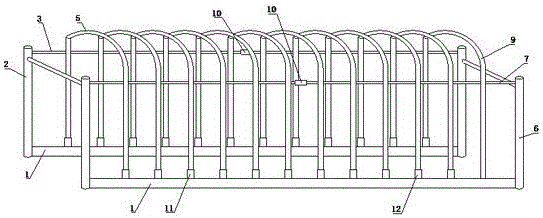

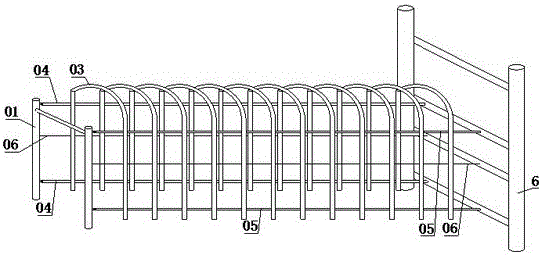

Foldable vegetable cultivation greenhouse

InactiveCN106613515AAccurate and stable positionRetractableClimate change adaptationGreenhouse cultivationGreenhouseAgricultural engineering

The invention provides a foldable vegetable cultivation greenhouse. In order to solve the problem that an existing greenhouse is troublesome to disassemble and assemble, the foldable vegetable cultivation greenhouse comprises a front greenhouse body and a rear greenhouse body, and the folding weight is lowered; the front greenhouse body slides on a front connecting rod through a front U-shaped rod, so that the front greenhouse is folded or unfolded; the position of the front U-shaped rod can be fixed by inserting a threaded sleeve into a positioning hole; the connecting rod is stretchable and convenient to fold; the rear greenhouse body and the front greenhouse body are the same in working principle. The foldable vegetable cultivation greenhouse is convenient to assemble and disassemble, can be folded when not in use, can be unfolded at any time when in use, and can be repeatedly used, resources are saved, and the cost is lowered. By adopting a guide rail, the front threaded sleeve and a rear threaded sleeve can be prevented from being corroded by the ground. In a climbing frame, the U-shaped frame can move back and forth on the connecting rod, the connecting rod is composed of short rods hinged together in sequence, so that the connecting rod is convenient to fold, and the whole frame body is convenient to fold and unfold.

Owner:黄平县往上走生态种养殖科技有限公司

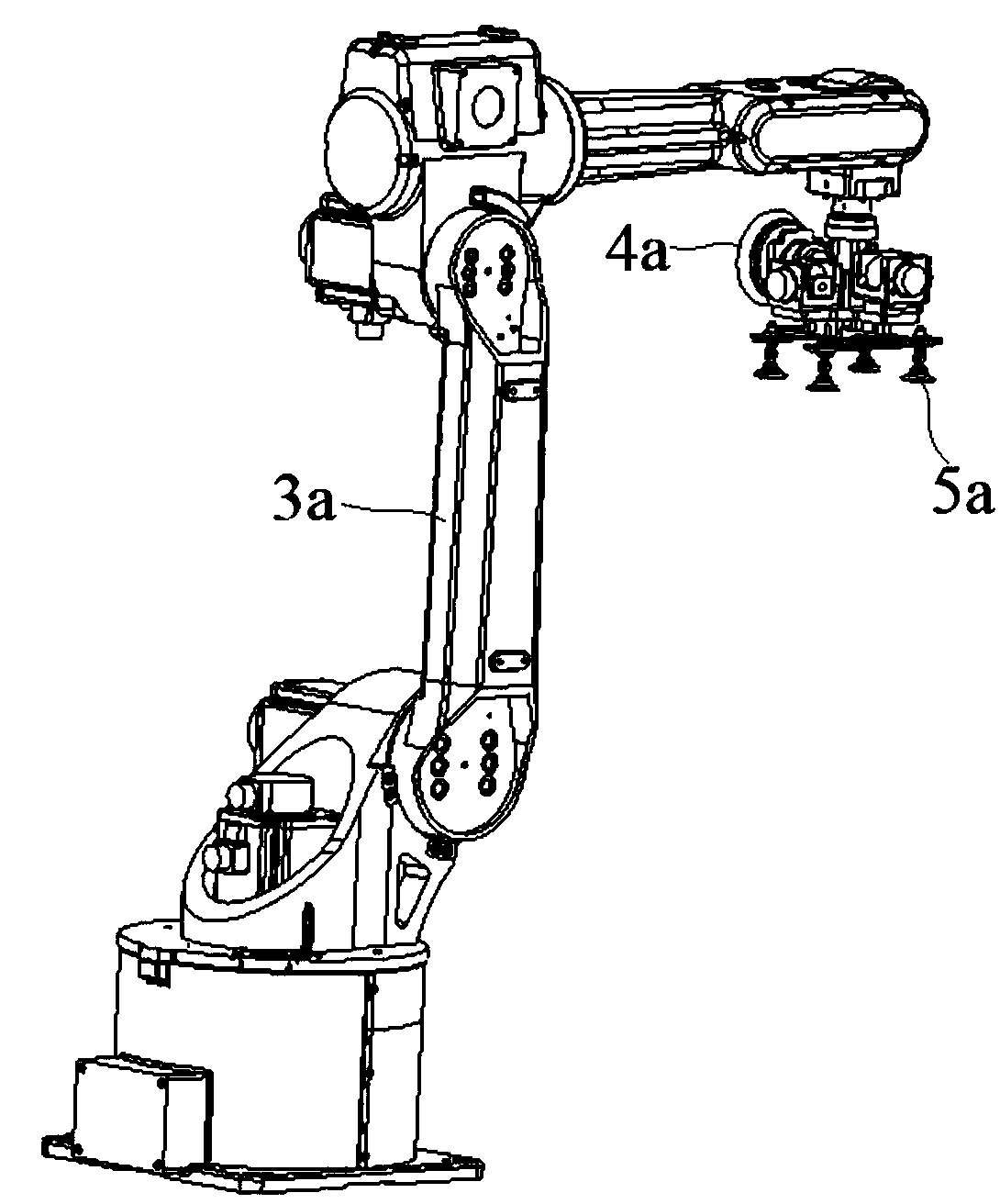

Automatic machining mechanism for notebook computer shell

InactiveCN109623567ASave materialReduce grinding time and processProgramme-controlled manipulatorGrinding carriagesEngineeringRubber ring

The invention discloses an automatic machining mechanism for a notebook computer shell. The automatic machining mechanism comprises feeding supports, polishing supports, a plurality of mechanical arms, a polishing head and a material-conveying clamp, the polishing head and the material-conveying clamp are mounted at and connected with end joints of the mechanical arms correspondingly, and the feeding supports and the polishing supports are arranged in the circumferential directions of the mechanical arms correspondingly; and a rubber ring is mounted at the tail end of a lower shaft part in a sleeving mode, a bearing is arranged in a shell part of a rotating shell, a sealing washer is arranged on the lower part of the bearing, an annular gasket is arranged on the lower part of the sealing washer, a washer is mounted on a lower shaft part of a core body in a sleeving mode and embedded into a through hole in the upper surface of a lower bearing seat, and the upper surface of the washer ishigher than the upper surface of the lower bearing seat. According to the automatic machining mechanism for the notebook computer shell, the situation that a rotating head is stuck when downward-pressing force is excessively large can be prevented, flexible rotation of the rotating head is ensured, through eccentric arrangement that the rotating head and the core body for driving the rotating head to rotate have different axes, a polishing trajectory is not left in the polishing process, and the elaborate degree of polishing is increased.

Owner:苏州丰川电子科技有限公司

Novel plastic injection mold

InactiveCN103481459AReasonable structural designSimple and efficient operationMaterials scienceInjection product

The invention discloses a novel plastic injection mold which comprises an upper mold and a lower mold, wherein a plastic injection mold cavity is formed when the two molds are closed; a material filling hole is formed in the top of the upper mold; the upper mold and the lower mold are connected by screws to achieve positioning and locking; the screws are connected to the left side and the right side of the outside of the plastic injection mold cavity respectively; light holes are formed in the upper mold; threaded holes are formed in the upper surface of the lower mold; and the locking force of the screws for connection are adjustable. According to the novel plastic injection mold, the structure design is reasonable; the upper mold and the lower mold are connected by the screws, the connecting mode is simple and convenient to operate, the connecting performance is stable; meanwhile, marks and scales are formed in the heads and the peripheral surfaces of the screws, so that the locking force is conveniently determined, the two ends of the mold are uniformly stressed in theory, the position of the jointing surface of the mold is more accurate and stable, and the appearance performance and the surface quality of a finished plastic injection product are guaranteed.

