Automatic core setting robot and automatic core setting method

A robot and automatic technology, applied in cores, casting molding equipment, casting molds, etc., can solve problems such as low production efficiency, high labor intensity of operators, and low accuracy of sand core placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

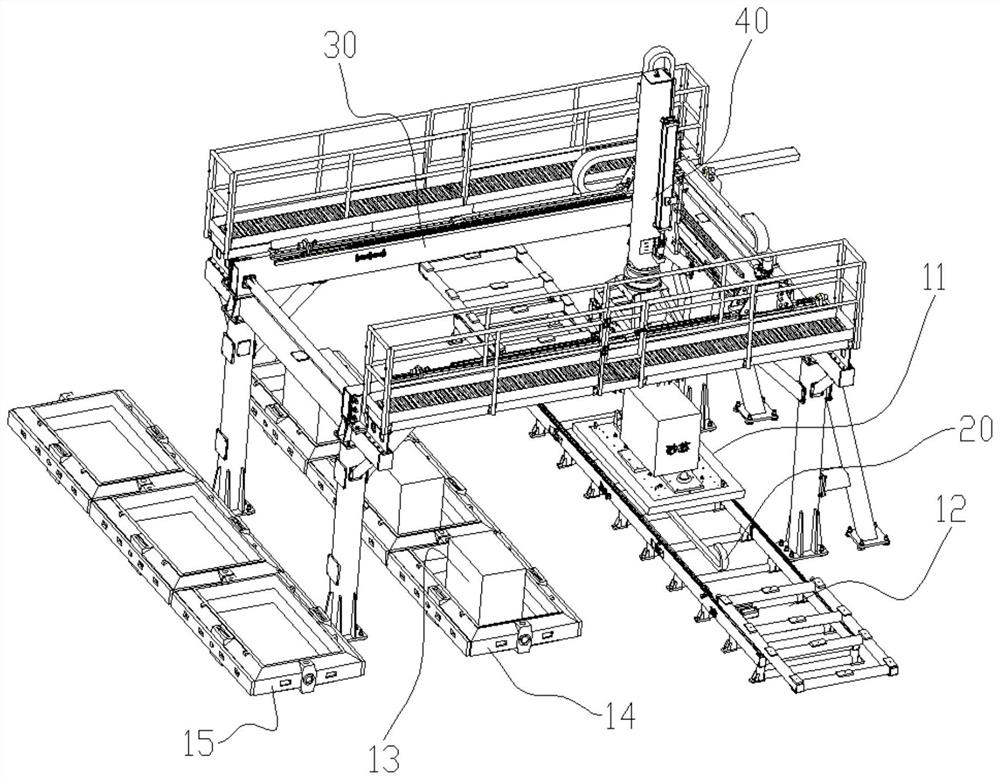

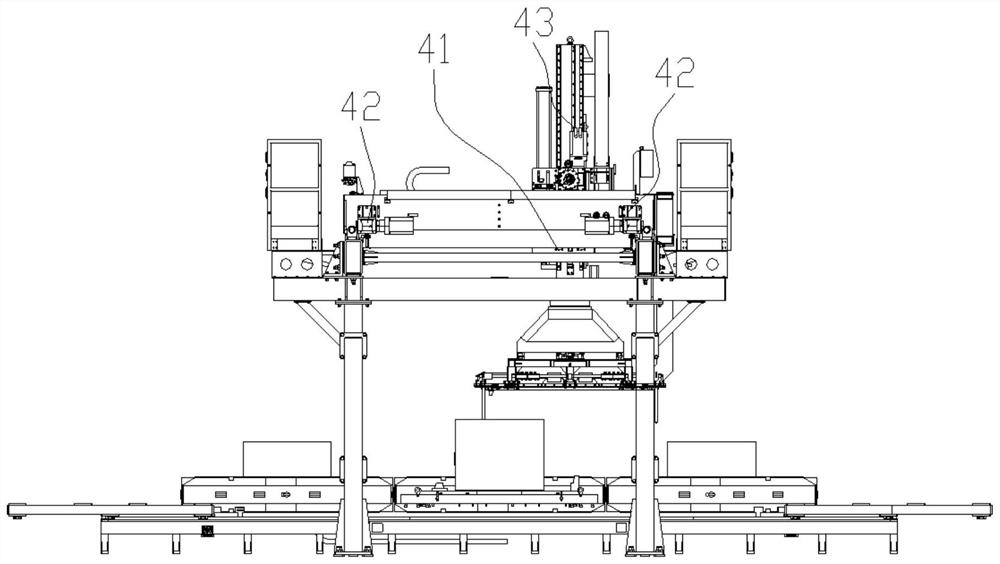

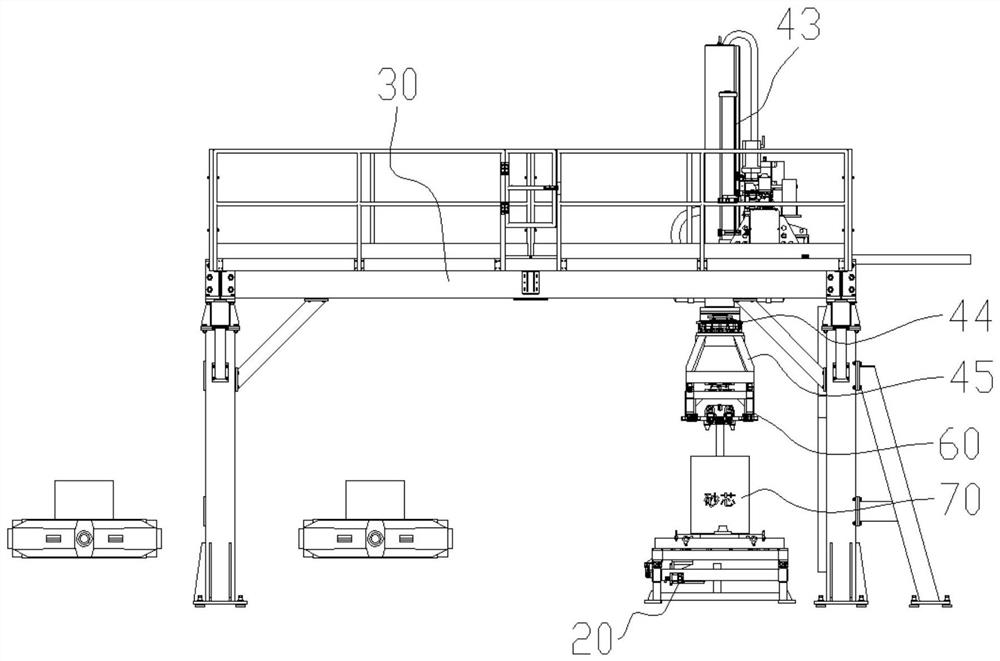

[0045] Such as Figure 1-11 As shown, an embodiment of the present invention is: an automatic core setting robot, including a first station 11 for hoisting sand cores, a second station 12 for grabbing sand cores, and a second station 12 for placing sand cores Put it into the third station 13 of the lower mold, a linear transmission device 20 is provided between the first station and the second station, and a gantry truss 30 and a transfer device are provided between the second station and the third station. The robot 40; the linear transmission device 20 includes a transmission guide rail, a translation drive mechanism and a transmission plate, and the translation drive mechanism drives the transmission plate to move between the first station and the second station along the transmission guide rail; the transfer robot 40 includes X-axis moving mechanism 41, Y-axis moving mechanism 42, Z-axis moving mechanism 43 and rotation mechanism 44, the base of Y-axis moving mechanism 42 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com