Annular multi-station synthesis valve body machining device

A processing device and multi-station technology, which is applied in the direction of manufacturing tools and other manufacturing equipment/tools, can solve the problems of labor-intensive and time-consuming, short tool life, and large workshop occupation, and achieve high efficiency, high processing accuracy, The effect of reduced investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable those skilled in the art to better understand the solution of the present invention, and to make the above-mentioned purpose, features and advantages of the present invention more obvious and comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

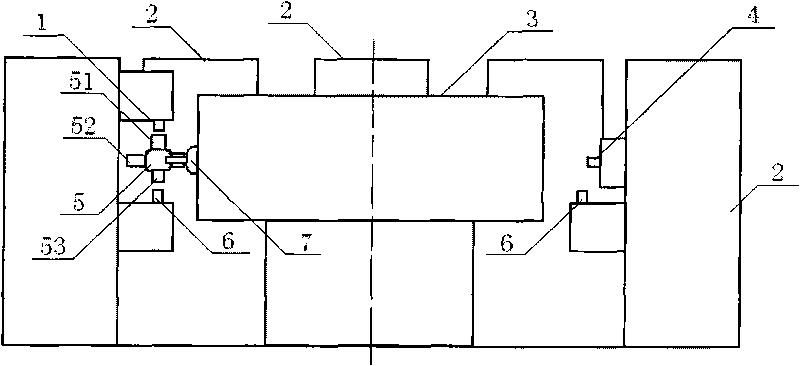

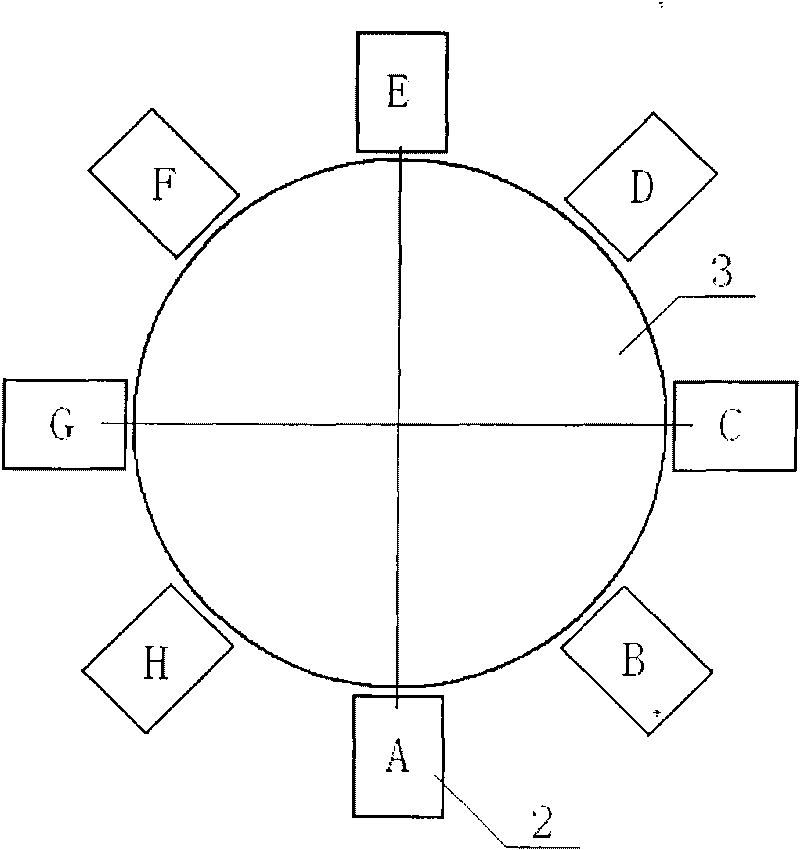

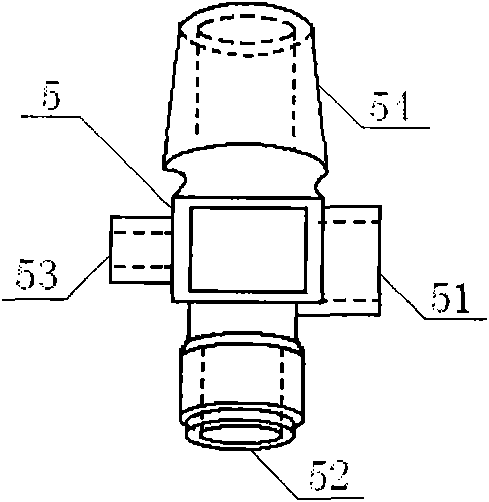

[0019] Such as figure 1 , figure 2 , image 3 As shown, including: A, B, C, D, E, F, G, H eight stations, the eight stations are in eight positions around the rotating disk 3, and the A station is used to place the valve body blank or take The lower semi-finished valve body, and the remaining seven stations are used to process the valve body blank; these seven stations are placed with a power head box seat 2, and each power head box seat 2 is provided with a radial power head 4 and an upward power head 6 , The combination of any two direction power heads among the three direction power heads of downward power head 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com