Patents

Literature

53results about How to "Save nitrogen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

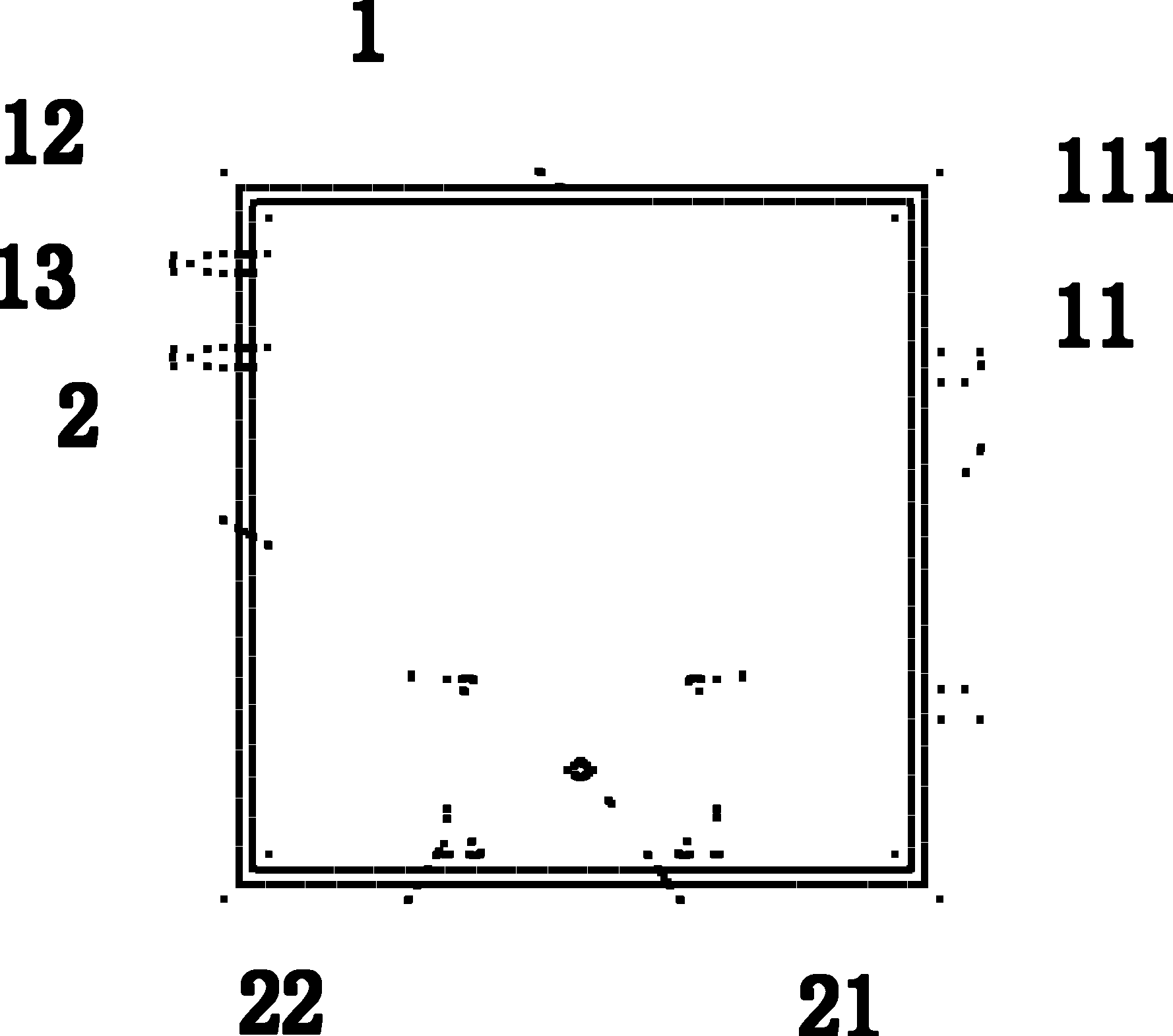

Ricefield milk vetch cultivating method for saving cost and increasing production

InactiveCN1774986AReduce the amount of seed usedLow costHorticulture methodsRice cultivationCropping systemPaddy field

The present invention discloses a Chinese milkvetch cultivation method in rice field, and relates to a Chinese milkvetch cultivation and utilization technique under the condition of paddy field rice-green fertilizer rotation cropping system. It is characterized by intersowing Chinese milkvetch seeds in the rice field, and adopting a series of measures of channelling and discharging water after the rice is harvested so as to implement said invention.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

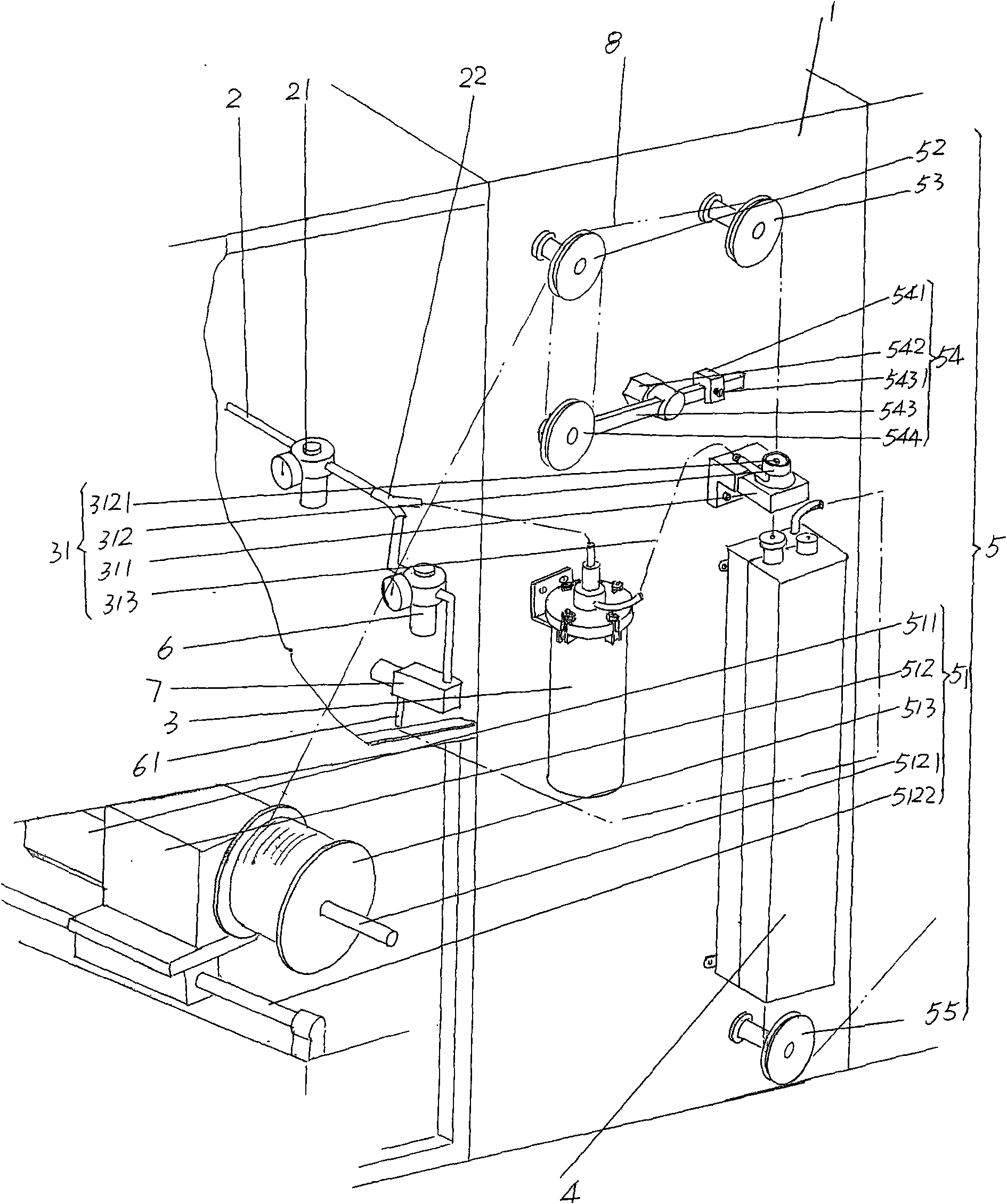

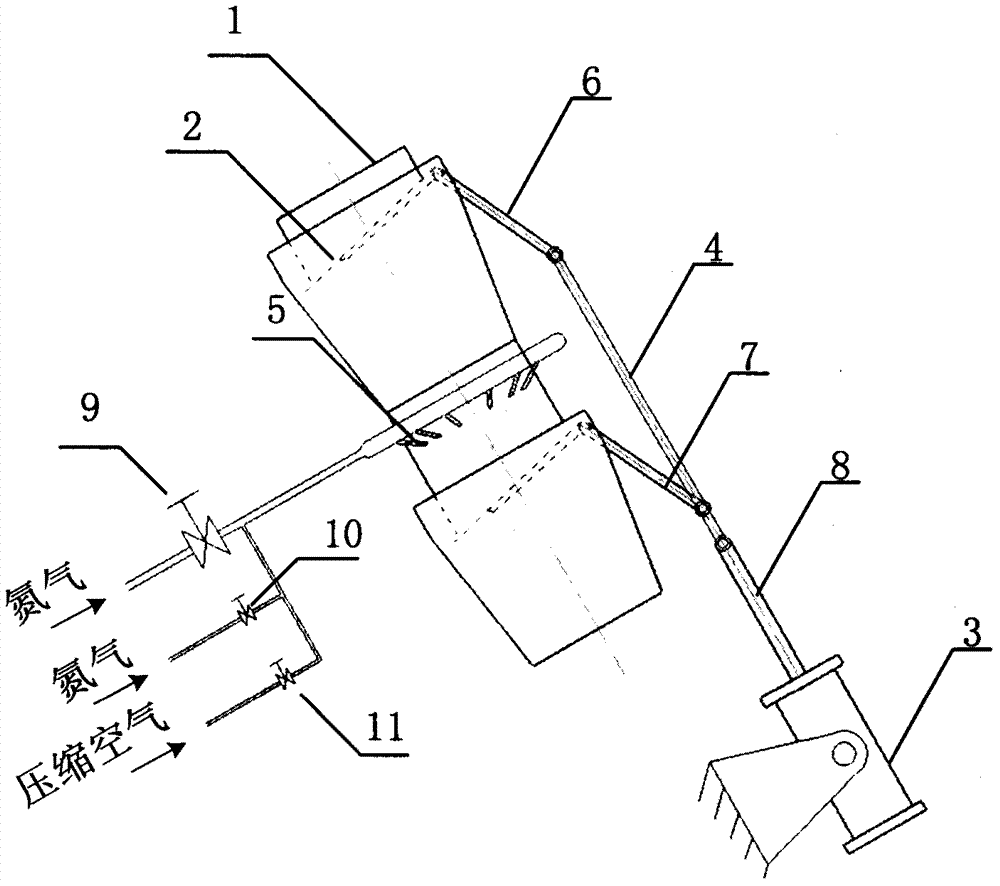

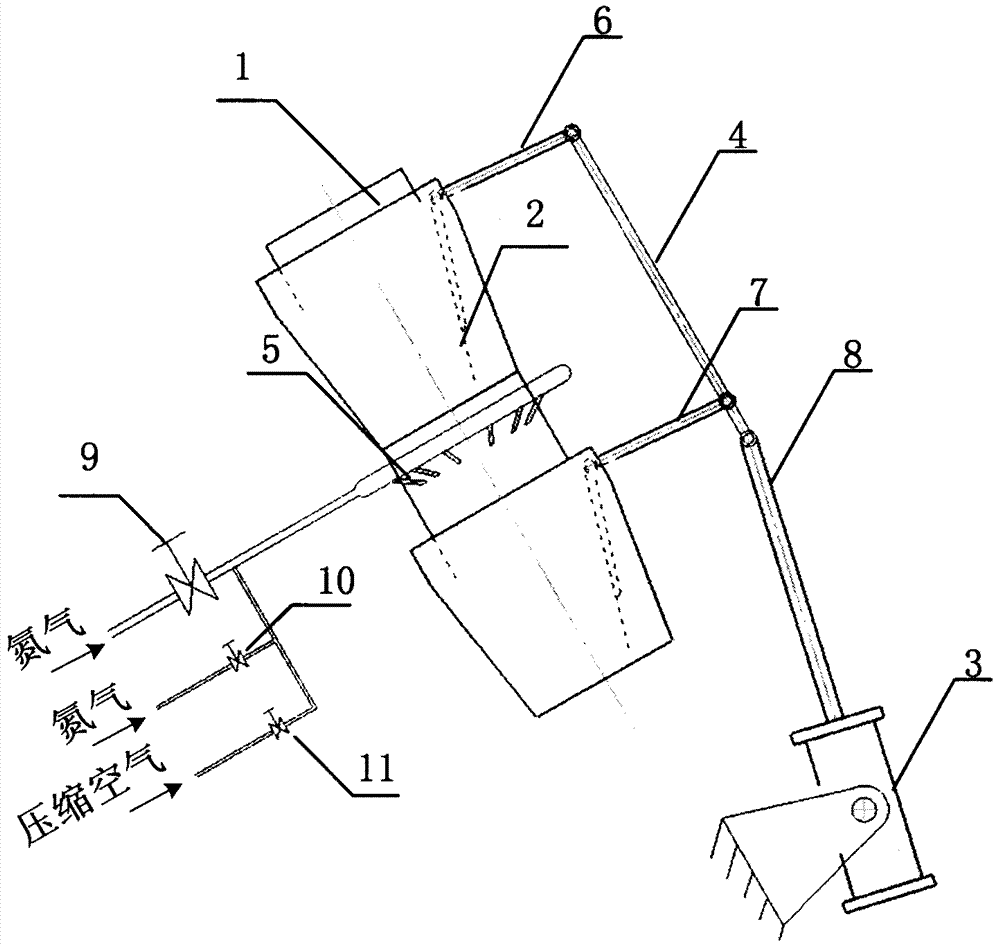

Coloring and curing mechanism of optical fiber coloring machine

ActiveCN101592764AImprove protectionNitrogen volume increasedFibre mechanical structuresPrinting inkExcess nitrogen

The invention discloses a coloring and curing mechanism of an optical fiber coloring machine and belongs to the technical field of optical cable processing devices. The optical fiber coloring machine comprises a machine frame box body, and the coloring and curing mechanism comprises a nitrogen inlet pipe provided with a first pressure regulating valve, a printing ink tank, a curing oven and an optical fiber guide device, wherein the printing ink tank and the curing oven are arranged on the machine frame box body; the nitrogen inlet pipe is provided with a three-way connector which arranged in the nitrogen inlet pipe at a position on the air outlet side of the first pressure regulating valve and is connected with the pipes of the printing ink tank and the curing oven respectively; and a second pressure regulating valve is arranged on the pipe connecting the three-way connector and the curing oven. The coloring and curing mechanism of the optical fiber coloring machine has the advantages of increasing nitrogen volume acquired by the printing ink tank, preventing excess nitrogen flow in the curing oven, improving the coloring speed, guaranteeing processing efficiency, saving nitrogen and protecting environment.

