Cross wind recycling type wet cooling tower

A wet-cooling tower and cross-wind technology, applied in the direction of water shower coolers, direct contact heat exchangers, heat exchange equipment, etc., can solve the problems of transformation and utilization, achieve enhanced heat dissipation, enhanced ventilation characteristics and cooling performance, and improved Effect of Circumferential Uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, working principle, concrete structure and implementation of the present invention are further described:

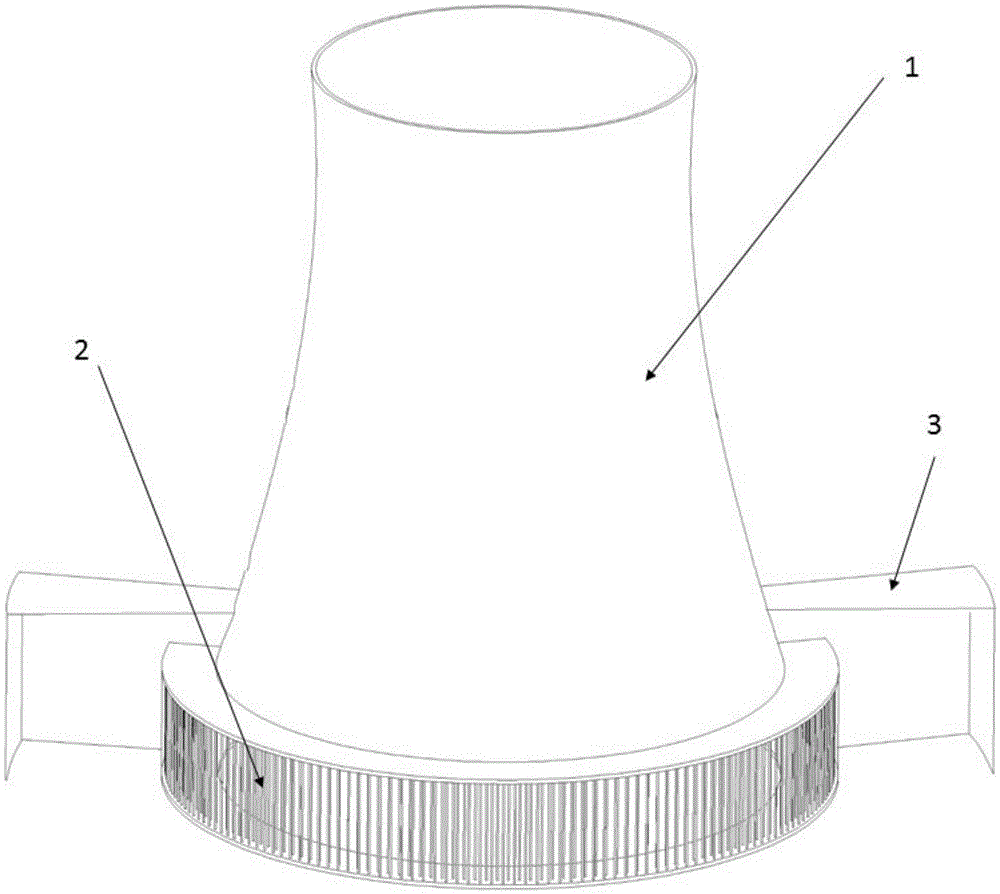

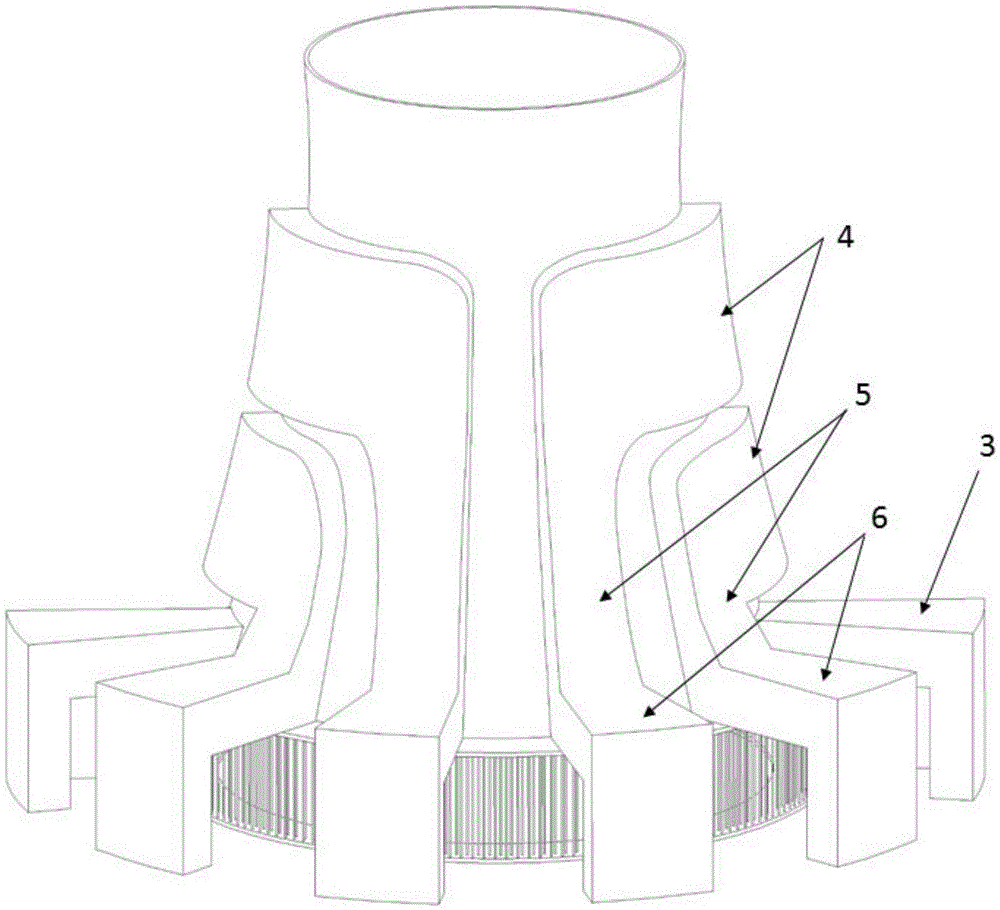

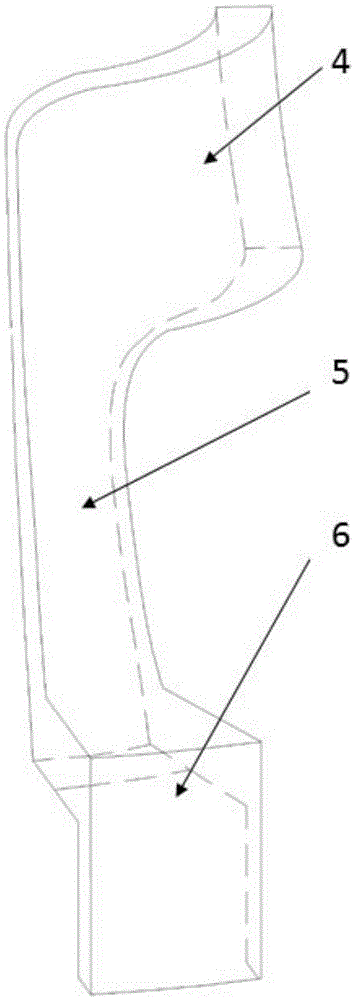

[0019] figure 1 It is a structural schematic diagram (front view of the windward side) of an embodiment of a wet cooling tower equipped with a wind chamber in the present invention. The wet cooling tower includes a wet cooling tower shell 1, a bottom air inlet 2 and at least one collection arranged outside the bottom air inlet. The air chamber 3 and the air receiving chamber 3 are arranged along the circumference of the wet cooling tower. The air receiving chamber 3 is open to the direction of the incoming ambient wind, and it is closed on the leeward side. It is preferable to arrange two wind collections, which are respectively arranged on both sides of the wet cooling tower. The height of the upper edge, the width of the side extension, and the depth along the wind direction of the air collection chamber can be com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com