Rotary harrow total pressure test system and test method suitable for aircraft air inlet channel

A technology of air inlet and rotary rake, which is applied in the field of total pressure test device at the outlet of the air inlet for wind tunnel tests, which can solve the problem of large area occupied by the support and fixed structure, the inability to obtain the true distribution of the total pressure of the outlet, and the aggravation of the degree of throttling at the outlet and other problems, to achieve the effect of simple structure, increase the total pressure test range, and reduce the outlet clogging degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

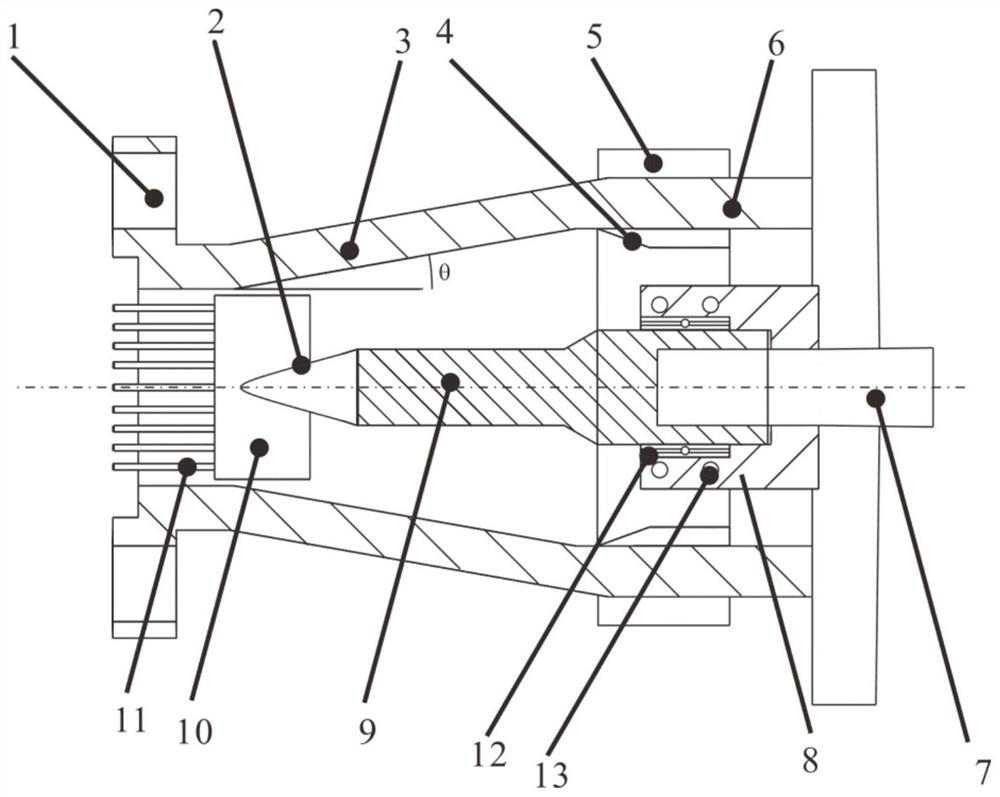

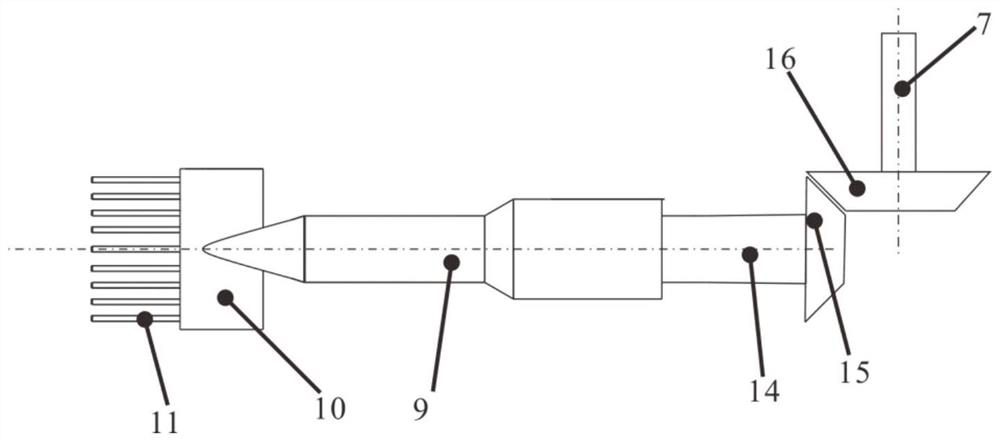

[0021] see figure 1 and figure 2 , the invention discloses a rotary rake total pressure testing system suitable for an aircraft air intake. Including total pressure rake module, rotating module, stepper motor. The total pressure rake module includes a total pressure probe 5 and a probe integrated board 10 for testing the total pressure signal. The total pressure probe is uniformly assembled on the probe integrated board 10 with the center of the inlet outlet circle as the center point, as The total pressure acquisition part on the total pressure rake.

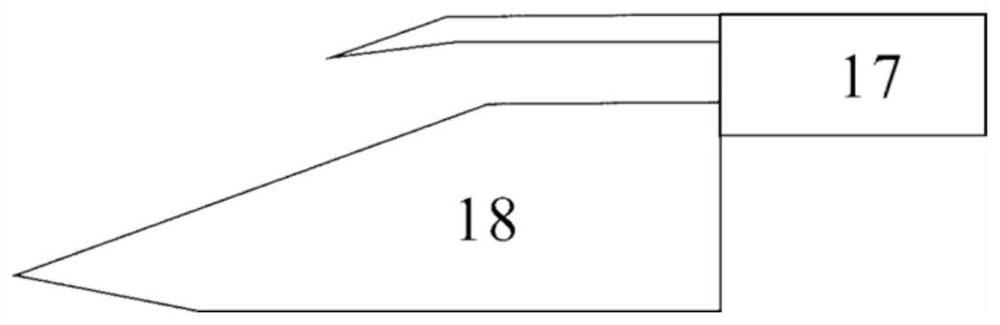

[0022] According to different wind tunnel sizes and test scale model sizes to the sensitivity of the intake port outlet blockage, the present invention provides two transmission implementation modes, such as figure 1 As shown, the first embodiment includes a rectification and positioning module; figure 2 As shown, the second embodiment includes the torque transmission and steering module, and the second embodiment does no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com