Owner:YANGTZE ZHONGLI OPTICAL FIBER & CABLE (JIANGSU) CO LTD +1

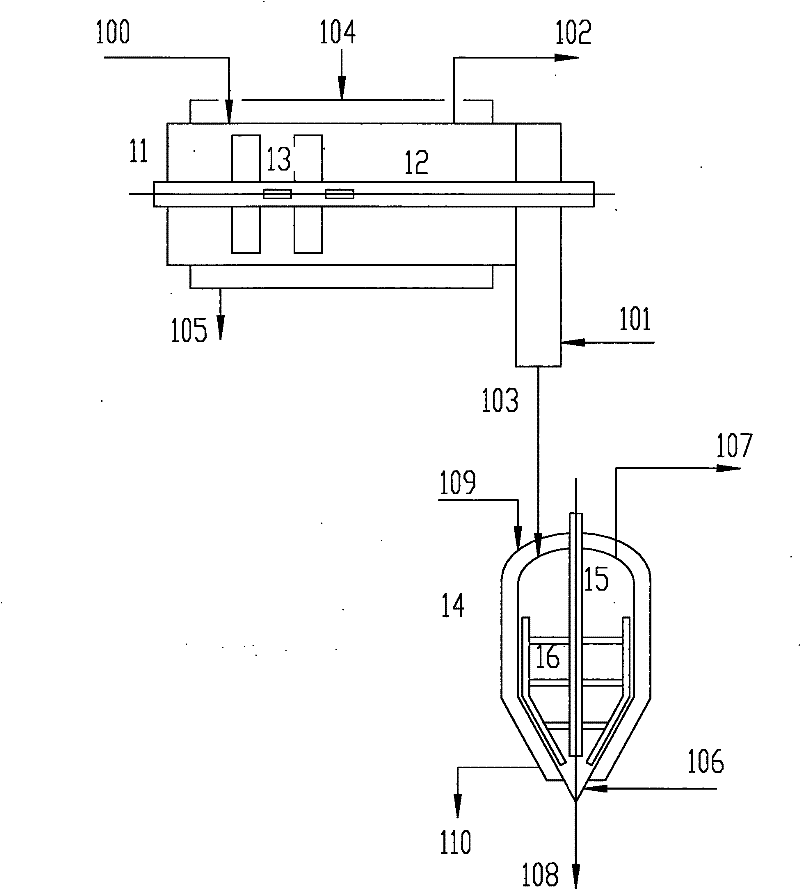

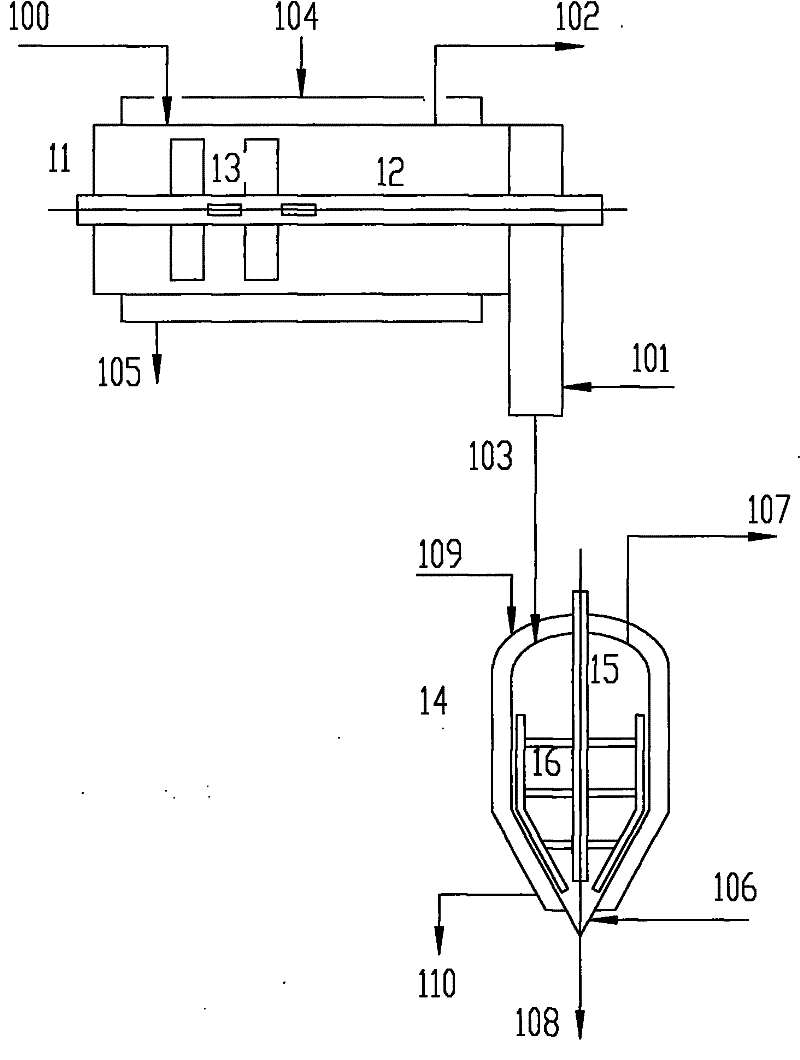

Post-processing method for polypropylene powder

The invention provides a post-processing method for polypropylene powder, which belongs to the petroleum chemical field. In the polypropylene post-processing method of the prior art, the method comprises the following steps: polypropylene powder which departs from a polymerization system and is carried out preliminary gas / solid separation enters into a drier, indirectly heated through steam and nitrogen is introduced, hydrocarbons can be removed in powder and then enters in a steamer, nitrogen and water vapor are introduced for inactivation of a catalyst; or the polypropylene powder which departs from a polymerization system and is carried out preliminary gas / solid separation enters into a degassing chamber, water vapor-containing nitrogen is introduced in the degassing chamber; the present invention modifies the prior art. The post-processing method of the invention comprises the following steps: introducing water vapor, modifying the drier to a steam drier used for recovering hydrocarbons and inactivating the catalyst, introducing a hydrocarbons-removed polymer in the steam drier (or a degassing chamber), adding nitrogen without water vapor in the steam drier, modifying the steam drier to a moisture eliminator used for removing water vapor in powder. The method of the invention is capable of thoroughly recovering hydrocarbons which depart from the polymerization system by an economic method, reducing the unit consumption and energy consumption, and thoroughly solving the problem on environmental protection.

Owner:高煦

A copper pipe processing technology

The invention discloses a copper pipe processing technology, which comprises the following steps: selecting a copper pipe billet stretched in series; putting the copper pipe billet into a coil drawing machine, injecting lubricating oil into the inner wall of the copper pipe, and drawing Stretching; after the stretching is completed, the copper tube is finished and wound; annealed; the finished product is put into storage. The processing technology of the invention eliminates the generation of cleaning waste liquid and waste, improves production efficiency, and realizes high efficiency, cleanness and environmental protection in the production process of copper pipes.

Owner:广东龙丰精密铜管有限公司

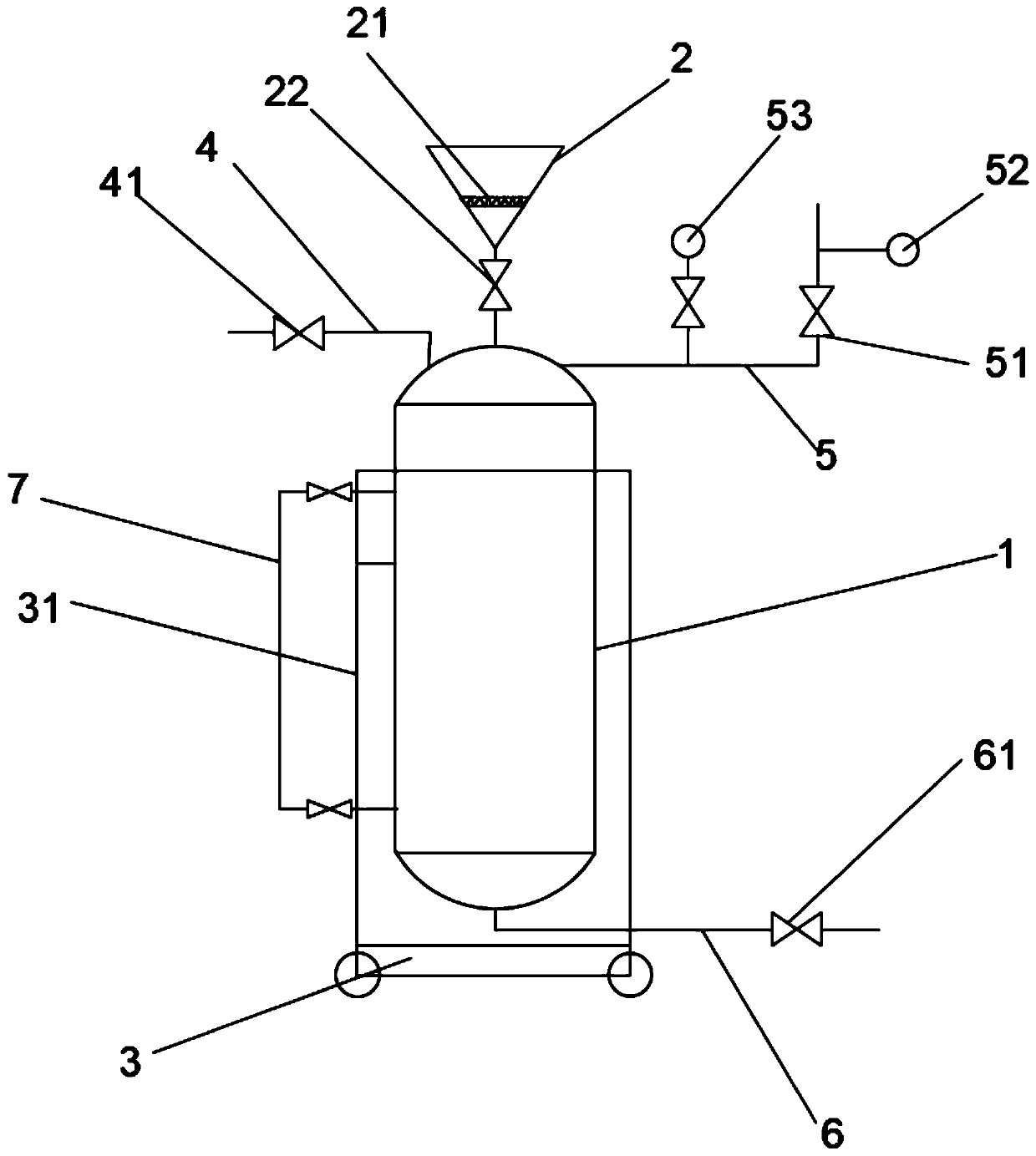

Scattered oil recovery device and method

The invention discloses a scattered oil recovery device. The scattered oil recovery device comprises a collecting tank, a mobile platform, an oil drain pipe, a gas inlet pipe and an exhaust pipe, wherein the collecting tank is a pressure-withstanding tank and arranged on the mobile platform, an oil filling port is formed in the top of the collecting tank, a first valve is arranged at the oil filling port, an input end of the oil drain pipe communicates with the bottom of an inner cavity of the collecting tank, a second valve is arranged on the oil drain pipe, an output end of the oil drain pipe is used for communicating with a slop tank, an input end of the gas inlet pipe is used for communicating with nitrogen supply equipment, an output end of the gas inlet pipe communicates with the topof the inner cavity of the collecting tank, a third valve is arranged on the gas inlet pipe, an input end of the exhaust pipe communicates with the top of the inner cavity of the collecting tank, anda fourth valve is arranged on the exhaust pipe. The invention further discloses a scattered oil recovery method. According to the scattered oil recovery device and method, scattered oil discharged from the tank body can be recovered to the slop tank safely, reutilization of the scattered oil is facilitated, and safety is high.

