Computer case stamping and feeding device and operation method

A feeding device, computer case technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of restricting punching speed, existence safety, low efficiency, etc., and achieve stable feeding action, safe use, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below according to accompanying drawing and embodiment the present invention will be described in further detail:

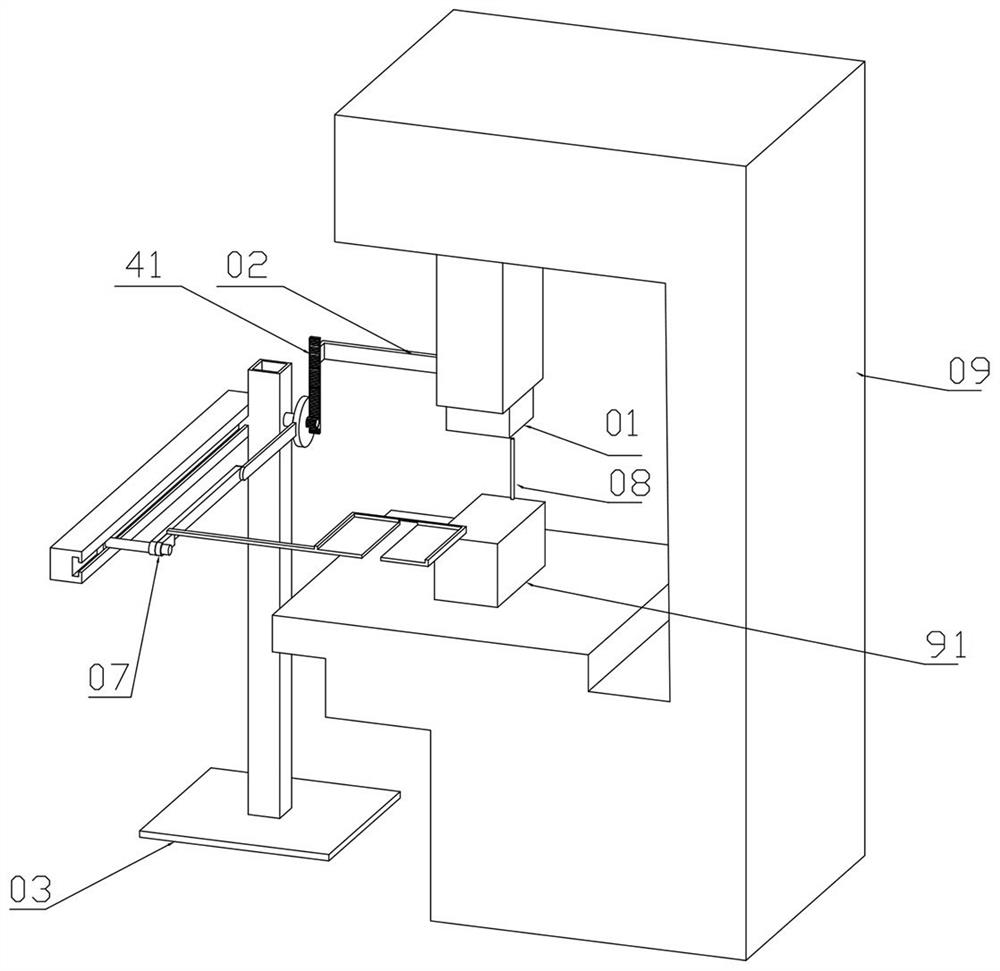

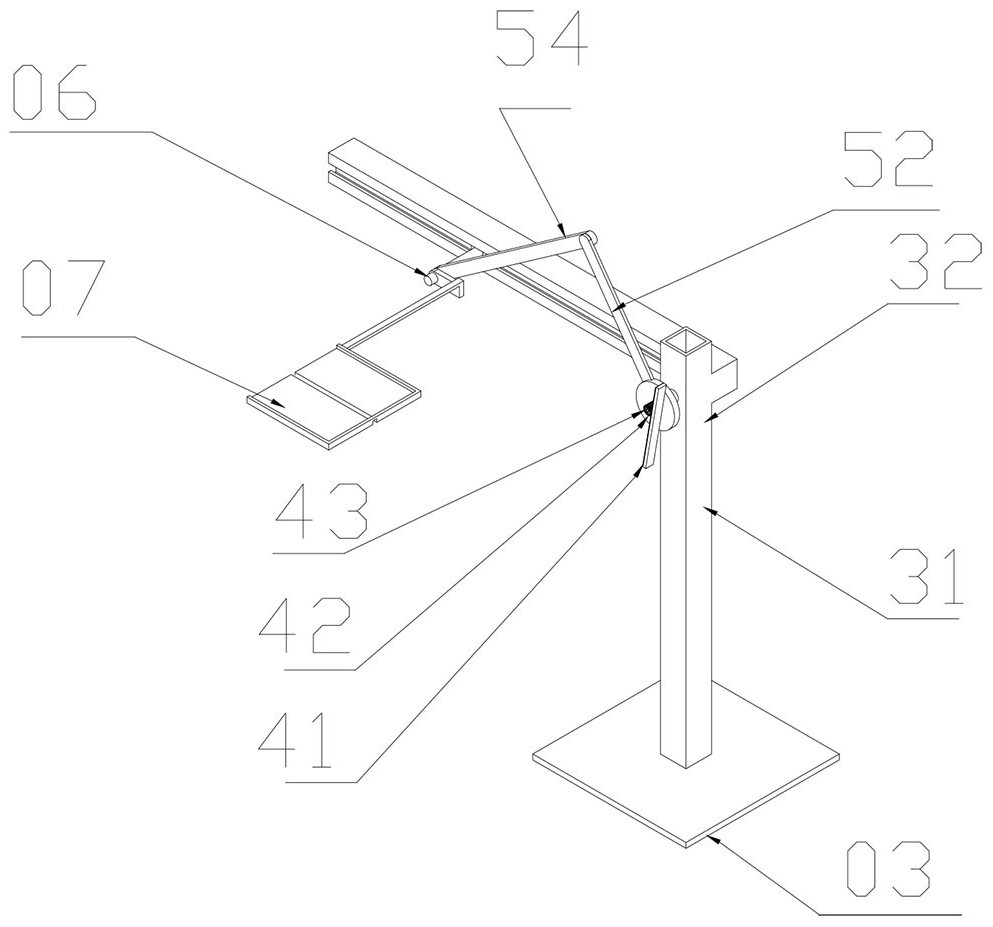

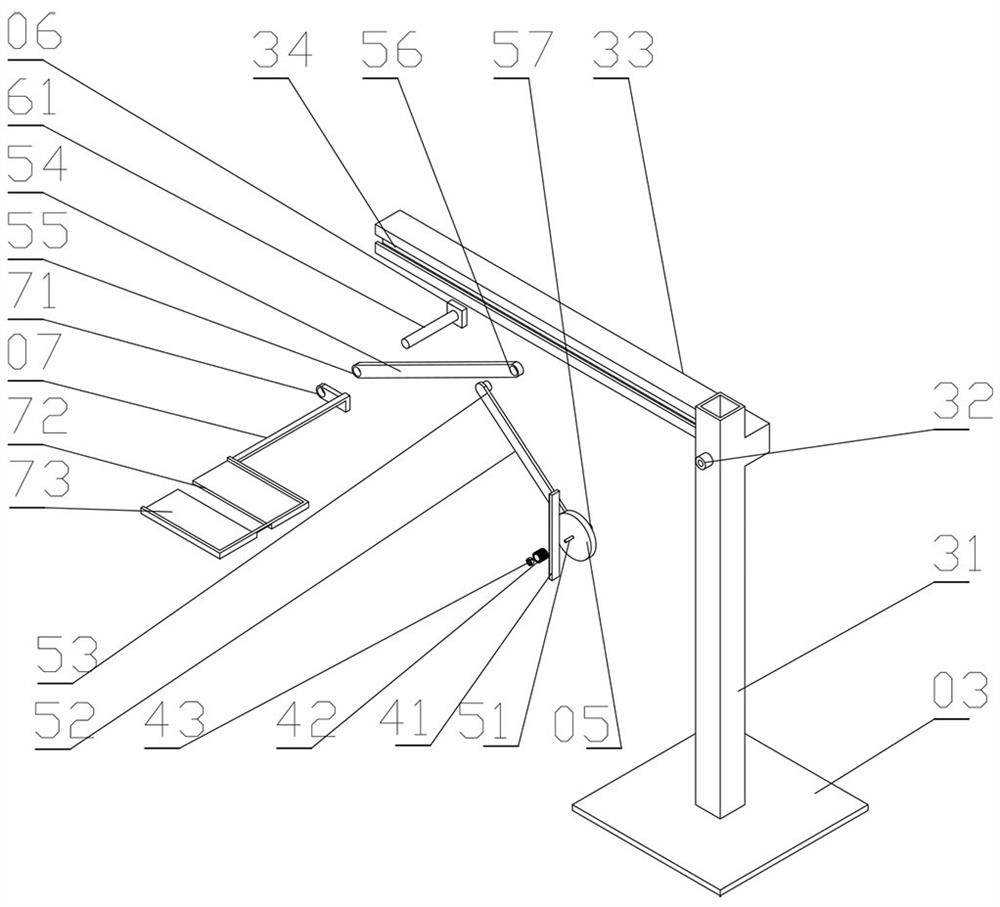

[0021] A punching and feeding device for a computer case, including a punching machine 09, a punch 01, a connecting arm 02, a frame 03, a chute 34, a rack 41, a gear 42, a one-way bearing 43, a crank 05, a slider 06, and a feeding tray 07. The upper part of the stamping machine tool 09 has a mold base 91, one side of the mold base 91 is connected to the positioning pin 08, the middle part of the stamping machine tool 09 is connected to the frame 03, the upper part of the frame 03 has a column 31, and the upper part of the column 31 has a fixing hole 32, behind the fixing hole 32 There is a slider seat 33 on the side, a chute 34 is arranged in the middle of the slider seat 33, a crank 05 is arranged in the middle of the fixing hole 32, a crank shaft 57 is arranged on the rear side of the crank 05, and the crank shaft 57 is connected to the fixing hole 32 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com