Owner:SUZHOU YIQUN MOLD

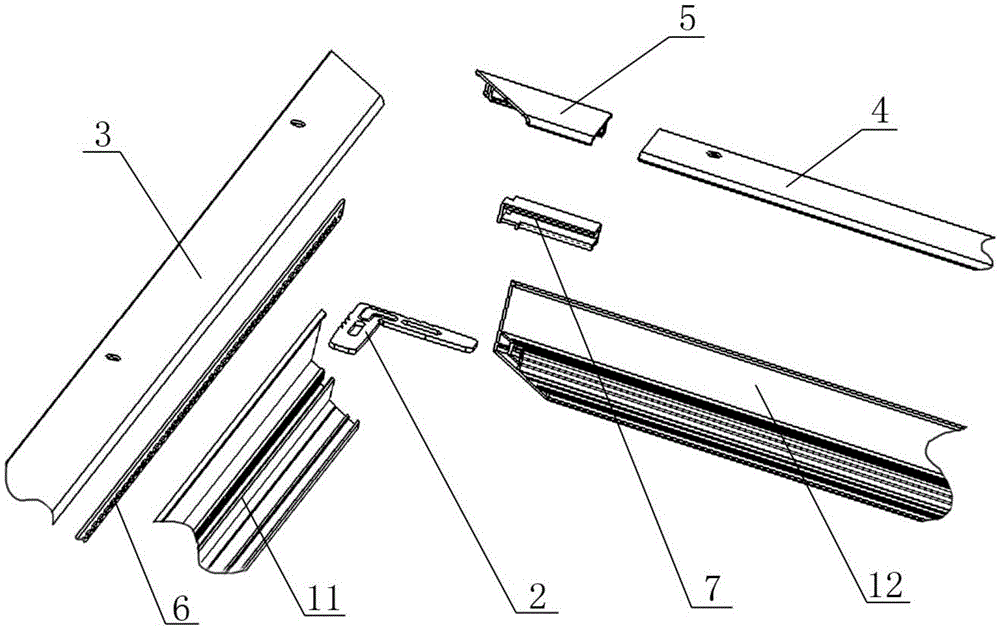

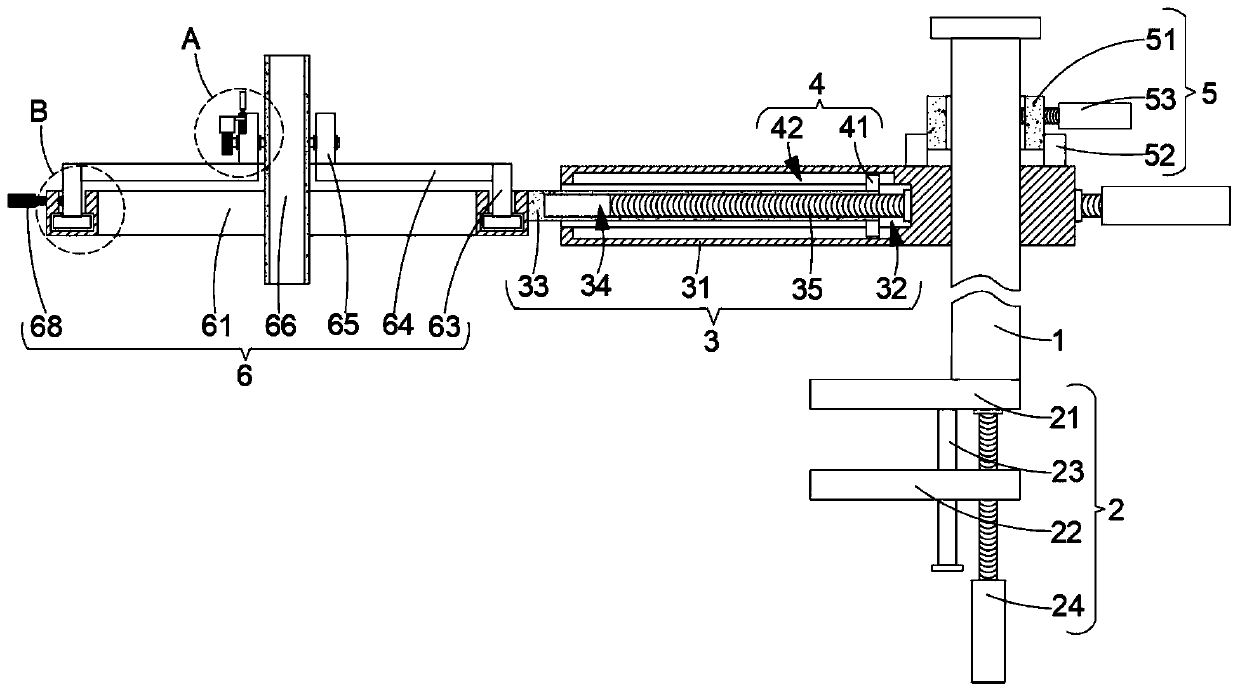

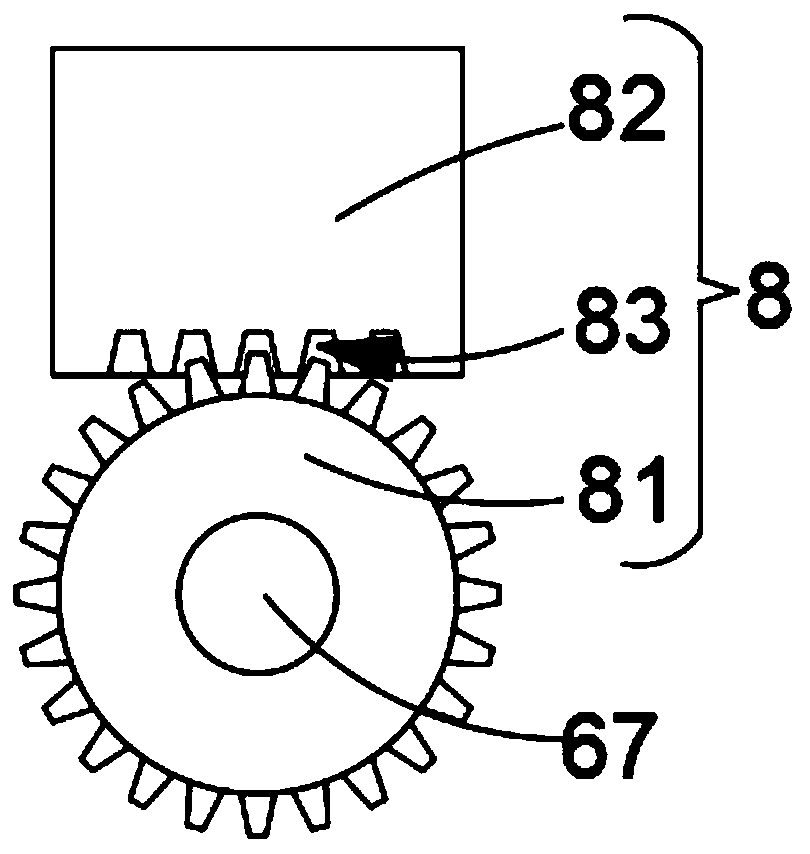

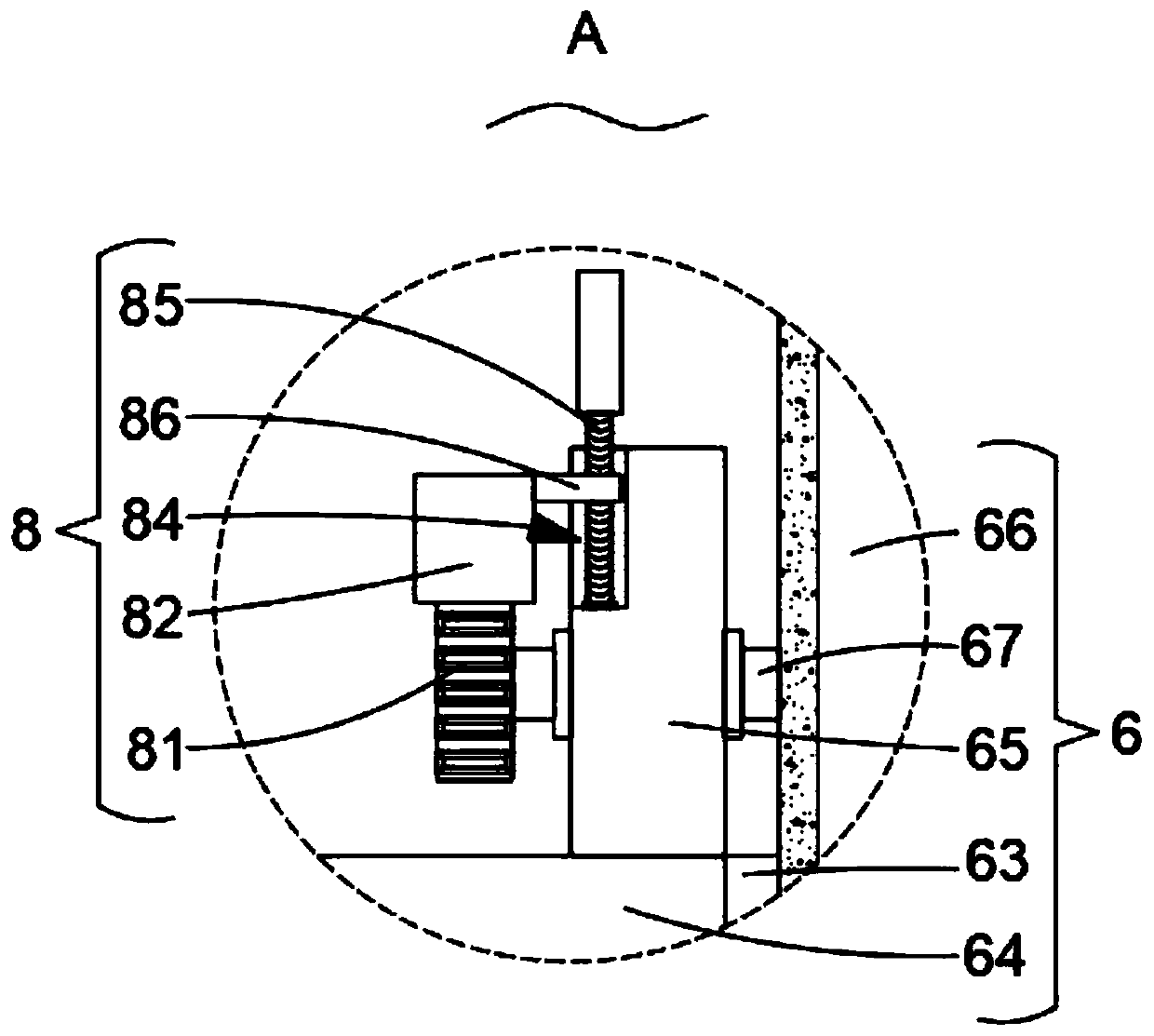

Computer case stamping and feeding device and operation method

ActiveCN112317596AReduce labor intensityEasy to installMetal-working feeding devicesStripping-off devicesCrankGear wheel

The invention discloses a computer case stamping and feeding device and an operation method. The computer case stamping and feeding device comprises a stamping machine tool, a punch, a connecting arm,a machine frame, a sliding groove, a rack, a gear, a one-way bearing, a crank, a sliding block and a feeding disc; a mold seat is arranged at the upper part of the stamping machine tool; a positioning pin is connected to one side of the mold seat; the machine frame is connected to the middle of the stamping machine tool; a stand column is arranged at the upper part of the machine frame; a fixinghole is formed in the upper part of the stand column; a sliding block seat is arranged on the back side of the fixing hole; a sliding groove is formed in the middle of the sliding block seat; the crank is arranged in the middle of the fixing hole; a crank rotating shaft is arranged on the back side of the crank; the crank rotating shaft is rotationally connected with the fixing hole; the crank rotating shaft rotates in the fixing hole; a crank arm is arranged on the left side of the crank; a connecting rod shaft is arranged on the left side of the crank arm; a second hole is formed in the right side of a connecting rod and is rotationally connected with the connecting rod shaft; and the connecting rod shaft rotates in the second hole.

Owner:重庆化工职业学院

led panel light

ActiveCN105650549BImprove structural strengthFirmly connectedPlanar light sourcesMechanical apparatusLight guideLED lamp

The invention relates to an LED panel lamp which comprises a frame, an LED lamp bar, positioning blocks and a light guide plate assembly, wherein the frame is formed by connection of two first frame profile bars and two second frame profile bars through four corner connection pieces, the two first frame profile bars are arranged oppositely, four corners of the light guide plate assembly are limited in clamping spaces of the four positioning blocks respectively, the four positioning blocks are fixed at the four corners of the frame, first profile bar cover plates are arranged on the first frame profile bars and mounted on the first frame profile bars in a detachable connection manner, the middles of the first profile bar cover plates extend downwards to form positioning bars, and the LED lamp bar is limited among the positioning bars and the positioning blocks; second profile bar cover plates are arranged on the second frame profile bars. The LED lamp bar is easy and convenient to replace, maintain and operate and is time-saving and labor-saving.

Owner:ANHUI ZERUN OPTOELECTRONICS

A detection system and method for monitoring the development of floor cracks in gob-free entry retaining without coal pillars

ActiveCN106285628BReasonable structural designSafe and stable drillingSurveyConstructionsEngineeringCoal pillar

The invention relates to a detection system and a method for monitoring fracture development of a coal pillar-free gob-side entry retaining floor. The method comprises the following steps of chiseling a floor drilling field at one side of the coal pillar-free gob-side entry retaining, drilling in a floor rock layer according to different angles, gradually butting transparent hollow pipe sections by a butting sealing system, and sending into each drilling hole; grouting and anchoring a gap between each drilling hole and the corresponding transparent hollow pipe, enabling a detection positioning assembly to record the fracture of the drilling surrounding rock according to different scales of a measuring tape, performing monitoring tasks on evolution of floor mining failure rule for multiple times in different mining phases until the data is stable, and then finishing the observation. The method has the advantages that the floor small-angle drilling hole, the floor medium-angle drilling hole, and the floor large-angle drilling hole extend from the drilling field to the floor of a to-be-mined coal layer and are distributed in parallel in a stereo way; by observing the fracture condition of adjacent drilling holes in the same time and the fracture condition of the same drilling hole in different coal mining phases, the development state of the plastic failure area of the floor and the development state of the failure area of the floor after the coal bed is mined are determined, so as to provide reliable data reference for safety construction.

Owner:XIAN UNIV OF SCI & TECH

Crankshaft rotating speed sensor positioning tool

PendingCN113189359APrecise positioningSmooth positioningLinear/angular speed measurementSpeed/acceleration/shock instrument detailsControl engineeringMechanical engineering

The invention discloses a crankshaft rotating speed sensor positioning tool. Thecrankshaft rotating speed sensor positioning tool comprises: a first tool step, wherein a clamping block is welded to one end of the first tool step, a handle is welded to the other end of the first tool step, and an anti-disengaging head is welded to the end, away from the first tool step, of the handle; a second tool step, wherein the second tool step is embedded in the side surface of the handle, and a limiting step is welded to the side face of the second tool step; and a knob, wherein the knob is nested on the outer side of the anti-disengaging head, wherein a threaded rod is fixedly connected to the middle position of the inner side of the knob. According to the invention, the crankshaft rotating speed sensor positioning tool can quickly and accurately position the mounting position of the crankshaft sensor bracket, so that the crankshaft rotating speed sensor can be smoothly mounted, the working efficiency is improved, the crankshaft rotating speed sensor positioning tool can be matched with different brackets, and the adaptability is improved.