Owner:SHANXI LUAN COAL BASED CLEAN ENERGY

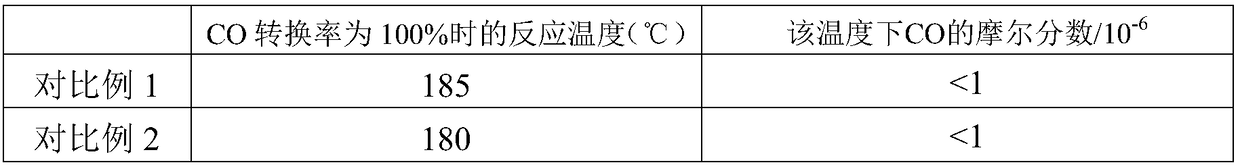

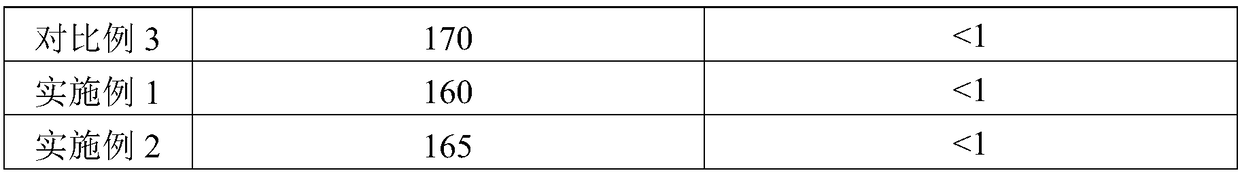

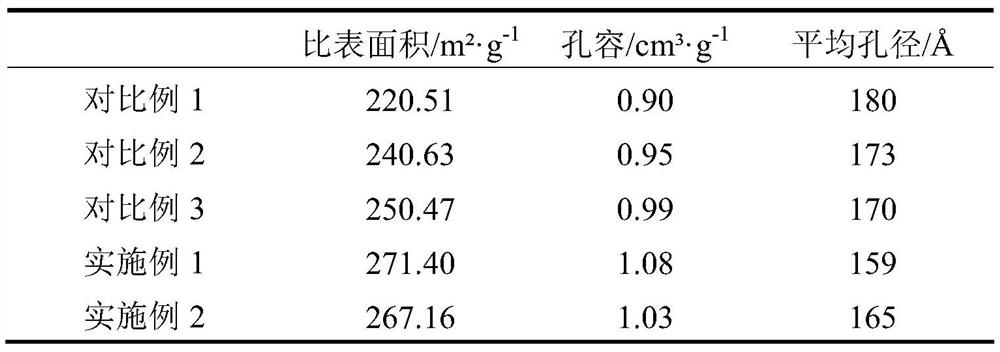

Nickel-based CO hydrogenation catalyst, preparation method therefor and application of nickel-based CO hydrogenation catalyst

ActiveCN108816238ALarge specific surface areaHigh content of active ingredientsCatalyst activation/preparationLiquid hydrocarbon mixture productionMethanationAdditive ingredient

The invention discloses a nickel-based CO hydrogenation catalyst, a preparation method therefor and an application of the nickel-based CO hydrogenation catalyst. The nickel-based CO hydrogenation catalyst is prepared from the ingredients, i.e., nickel oxide, aluminum oxide and auxiliaries, wherein the content of the nickel oxide accounts for 55% to 90% the total mass of the nickel-based CO hydrogenation catalyst, and the content of the auxiliaries accounts for 1% to 5% the total mass of the nickel-based CO hydrogenation catalyst; and the nickel oxide has the particle size of 3nm to 17nm. The nickel-based CO hydrogenation catalyst is prepared by adopting a coprecipitation method; through adding the auxiliaries of different kinds, improving an auxiliary adding mode and improving a drying process, the reaction activity of the catalyst is improved, and thus, the reaction temperature of a methanation reaction can be greatly lowered; and very high reaction activity and stability can be maintained under low-temperature conditions, so that the nickel-based CO hydrogenation catalyst can be applied to the complete removal of CO from hydrogen-enriched gases under the low-temperature conditions.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

Fire extinguishing device in coal mine gob

The invention provides a fire extinguishing device in a coal mine gob. A nitrogen generation device is connected with a nitrogen purification device through a pipeline. The nitrogen purification device is connected with a nitrogen pressurization device through a pipeline. The nitrogen pressurization device is connected with a low-temperature processing pump through a pipeline. The low-temperature processing pump is connected with a nitrogen liquefying device through a pipeline. The nitrogen liquefying device is connected with a jetting device through a pipeline. The tail end of the jetting device is provided with a nozzle. The jetting distance of the nozzle and the nitrogen jetting pressure can be adjusted. According to the fire extinguishing device, the jetting distance and the nitrogen jetting pressure of the arranged nozzle can be adjusted so that the specific conditions of nitrogen jetting can be adjusted according to the needs of practical fire distinguishing conditions, the nitrogen amount can be effectively saved, in addition, the special nitrogen generation device is arranged and purifying and oxidizing are conducted so that high-purity preparing of nitrogen can be effectively achieved, and the fire distinguishing effect is improved.

Owner:NORTH CHINA INST OF SCI & TECH

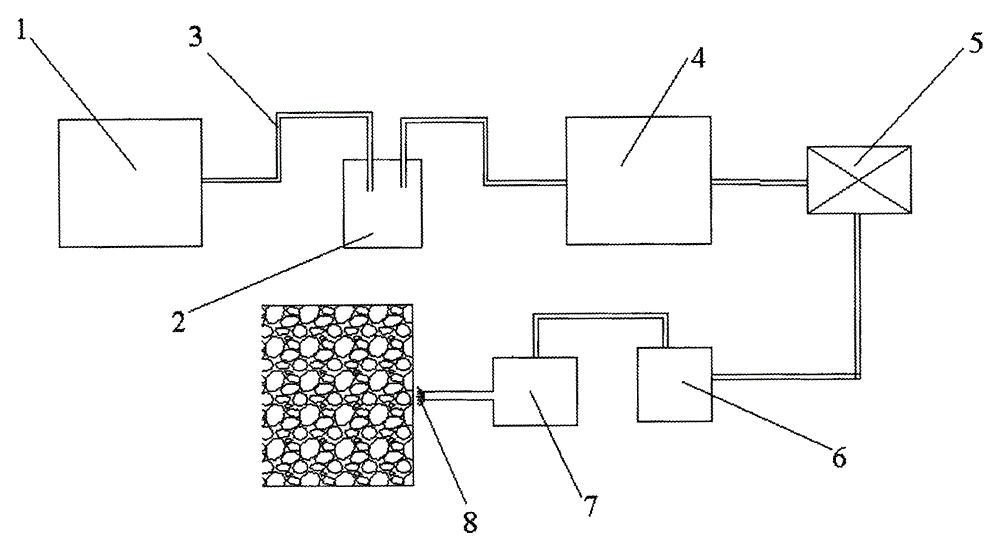

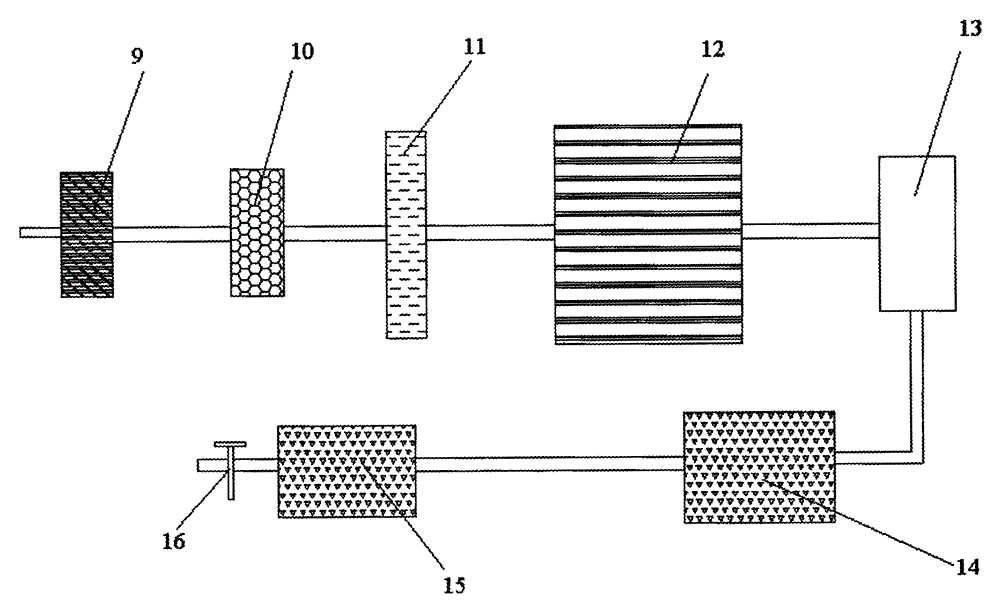

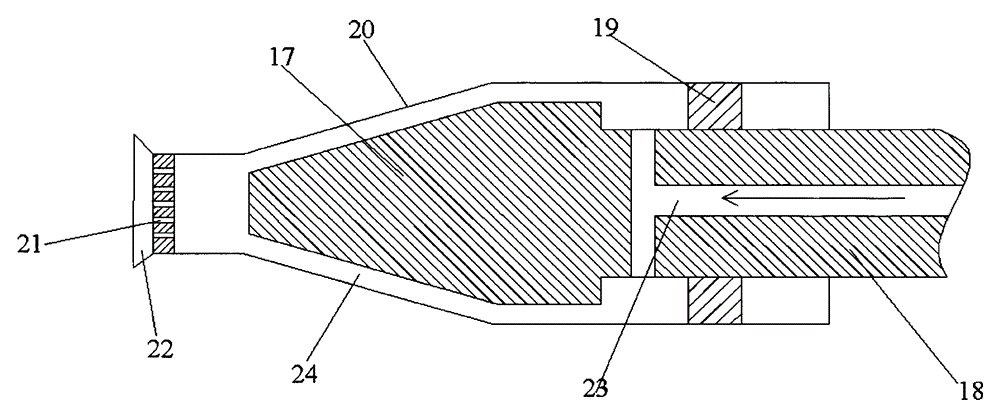

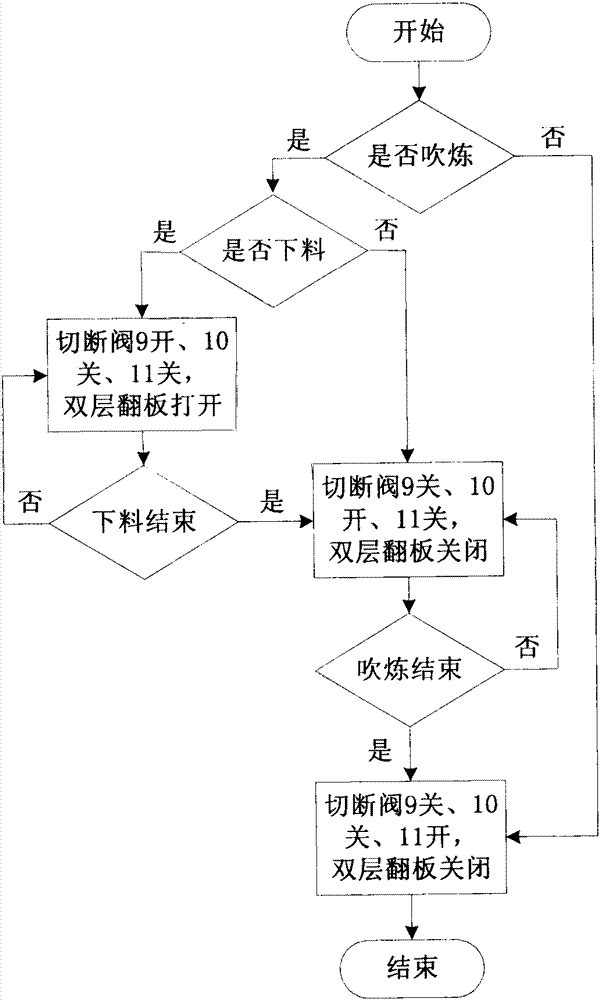

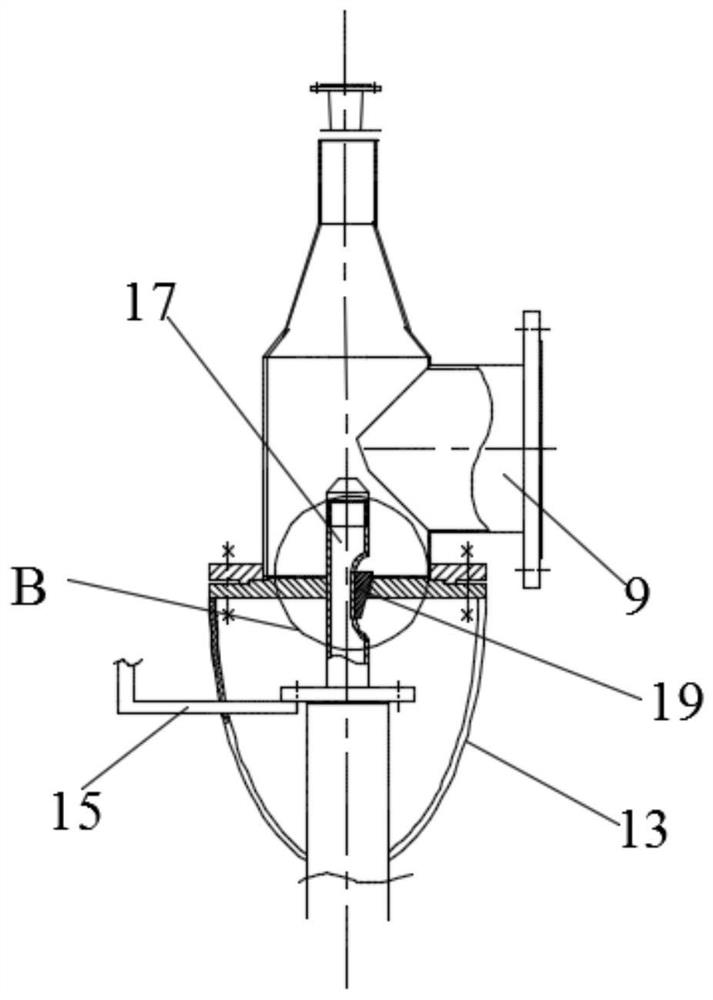

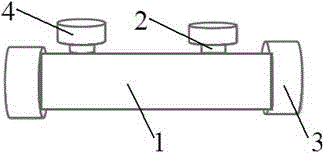

Double-layer flap valve blanking system

InactiveCN107269855AEasy to recycleReduce wearOperating means/releasing devices for valvesManufacturing convertersFlue gasEngineering

The invention relates to the field of metallurgical feeding system feed openings, and specially provides a double-layer flap valve blanking system. A novel double-layer flap valve device comprises a blanking hose pipe (1), double layers of turning plates (2), a cylinder (3), a lever (4) and air holes (5) which are uniformly distributed in the periphery of the central part of the hose pipe. A PLC controls the cylinder to turn over the turning plates, and controls gas flowing into trip valves (9), (10), (11), and a combination mode of gas and the double layers of turning plates is employed for seal to prevent high temperature flue gas from going upwards. The double-layer flap valve blanking system is compact in structure and good in seal performance, and is safe and reliable.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

