Novel desulfurization method of biodiesel

A technology of biodiesel and a new method, which is applied to the removal of sulfur-containing compounds in biodiesel and the field of biodiesel desulfurization, can solve problems such as difficulties in desulfurization of biodiesel, and achieve the advantages of less equipment investment, stable oil quality and safe desulfurization process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

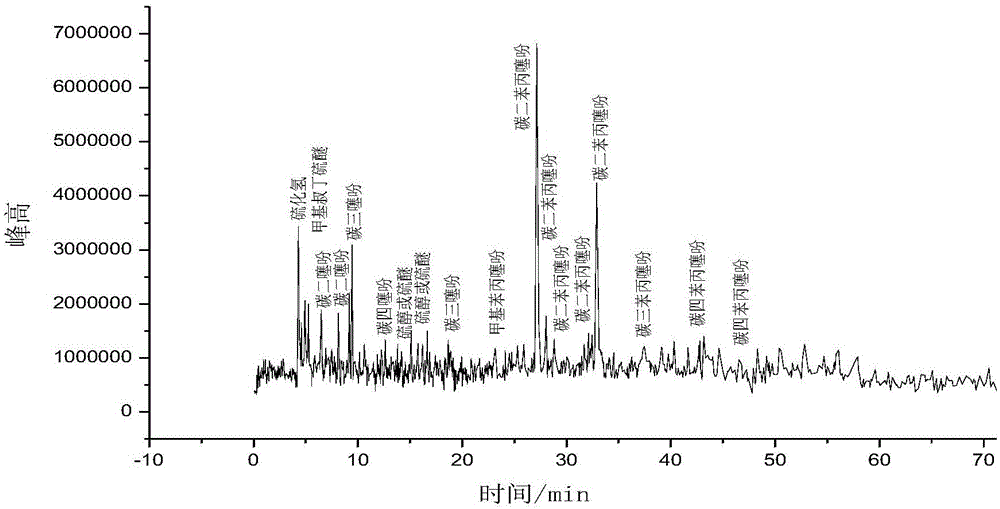

[0020] Example 1 The crude biodiesel raw material used is waste grease gutter oil, its sulfur content is about 50ppm (detected by ultraviolet fluorescence method), and its fatty acid methyl ester content distribution is shown in Table 1, wherein C14-0 is methyl myristate, C16 -0 is methyl palmitate, C18-0 is methyl stearate, C18-1 is methyl oleate, C18-2 is methyl linoleate, C18-3 is methyl linolenate:

[0021] Table 1 Contents of fatty acid methyl esters in waste oil

[0022]

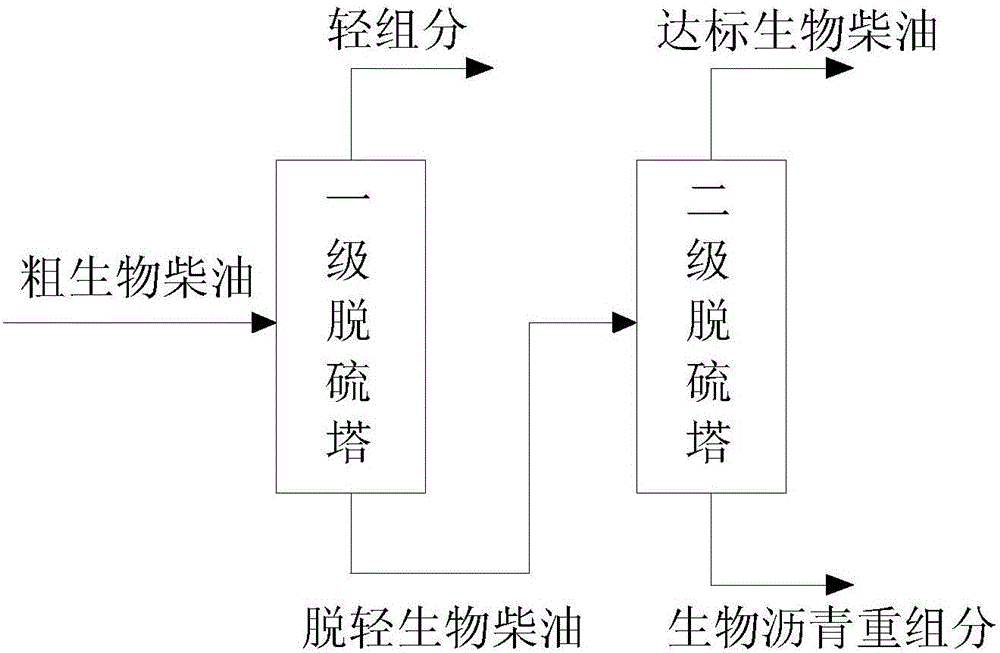

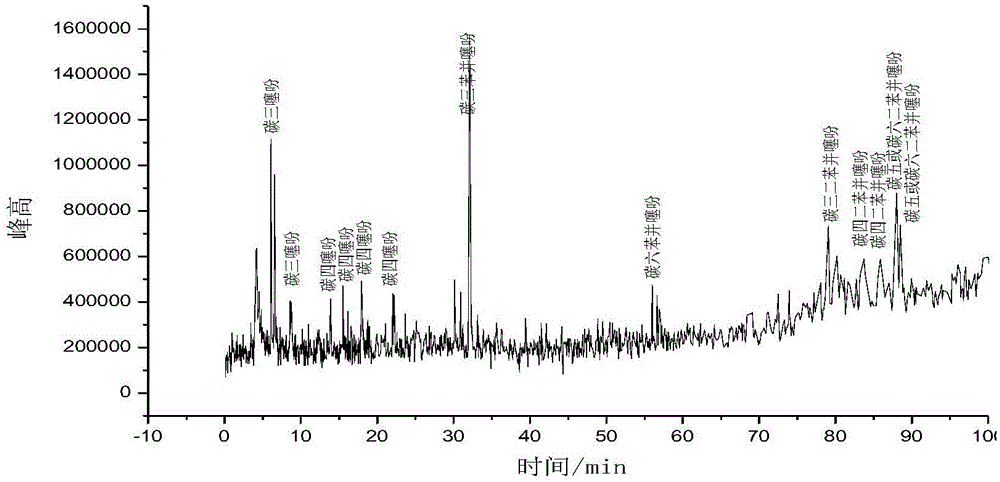

[0023] Such as figure 1 As shown, crude biodiesel produced from gutter oil is pumped into the primary desulfurization tower 1, the heating temperature of the first stage desulfurization tower 1 is controlled at 200°C, the operating absolute pressure is 50Pa, and the reflux ratio is 20. In the primary desulfurization tower 1 Light components are obtained from the top of the tower, and the still liquid of the first desulfurization tower 1 is injected into the second desulfurization tower 2. The heati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com