Owner:GUANGXI YUCHAI MASCH CO LTD

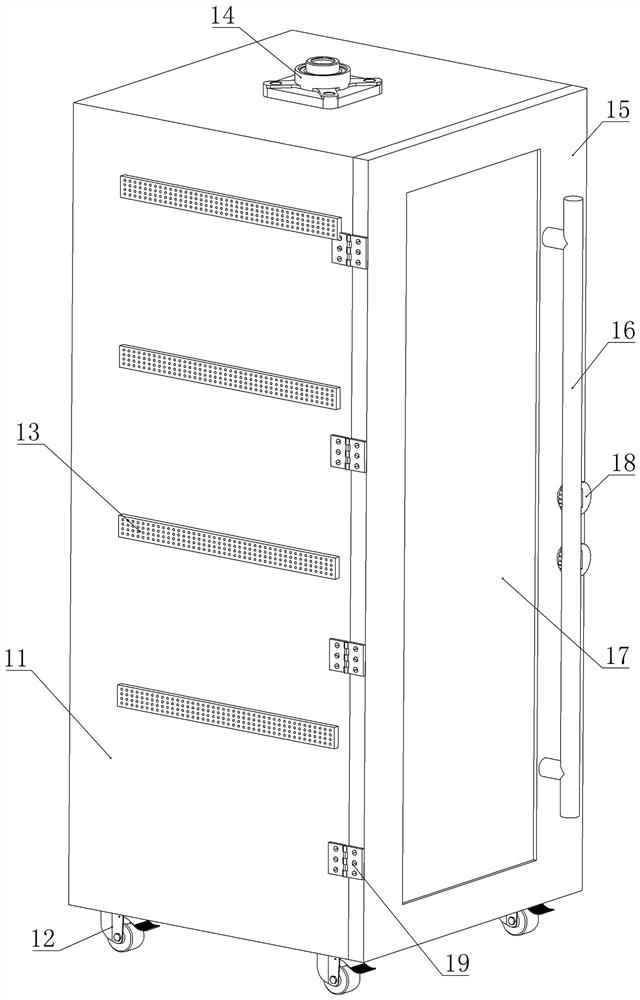

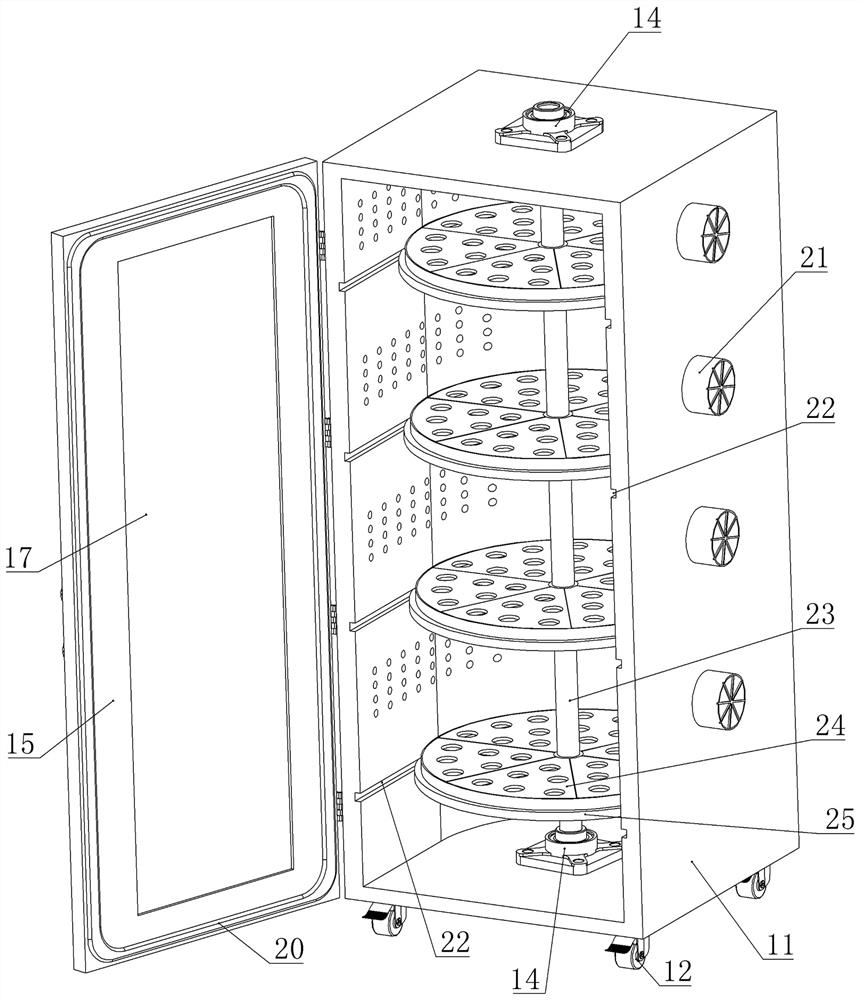

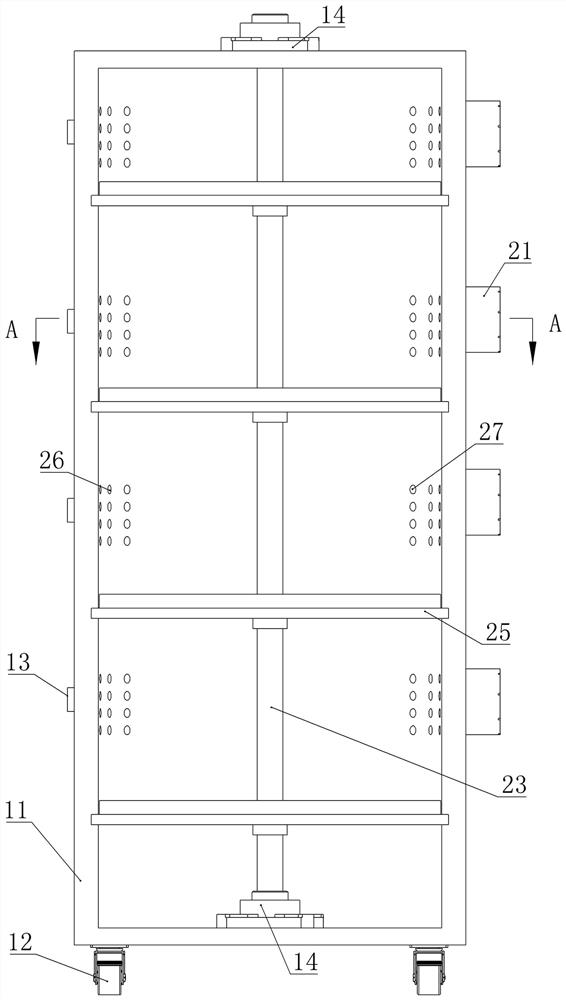

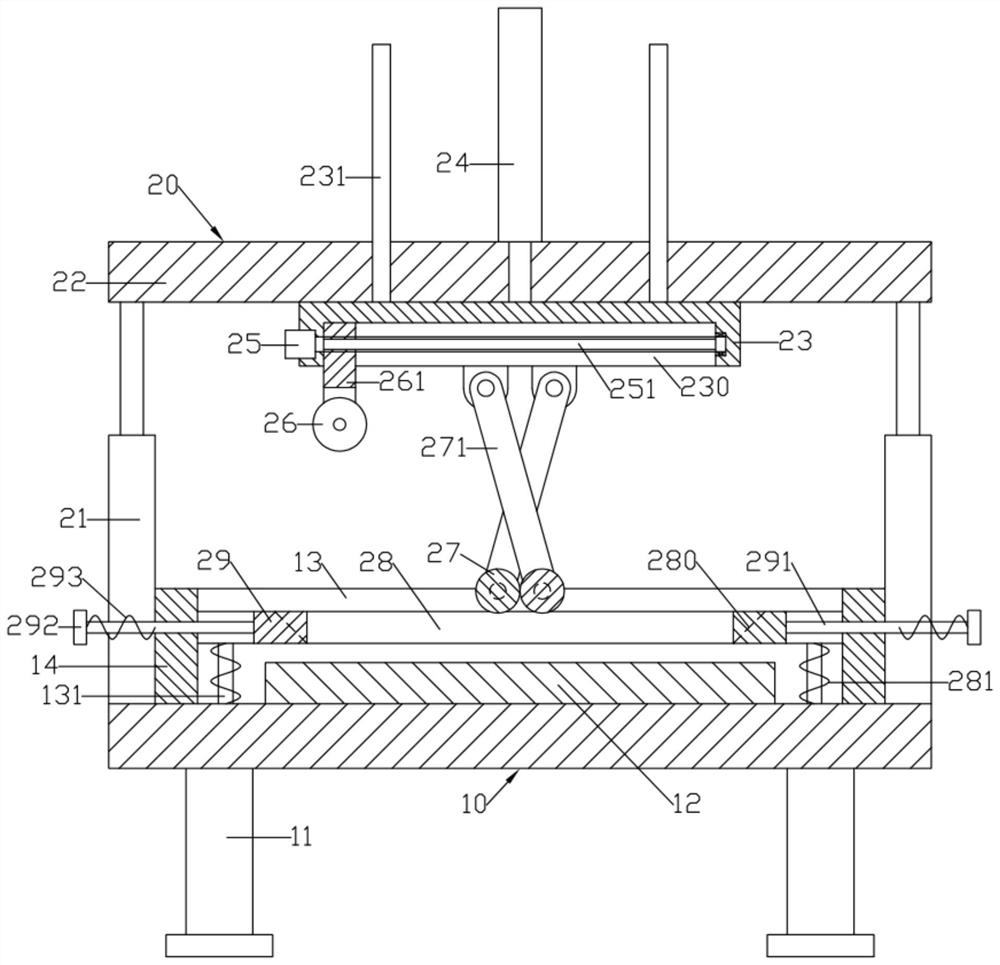

Intelligent management system for dangerous chemicals and use method thereof

PendingCN113349569AEasy to recordEasy to manageCharacter and pattern recognitionCabinetsData connectionIdentity recognition

The invention relates to an intelligent management system for dangerous chemicals, which comprises a cabinet body, a temperature and humidity liquid crystal display screen and an intelligent controller are arranged on the cabinet body, a face recognition camera is arranged on a panel of the cabinet body, and reagent properties and information of users are displayed through the display screen of the intelligent controller, the information is in data connection with a dangerous chemical system platform through the Internet, and information sharing is achieved. A temperature and humidity sensor and a pressure weighing sensor are arranged in the cabinet body and used for measuring temperature and humidity in the cabinet body and reagent weight, and an alarm device is arranged outside the cabinet body and can display the temperature and humidity in the cabinet in real time. According to the device, a user is controlled through identity recognition; chemical reagent information is solidified to a bottle wall and a bottle bottom of a reagent bottle through a two-dimensional code electronic tag, code scanning can be carried out through a scanning gun, data butt joint with a dangerous chemical system platform can be achieved, reagents can be effectively supervised, and the dangerous chemical management level can be improved.

Owner:HENAN UNIV OF ANIMAL HUSBANDRY & ECONOMY

Cutting machine capable of compressing periphery

ActiveCN112030525AAccurate and stable positionSimple structureSevering textilesStructural engineeringMachine

The invention discloses a cutting machine capable of compressing the periphery. A cutting device comprises a lifting supporting plate. The lifting supporting plate is arranged over a workbench in a lifting manner. A cutting support plate is arranged on the bottom surface of the lifting supporting plate in a lifting manner; a cutting moving seat is arranged on the bottom surface of the cutting support plate in a left-right moving manner; a cutting circular knife is arranged at the bottom of the cutting moving seat; the left and right ends of the lower end surface of the cutting support plate are respectively and elastically hinged with a pair of swing connecting plates which are symmetrically arranged front and back; the pair of swing connecting plates at the left side is located between the pair of swing connecting plates at the right side; cylindrical smoothing rollers are rotationally arranged between the lower ends of the pair of swing connecting plates at the left side and betweenthe lower ends of the pair of swing connecting plates at the right side; and the pair of swing connecting plates at the left side and the pair of swing connecting plates at the right side are arrangedin a crossed manner.

Owner:TAIZHOU ZHONGGANG CHEM & CONSTR CO LTD

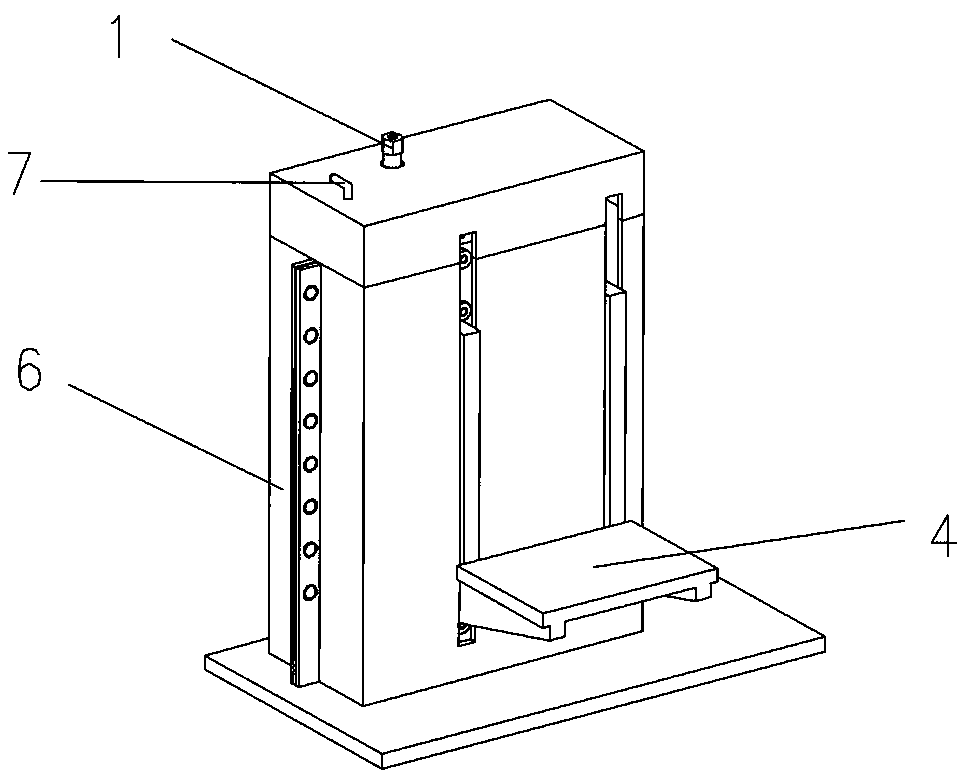

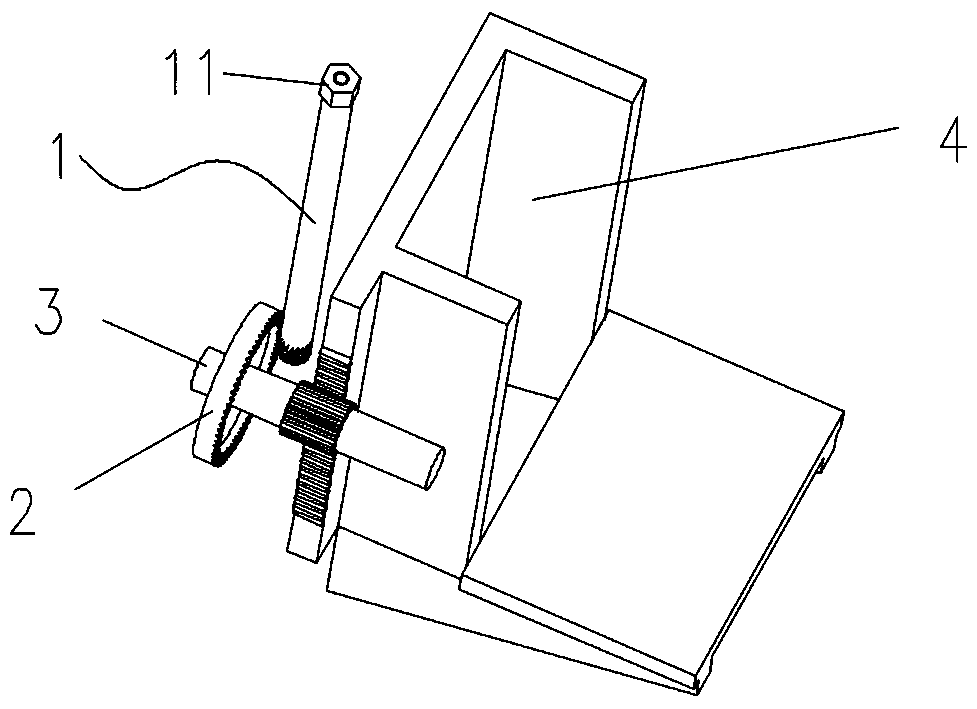

Jack for prefabricated building component installation and using method

PendingCN110805287ASimple structureEasy to operateBuilding material handlingGear wheelArchitectural engineering

The invention discloses a jack for prefabricated building component installation and a using method. The jack comprises a rotary gear rod, a gear disc, a gear rotating shaft, a lifting supporting plate and a limiting rail which are arranged in a shell, the rotary gear rod is driven to rotate by a handheld electric drill, power is transmitted to the gear disc through gear meshing, the gear disc drives the gear rotating shaft to rotate together, and the gear rotating shaft is meshed with gear teeth arranged on the side edge of a back plate of the lifting supporting plate to drive the lifting supporting plate to ascend so as to lift a wall body on the supporting plate. The handheld electric drill in a construction site is used as a power source, power transmission is carried out through a gear meshed transmission system, lifting and leveling of the wall body are realized, and the utilization rate of tools is improved through field tools. The jack has the advantages of being simple in structure, stable, reliable, convenient to operate, convenient and fast to move and transport, and capable of effectively reducing labor intensity and improving construction efficiency.

Owner:北京市住宅产业化集团股份有限公司

LED panel lamp and positioning blocks

ActiveCN105650555AImprove structural strengthAccurate and stable positionPlanar light sourcesMechanical apparatusLight guideEngineering

The invention belongs to the field of lighting lamps and particularly relates to a detachable LED panel lamp and positioning blocks of the LED panel lamp. Each positioning block comprises a positioning plate, a side plate, an upper panel and a lower panel, wherein the positioning plate is mounted between an LED lamp bar and an incident light side of a light guide plate assembly, the side plate is mounted on a non-incident light side of the light guide plate assembly, the upper end and the lower end of the positioning plate are fixed with the upper panel and the lower panel respectively, the upper end and the lower end of the side plate are fixed with the upper panel and the lower panel respectively, and a clamping space is formed among the positioning plate, the side plate, the upper panel and the lower panel. According to the structures of the positioning blocks, the positioning blocks abut against the LED lamp bar, the integral structure of the LED lamp bar is not damaged, and the structural strength of the LED lamp bar is improved; a limit relationship exists between the positioning blocks and a profile, so that the position between a back light plate assembly and the LED lamp bar is more accurate and stable, the emergent light of a light-emitting surface of the LED panel lamp is ensured to be uniform, and the product quality is good.

