A horizontal heavy sludge flocculation reaction device

A reaction device, heavy technology, applied in water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, water/sewage treatment, etc., can solve the problem of fast deposition, large amount of sludge deposition, and increased reactor load Reactor overload and other problems, to achieve the effect of simple operation management, safe and reliable operation, and avoid the release of sludge phosphorus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

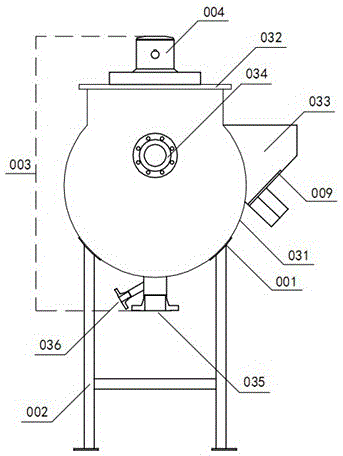

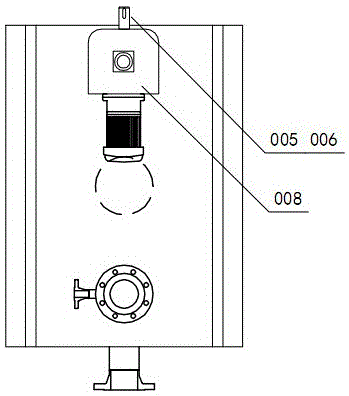

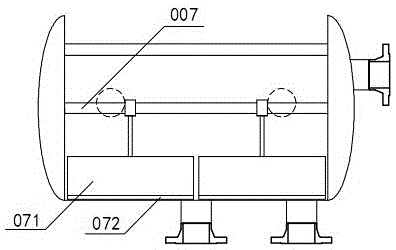

[0018] A horizontal heavy sludge flocculation reaction device, including a chassis support 001, a reaction device 003 arranged on the support 002, the reaction device 003 includes a U-shaped groove-shaped housing 031 horizontally placed on the support 002, the The upper end of the housing 031 is provided with a cover body 032, and the cover body 032 is provided with a reaction motor 004. The reaction motor 004 is a variable frequency motor, and the reaction motor 004 is connected through a reducer 005, a sprocket chain group 006 and one end of the transmission spindle 007. The transmission main shaft 007 is horizontally placed in the casing 031, and the two ends of the transmission main shaft 007 protrude from the two ends of the casing 031 and are fixed by the bearing seat 008. Two connecting plates 071 in the vertical direction are welded on the transmission main shaft 007, and the connecting plate 071 The end is connected to the push flow paddle 072, and they are arranged si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com