Low temperature environment testing apparatus

A test device and low-temperature environment technology, which is applied in the field of low-temperature performance test devices for electronic products, can solve the problems of poor low-temperature constant state, slow cooling speed, complex structure, etc., and achieve the effects of ensuring stability, improving stability, and being easy to use and operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

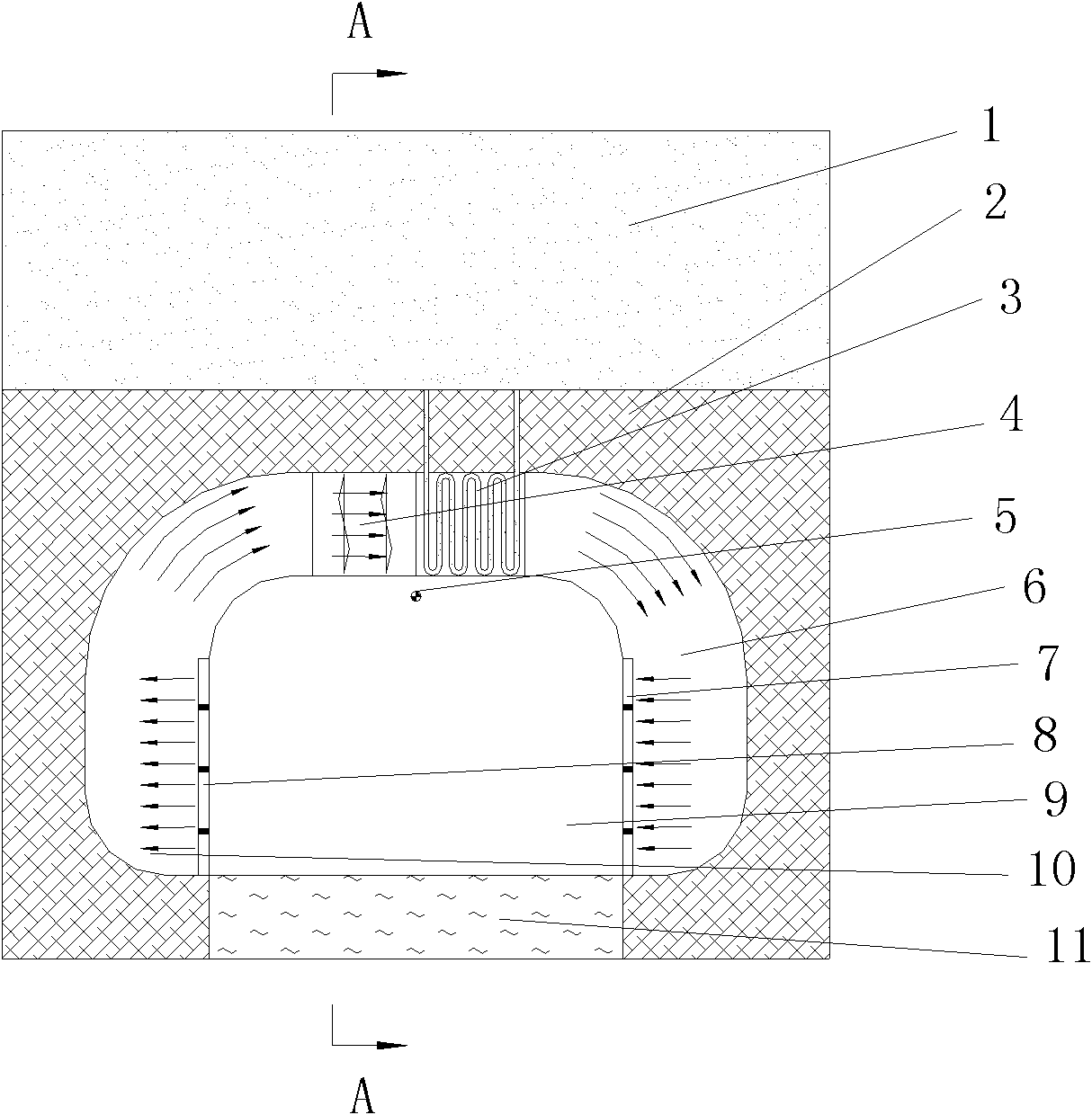

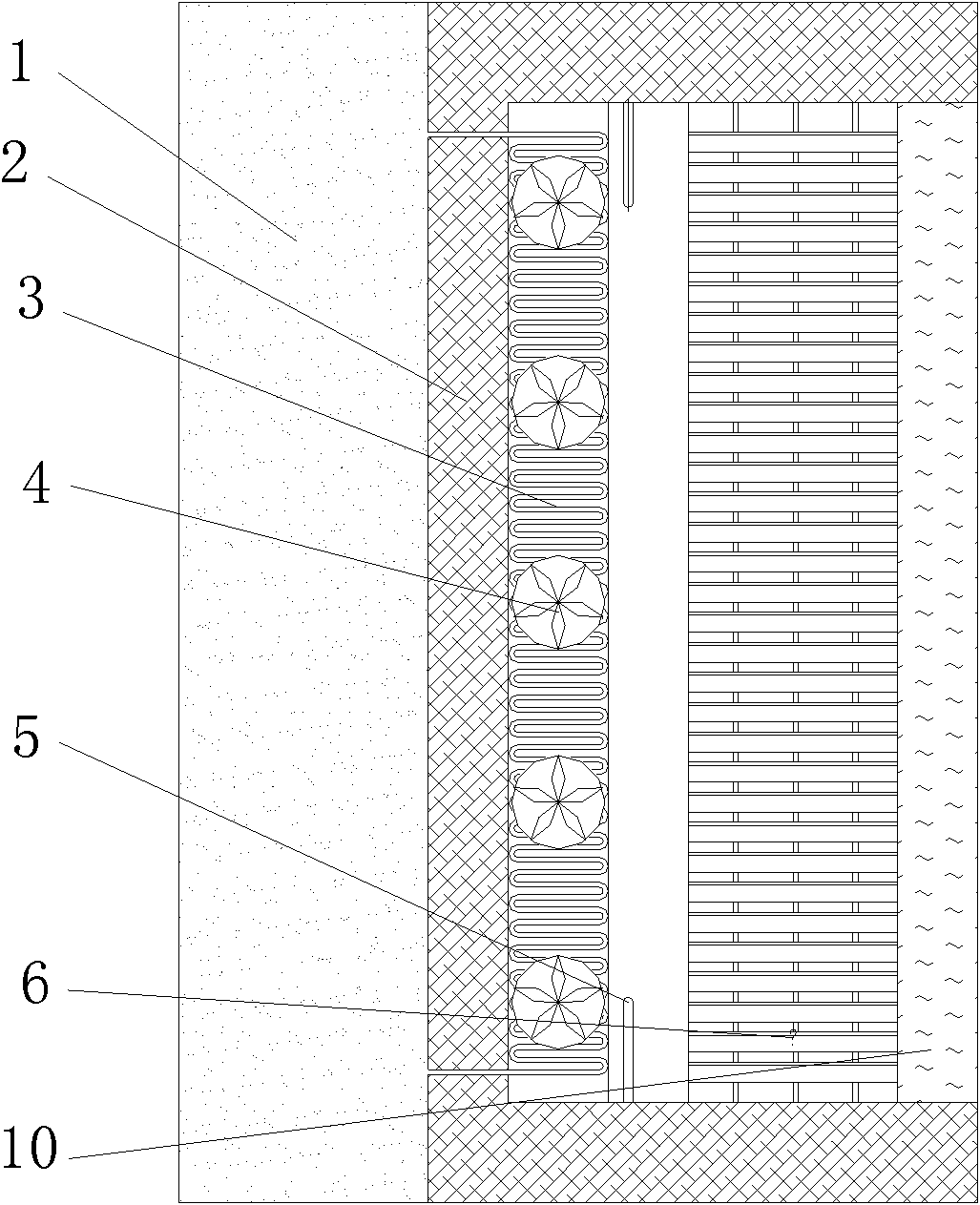