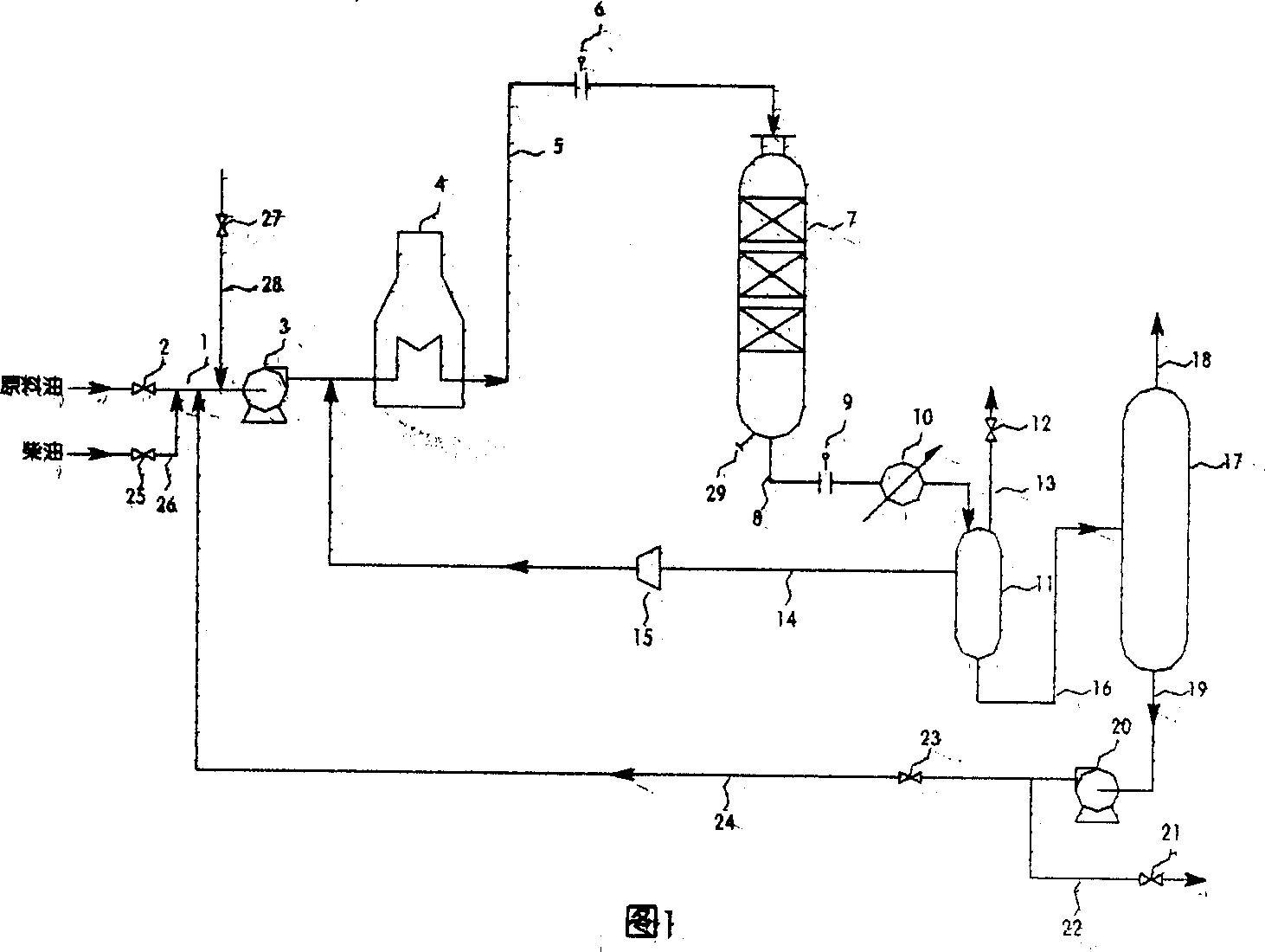

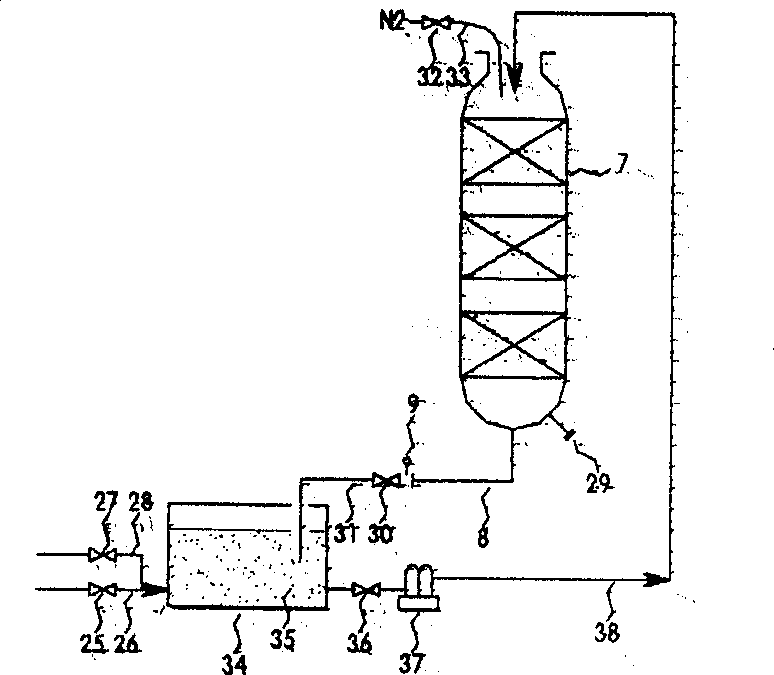

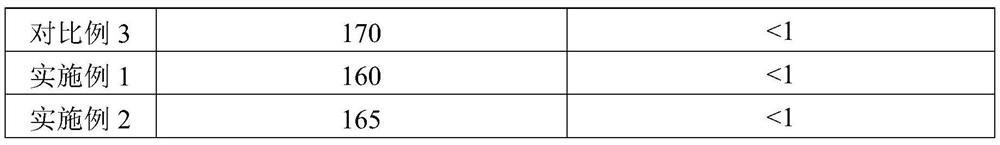

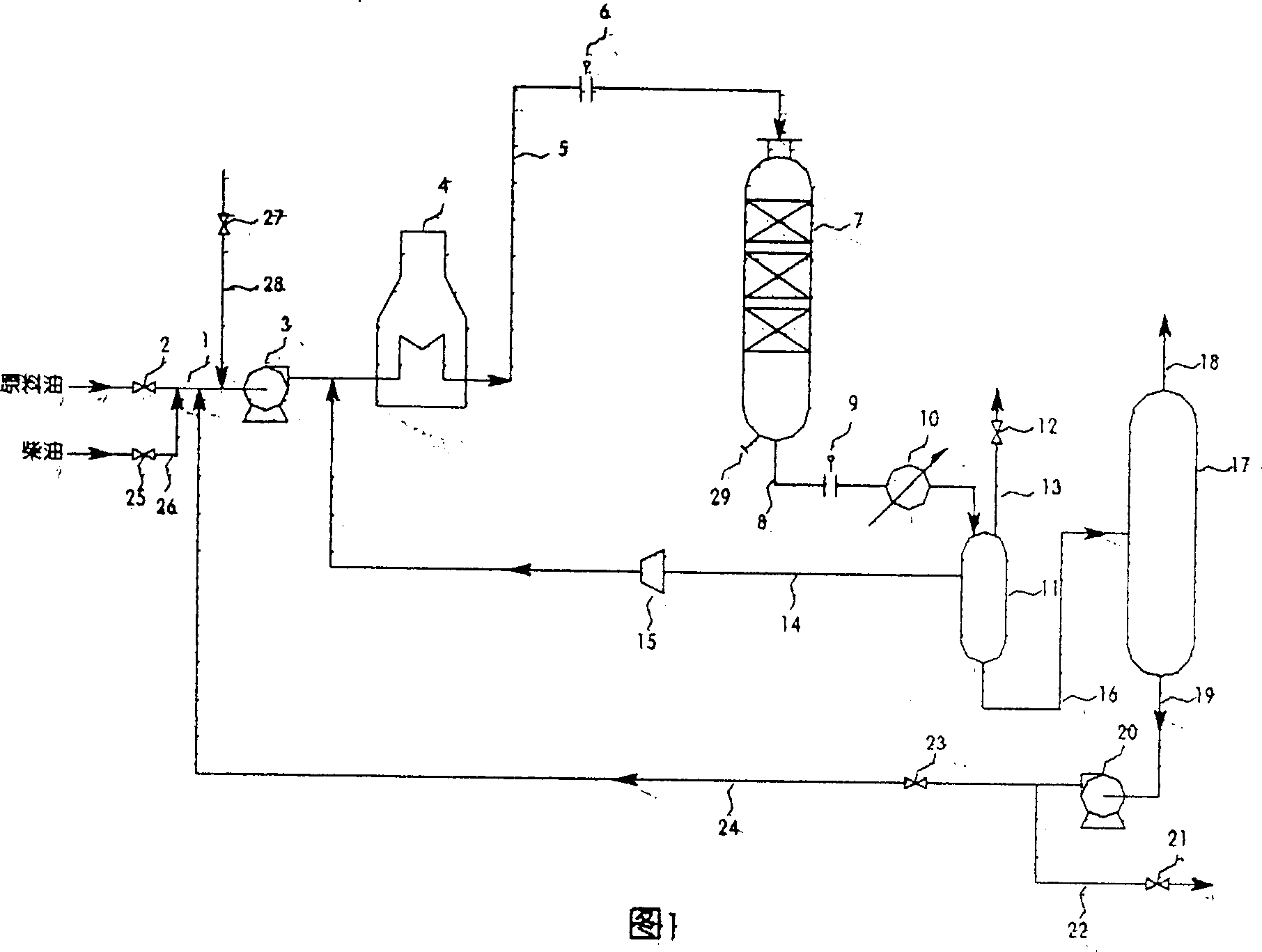

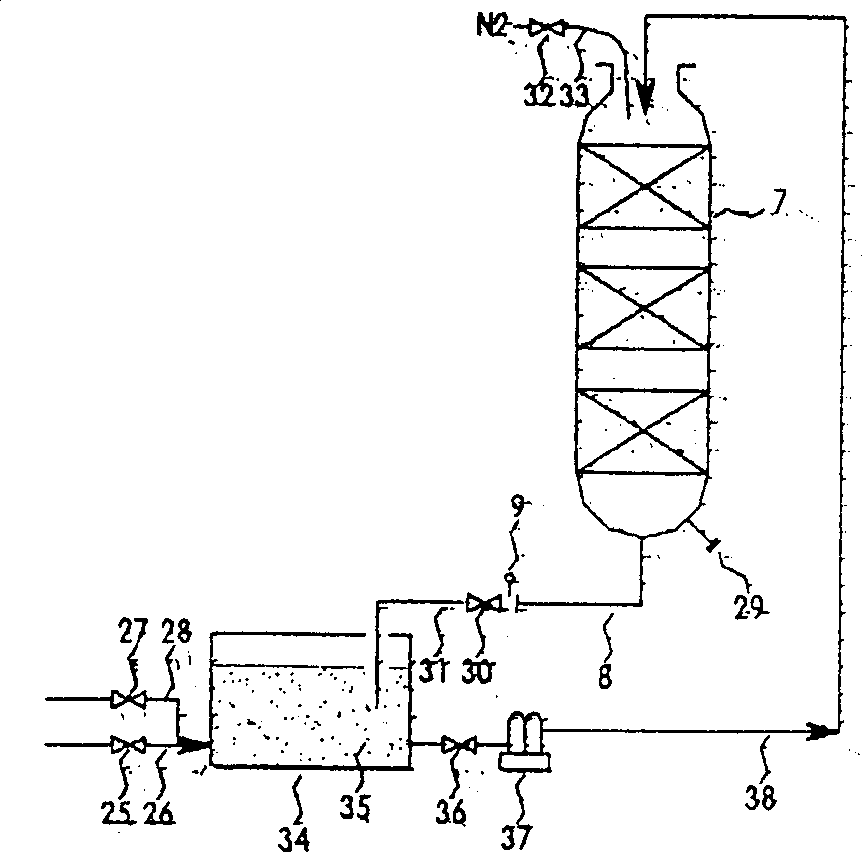

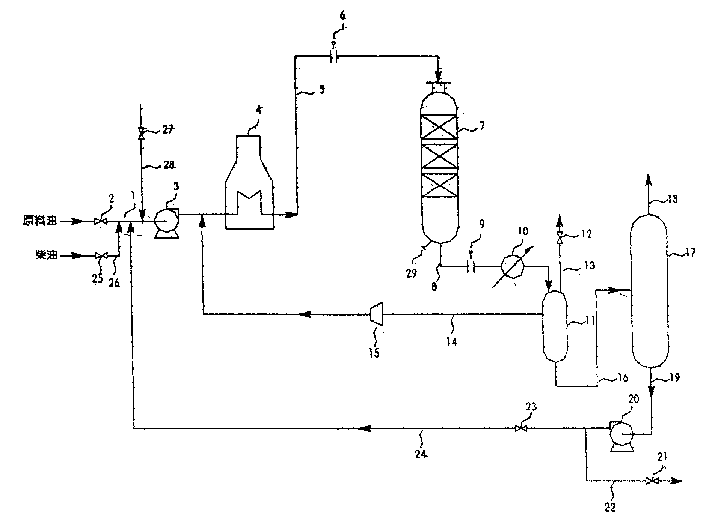

Process for unloading catalyst from petrochemical equipment

InactiveCN1376765ASave nitrogenReduce the cost of unloading agentPressurized chemical processHydrocarbon oil crackingOil phasePetrochemical

A process for unloading catalyst from petrochemical equipment features that before the catalyst is unloaded, it is immersed in oil phase compared from solvent and filming agent for 4-10 hr or cyclically contacted with said oil phase for 10-30 hr to generate a layer of film on the surface of catalyst, resulting in no generation of ash dust.

Owner:JIANGSU TIANPENG PETROCHEMICAL TECH CO LTD

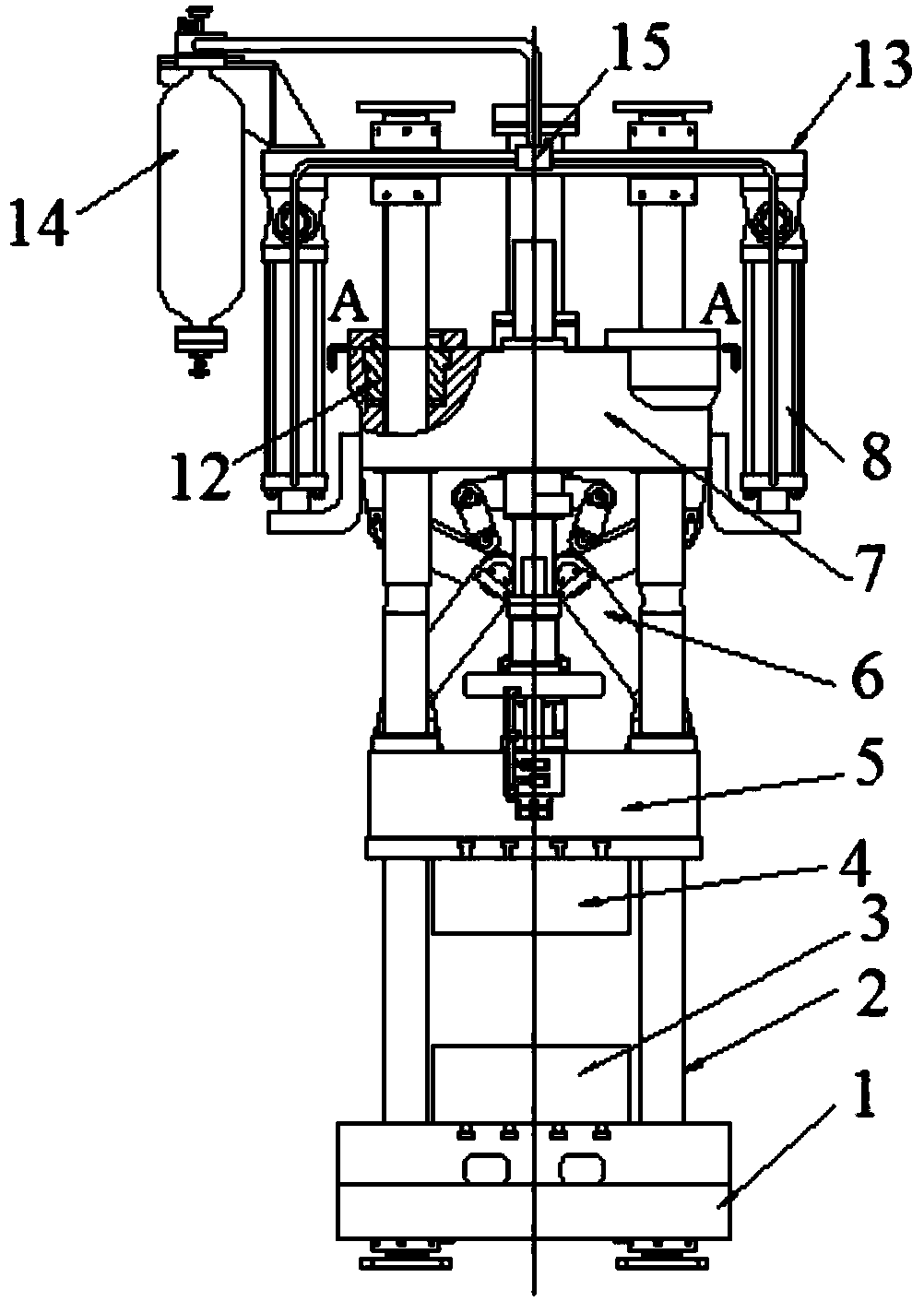

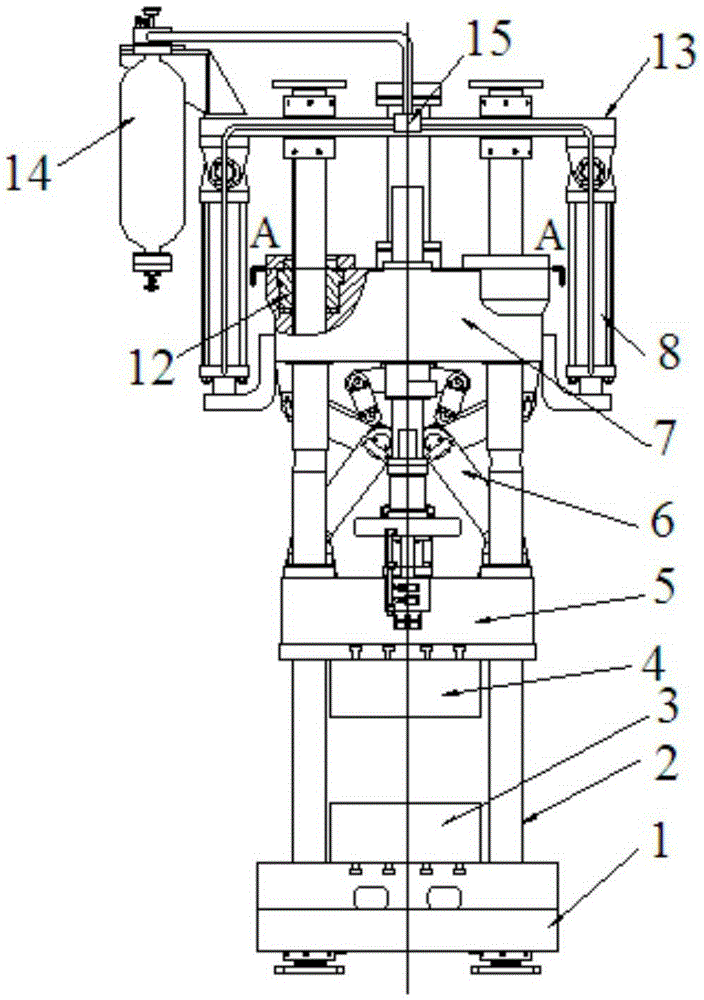

Auxiliary die adjusting system and die adjusting method of vertical type extrusion casting machine

The invention discloses an auxiliary die adjusting system of a vertical type extrusion casting machine and relates to the technical field of casting machines. The auxiliary die adjusting system comprises a nitrogen gas cylinder and a tail board. Two sides of the tail board are respectively provided with one auxiliary die adjusting cylinder, piston rods of the auxiliary die adjusting cylinders are respectively connected with two sides of the tail board, each auxiliary die adjusting cylinder is divided into a front cavity and a rear cavity, the front cavities are communicated with a nitrogen gas cylinder pipe, the rear cavities are communicated with the atmosphere, and a high-pressure air valve is arranged on a pipe between the nitrogen gas cylinder and the front cavities. The auxiliary die adjusting system of the vertical type extrusion casting machine facilitates die adjustment, reduces abrasion of draglinks and threads of adjusting nuts and saves nitrogen gas.

Owner:SUZHOU SANJI FOUNDRY EQUIP

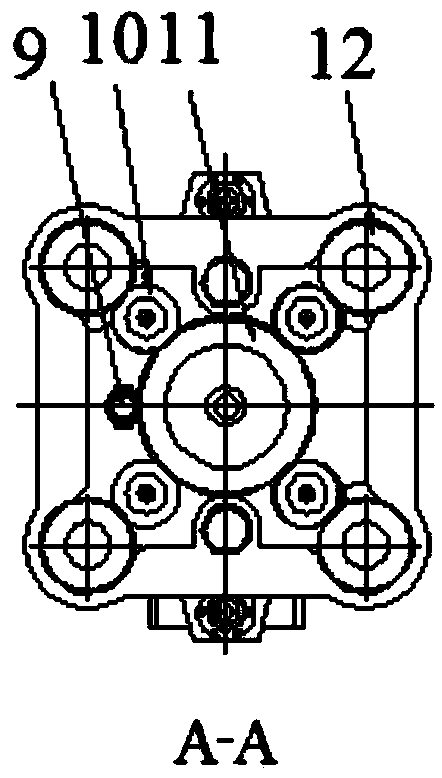

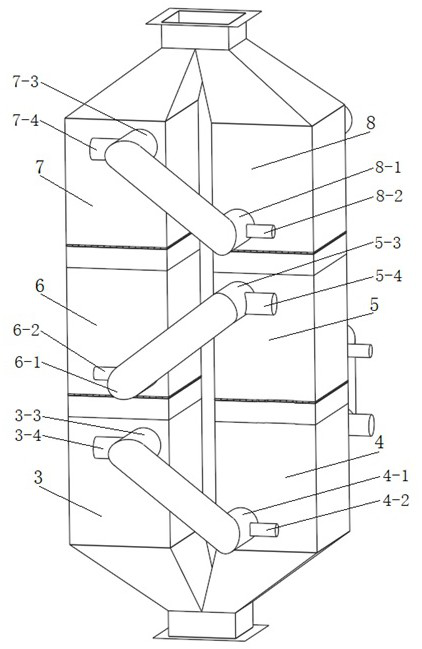

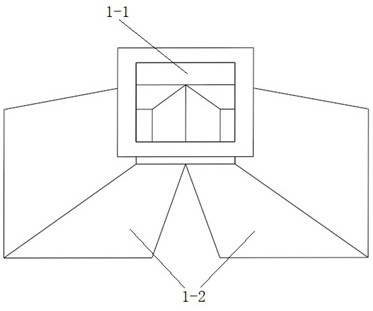

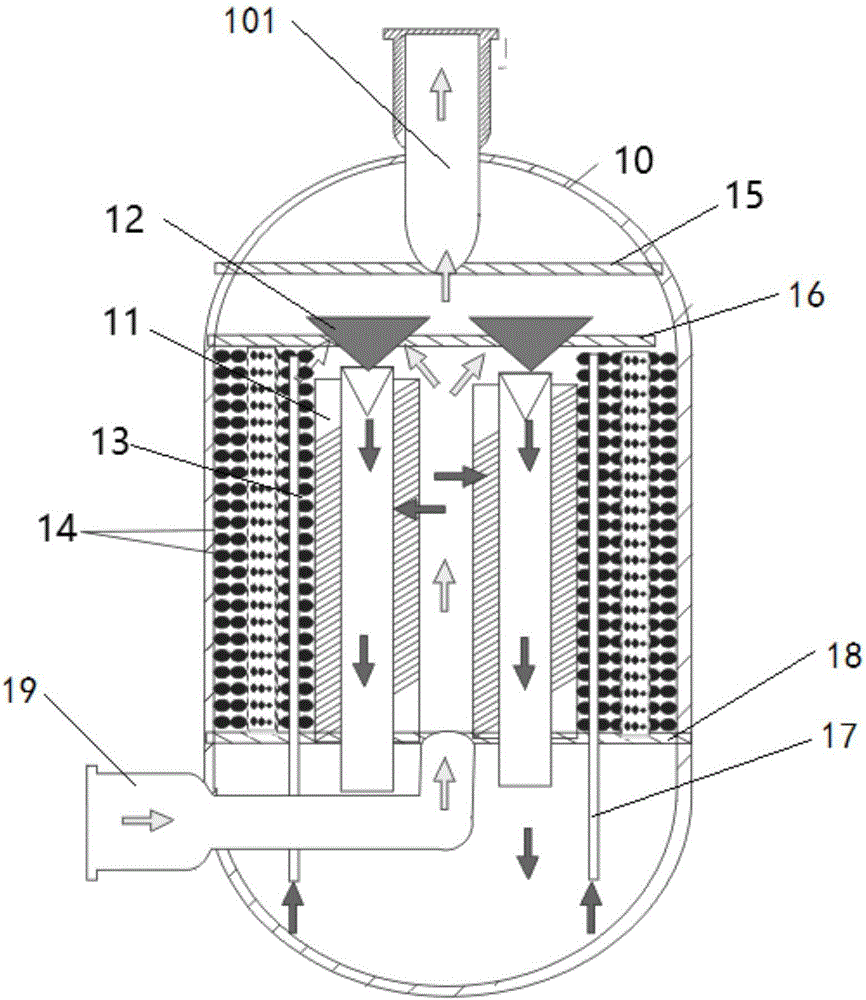

Industrial tail gas treatment multi-cycle adsorption tower

PendingCN113144825AReduce construction costsIncrease throughputGas treatmentDispersed particle separationFlue gasEngineering

The invention relates to an industrial tail gas treatment multi-cycle adsorption tower which comprises a plurality of tower bodies arranged side by side, each tower body comprises an active coke feeding section, at least two flue gas purification sections and an active coke discharging section which are sequentially arranged from top to bottom, the flue gas purification sections in each tower body are the same in number and at least two, and a transition sealing section is arranged between two adjacent flue gas purification sections on the same tower body; a gas inlet pipe and a gas outlet pipe are respectively arranged at the lower part and the upper part of each flue gas purification section; the gas outlet pipe of one flue gas purification section is connected with the gas inlet pipe of another corresponding flue gas purification section at the same height of other tower bodies or the gas inlet pipe of the adjacent flue gas purification section above the same tower body; and the gas inlet pipe of the flue gas purification section at the bottom is the gas inlet pipe of the adsorption tower, and the gas outlet pipe of the flue gas purification section at the top is the gas outlet pipe of the adsorption tower. The adsorption tower improves the utilization rate of active coke in the adsorption tower.

