Multifunctional muffler structure

A muffler, multi-functional technology, applied in mufflers, machines/engines, engine components, etc., can solve problems such as increasing the back pressure of the exhaust system, reducing the service life of the muffler, and rusting the muffler, ensuring power and torque output, reducing Transmission of small radiated noise and improvement of exhaust back pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention are described in detail below through the examples. It should be understood that the following examples are only illustrative, and can only be used to explain and illustrate the technical solutions of the present invention, and cannot be construed as limitations of the present invention.

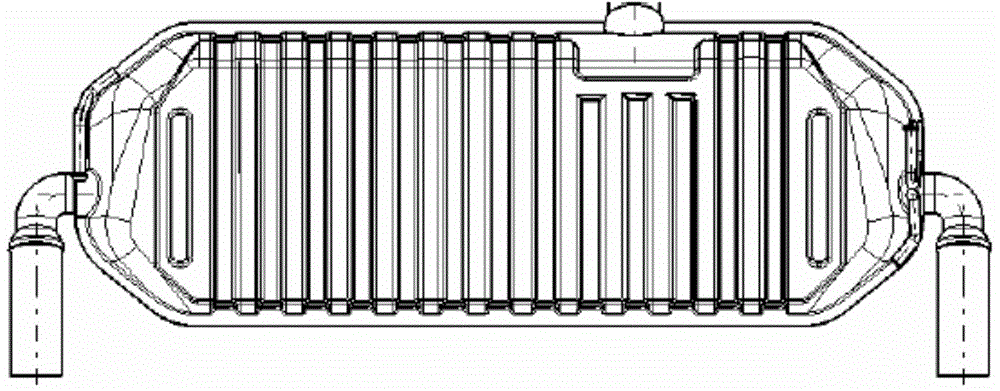

[0034] Multifunctional muffler structure, including cylinder, see figure 1 , double low tailpipe, siphon exhaust muffler barrel is formed by stamping. In this embodiment, the barrel is composed of upper and lower stamping shells. The strength reduces the transmission of radiation noise, and it also has a great effect on the shielding of transmitted noise. In other embodiments of the present invention, a traditional cylinder can also be used, but the best technical effect of the present invention cannot be achieved.

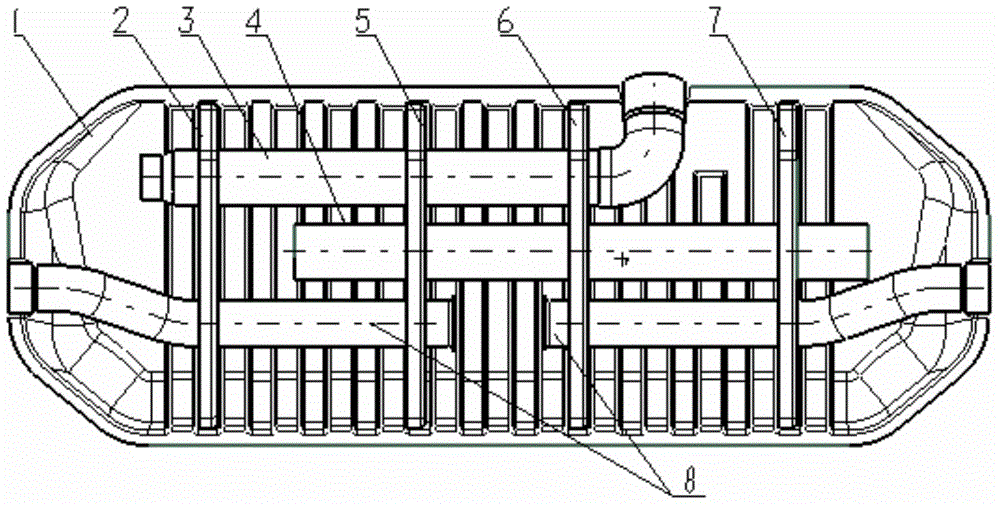

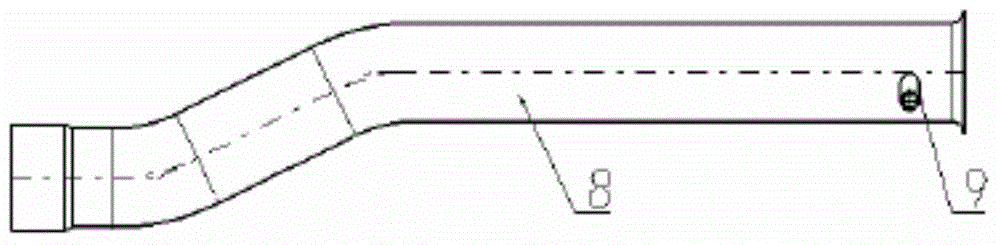

[0035] see figure 2 , Figure 5A , Figure 5B and Figure 5C As shown, the cylinder is provided with inner partitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com