Wheel rim-driven shaftless fan

A rim drive and fan technology, which is applied to machines/engines, liquid fuel engines, mechanical equipment, etc., can solve the problems of reduced energy conversion efficiency, low energy conversion efficiency, increased aerodynamic noise, etc., to improve energy conversion efficiency and transportation. And the effect of easy installation and improved flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

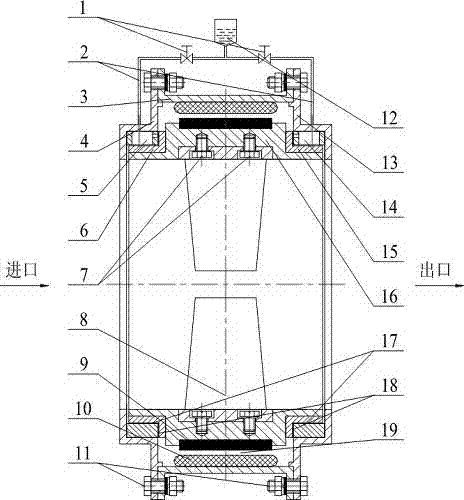

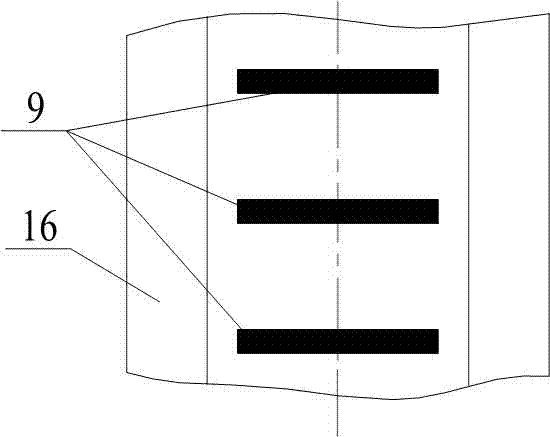

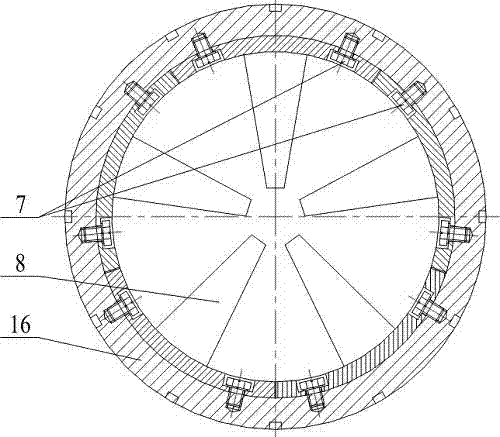

[0020] Such as Figure 1 to Figure 3 The rim-driven shaftless fan shown includes a stator part, a rotor part and a lubricating device; the stator part includes a front cover 4, an inlet side sliding bearing 5, an air duct 3, an armature 10, an outlet side sliding bearing 14 and a rear end The cover 13 and the air cylinder 3 are cylindrical structures, the two ends of the air cylinder 3 are provided with flanges, and the flanges are provided with a plurality of evenly distributed through holes, and the front end cover 4 and the rear end cover 13 are provided with stoppers. The outer diameter of the mouth is equal to the inner diameter of the air cylinder 3, and the front end cover 4 and the rear end cover 13 are also provided with a plurality of evenly distributed through holes, which are equal in diameter and number to the through holes on the flange of the air cylinder 3 , and the center line coincides, the front end cover 4 and the rear end cover 13 are installed on both end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com