Apparatus for the heat treatment of a web of textile material

A technology for textiles and fabric webs, applied in lighting and heating equipment, heating devices, progressive dryers, etc., can solve the problems of not completely avoiding heat loss, increase costs, etc., and achieve the effect of simple maintenance and cleaning operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

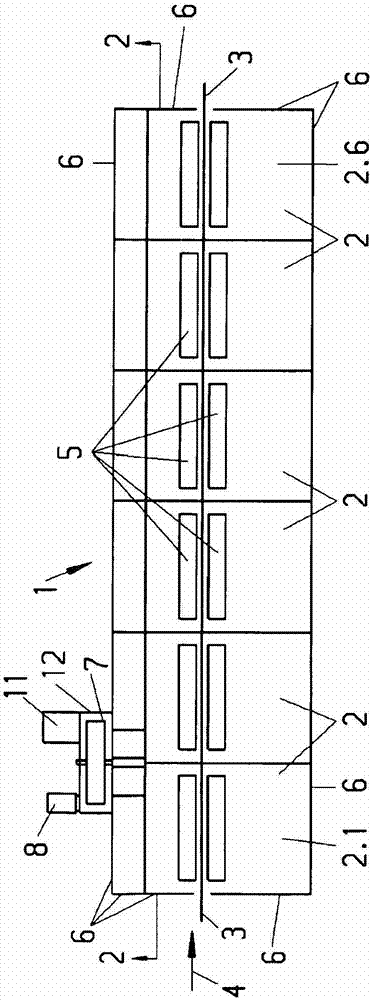

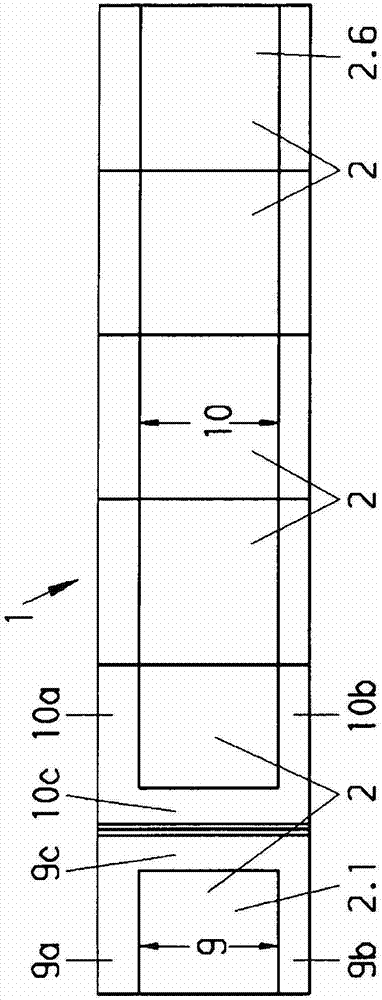

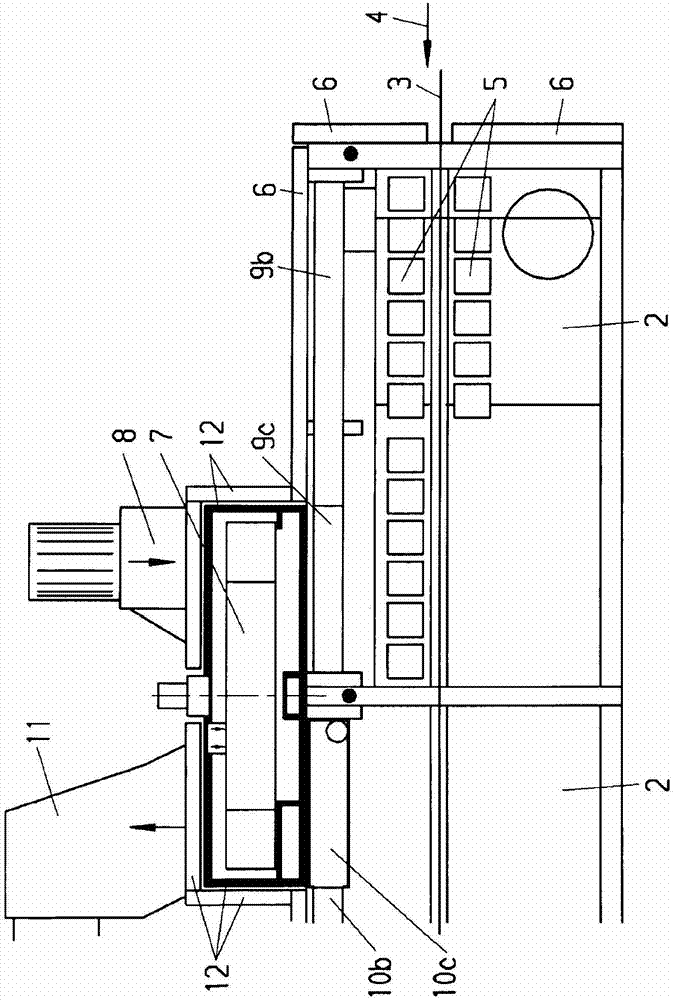

[0021] as from Figures 1 to 3 As can be seen, in the first exemplary embodiment, the device for the heat treatment is designed here as a tenter frame 1 . The tenter frame consists of a large number, here six, of substantially identically constructed chambers 2 . The textile web 3 can be transported horizontally in the direction of the arrow 4 through the tenter frame 1 and guided there by means of transport chains and grippers. Each chamber 2 comprises means for blowing the treatment gas onto the fabric web 3, consisting at least of nozzle boxes 5 arranged above and below the fabric web 3, a circulating air blower, means for heating the treatment gas and means for guiding and means for regulating the process gas (circulation air) guided in the circulation.

[0022] The tenter frame 1 is largely surrounded by a housing 6 ; on the input side of the tenter frame 1 there is an input slot for the textile web 3 and on the output side an output slot is provided.

[0023] Furtherm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com