Owner:GUODIAN ENVIRONMENTAL PROTECTION RES INST CO LTD

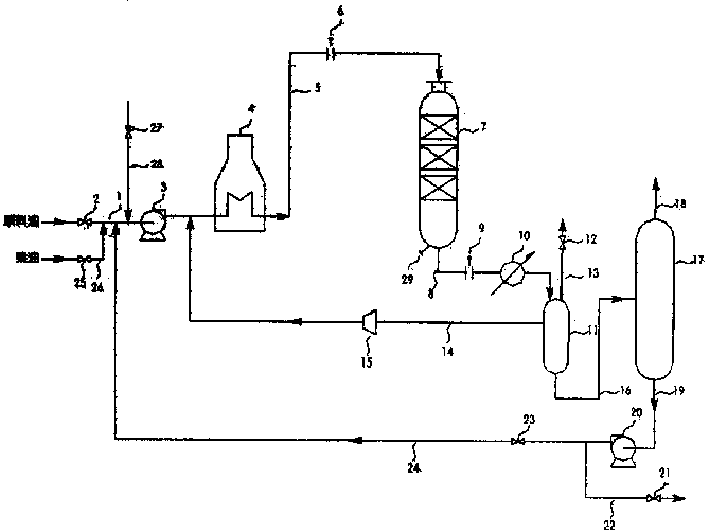

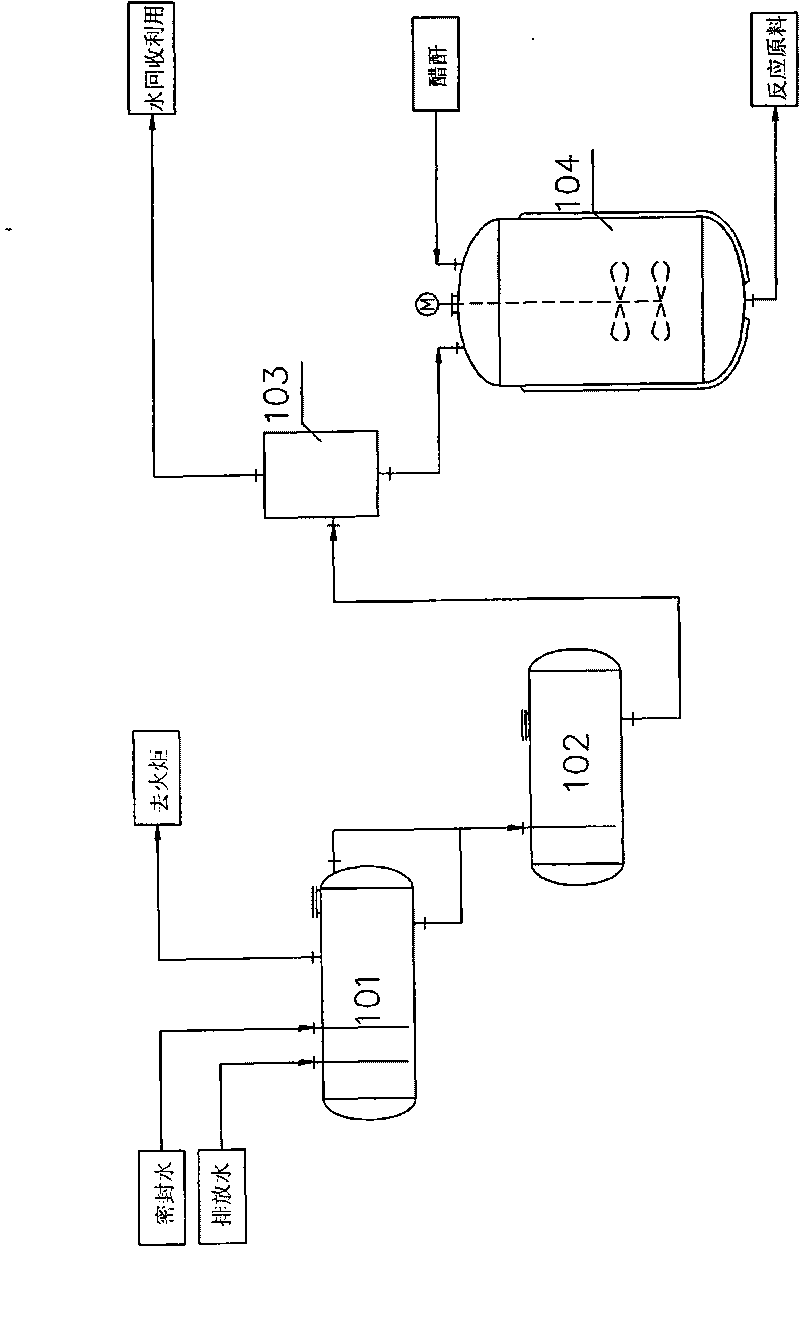

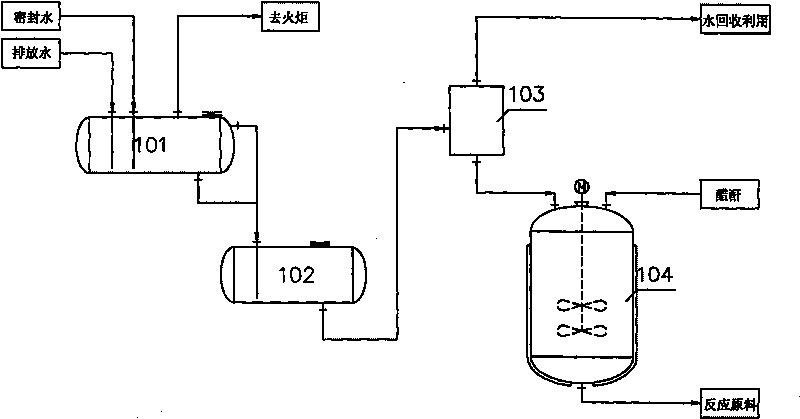

Method for processing methyl iodide-contained combustible gas discharged into torch system by carbonylation compounding device

ActiveCN101721896ASolve intractableImprove securityDispersed particle separationMultistage water/sewage treatmentHydration reactionAcetic anhydride

The invention discloses a method for processing a methyl iodide-contained combustible gas discharged into a torch system by a carbonylation compounding device. The methyl iodide-contained combustible gas discharged into the torch system by the carbonylation compounding device enters a torch water seal tank firstly, and then is discharged into the torch system; after being collected, the methyl iodide-contained sewage generated in the torch water seal tank carries out film concentration processing to obtain concentrated methyl iodide wastewater; the concentrated methyl iodide wastewater and acetic anhydride carry out hydration reaction to remove water; and a reactant is used as one part of carbonylation reaction raw materials and returned to a carbonylation compounding system. The invention solves the problem that the methyl iodide wastewater can not be processed by a common environmental protection approach; and by adopting the method, the torch system of the carbonylation compounding device of acetic acid, acetic anhydride, and the like can be provided with the water seal tank which strengthens the safety of the torch system and can save nitrogen.

Owner:SINOPEC NANJING ENG & CONSTR

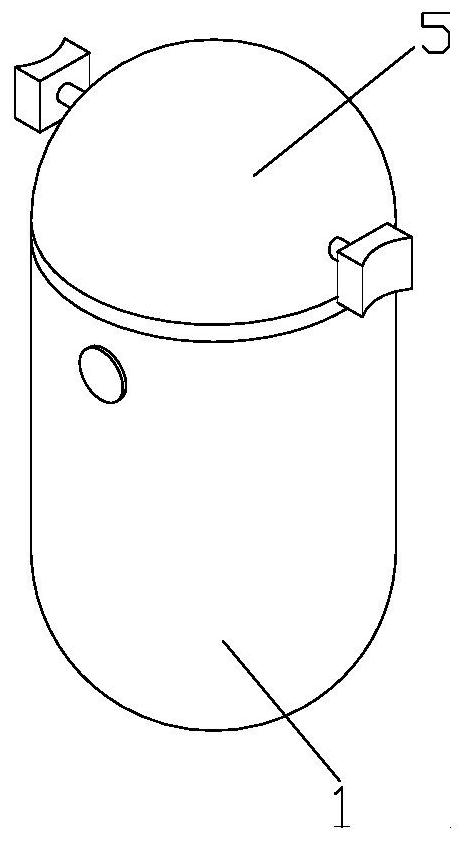

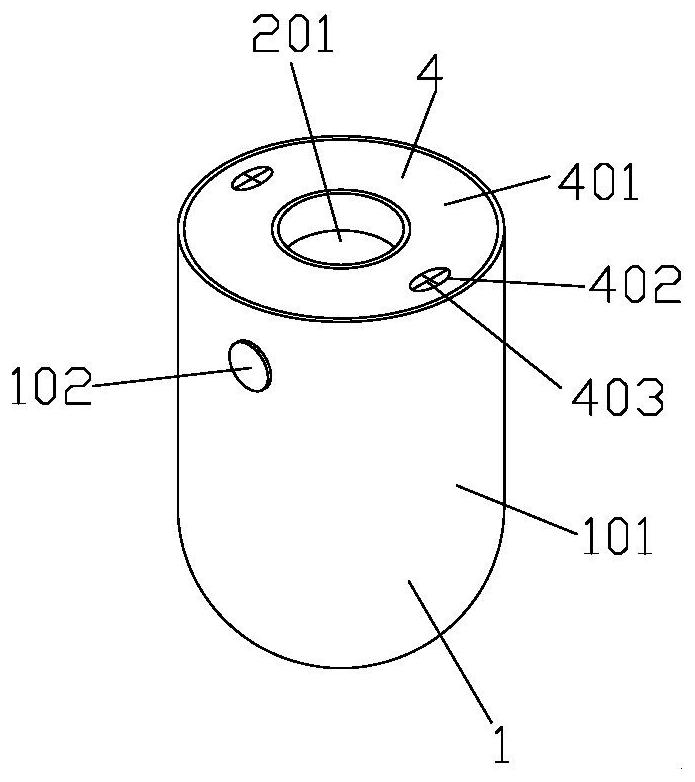

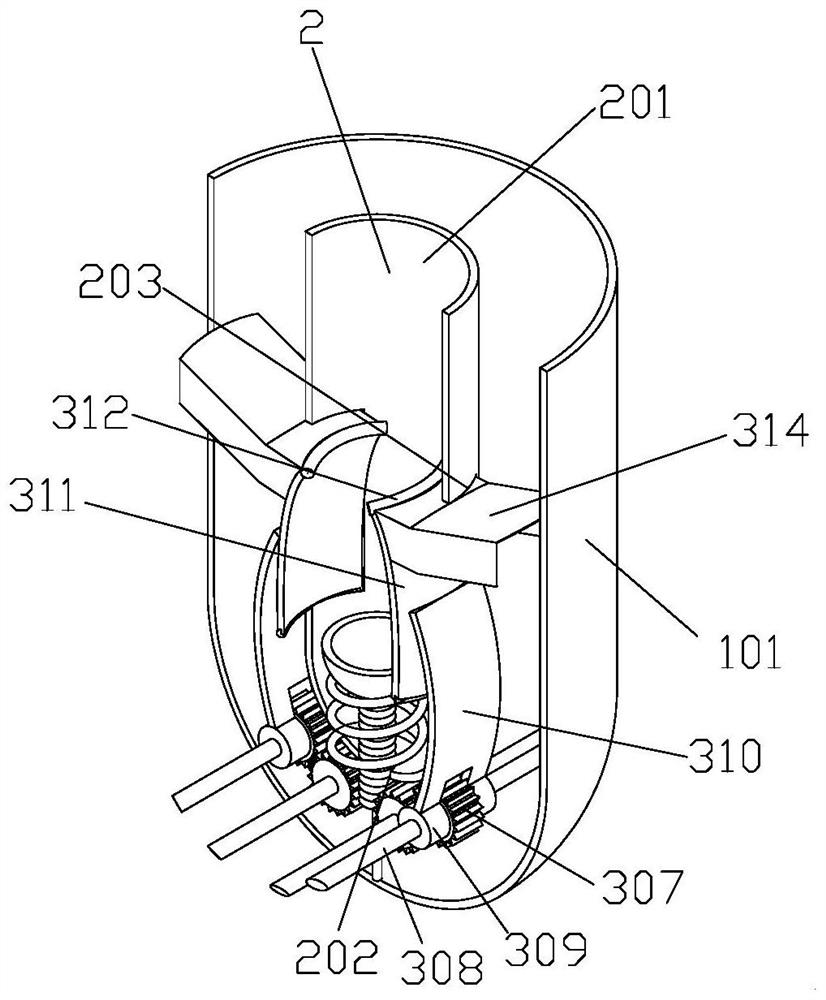

Water removing device for oil storage tank

ActiveCN106742857ASafe and easy separationRelieve pressureLarge containersTank wagonsOil waterWater mass

The invention provides a water removing device for an oil storage tank. The water removing device comprises an oil tank filtering separator and a floating ball device, a crude oil inlet pipe is arranged on the bottom of a tank body, and the oil tank filtering separator is used for carrying out oil-water separation on water-contained oil entering the tank body of the oil tank filtering separator through the crude oil inlet pipe; and an inlet of the floating ball device is connected with a liquid outlet in the top of the filtering separator, and oil entering the floating ball device is drained through a siphon device. By means of the oil-water separation process in inner circulation of the water removing device, water is separated and concentrated in the lower tank body of the device after hydrone enters the oil tank from the outside and before the hydrone forms large-scale water mass.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA +2

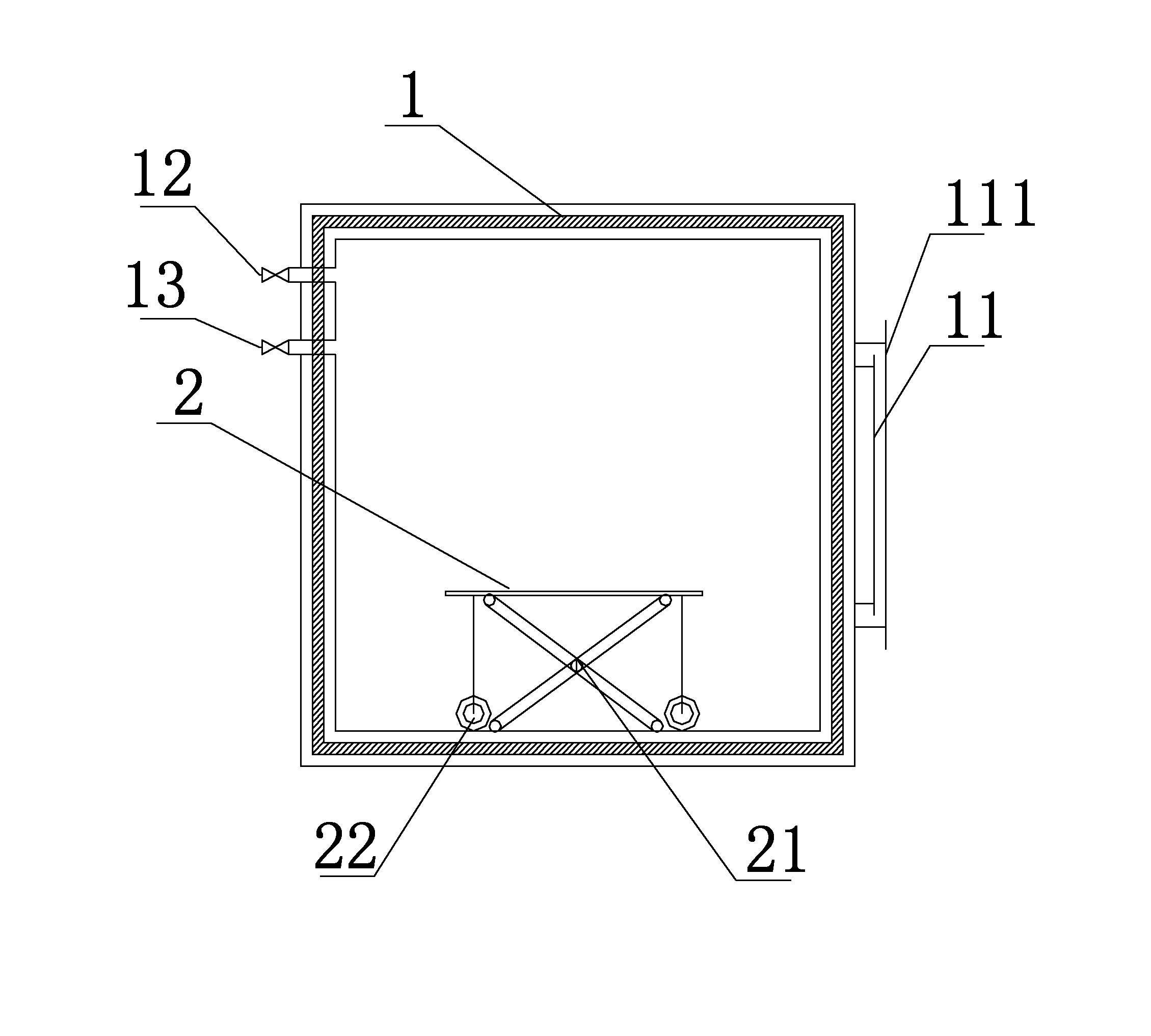

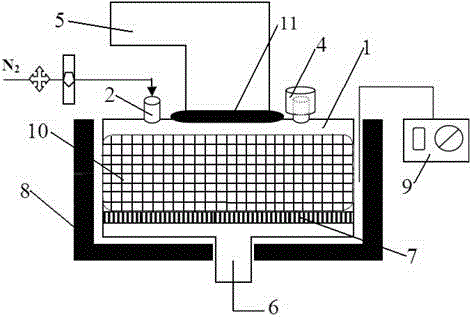

Device for recovering Nd-Fe-B magnetic powder

The invention discloses a device for recovering Nd-Fe-B magnetic powder, comprising a vacuum box and an article table. The vacuum box is filled with nitrogen; the article table is arranged in the vacuum box; the vacuum box is provided with a feeding and discharging port, a gas inlet and a vacuum port; the feeding and discharging port is opened and closed through a sealing door; one end of the sealing door is articulated with the vacuum box; the gas inlet is communicated with a nitrogen pipe; during feeding and discharging, the nitrogen is filled into the vacuum box through the gas inlet; the vacuum port is connected with the vacuum pie; when the feeding and discharging port and the gas inlet are closed, the vacuum box is vacuumized through the vacuum port; the bottom of the article table is provided with sliding rolling wheels; a guiderail is arranged in the vacuum box; and the article table moves on the guiderail through the rolling wheels. The device for recovering the Nd-Fe-B magnetic powder is arranged in the nitrogen surrounded or vacuum environment so as to prevent the oxidization of the Nd-Fe-B magnetic powder. Because the vacuum box is provided with the sealed feeding and discharging port, the Nd-Fe-B magnetic powder can be put in or taken out repeatedly, and the Nd-Fe-B magnetic powder can be taken out after accumulating to a large amount.

