Rotatable ship rudder with bulge front edges

A technology for ships and leading edges, which is applied in the direction of steering with rudder, ship parts, steering gear, etc. Hydrodynamic performance, effect of reducing cavitation erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

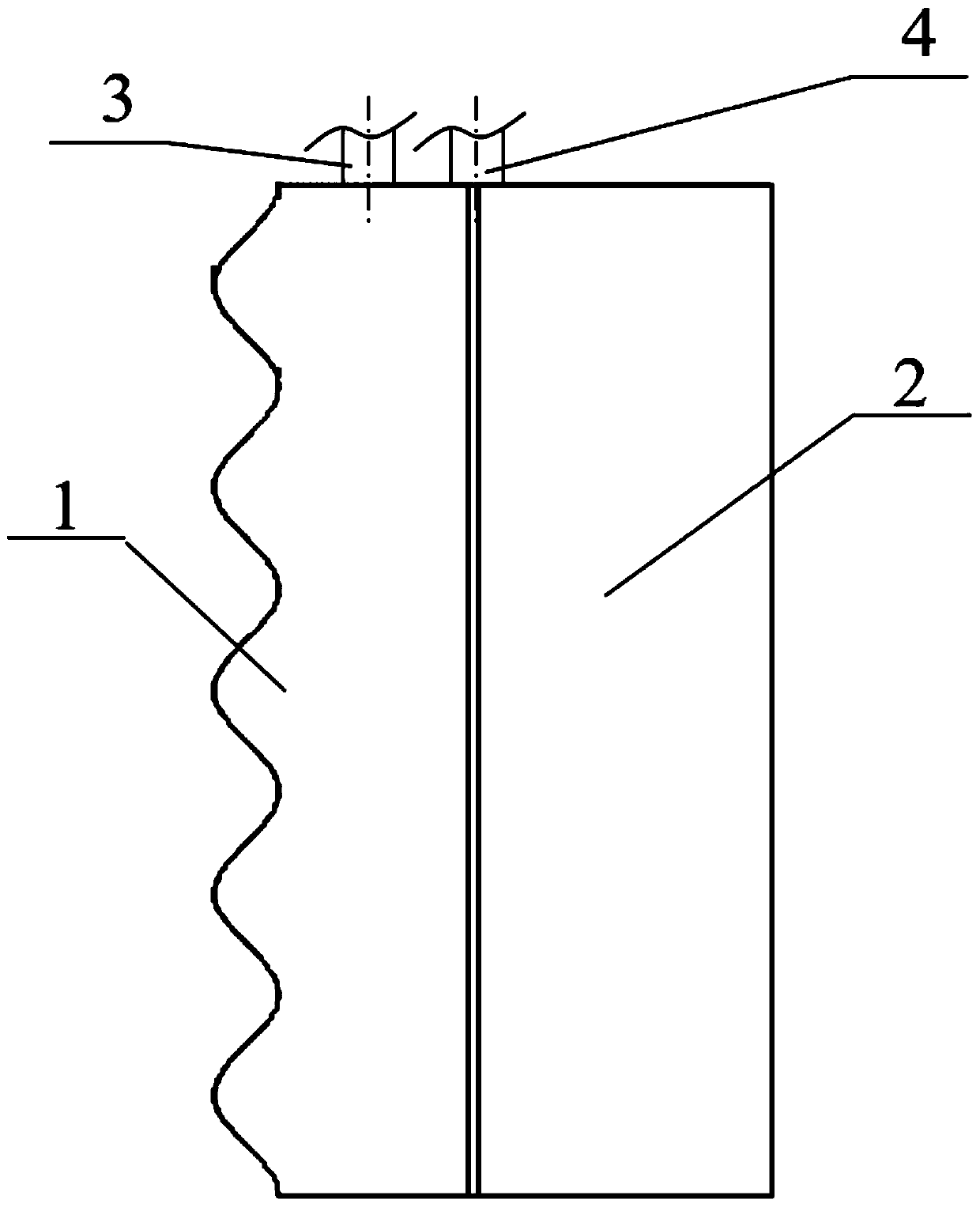

[0034] like figure 1 As shown, this embodiment provides a rotatable ship rudder with a bulging leading edge, the rudder includes a main rudder blade and a tail rudder blade, the tail rudder blade is arranged at the rear end of the main rudder blade, and the The front end of the main rudder blade is provided with a plurality of bulging leading edges protruding forward.

