High-pressure disc thrust gas bearing adopting double symmetrical contraction sections for gas supply and design method

A technology of gas bearing and shrinkage section, which is applied in the field of high-pressure disc thrust gas bearings, and can solve the problems of unsatisfactory improvement of bearing capacity and lack of information.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

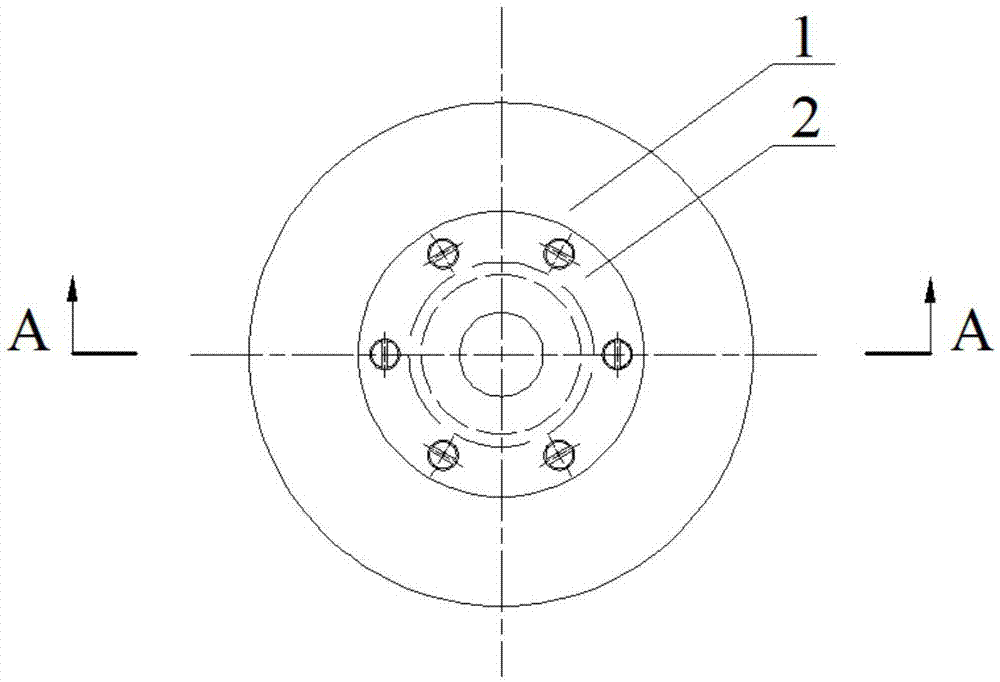

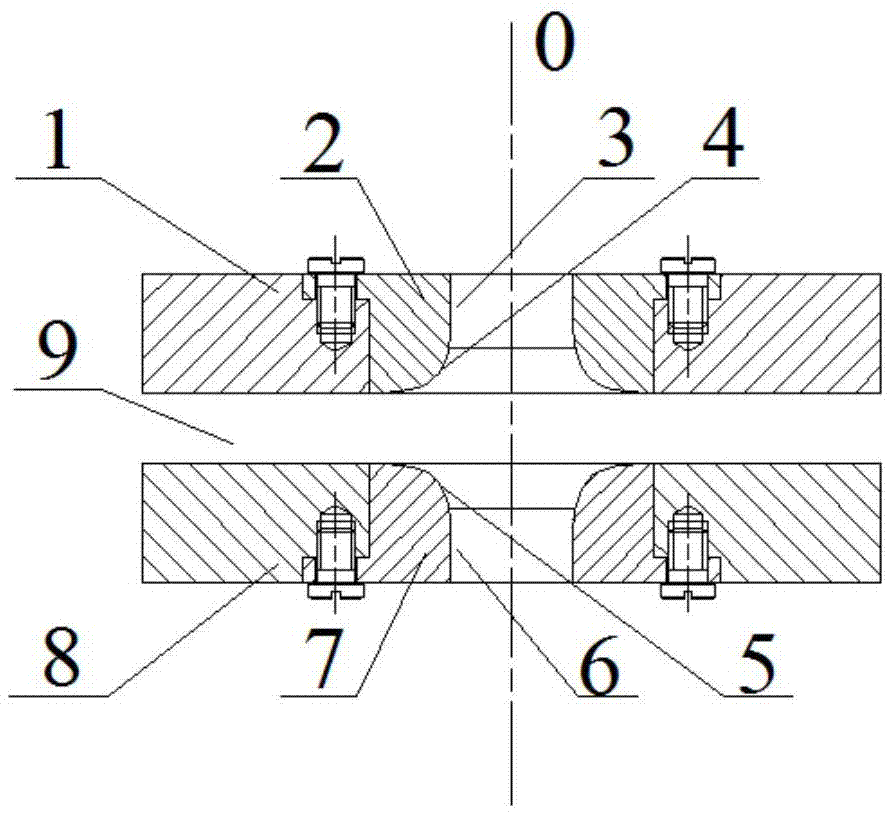

[0034] see figure 1 , figure 2 , shows a high-pressure disc thrust gas bearing with gas supply from double symmetrical contraction sections, which includes:

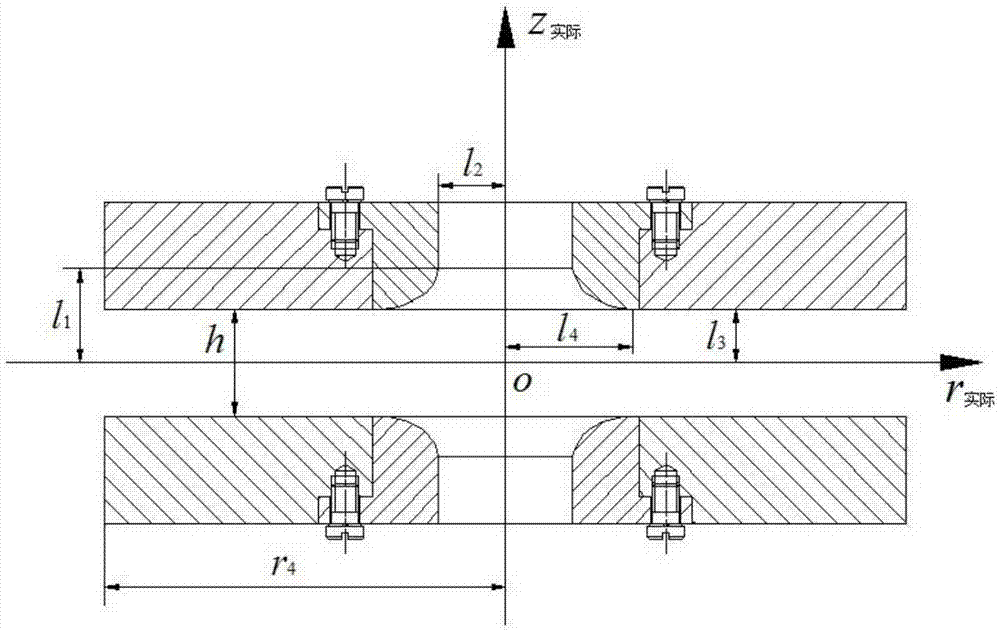

[0035] The air supply holes 3, 6 are set at the center of the air supply parts 2, 7 respectively, and are used to introduce the high-pressure gas in the pressure stabilizing chamber to prepare for entering the shrinkage sections 4, 5 with specific curved surface shapes. The constricted sections 4 and 5 not only form an axisymmetric structure with respect to the rotation axis 0, but also their shapes and structures are completely symmetrical with respect to the air film gap, so it is called the use of double symmetric constricted sections for air supply.

[0036] The two air supply parts 2, 7 are used to connect the upstream plenum (not shown in the figure). In order to meet the needs of adjusting the bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com