Owner:宁德市星宇科技有限公司

Paddyfield astragalus planting method

InactiveCN100379335CReduce the amount of seed usedLow costHorticulture methodsRice cultivationCropping systemPaddy field

The present invention discloses a Chinese milkvetch cultivation method in rice field, and relates to a Chinese milkvetch cultivation and utilization technique under the condition of paddy field rice-green fertilizer rotation cropping system. It is characterized by intersowing Chinese milkvetch seeds in the rice field, and adopting a series of measures of channelling and discharging water after the rice is harvested so as to implement said invention.

Owner:JIANGSU ACAD OF AGRI SCI

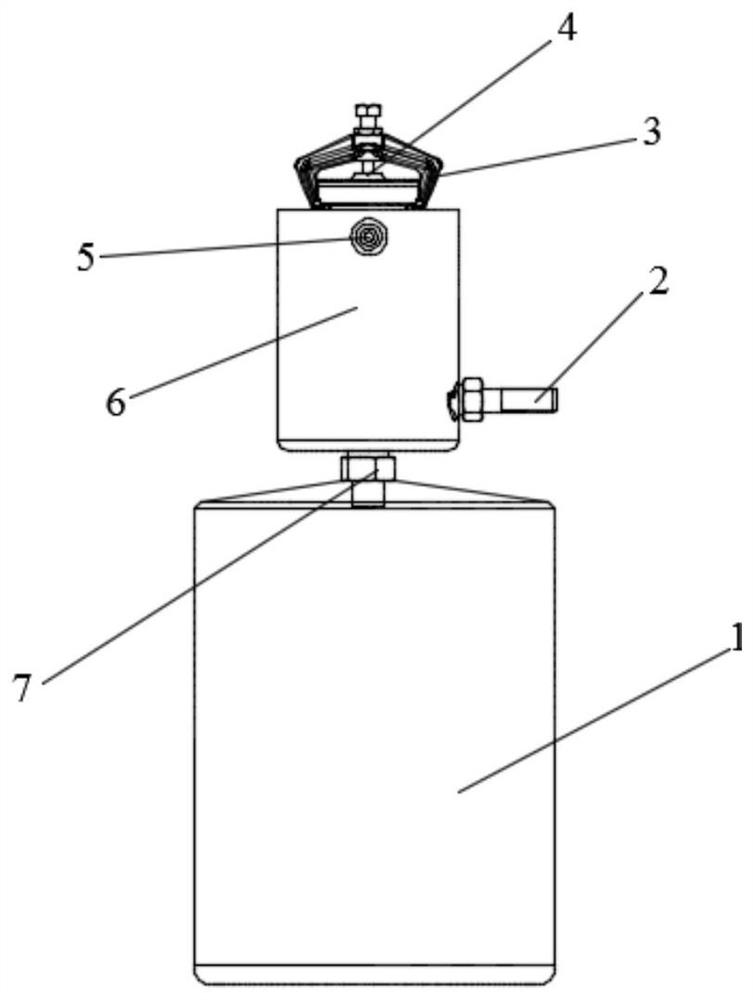

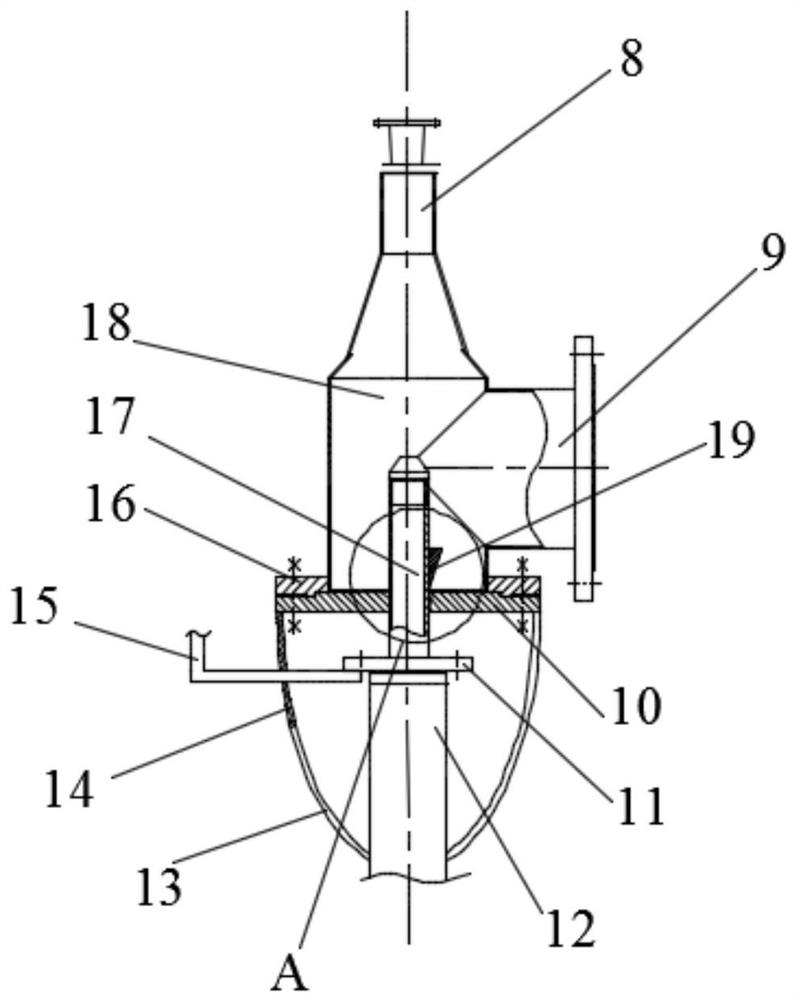

Saving type high-pressure water mist fire extinguisher

The invention discloses a saving type high-pressure water mist fire extinguisher. A water-gas mixing control mechanism and a control mechanism are arranged, the water-gas mixing control mechanism enables high-pressure water supplied by a high-pressure water supply pipe to be mixed with nitrogen supplied by a high-pressure nitrogen tank, the control mechanism can adjust and control the proportion of high-pressure water and high-pressure nitrogen in the water-gas mixing control mechanism, so that when the aerial fog is sprayed, the proportion of water and nitrogen in the aerial fog sprayed by an aerial fog spraying nozzle is changed, therefore, the fire extinguishing capacity and effect are improved through the change of the proportion, and meanwhile nitrogen can be saved. The proportion of water to nitrogen in aerial fog sprayed by the aerial fog spraying nozzle is variable, contact between air and fire can be effectively isolated by adding the nitrogen, the temperature can be effectively reduced by utilizing the water fog, the fire extinguishing capacity and effect can be effectively improved, meanwhile, different control and operation can be achieved according to different fire extinguishing stages, and the purpose of saving nitrogen is achieved, and the fire extinguishing effect is improved.

Owner:JILIN JIANZHU UNIVERSITY

Method for continuously synthesizing isoproturon

ActiveCN110938019AIncrease profitReduce processing costsUrea derivatives preparationOrganic compound preparationIsopropylNitrogen gas

The invention discloses a method for continuously synthesizing isoproturon. The method comprises the steps of: taking isopropylaniline as an initial raw material, carrying continuous kettle type phosgenation reaction on isopropylaniline with phosgene, then performing continuous thermal decomposition to obtain isopropylphenyl isocyanate, and carrying out kettle type continuous amination reaction onisopropylphenyl isocyanate and dimethylamine to obtain the product isoproturon. According to the invention, continuous production of isopropylphenyl isocyanate is achieved, and continuous tower-typethermal decomposition and light driving are adopted to replace kettle-type light driving, so that nitrogen is saved, and the operation machine hour is reduced; unreacted phosgene is pumped into the photochemical kettle again for reaction after being cooled, separated and absorbed by methylbenzene, so that the phosgene utilization rate is increased, and the phosgene tail gas treatment cost is reduced; and continuous automatic operation of isoproturon synthesis is achieved.

