A vertical axis wind turbine blade assembly and synthetic jet control method thereof

A technology of wind turbine blades and synthetic jets, which is applied in the control of wind turbines, wind turbines at right angles to the wind direction, wind turbines, etc., can solve the periodic change of the blade angle of attack, the decline of system reliability, and the complex flow field structure, etc. problem, to achieve the effect of improving aerodynamic performance, reducing wake strength, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Figure 7 is the Lamuda type synthetic jet control function and its schematic diagram in the embodiment of the present invention.

[0082] Such as Figure 7 shown in the figure

[0083]

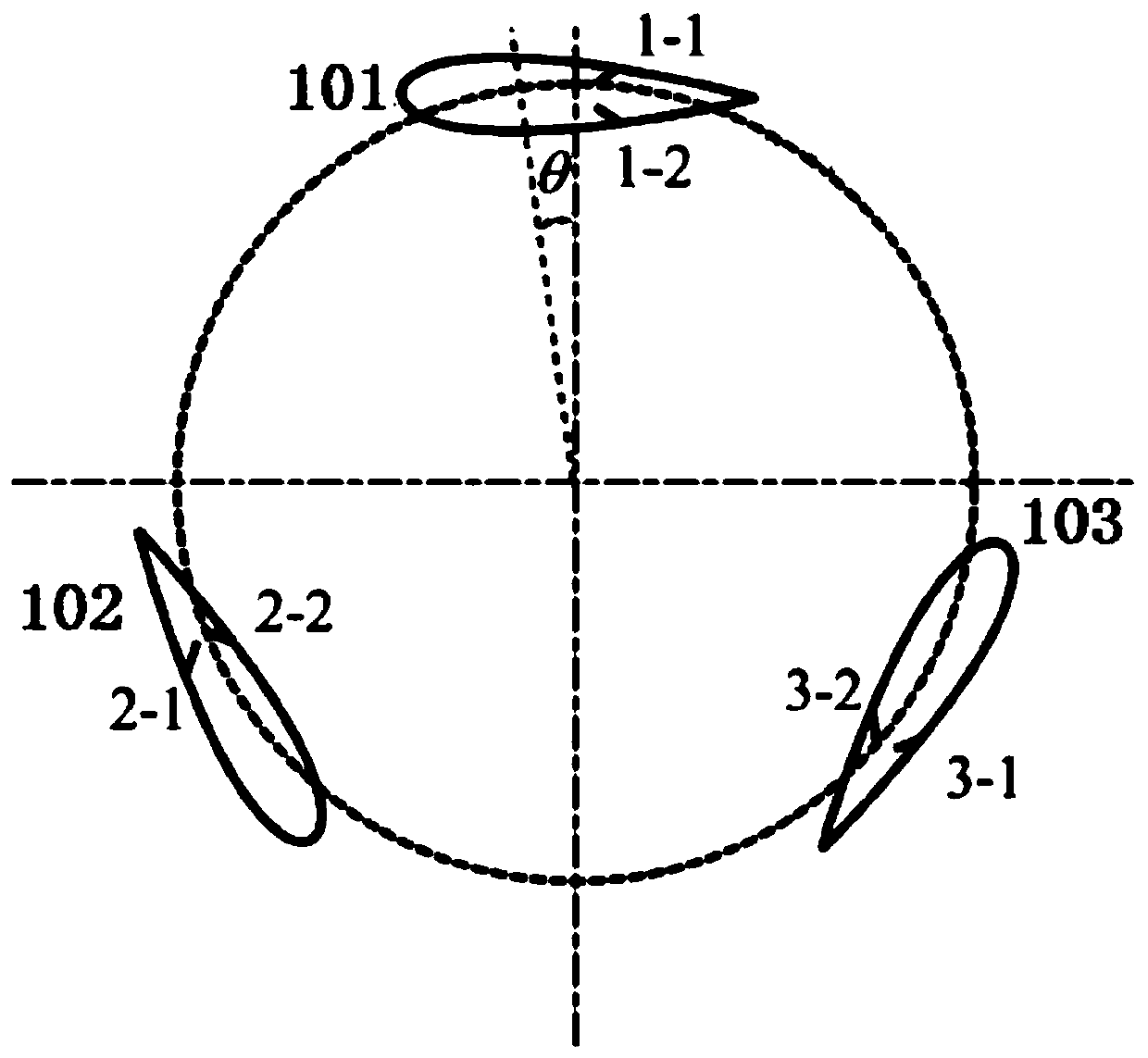

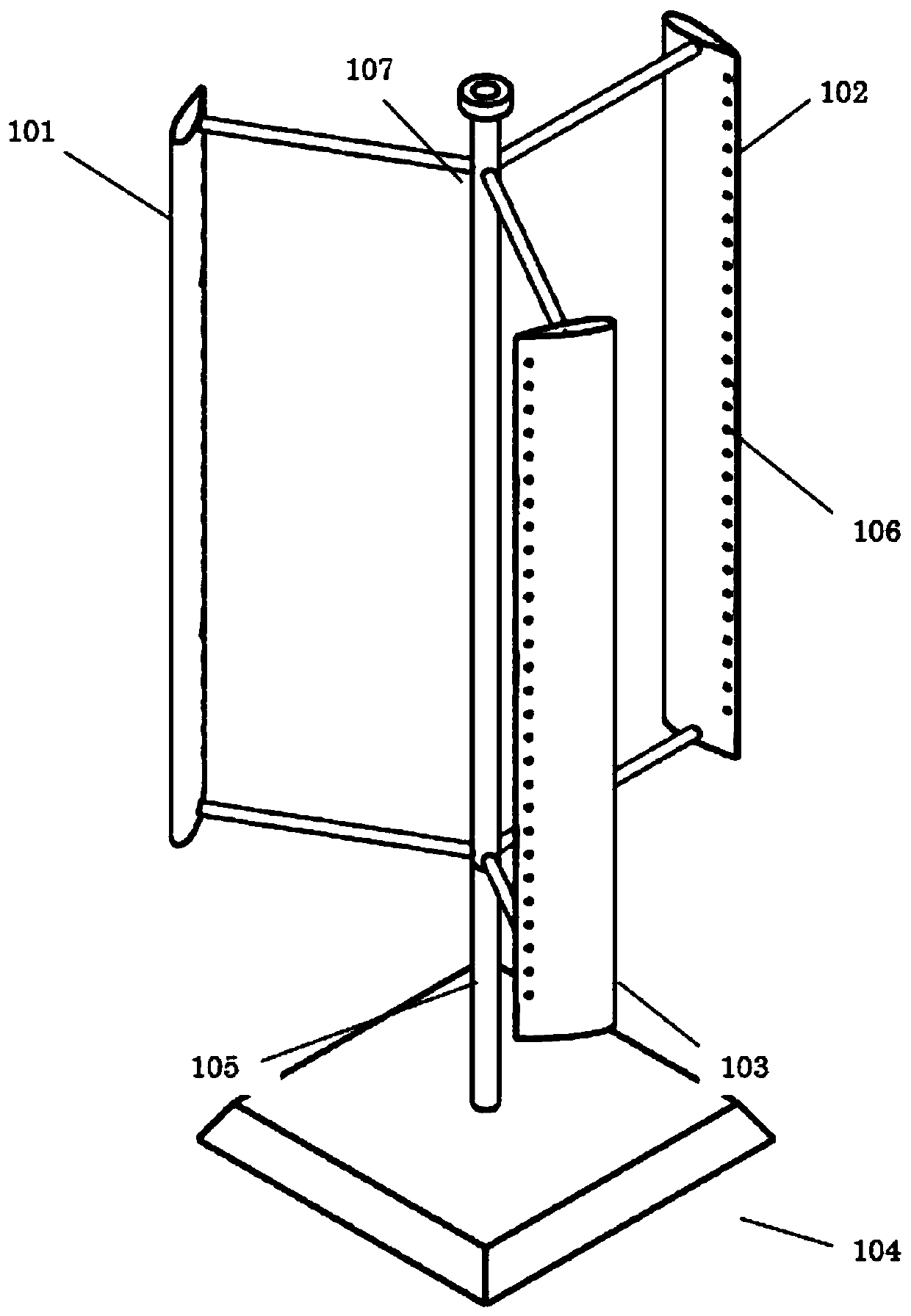

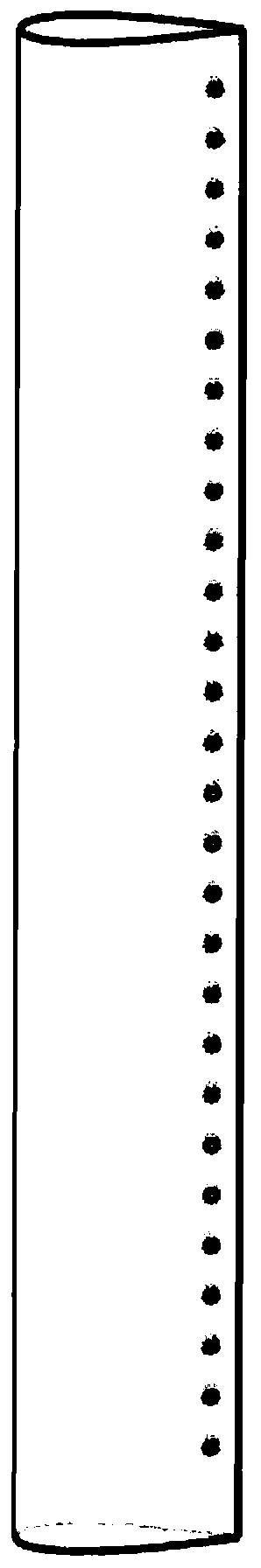

[0084] When the jet hole 106 is on the pressure side of the blade, the jet is closed, and when it is on the suction side, the jet is turned on, and the fluid is blown / absorbed at a certain working frequency; the amplitude of the piezoelectric film can be controlled, and the excitation frequency of the exciter can also be controlled to make the jet blowing coefficient C μ As the effective angle of attack of the blade increases, the jet blowing coefficient C at zero angle of attack μ is 0. combine figure 1 , the initial position of jet hole 1-1 is on the pressure surface of the blade, and the initial position of jet hole 1-2 is on the suction surface of the blade, so jet hole 1-2 should open the jet, and the jet blowing coefficient C μ size should vary with Figure 7 The Lamuda co...

Embodiment 2

[0086] Figure 8 is the piecewise linear synthetic jet control function and its schematic diagram in the embodiment of the present invention.

[0087] Such as Figure 8 shown in the figure

[0088] When the jet hole 106 is on the pressure side of the blade, the jet is closed, and when it is on the suction side, the jet is turned on, and the fluid is blown / absorbed at a certain working frequency; the amplitude of the piezoelectric film can be controlled, and the excitation frequency of the exciter can also be controlled, so that the jet blowing coefficient can be adjusted accordingly. The effective angle of attack of the blade increases, and the blowing coefficient of the jet is 0 when the angle of attack is zero. combine figure 1 , the starting position of jet hole 1-1 is on the pressure surface of the blade, and the starting position of jet hole 1-2 is on the suction side of the blade, so jet hole 1-2 should open the jet, and the jet blowing coefficient should vary with ...

Embodiment 3

[0090] Figure 9 is the Sin-type synthetic jet control function and its schematic diagram in the embodiment of the present invention.

[0091] Such as Figure 9 shown in the figure

[0092] When the jet hole 106 is on the pressure side of the blade, the jet is closed, and when it is on the suction side, the jet is turned on, and the fluid is blown / absorbed at a certain working frequency; the amplitude of the piezoelectric film can be controlled, and the excitation frequency of the exciter can also be controlled, so that the jet blowing coefficient can be adjusted accordingly. The effective angle of attack of the blade increases, and the blowing coefficient of the jet is 0 when the angle of attack is zero. combine figure 1 , the starting position of jet hole 1-1 is on the pressure surface of the blade, and the starting position of jet hole 1-2 is on the suction side of the blade, so jet hole 1-2 should open the jet, and the jet blowing coefficient should vary with Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com