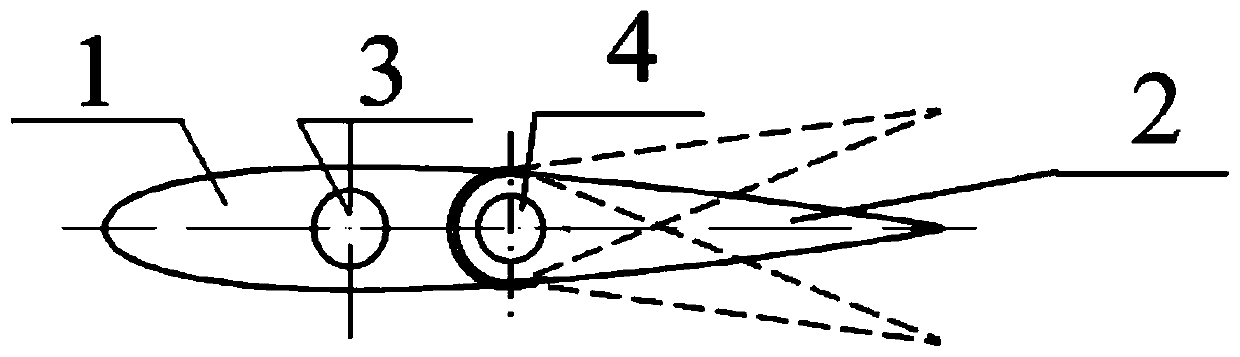

[0035] In this specific example, if figure 1 , figure 2 and Figure 6 As shown, the front end contour of the longitudinal section of the rudder is a parabola. The cross-sectional shape of the rudder is an airfoil. An auxiliary rudder stock is arranged between the main rudder blade and the tail rudder blade, and the tail rudder blade is rotatably arranged on the auxiliary rudder stock. A main rudder stock is arranged inside the main rudder blade, and the main rudder stock is used for connecting the main rudder blade with the hull.

[0036] like Figure 7 As shown, the front end longitudinal section conto...

Embodiment 2

[0039] This embodiment is an embodiment improved on the basis of the first embodiment.

[0040] In this specific example, if Figure 8 As shown, the front end longitudinal section contour lines of the plurality of bulge leading edges are semicircular.

[0041] like Figure 11 As shown, the transition between the body and the front edge of the bulge is a continuous curvature transition, that is, the curvature of the front edge of the bulge and the body at the connection points P1 and P2 are consistent, and the section line type of the front edge of the bulge is a Besser crossing P1, O, and P2 Seoul curve.

[0042] The radii of the plurality of bulge leading edges may be the same or different. The intervals between adjacent front edges of the bulges may be equal or unequal.

Embodiment 3

[0044] This embodiment is an embodiment improved on the basis of the first embodiment.

[0045] In this specific example, if Figure 9 As shown, the front contour lines of the plurality of bulge front edges are a plurality of semi-elliptical shapes arranged at intervals. The radii of the major axes or the minor axes of the multiple bulge leading edges may be the same or different. The intervals between adjacent front edges of the bulges may be equal or unequal.

[0046] The bulging leading edge protruding forward can play a role in stabilizing the flow. The geometric structure parameter selection of the bulging leading edge is related to the specific ship’s lateral sway angle and ship’s sailing speed. The continuous transition between the bulging leading edge structure and the curvature of the body is adopted to reduce the Flow separation improves the hydrodynamic performance of the fin stabilizer and reduces the fin stabilizer resistance during forward movement, thereby red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com