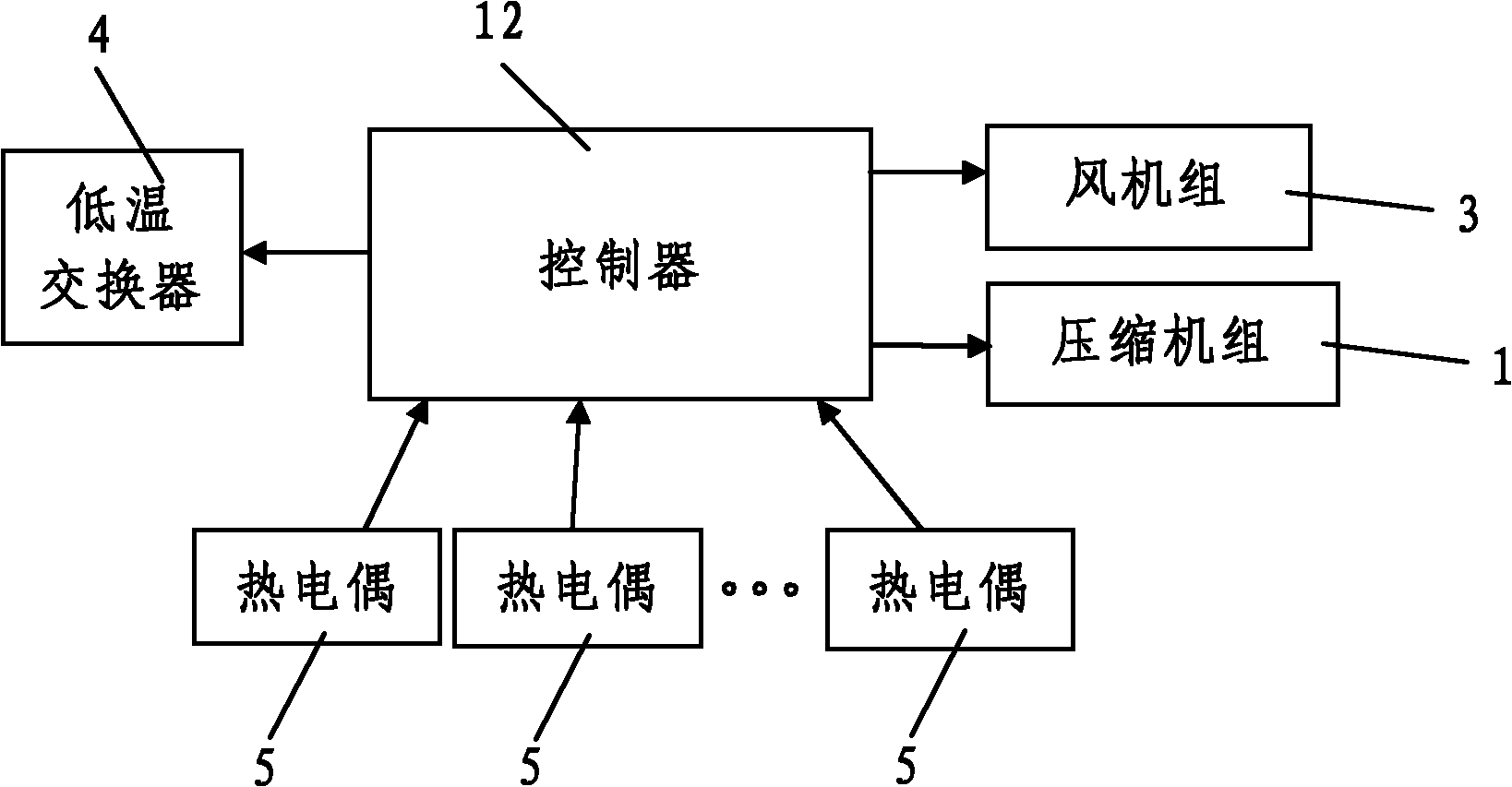

[0026] Such as figure 1 , figure 2 and image 3 As shown, the present invention includes a low-temperature working chamber 9, a controller 12, a cold air intake window 7 installed on the left or right side wall of the low-temperature working chamber 9, and installed on the right or left side wall of the low-temperature working chamber 9. The upper airflow return window 8, a cold air circulation channel arranged on the outside of the low-temperature working chamber 9 and continuously inputting cold air into the low-temperature working chamber 9, and a temperature detection device that detects the internal temperature of the low-temperature working chamber 9 in real time. The cold air circulation channel includes a cold air inlet channel 6 and an air return air channel 10. The upper ends of the cold air inlet channel 6 and the air return air channel 10 are connected, and the connection between the two is arranged to be connected to the compressor unit 1. The lower ends of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com