Culvert device of horizontal axis wind-driven generator

A wind power generator, horizontal axis technology, applied to wind power generators, wind power generators consistent with the wind direction, wind power generation, etc., can solve the problems of blade damage, blade aerodynamic noise, low power generation efficiency of wind power generators, etc., to reduce Effects of weight, improvement of quiet performance, and improvement of material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

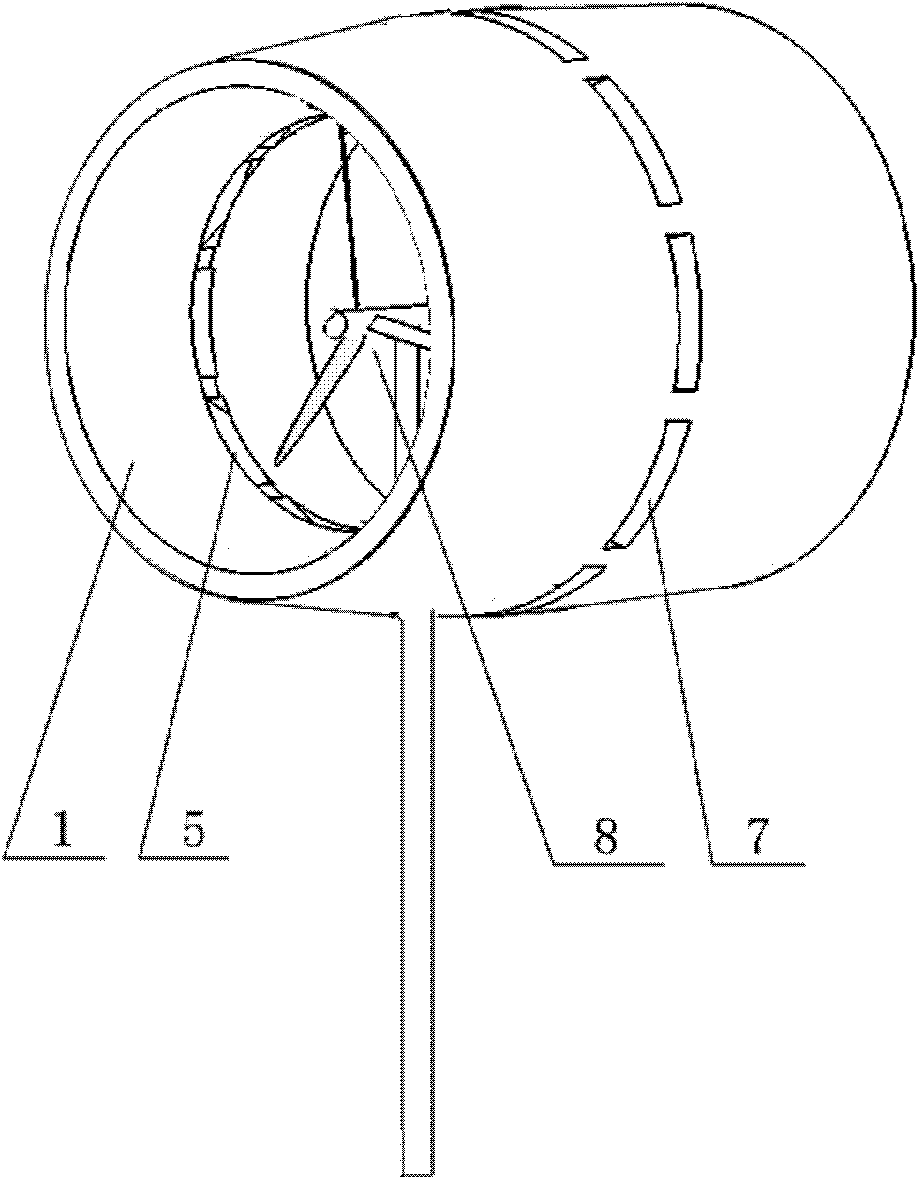

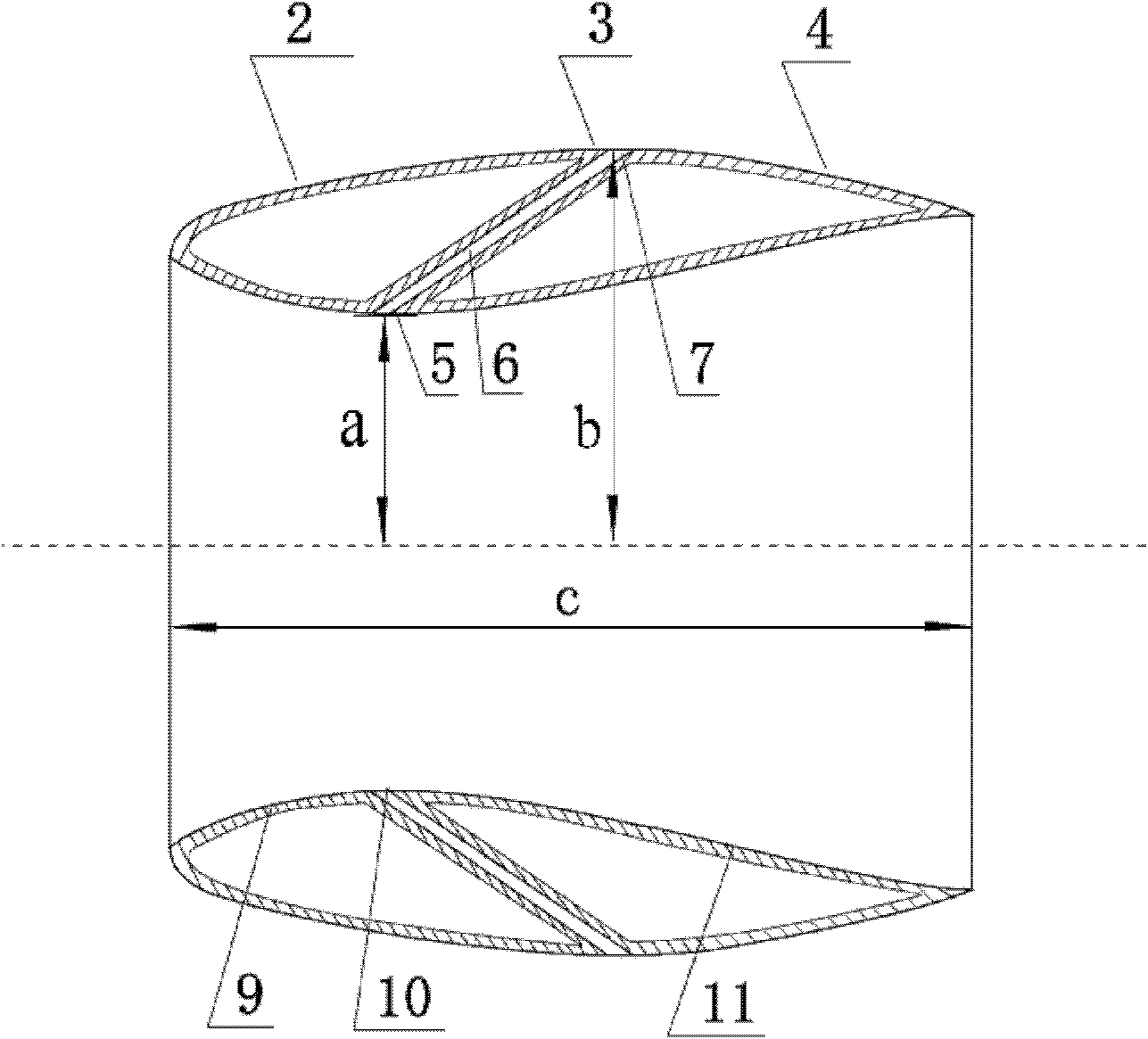

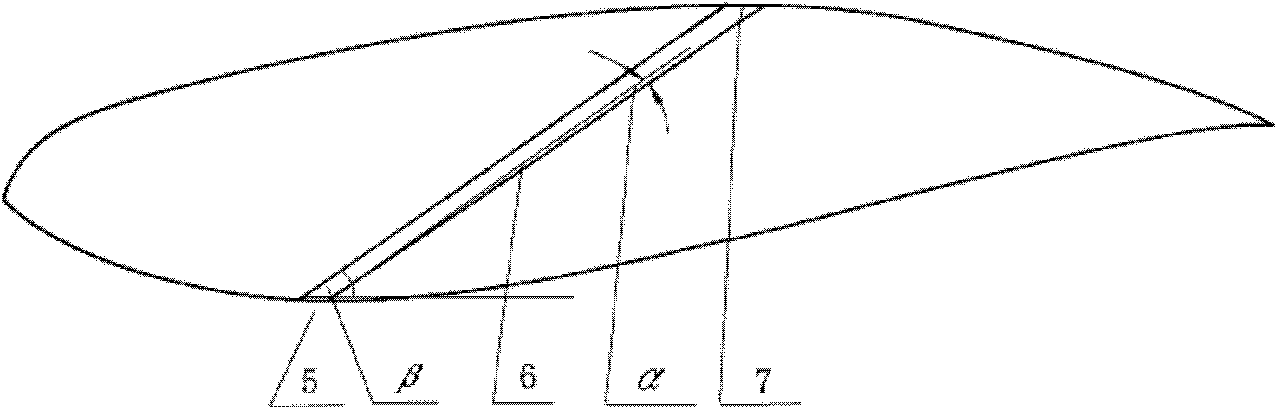

[0024] Such as figure 1 and figure 2 As shown, the horizontal-axis wind turbine duct device of the present invention is to install the duct device 1 on the horizontal-axis wind generator 8, including the inner flow channel arranged inside the duct, and the outer flow channel outside the duct and a suction device arranged inside the duct to connect the inner flow channel and the outer flow channel and a control device for controlling the opening size of the suction device. The inner flow passage includes an inner acceleration section 9 , an inner transition section 10 and an inner deceleration section 11 connected in sequence. The outer flow passage includes an outer acceleration section 2 , an outer transition section 3 and an outer deceleration section 4 which are connected in sequence.

[0025] Through the surface design of the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com