Owner:ANHUI ZERUN OPTOELECTRONICS

High precision machining apparatus used for electronic equipment outer shell

InactiveCN109605212ASave materialShorten the timeGrinding feed controlGrinding feedersElectric equipmentElectron

The invention discloses a high precision machining apparatus used for an electronic equipment outer shell. The high precision machining apparatus used for the electronic equipment outer shell comprises a feeding supporting seat, a polishing supporting seat, a plurality of mechanical arms, a polishing head and a material conveying clamping fixture, the polishing head and the material conveying clamping fixture are correspondingly connected with the tail end nodes of the mechanical arms in an installing mode, the feeding supporting seat and the polishing supporting seat are arranged in the circumferential direction of the mechanical arms, the feeding supporting seat comprises a supporting frame and a feeding table installed on the supporting frame, the tail-end nodes of the mechanical arms are connected with an installing seat, the polishing head and the material conveying clamping fixture are installed on the installing seat, an air outlet communicates with a second cavity body, the lower end of a core body is connected with a rotating shell, the central axes of the installing seat, a bearing and a rotating head coincide, and the central axis of the rotating head does not coincide with the central axis of the core body. According to the high precision machining apparatus used for the electronic equipment outer shell, vacuum adsorption of a workpiece is realized through an adsorption hole and an adsorption line groove, the accurate position and stability of the workpiece are ensured in the polishing process, the situations of offset and the like in the polishing process are avoided, and the polishing accuracy and stability are ensured.

Owner:苏州丰川电子科技有限公司

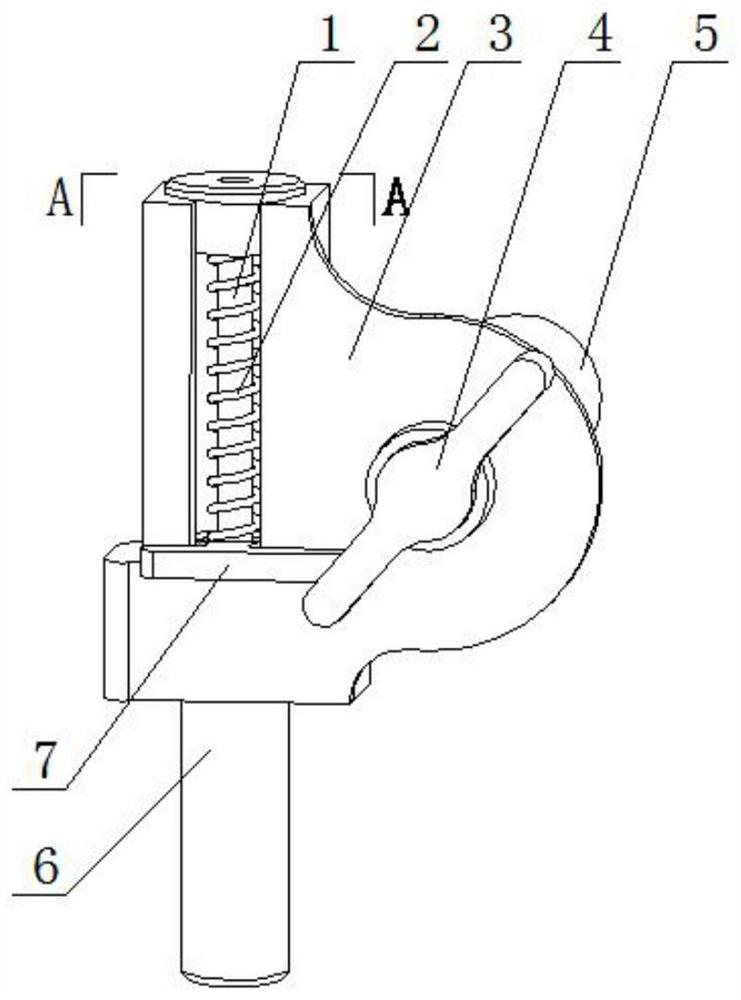

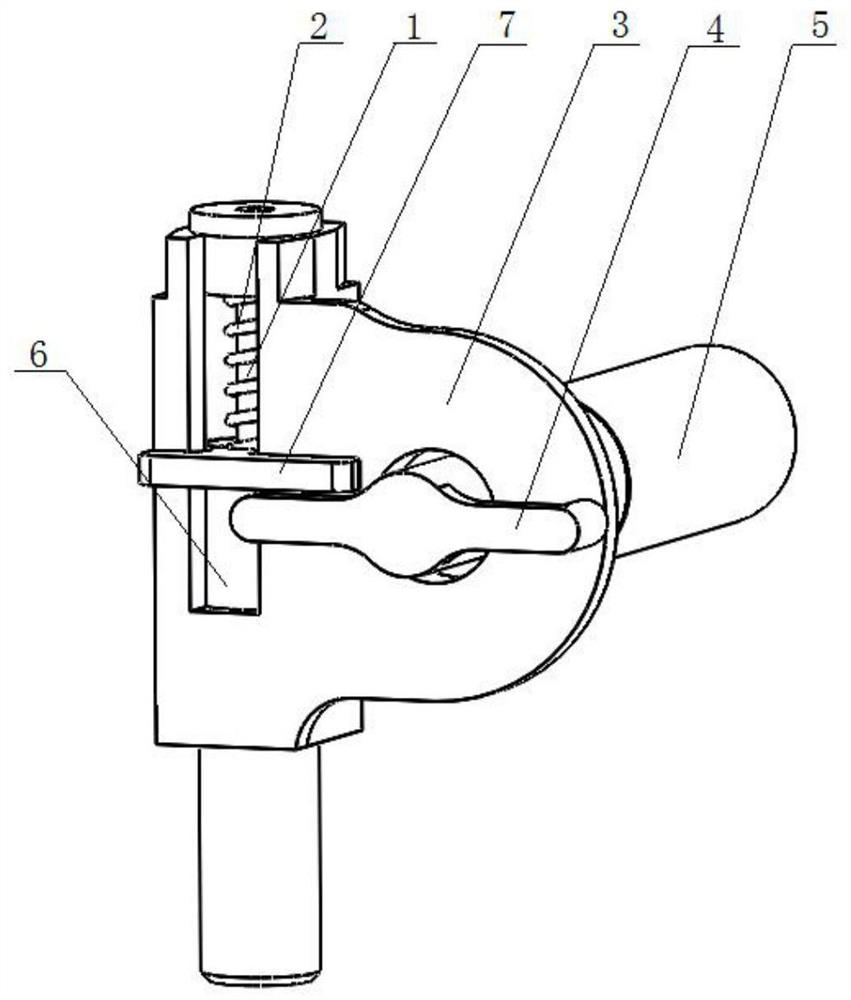

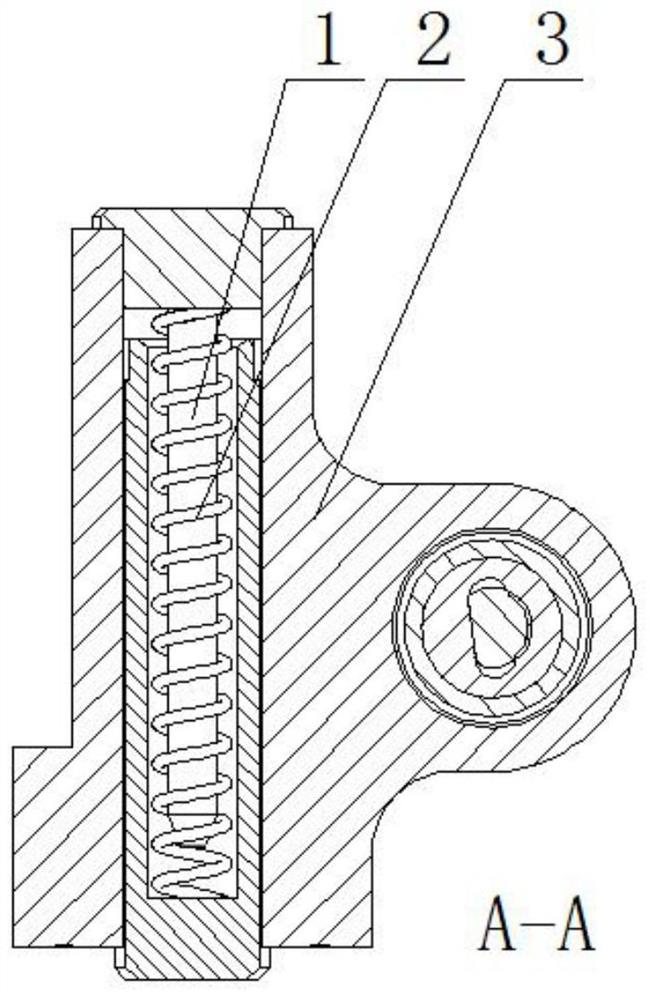

Bone surgery positioning adjustor

InactiveCN110151284ARehabilitationAccurate and stable positionInternal osteosythesisFastenersLocking mechanismEngineering

The invention provides a bone surgery positioning adjustor. The bone surgery positioning adjustor comprises a connecting column, a clamping mechanism, a stretchable mechanism, a limiting mechanism, aheight adjusting mechanism, an angle adjusting mechanism, a limiting mechanism and a locking mechanism. The angle adjusting mechanism is fixedly connected to the end, away from the connecting column,of the stretchable mechanism, the angle adjusting mechanism comprises a fixing ring, an annular rotating groove, an annular rotating block, a connecting rod, a connecting plate, a positioning pipe, arotating block and a second fastening bolt, the fixing ring is fixedly connected to one end of the stretchable mechanism, the annular rotating groove is formed in the fixing ring, the opening of the annular rotating groove faces upwards, the annular rotating block is rotationally connected to the annular rotating groove, and the upper end of the annular rotating block extends out of the fixing ring. The bone surgery positioning adjustor has the advantages of being accurate and stable in bone nail positioning, bringing convenience to surgery, and facilitating postoperative rehabilitation of a patient.

Owner:湖南省鸿俊广升医疗科技有限公司

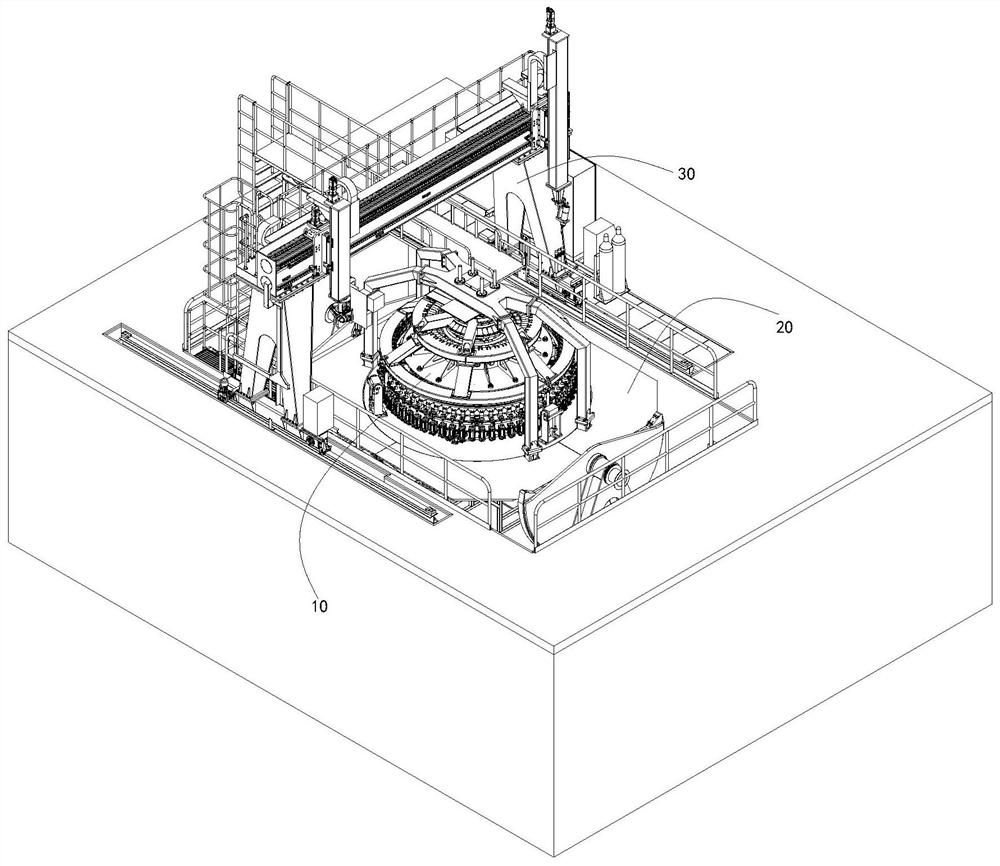

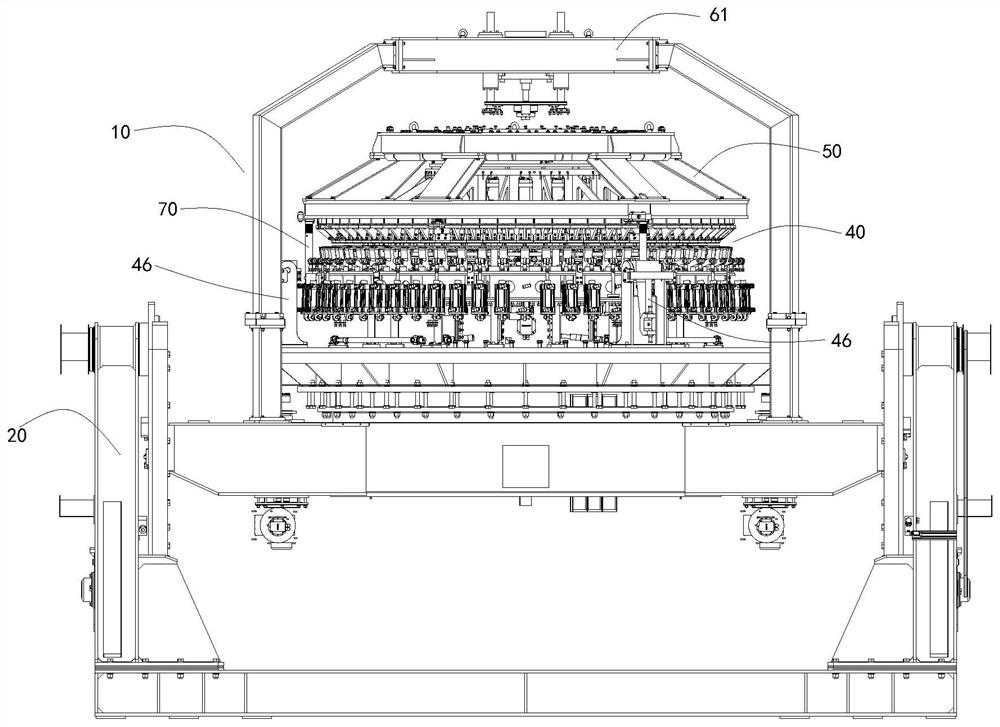

TIG girth welding device and TIG girth welding process for bottom of storage tank

PendingCN112171286AAccurate and stable positionQuality assuranceOther manufacturing equipments/toolsWelding accessoriesButt jointEngineering

The invention provides a TIG girth welding device and a TIG girth welding process for the bottom of a storage tank, and relates to the technical field of TIG girth welding. The TIG girth welding device comprises a girth welding mold, a positioner and a milling and welding gantry. The girth welding mold comprises a welding mold, a pressing device and a top cover pressing ring. The welding mold comprises a base, a lifting ring, a supporting device, a mandrel lifting device and a connecting cylinder. The TIG girth welding process sequentially comprises the following steps that S1, a fork-shaped ring is clamped; S2, a circular ring is clamped; S3, edge milling is conducted; S4, welding is performed; S5, the pressing device is locked; S6, edge milling is conducted; S7, a top cover is clamped; S8, edge milling is conducted; S9, welding is performed; and S10, form removal and part taking are carried out. According to the TIG girth welding device and the TIG girth welding process for the bottom of the storage tank, servo driving of a motion unit is achieved, pressing is realized pneumatically, the welding device can be adapted to changes of the thickness of the bottom wall of the storage tank, after a workpiece is pressed on the welding mold, a milling head mills out allowance and a welding groove, the motion trail during milling is consistent with the motion trail during welding, andthe quality of welding butt joints is guaranteed; and the high-precision welding requirement of the product is effectively ensured.

