Gear-rack driving type shaftless fan

A rack-and-pinion, driven technology, used in machines/engines, liquid fuel engines, axial flow pumps, etc. Large workable area, saving flow space, improving efficiency and noise performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

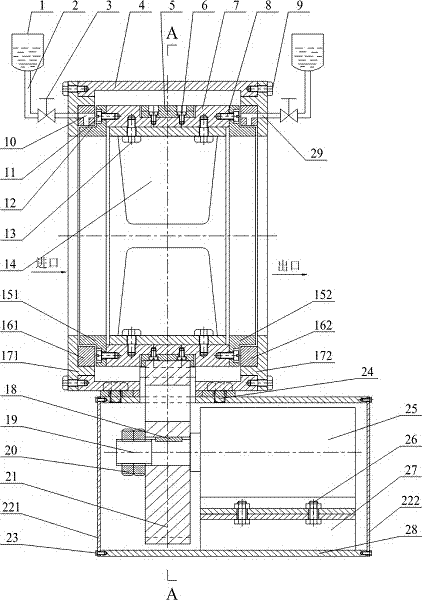

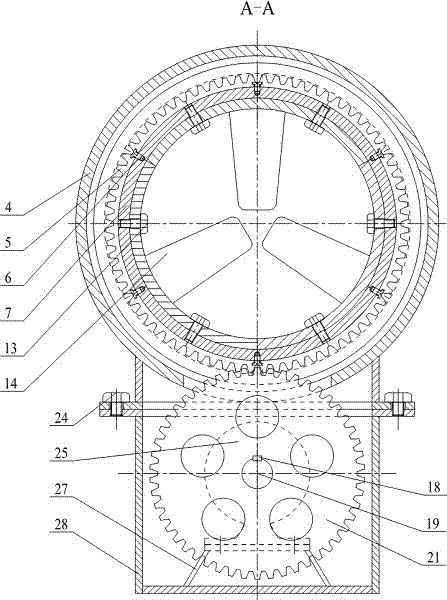

[0033] Such as Figure 1 to Figure 8 The rack and pinion driven shaftless fan shown includes the host part and the motor drive part;

[0034] The host part includes stator parts, rotor parts and lubricating devices;

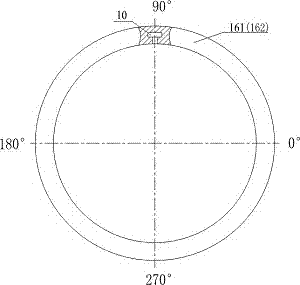

[0035] The stator component includes a front end cover 171, an inlet sliding bearing 161, an air cylinder 4, an outlet sliding bearing 162, and a rear end cover 172. The air cylinder 4 is a cylindrical structure with shoulders arranged on the inside of both ends, and a rectangular unfolded surface is arranged below it. The window is provided with a vertical plate around the window, one end of the vertical plate is welded on the fan cylinder 4 along the rectangular window, and the other end is provided with a rectangular flange, and the rectangular flange is provided with a plurality of through holes, the front cover 171 and the rear The end cover 172 is provided with a spigot and an oil guide hole 29, and the outer diameter of the spigot is equal to the inner di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com