TIG girth welding device and TIG girth welding process for bottom of storage tank

A technology for girth welding and storage tanks, which is applied in the direction of manufacturing tools, welding equipment, welding accessories, etc., can solve the problem of low girth welding accuracy at the bottom of storage tanks, meet the requirements of high-precision welding, accurate and stable positions, and facilitate milling Effects of edges and welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

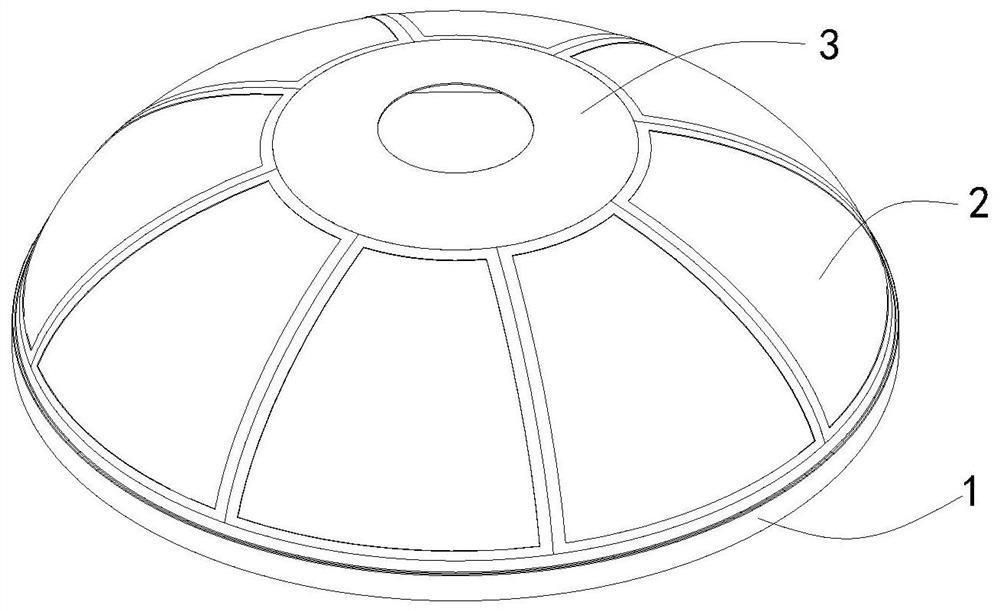

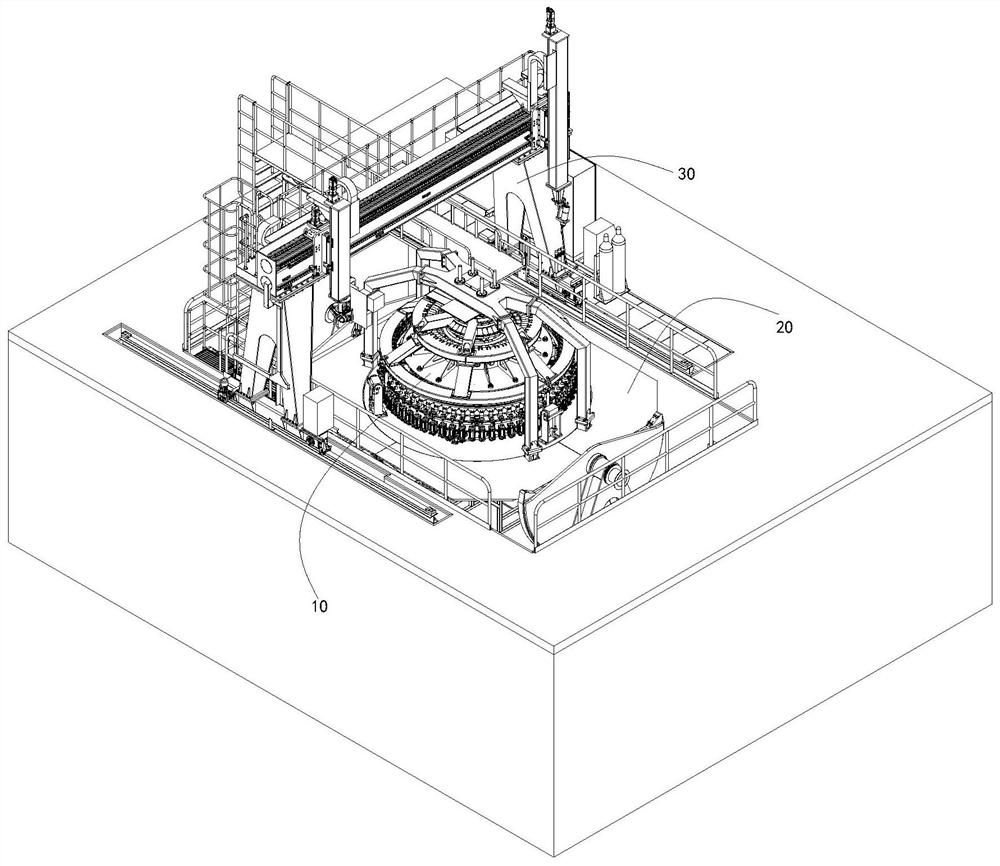

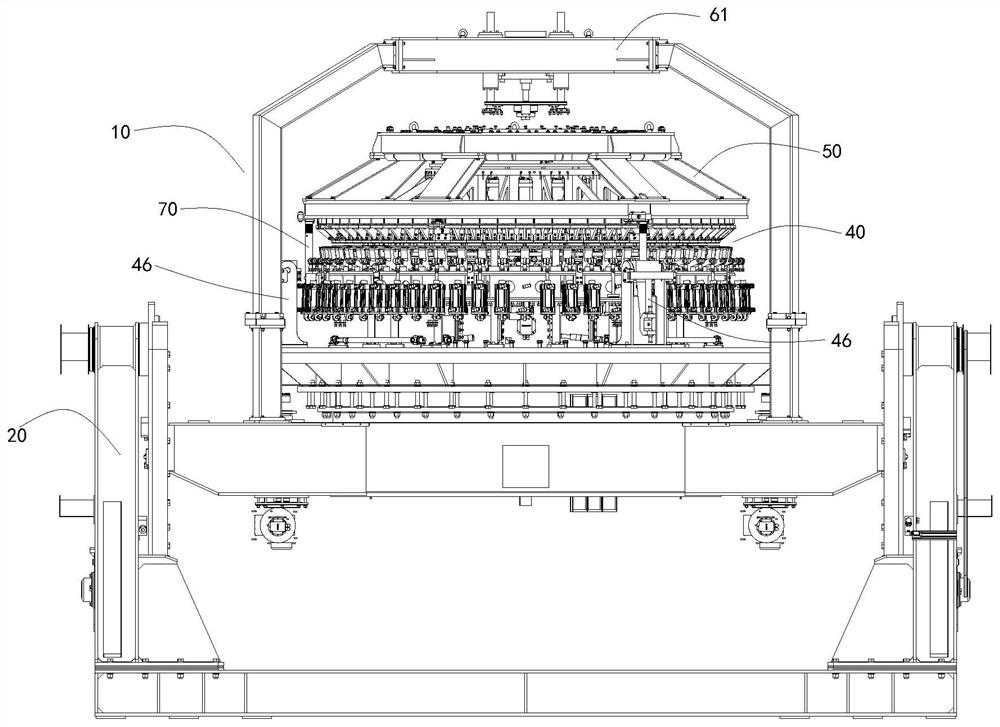

[0064] like Figure 2-7 As shown, the present invention provides a TIG girth welding device at the bottom of a storage tank. The TIG girth welding device includes: a girth welding tire tool 10, a positioner 20 and a milling and welding gantry 30; the girth welding tire The tool 10 is installed on the positioner 20, and the milling and welding gantry 30 is erected above the girth welding tool 10; the girth welding tool 10 clamps and positions the components to be welded at the bottom of the tank, and the variable The positioning machine 20 drives the circumferential seam welding tool 10 to displace, and cooperates with the milling and welding gantry 30 to perform edge milling and TIG circumferential seam welding at the weld;

[0065] The girth welding tire 10 includes: a welding mold tire 40, a pressing device 50 and a top cover pressure ring 60;

[0066] The welding mold tire 40 includes: a base 41, a lifting ring 42, a supporting device 43, a mandrel lifting device 44 and a ...

Embodiment 2

[0082] The present invention provides a TIG girth welding process using the TIG girth welding device described in Embodiment 1, and the TIG girth welding process includes the following steps in turn:

[0083] S1: Fork ring clamping

[0084] The hoisting fork ring 1 is placed on the lifting ring 42, the first inner support 421 is driven, and the fork ring 1 is tightened and fixed from the inside; the first piano key pressing block 422 is driven by the air cylinder, and the fork ring 1 is pressed from the outside, Realize the clamping and fixing of the fork ring 1;

[0085] S2: ring clamping

[0086] Place the hoisting ring 2 on the supporting device 43, drive the second inner support 431, and tighten and fix the hoop ring 2 from the inside; hoist the pressing device 50, insert the centering sleeve 541 into the centering hole 441, and fix the centering sleeve 541 through the bolt. The positioning assembly 54 is connected with the mandrel elevating device 44, drives the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com