Owner:厦门中科伊贝格机械有限公司

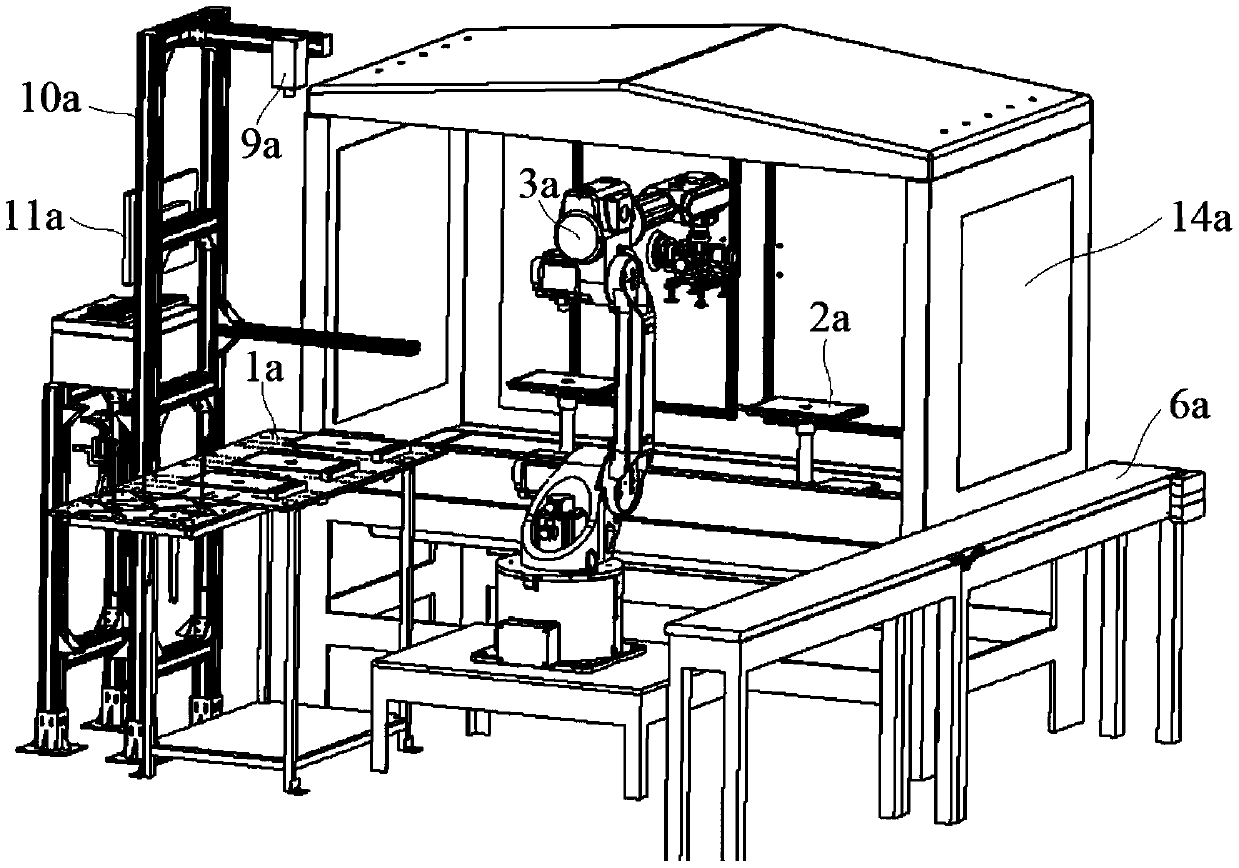

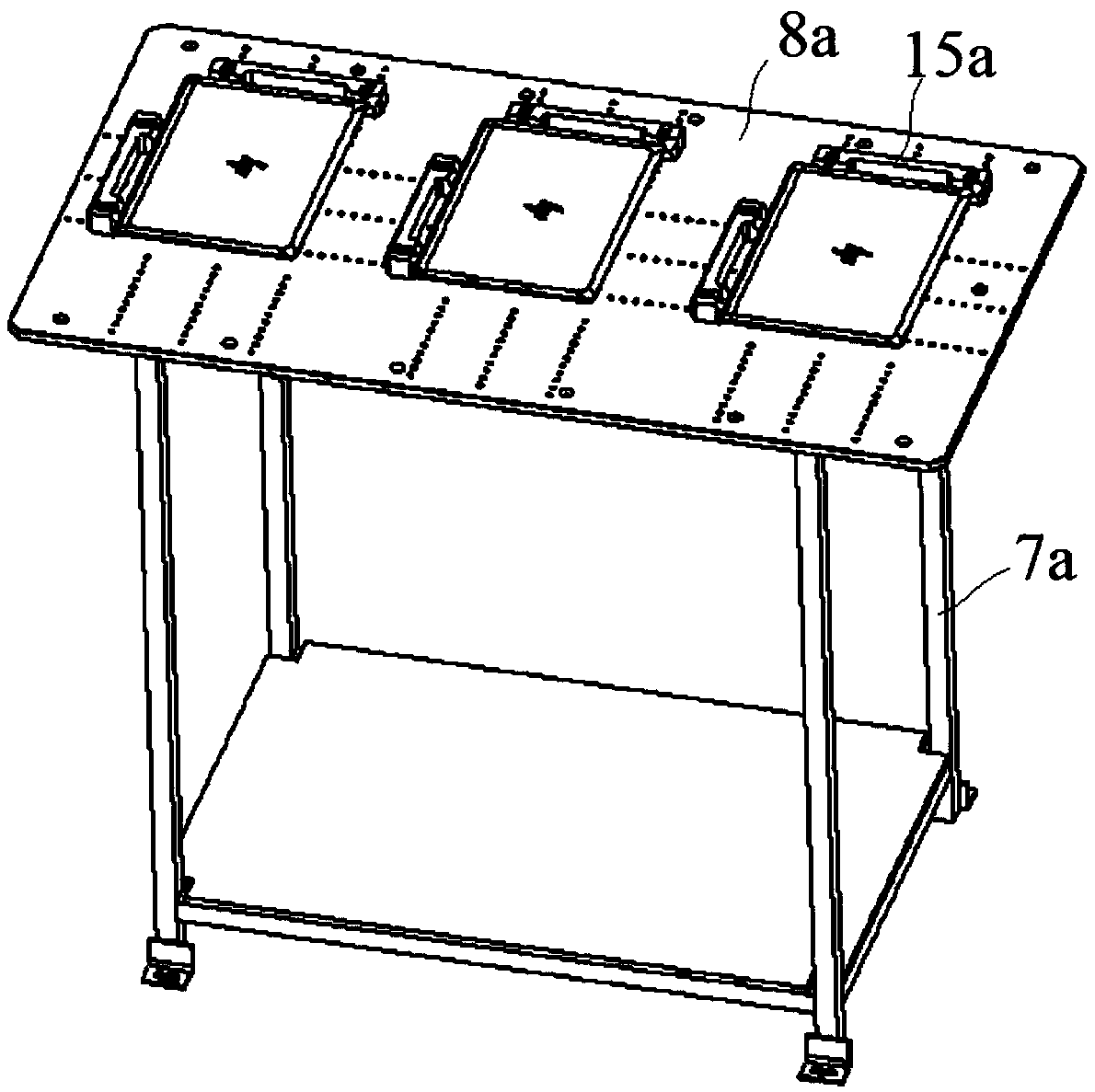

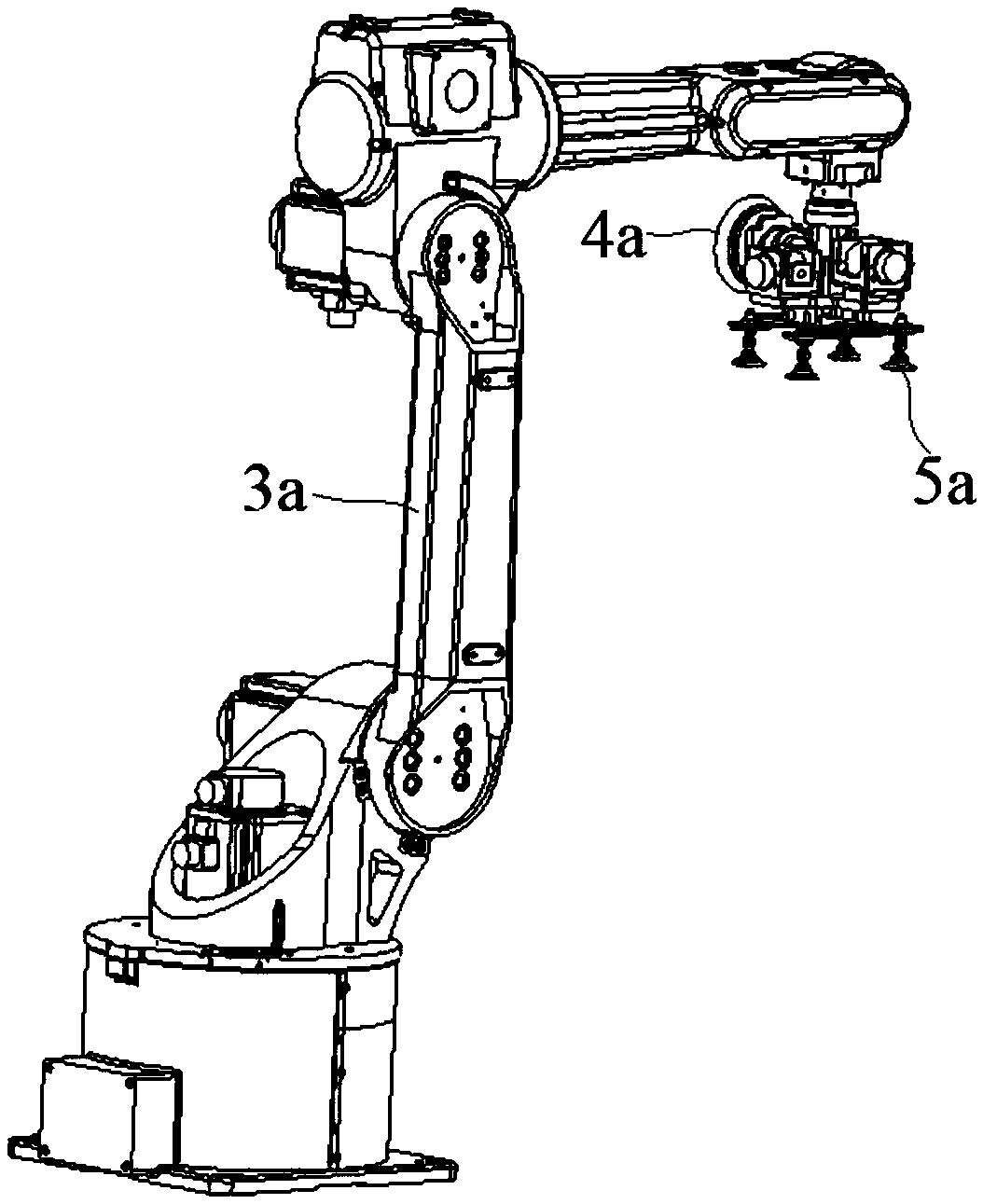

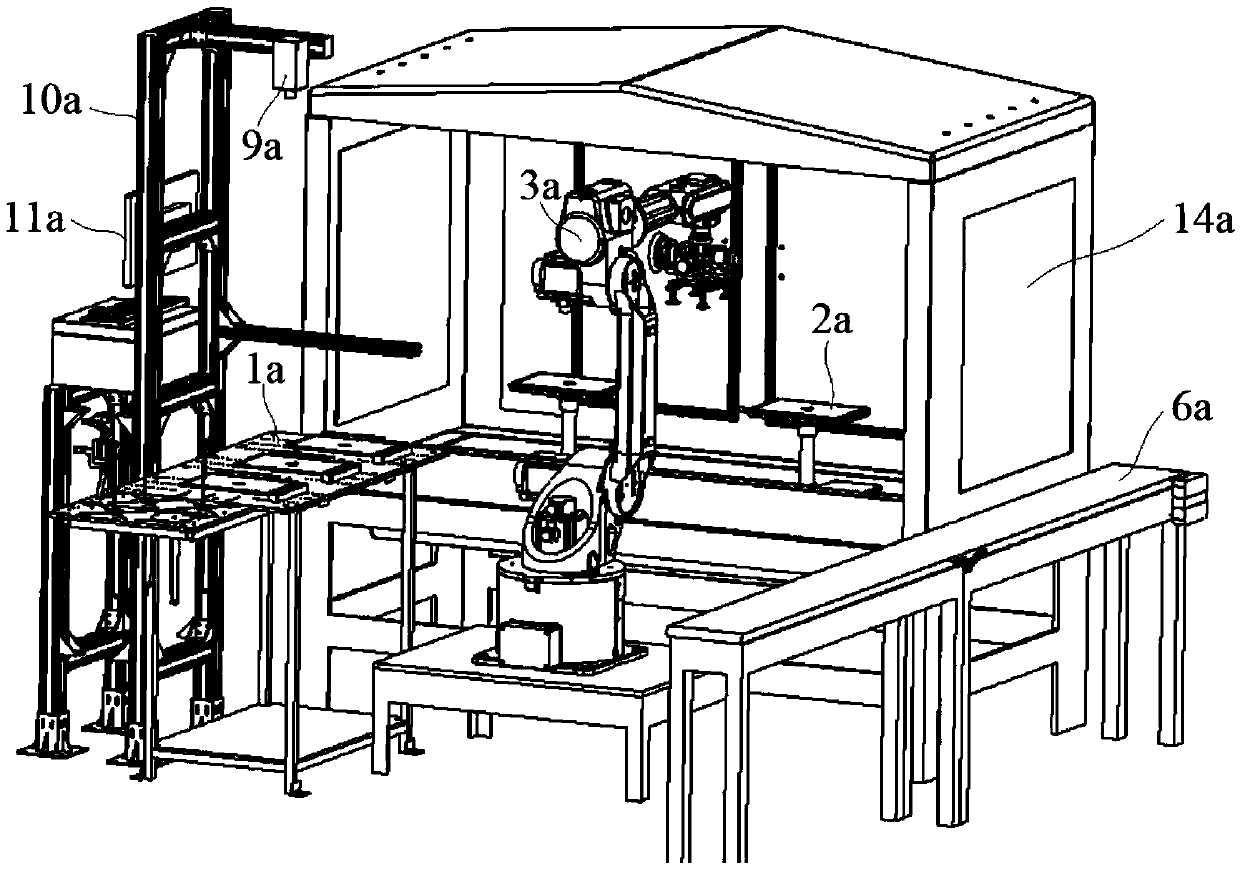

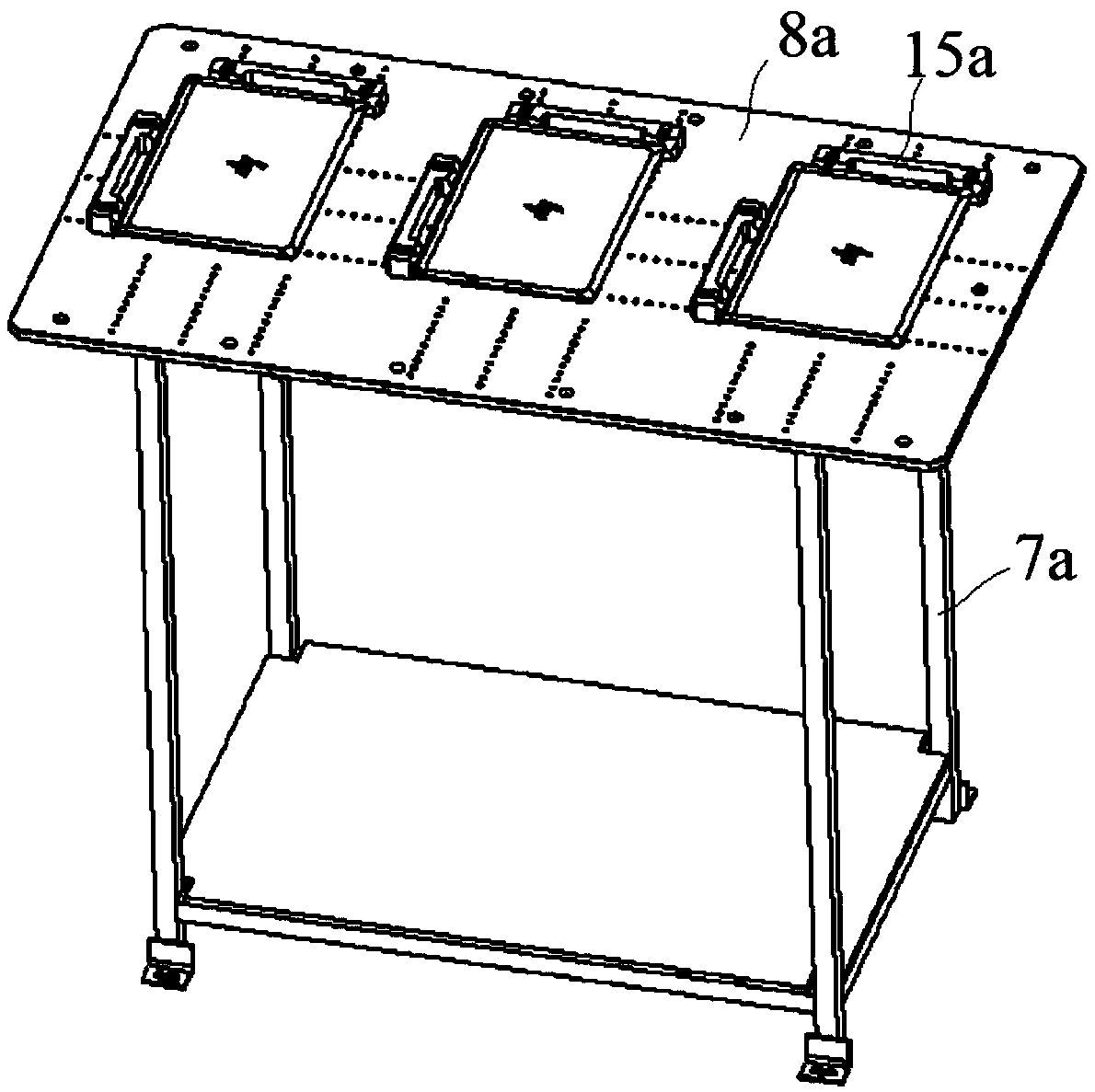

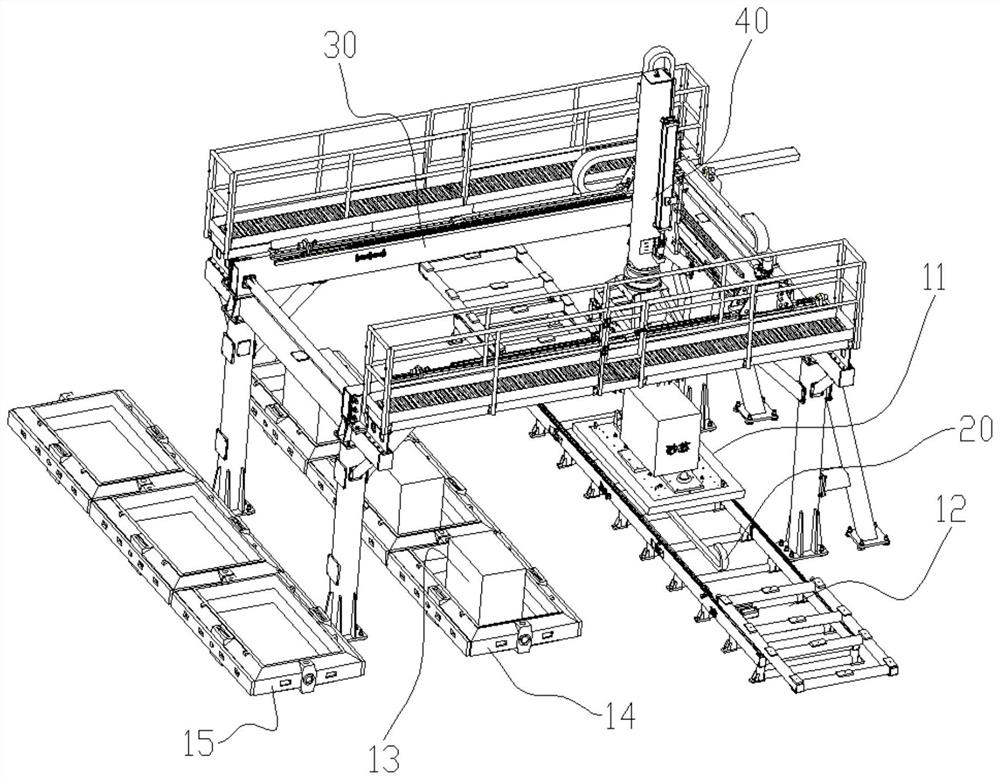

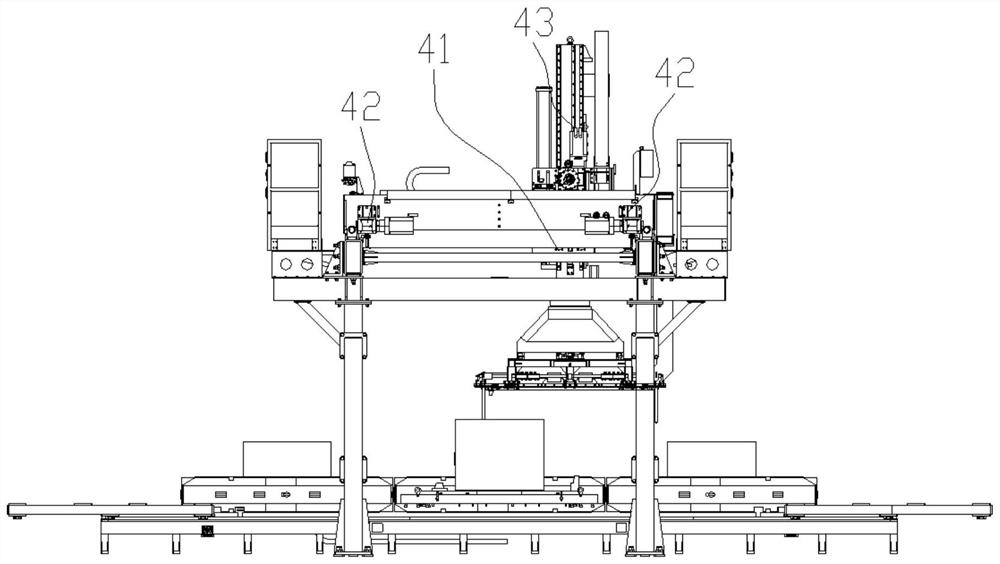

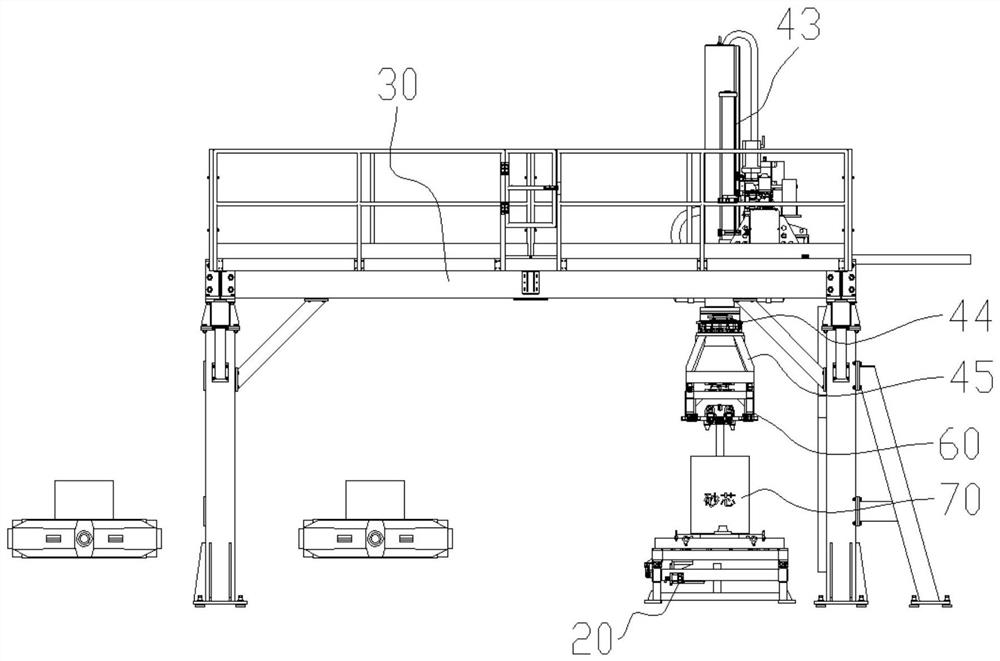

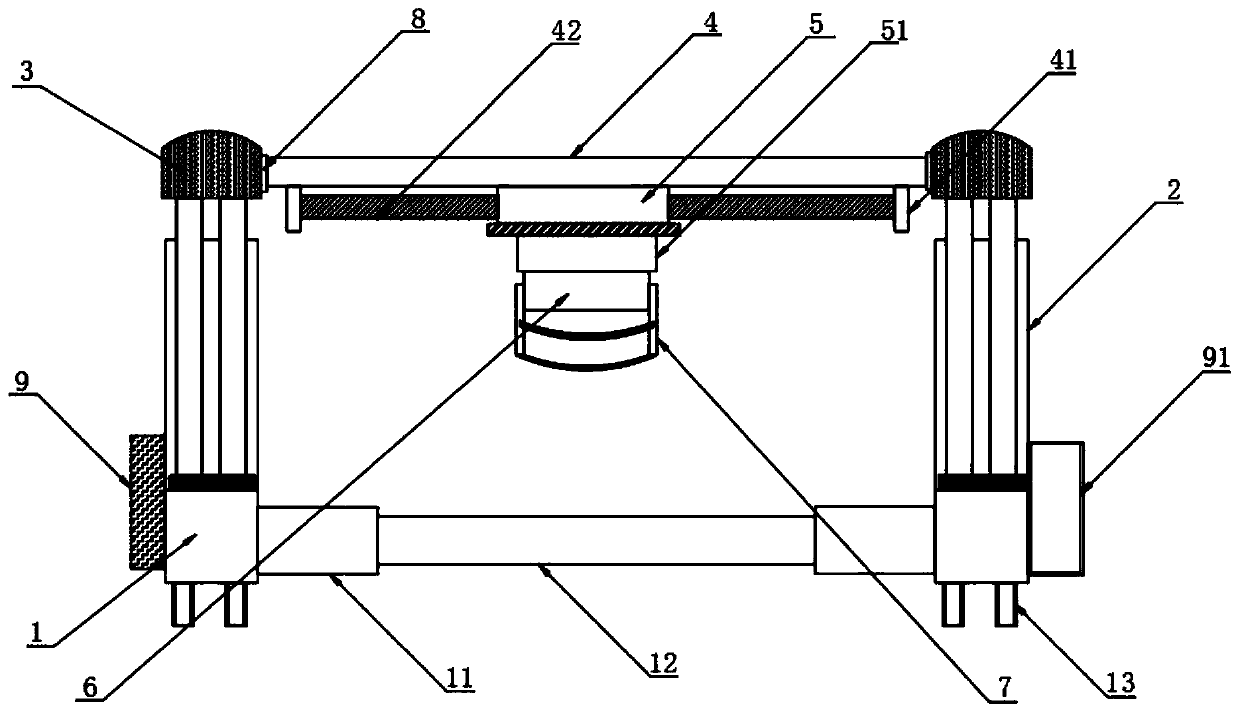

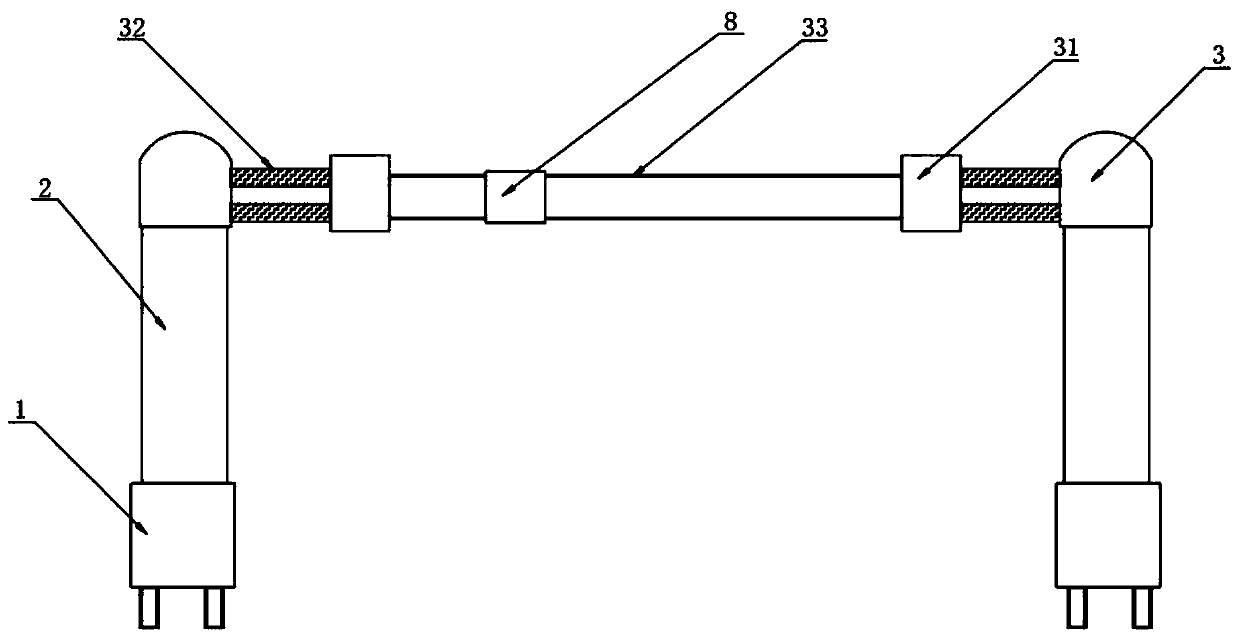

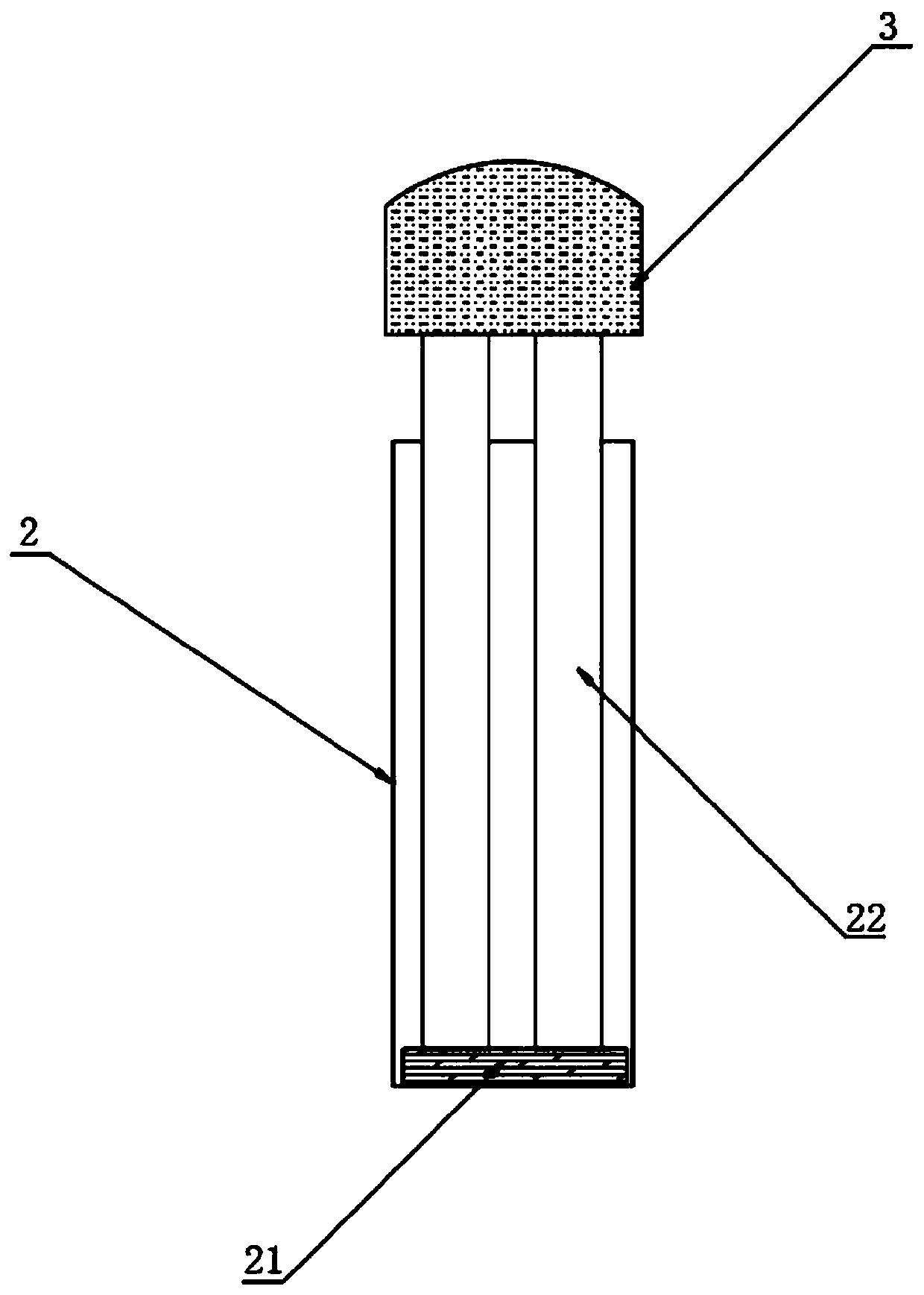

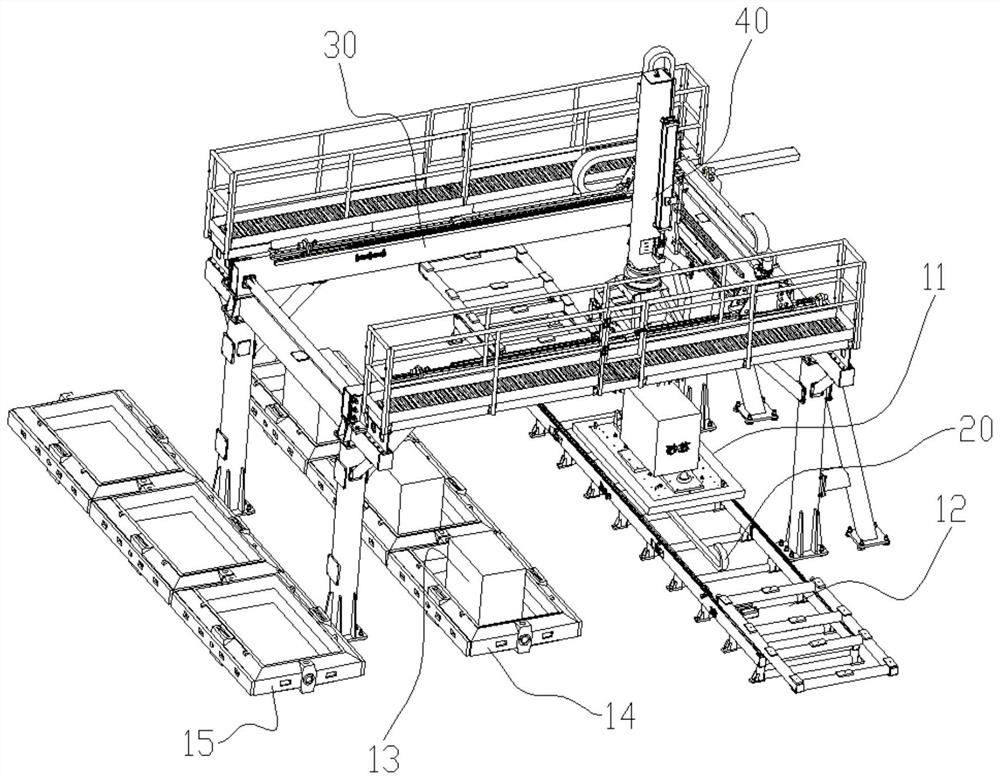

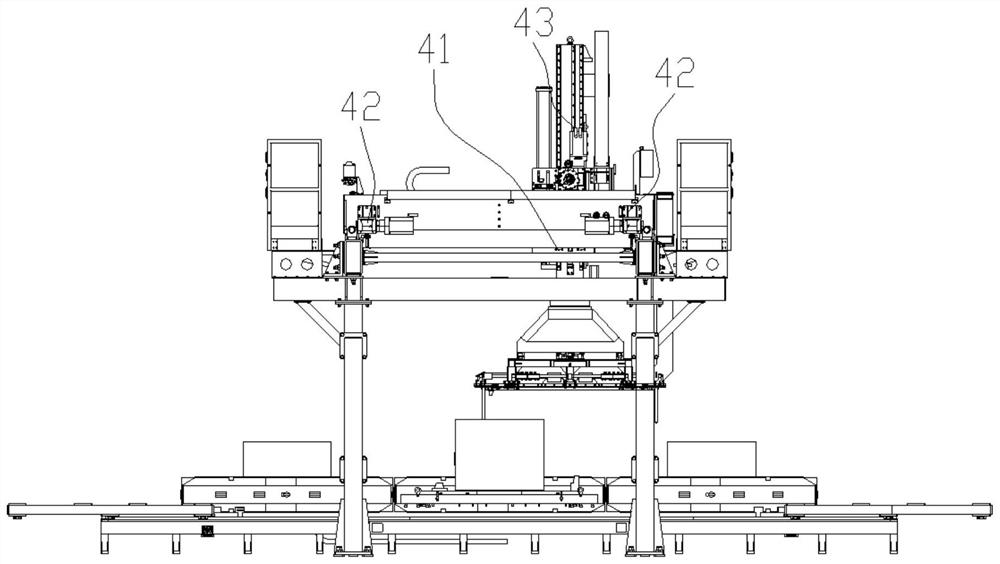

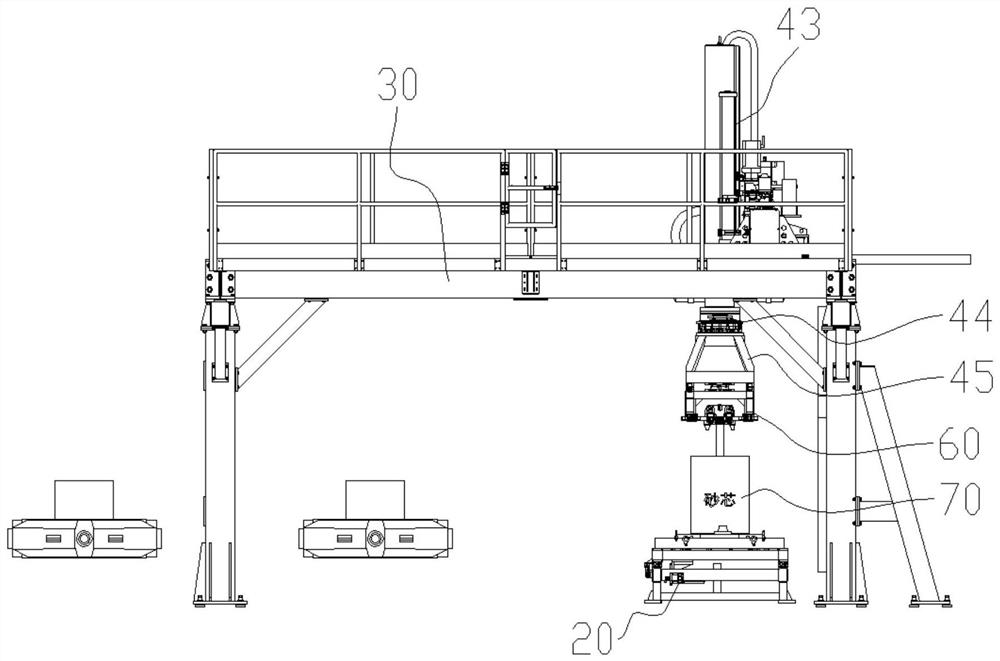

Automatic core setting robot and automatic core setting method

ActiveCN112743046AAccurate and stable positionQuick and stable installationFoundry mouldsFoundry coresStorage garageCore set

The invention provides an automatic core setting robot and an automatic core setting method. The automatic core setting robot comprises a linear transmission device, a gantry truss and a transfer robot, wherein the transfer robot comprises an X-axis moving mechanism, a Y-axis moving mechanism, a Z-axis moving mechanism and a rotating mechanism; and a first quick-connection mounting frame is mounted below a turntable of the rotating mechanism; a matched jig combination composed of a floating plate, a sand core clamping fixture, a fixture supporting frame, a sand core fixture and a second quick-connection mounting frame is further included; a positioning structure between the matched jig combination can ensure that the sand core fixture is quickly and stably mounted and replaced; during core setting, only a sand core needs to be hoisted to the sand core clamping fixture from a sand core warehouse, and the linear transmission device and the transfer robot can automatically complete core setting operation, so that the production efficiency is greatly improved; and the mounting position of the sand core in a casting forming lower die is accurate, so that reliable and stable casting quality is ensured.

