Dripping-proof low-bubble linkage-type filling structure

An anti-drip, interlocking technology, used in packaging, bottle filling, liquid bottling, etc., can solve the problems of inability to use, easy to generate air bubbles, affecting the accuracy of measurement, etc., to achieve high filling efficiency, buffer impact force , the effect of preventing dripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

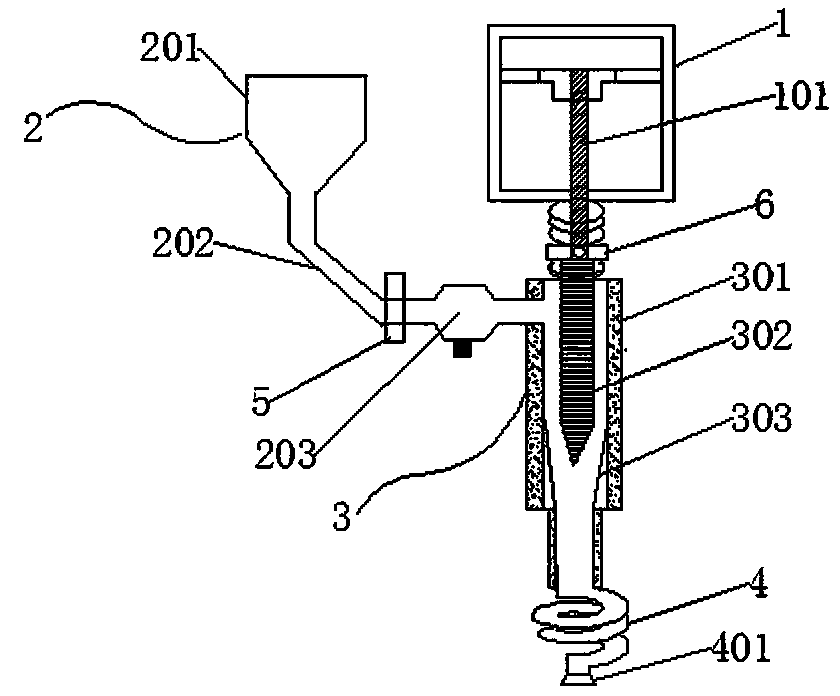

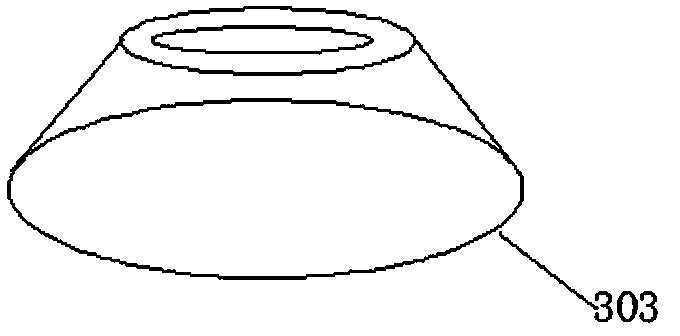

[0022] Such as figure 1 As shown, an anti-drip low-foaming interlocking filling structure includes a cylinder 1, a feeding device 2 and a filling head 3. The filling head 3 includes a material cavity 301, and the material cavity 301 is a cavity with a cavity at the center. body, the material cavity 301 is provided with a push rod 302, the top of the push rod 302 stretches out of the material cavity 301, the push rod 302 is connected with the piston rod 101 of the cylinder 1, the feed device 2 is connected with the material cavity 301, and the filling The bottom end of the head 3 is provided with a spiral discharge pipe 4 . The spiral discharge pipe is used to disperse the impact force of the liquid, so that the filling liquid is filled into the bottle or box with a small impact force to prevent air bubbles.

[0023] The feeding device 2 includes a storage barrel 201 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com