Sea chest suction structure

A technology of seabed doors and suction inlets, which is applied to ships and other directions, and can solve problems such as insufficient cooling water for ships, affecting the safety and stability of ship navigation, and difficulty in entering water into the suction structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

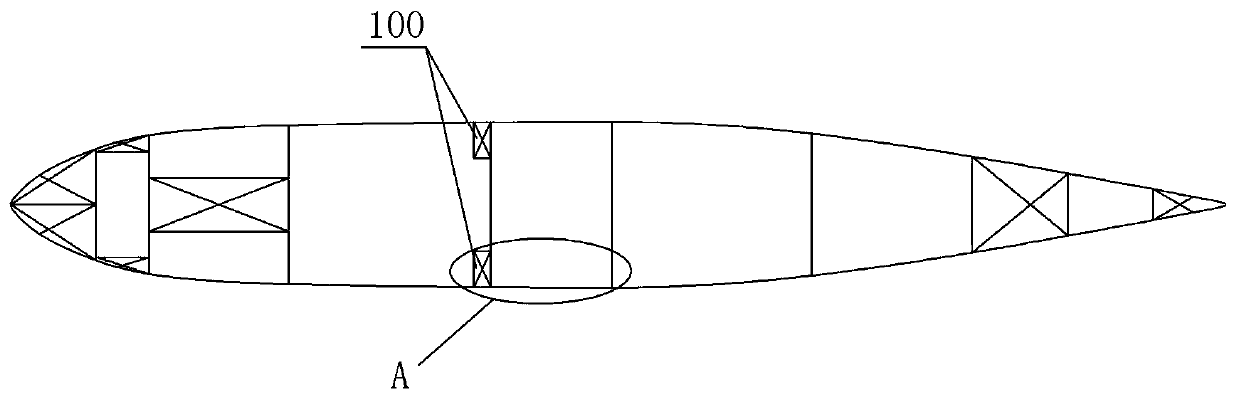

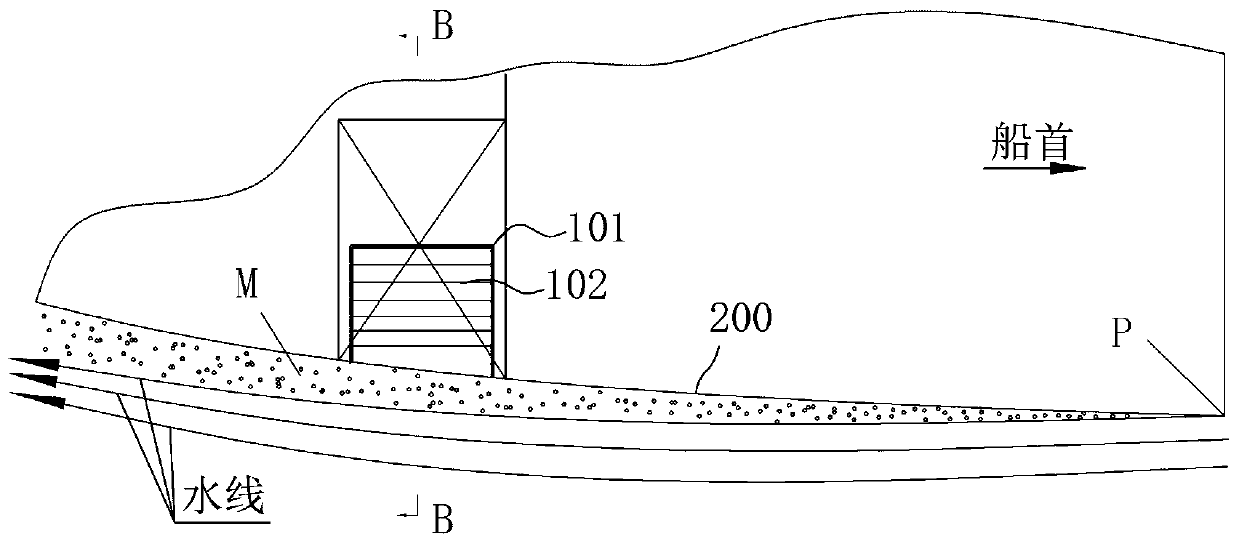

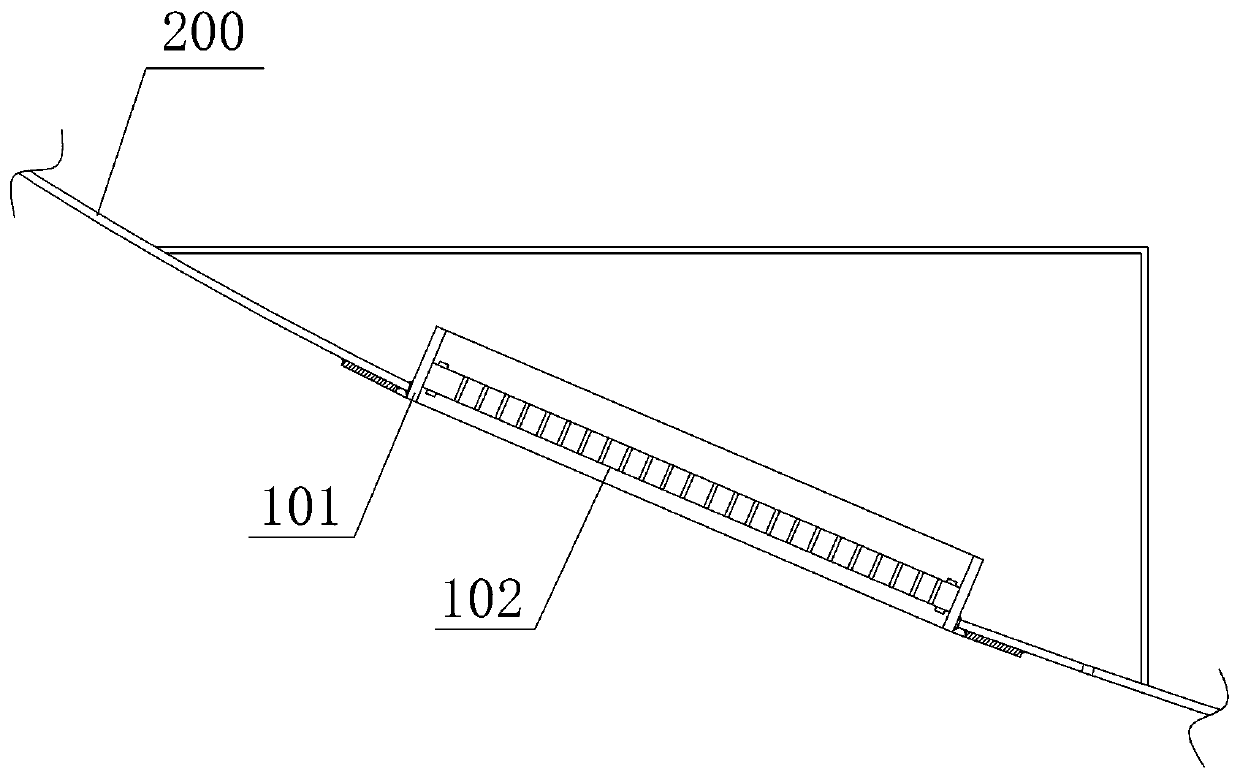

[0016] Such as Figure 4-9 shown.

[0017] A seabed door suction structure, comprising a seabed door suction inlet 2 arranged on a ship's outer plate 200 and a water baffle 3 protruding outward from the hull, the water baffle is arranged on the ship's outer plate to communicate with the seabed door suction inlet Adjacent to or at the entrance of the suction inlet of the seabed door, and the water baffle is arranged in the range from the side of the suction inlet of the seabed door toward the stern to the side of the ship on both sides.

[0018] Such as Figure 4-6 As shown, a coaming plate 1 is installed on the suction port 2 of the seabed door, and the water retaining plate 3 is arranged on the outer surface of the coaming plate towards the stern side, and the rest of the coaming plate outer surface is consistent with the line shape of the ship's outer plate 200 . Alternatively, a filter device is provided on the enclosure 1, and the water retaining plate 3 is provided on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com