Owner:昌坚华新机器人部件南通有限公司

Clinical fixation and operating device of B-mode ultrasound probe for B-mode ultrasound room

InactiveCN110123373APosition adjustment is accurate and stableSimple and fast positioning workUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsDrive motorEngineering

The invention discloses a clinical fixation and operating device of a B-mode ultrasound probe for a B-mode ultrasound room and particularly relates to the field of medical assist devices. The clinicalfixation and operating device comprises two bases; a pillar is arrange at the top of each base; a top seat is arranged at the top of each pillar; an ejector bar is arranged between the two bases; a sliding seat is arranged at the bottom of the ejector bar; a motor is arranged at the bottom of the sliding seat; a positioning seat is connected to the outer side of the motor and is in drive connection with the motor. Moving seats, the pillars and a driving mechanism are provided; adjusting is performed during use in accordance with different parts which an B-mode ultrasound probe is to scan; theheight of the B-mode ultrasound probe can be adjusted by controlling first hydraulic lifting bars to operate; the transverse position of the B-mode ultrasound probe can be adjusted by controlling anelectric push bar to operate; the vertical position of the B-mode ultrasound probe can be adjusted by controlling the driving motor to operate; adjusting is performed simply and quickly; medical personnel can check out B-mode ultrasound scanning results and data directly on a computer.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

Material rack mechanism achieving automatic guiding and locking

The invention discloses a material rack mechanism achieving automatic guiding and locking. The material rack mechanism comprises a material rack guiding and locking mechanism, a primary-secondary material rack and a preliminary locating material table. A guiding and clamping mechanism is arranged on the material rack guiding and locking mechanism. The primary-secondary material rack is arranged on the inner side of the guiding and clamping mechanism and is guided, clamped and located through the guiding and clamping mechanism. A locating mechanism is arranged on the preliminary locating material table, and the preliminary locating material table is used for cooperating with the material rack guiding and locking mechanism to carry out secondary locating on workpieces on the primary-secondary material rack to complete material replacement. The material rack mechanism has the beneficial effects that the material replacement time is short; the production efficiency is high; locating is reliable; the function of secondary locating is achieved; and the varieties of the replaced workpieces are simple.

Owner:西安精雕软件科技有限公司

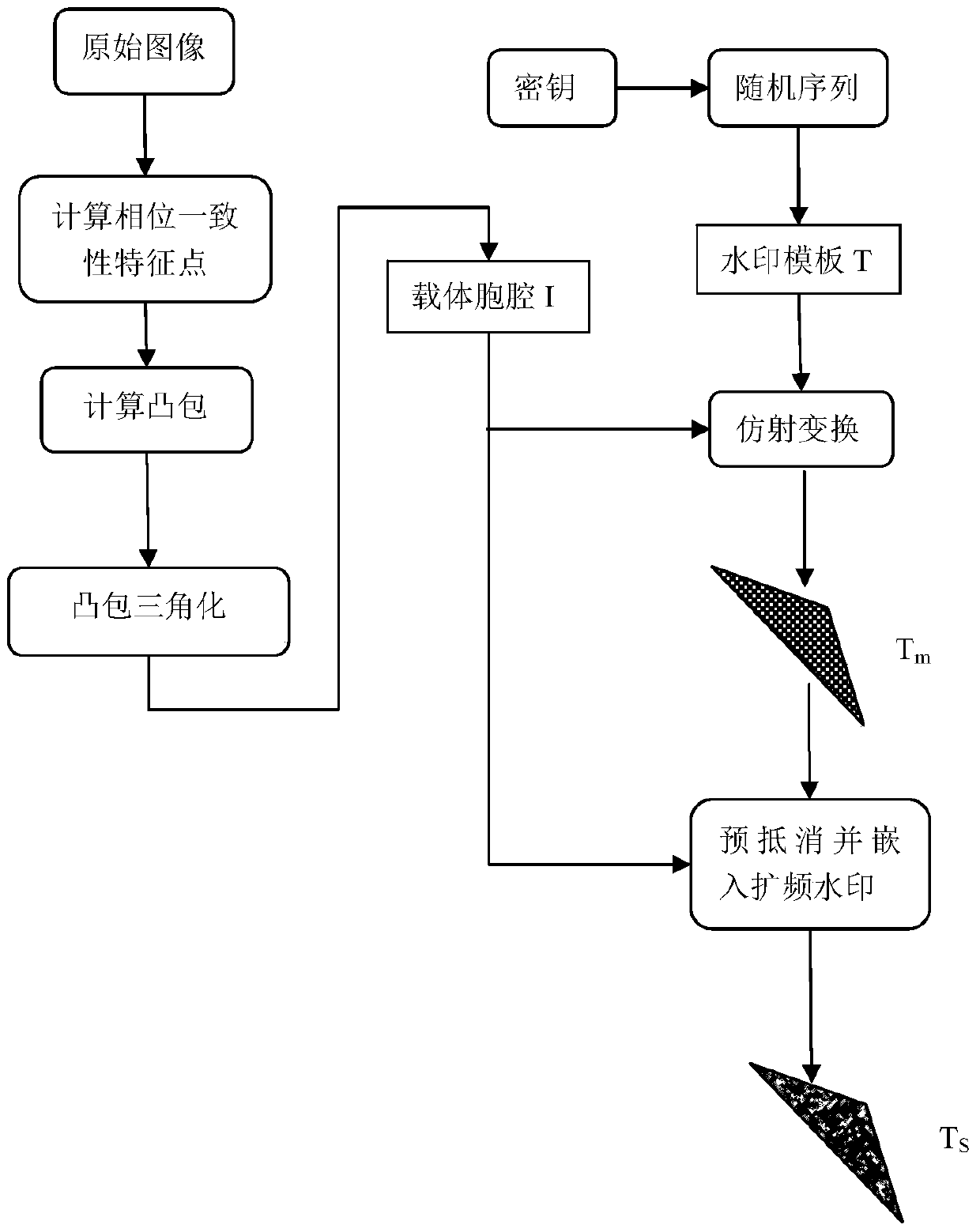

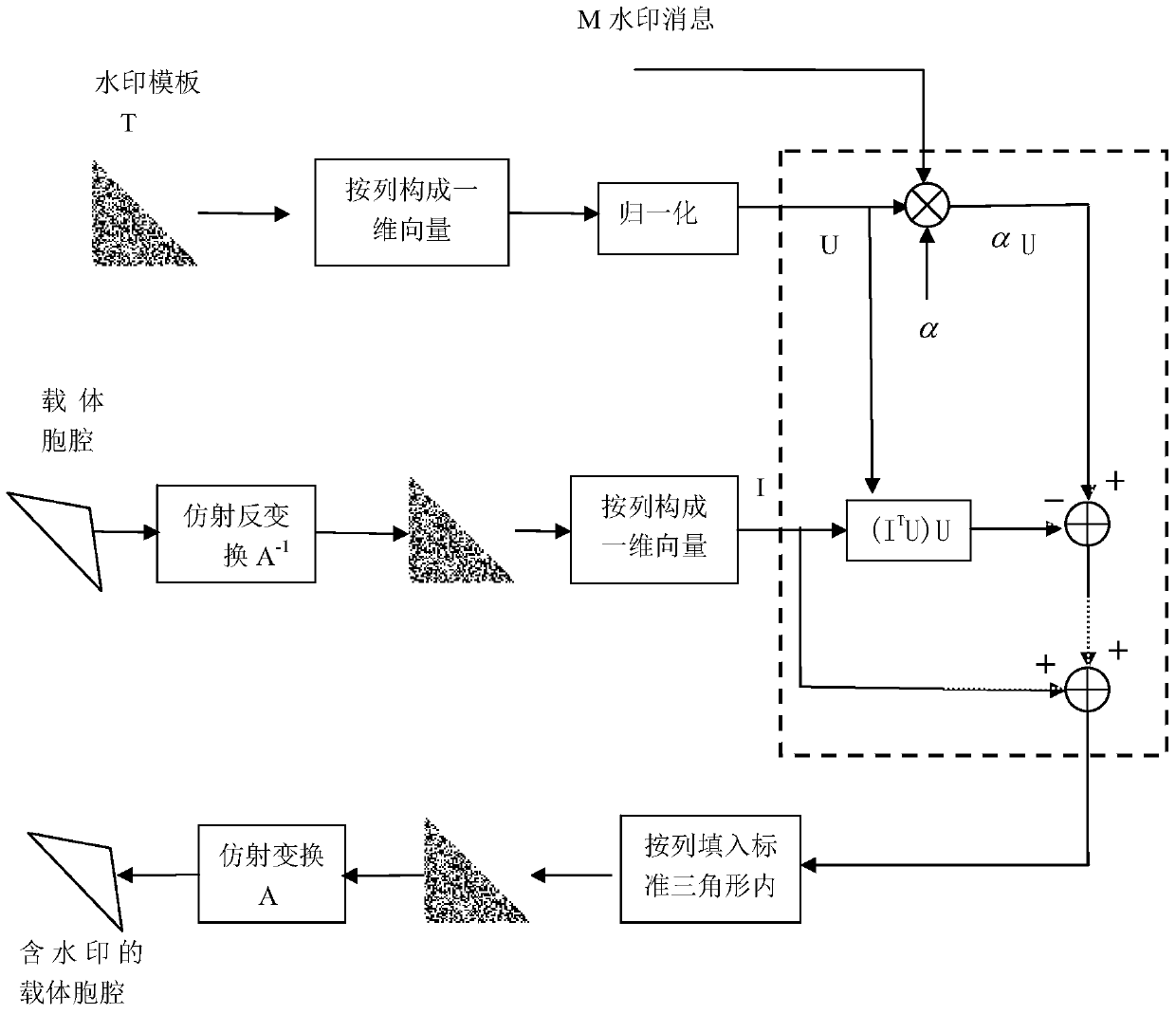

Digital watermarking method against geometric attack based on phase consistency and pre-cancellation

InactiveCN104574261BEasy to detectAccurate locationImage data processing detailsCell cavityAlgorithm

The invention discloses an anti-geometric attack digital watermarking method based on phase consistency and pre-cancellation. In the embedding process, first calculate and extract the points with high carrier phase consistency to form a feature point set; calculate the two-dimensional convex hull of the feature point set, number and divide the boundary points of the convex hull to form a triangular network, and each triangle It is called the carrier cell; the carrier cell is transformed into a standard triangle by affine inverse transformation; before embedding the watermark signal, it is pre-offset, and the projection of the carrier signal on the watermark signal is removed from the watermark signal; finally, the The watermark is superimposed on the standard triangle of the carrier, and the carrier cell containing the watermark is obtained through affine transformation. In the watermark extraction process, first analyze and extract the feature points with high phase consistency, calculate and divide the convex hull, generate a triangular network, transform it into a standard triangle, decode it with the watermark template, and extract the watermark in the carrier cell cavity. Even if the watermarked image is attacked by local geometry, the watermark can be extracted correctly.

Owner:SHANDONG UNIV OF SCI & TECH

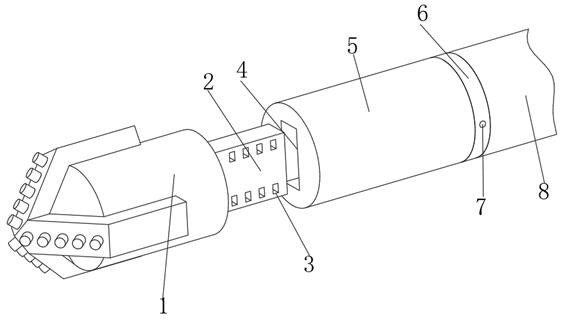

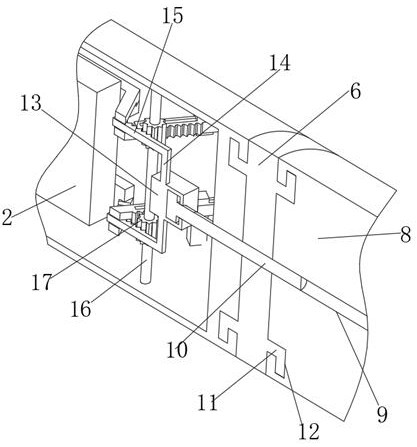

Drill bit with automatic gas detection function

PendingCN114033314AKeep the connection stableAvoid affecting useSurveyDrill bitsControl engineeringStructural engineering

The invention belongs to the technical field of geological drill bits and particularly relates to a drill bit with an automatic gas detection function. The drill bit comprises a three-wing drill bit, wherein a bottom end of the three-wing drill bit is fixedly connected with a connecting plate connected with a clamping block in a clamping manner, a clamping groove is formed in a surface of the connecting plate, and a lower end of the three-wing drill bit is connected with a first connecting rod in a clamping manner; a bottom end of the first connecting rod is rotationally connected with a rotating module, an inserting hole used for controlling opening and closing is formed in a surface of the rotating module, by arranging the connecting plate and the rotating module, connection between the three-wing drill bit and the first connecting rod is more convenient and stable, mounting and dismounting are convenient, the limiting effect is good, operation is easy, and time is saved; the three-wing drill bit is prevented from falling off during use to affect normal use of equipment, use stability and convenience are improved, a first adjusting rack and a second adjusting rack are limited by arranging a sliding groove and a second adjusting rack, the first adjusting rack and the second adjusting rack can only stably slide in the direction of the sliding groove, the position is stable and accurate, and practicability is improved.

Owner:山东省煤田地质局第三勘探队

An automatic core-setting robot and an automatic core-setting method

ActiveCN112743046BAccurate and stable positionQuick and stable installationFoundry mouldsFoundry coresIndustrial engineeringStorage garage

The invention provides an automatic core-setting robot and an automatic core-setting method. The automatic core-setting robot includes a linear transmission device, a gantry truss and a transfer robot. The transfer robot includes an X-axis moving mechanism, a Y-axis moving mechanism, a Z-axis moving mechanism and a rotating mechanism. It also includes a supporting jig combination composed of a floating plate, a sand core mold, a fixture support frame, a sand core jig and a second quick-connecting mounting bracket. The positioning structure between the matching jig combinations can ensure that the sand core jig quickly Stable installation and replacement; when setting the core, you only need to hoist the sand core from the sand core warehouse to the sand core mold, and the linear transmission device and transfer robot will automatically complete the core setting operation, which greatly improves the production efficiency; The installation position in the lower mold of the casting molding is precise, ensuring reliable and stable casting quality.

Owner:昌坚华新机器人部件南通有限公司

Acupoint knocking device

PendingCN112569109AStable and effective implementationAccurate and stable positionDevices for pressing relfex pointsVibration massagePhysical medicine and rehabilitationEngineering

Owner:天津市华碘源创科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com