Downdraft biomass gasification reaction chamber and gasification process thereof

A gasification reaction chamber and biomass technology, which is used in the petroleum industry, the manufacture of combustible gas, and energy input, etc., can solve the problem of inconvenient storage and transportation for large-scale popularization and application, inability to continuously and stably generate electricity by gas generator sets, and inability to discharge slag and feed materials. Continuous operation and other problems, to achieve effective and controllable leveling operation, improve gasification efficiency and gas calorific value, and stabilize and control the gasification reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described in detail below in conjunction with the accompanying drawings.

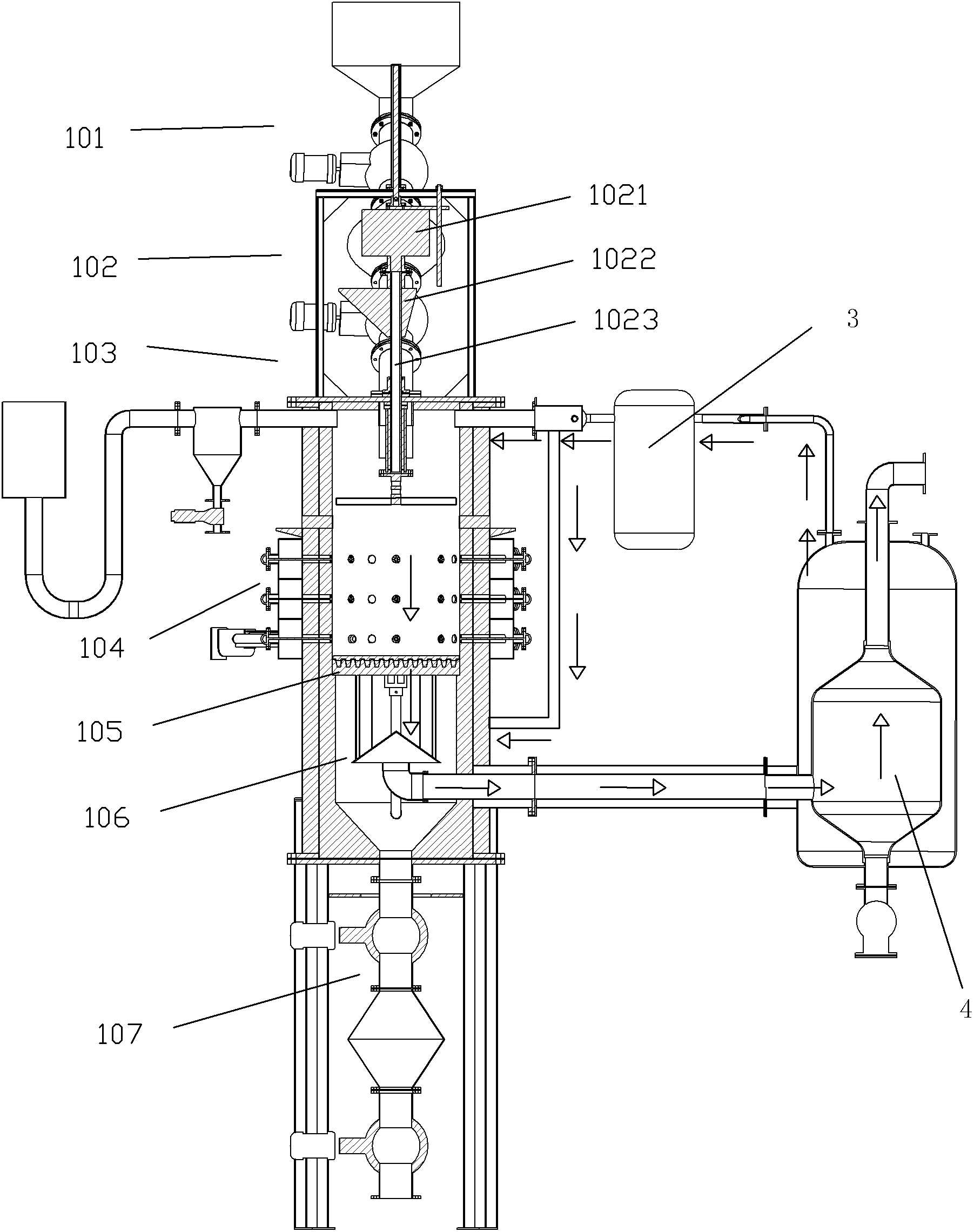

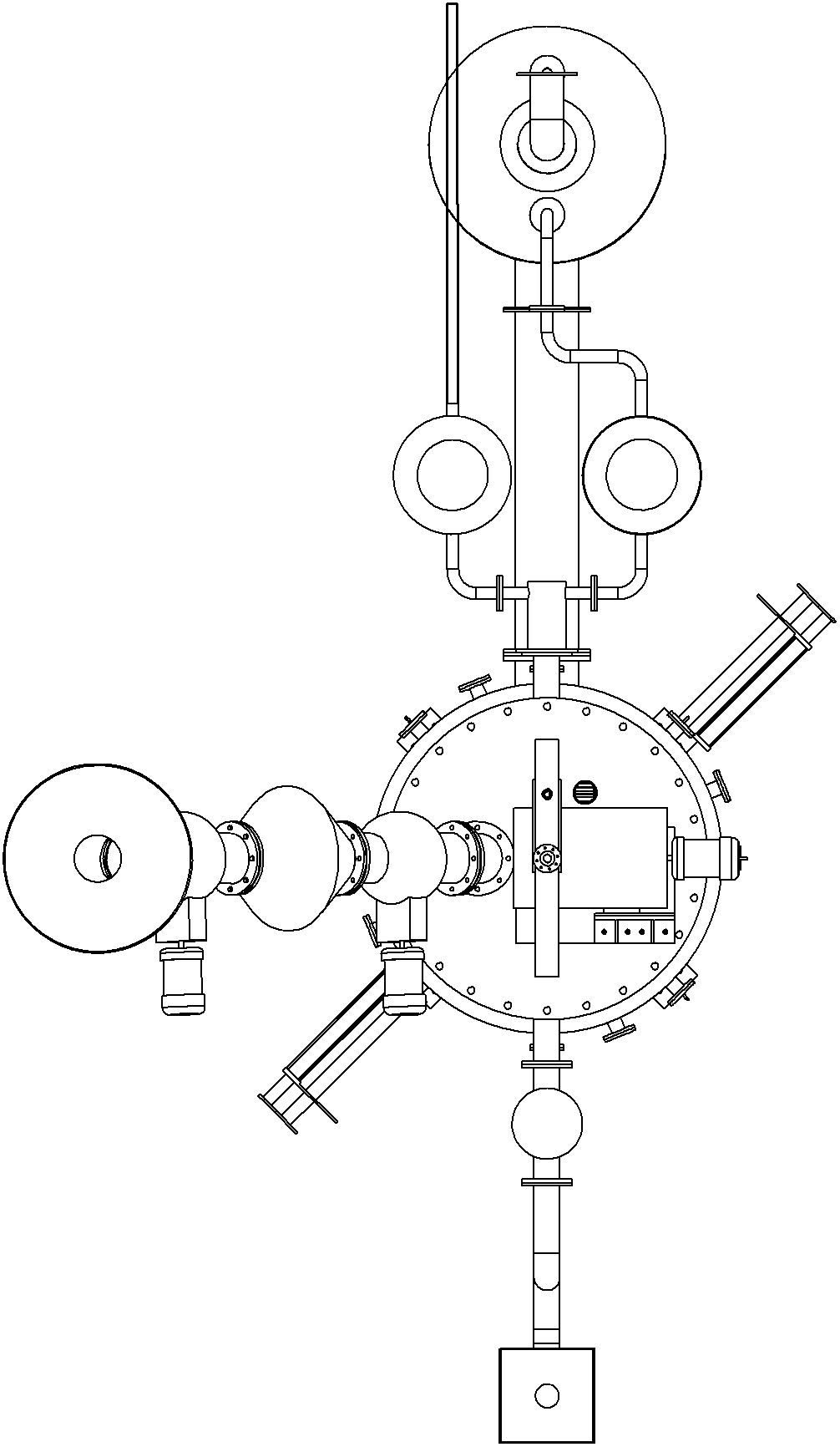

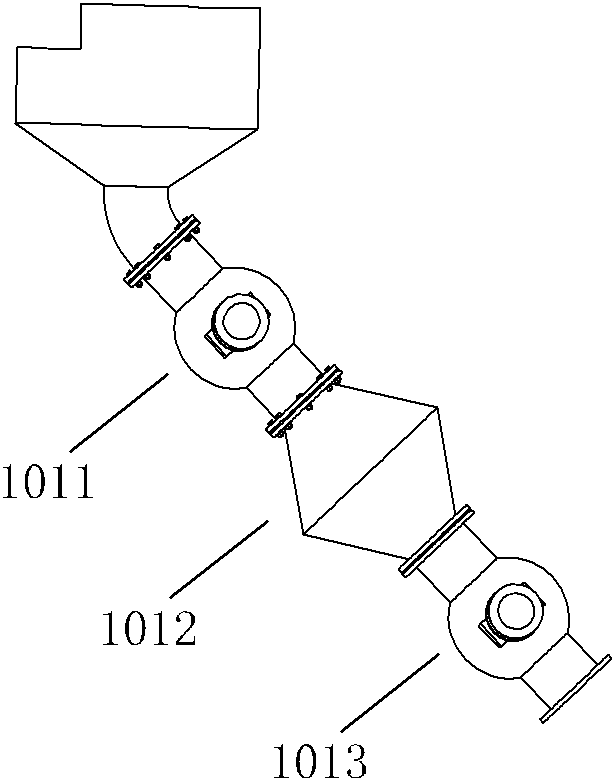

[0061] A downdraft biomass gasification reaction chamber, such as figure 1 , figure 2 As shown, from top to bottom, it includes an automatic feeding device 101, an automatic leveling device 102, a primary gasification zone 103, an automatic ignition device 104, a vibrating grate 105, a secondary gasification zone 106, an automatic slagging device 107, and Two sets of furnace pressure regulation systems located at the top of the primary gasification zone 103 and the top of the secondary gasification zone 106, a furnace temperature monitoring system composed of 12 thermocouples evenly distributed in the primary gasification zone 103, and two microwave ovens The material level detector consists of a furnace material level monitoring system installed in the primary gasification zone, an inlet and outlet gas temperature monitoring system and a gas inlet and outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com