Gas film cooling hole structure used for thin-walled hot end part of gas turbine engine

A technology of air film cooling and hot end components, which is applied in the cooling of engines, cooling of turbine/propulsion devices, engine components, etc., can solve the problems of reducing the jet flow of the cold air outlet, weakening the kidney-shaped vortex, and difficult to process and manufacture. , to reduce the processing difficulty, enhance the coverage effect, and increase the export area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Structure, principle and performance of the present invention are described below in conjunction with accompanying drawing:

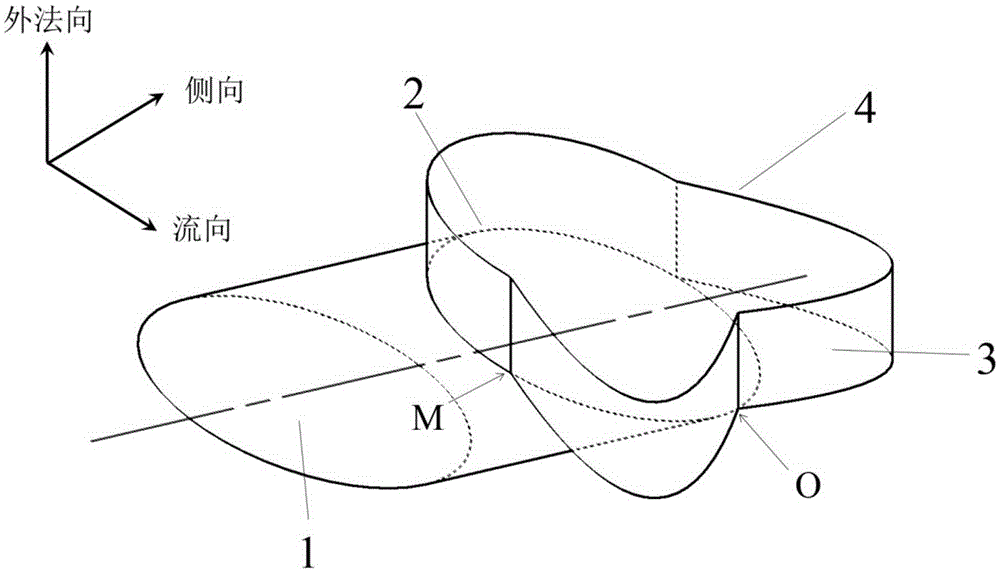

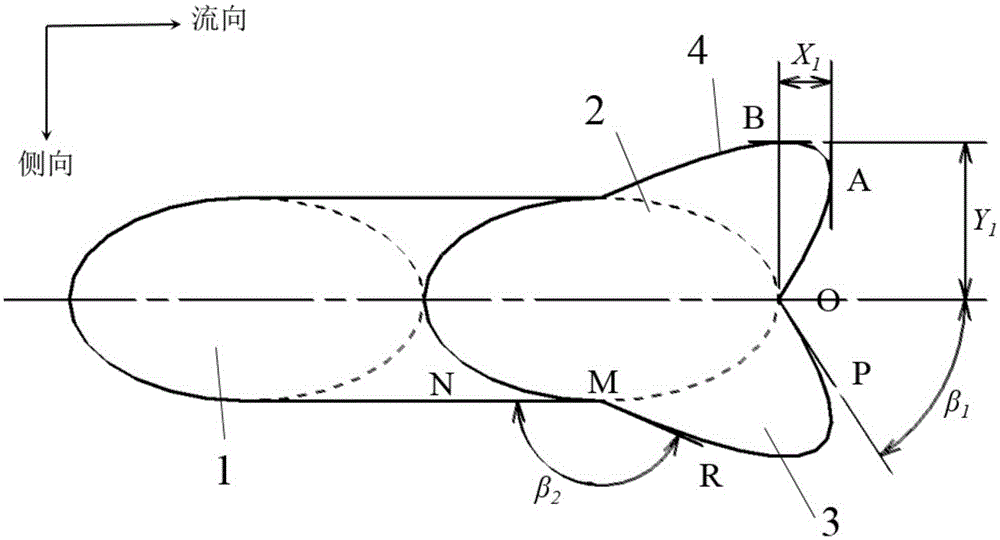

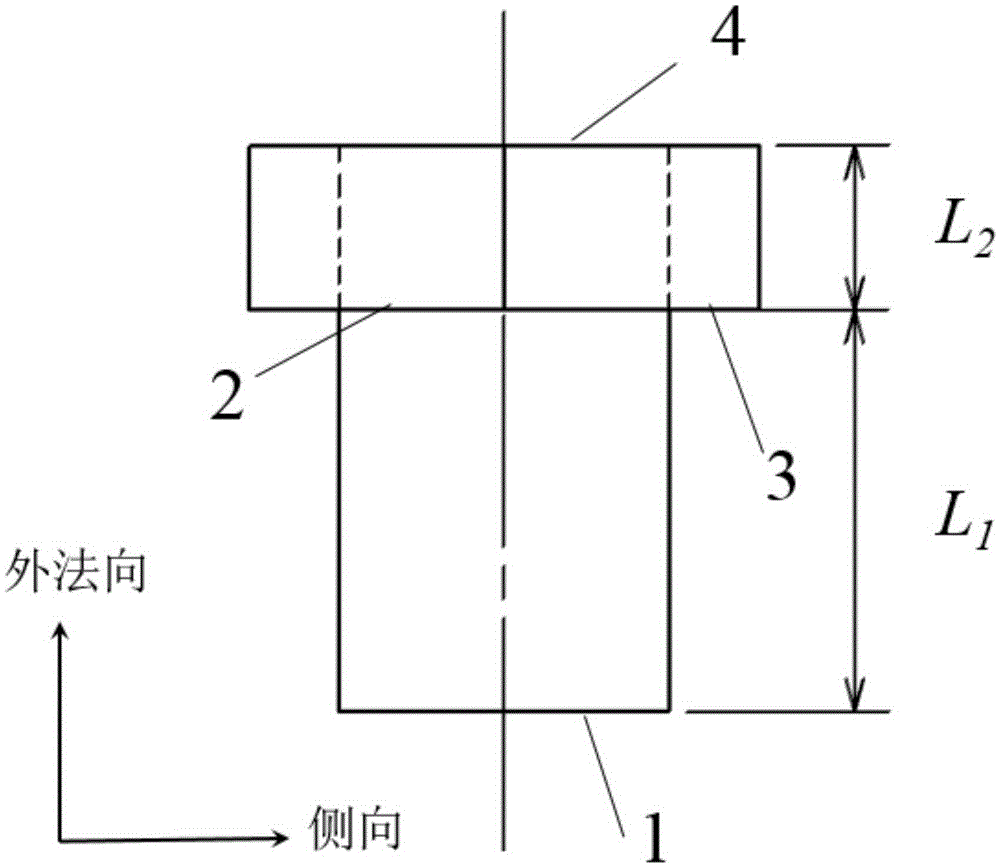

[0016] The present invention is a film cooling hole structure for thin-walled hot end parts of a gas turbine engine, and its basic geometric features are as follows: figure 1 , figure 2 with image 3 shown. The film cooling hole includes an inlet section 1 and a pit section 2. The inlet section is a cylindrical hole, and the pit section 2 is connected by a "heart-shaped" pit section 3 on the leeward side of the hole and a semi-cylindrical pit section 4 on the windward side of the hole. Formed, the pit section 2 starts from the center of the end of the inlet section 1 as the origin, stretches toward the windward side of the hole to form a semi-cylindrical pit section 4, and stretches toward the leeward side of the hole to form a "heart-shaped" pit section 3;" Heart-shaped "dimple section 3 and semi-cylindrical dimple section 4 take the center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com