Owner:JIANGSU KUAIDA AGROCHEM

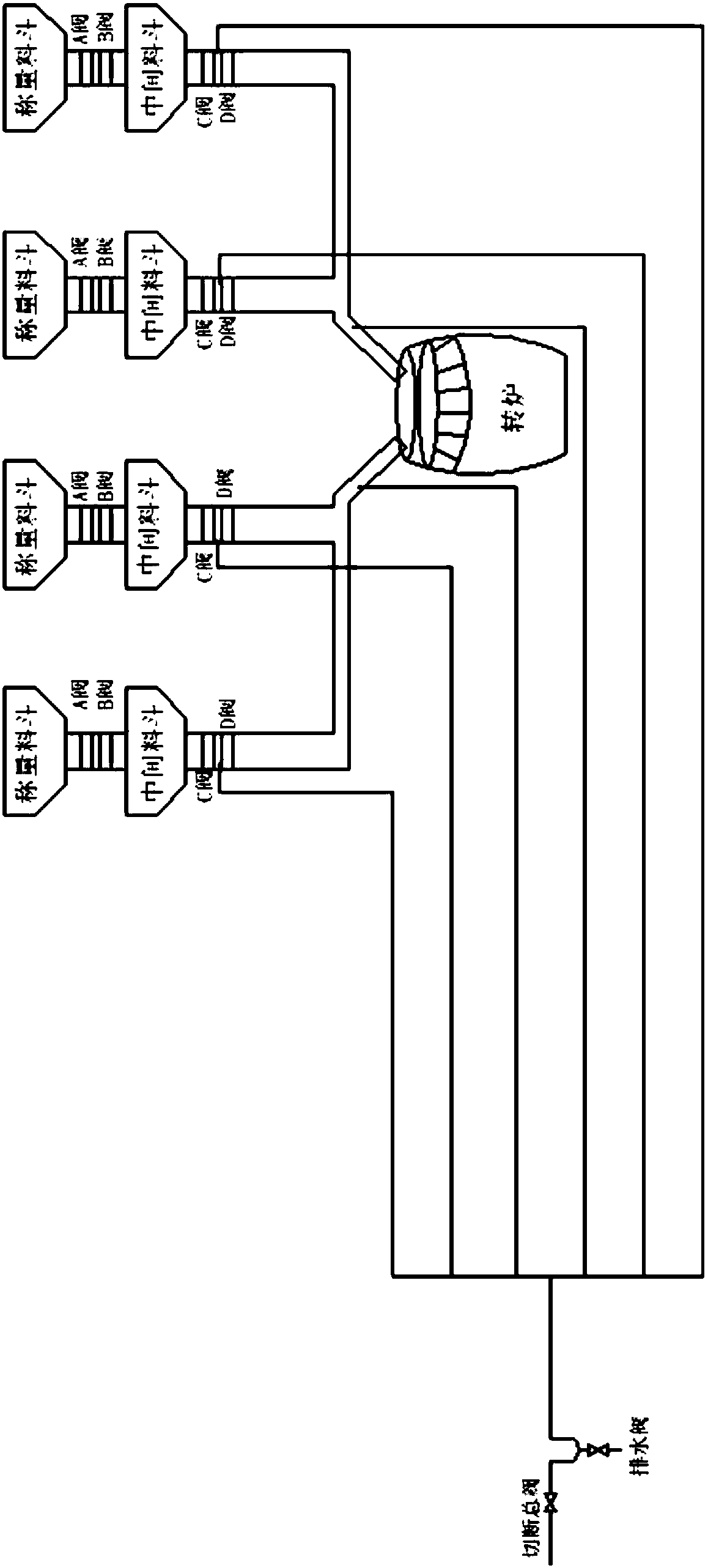

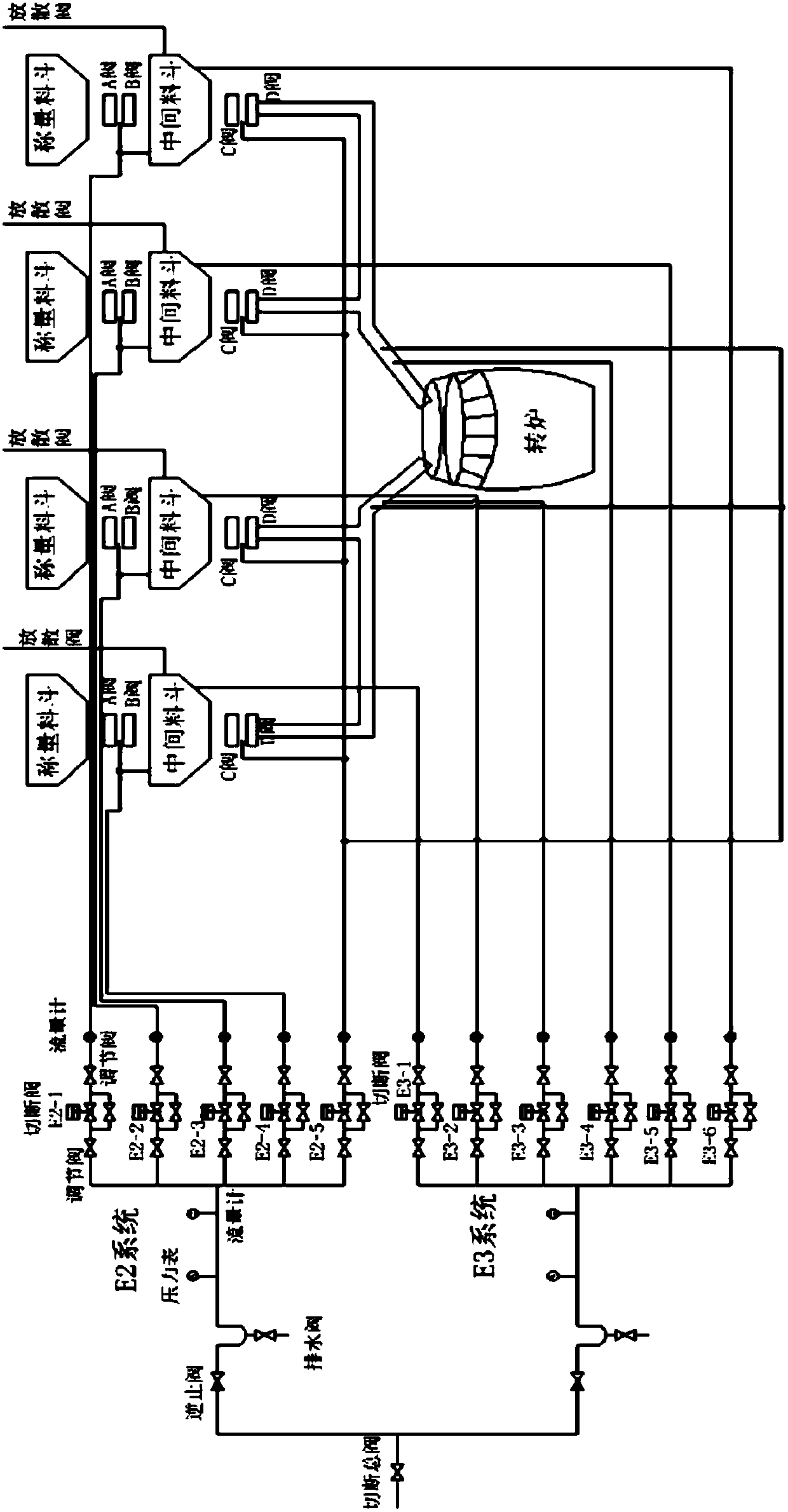

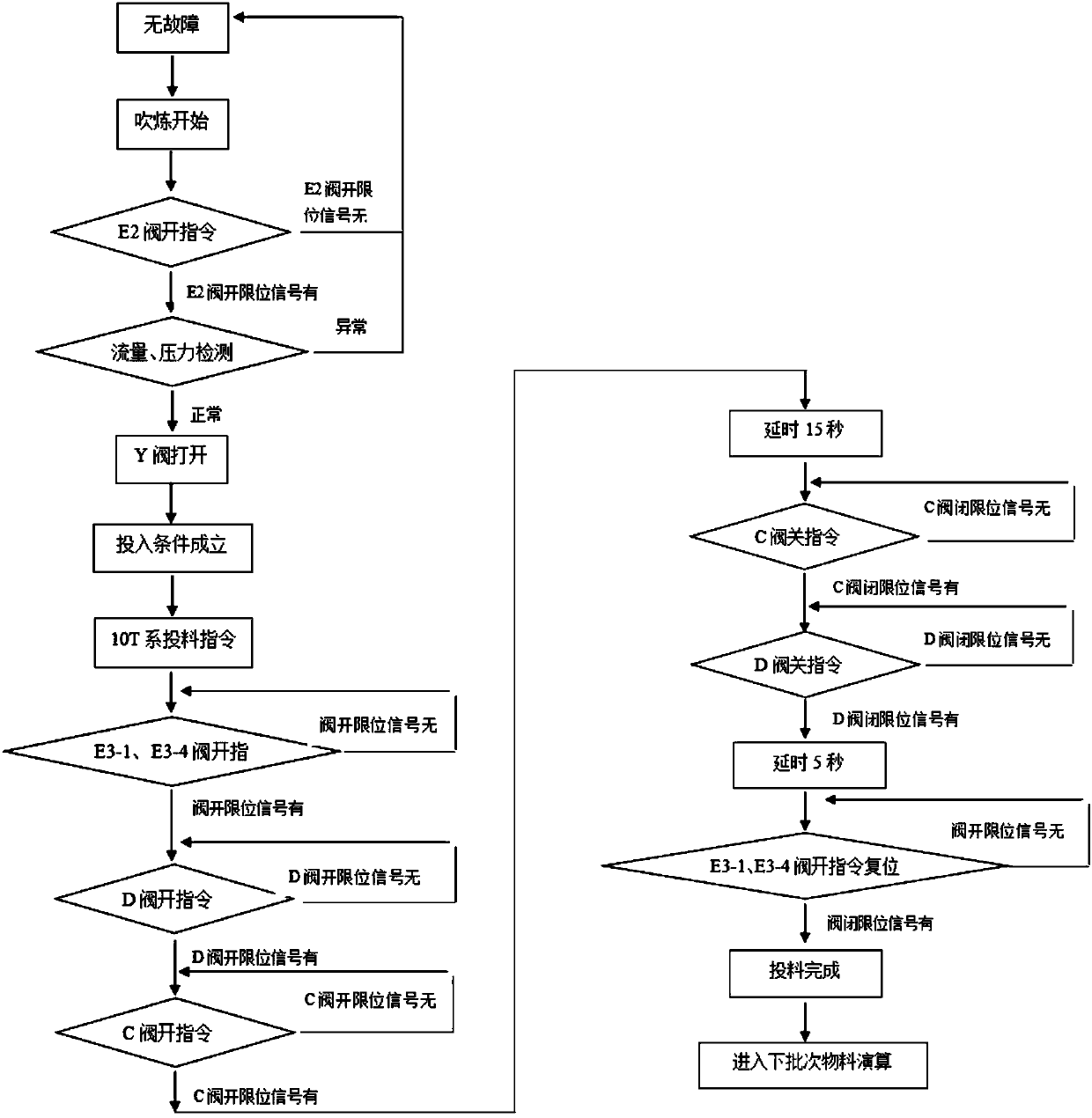

Nitrogen sealing device for auxiliary material and control method for nitrogen sealing of auxiliary material

The invention discloses a nitrogen sealing device for an auxiliary material and a control method for nitrogen sealing of the auxiliary material. The nitrogen sealing device comprises an intake manifold, a cut-off main valve, a check valve, a drain valve, a pressure gauge, a flowmeter, a weighing funnel, an intermediate hopper, a converter, a feeding pipe, a valve A, a valve B, a valve C, a valve D, an intermediate bunker anti-explosion nitrogen sealing E2 system and an auxiliary material feeding pipeline nitrogen sealing E3 system. The nitrogen sealing device for the auxiliary material is easyto maintain, has high reliability, saves the usage amount of nitrogen, presents good use effect, lowers the risk assessment result of the danger source of the device and improves work efficiency. According to the control method for nitrogen sealing of the auxiliary material, a control program is modified so as to realize improvement meeting process requirements; and a nitrogen-seal nitrogen valveis opened only during normal smelting and is not opened at other time, so the requirements of environmental protection are met and the purpose of nitrogen conservation is achieved.

Owner:BAOSHAN IRON & STEEL CO LTD

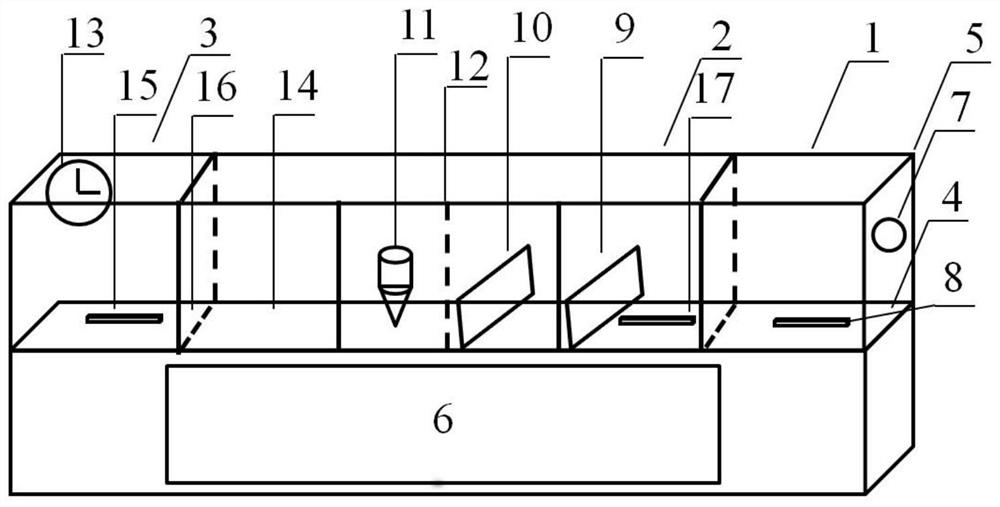

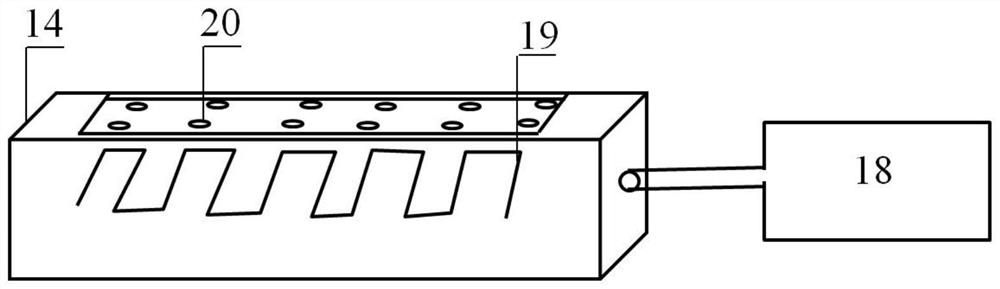

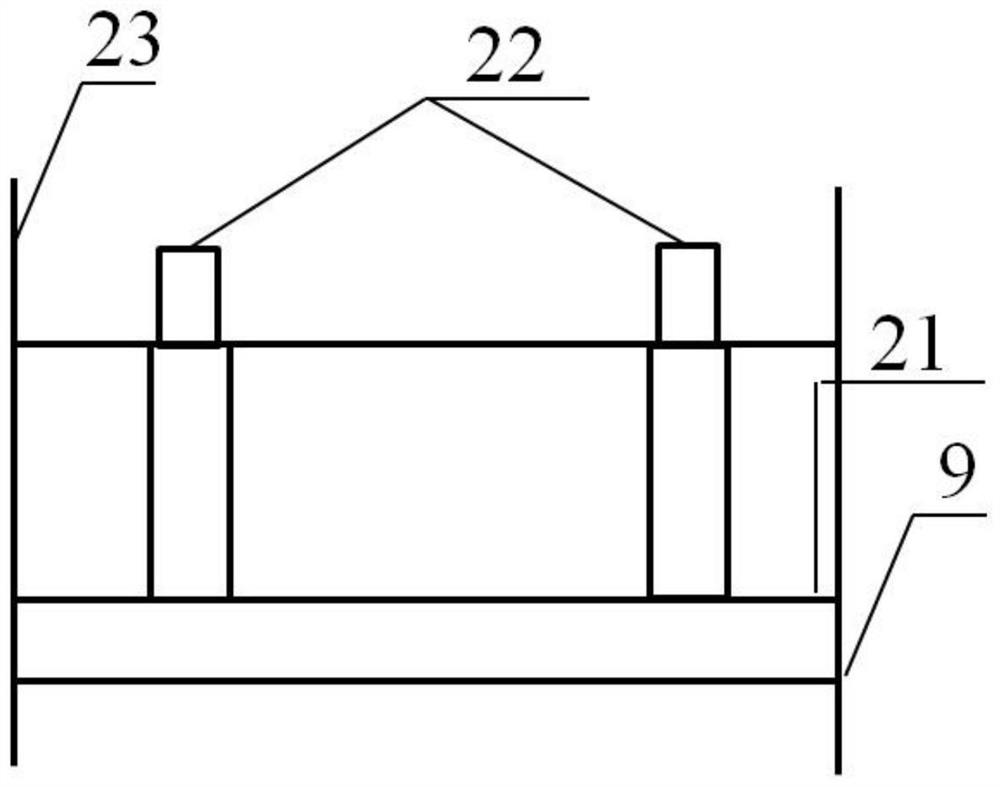

Advanced special equipment for large-area preparation of perovskite solar cell

PendingCN112582553ASave nitrogenReduce energy costsFinal product manufactureSolid-state devicesTemperature controlPerovskite solar cell

The invention discloses advanced special equipment for large-area preparation of a perovskite solar cell, and belongs to the technical field of photoelectricity. The equipment is composed of a preparation chamber, a sample preparation chamber, a heating chamber, a glass cavity, a heating plate and a panel control module. The preparation chamber includes a sample transmitter and a gas inlet. The sample preparation chamber comprises a scraper, a nitrogen knife, a solution funnel, a sample conveyor and a heating plate. The solution funnel has dual functions of storing and heating the solution, and the temperature is controllable from room temperature to 80 DEG C. The sample preparation chamber heating plate has double functions of heating and fixing a sample, and consists of a resistance wire, an air hole and an air pump; the panel control module is composed of a temperature control module, a sample transmission module, a scraper control module, a nitrogen knife control module, a solutioncontrol module and the like. The method overcomes the property that perovskite is afraid of water and oxygen and is difficult to prepare, and good equipment is provided for industrial development.

Owner:XINYU UNIV

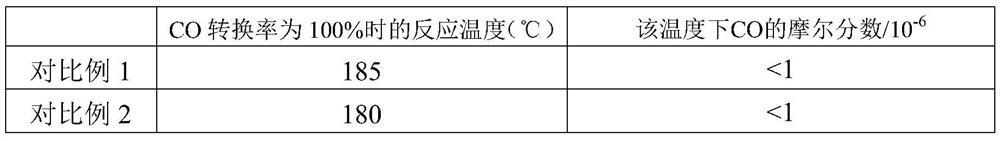

A kind of nickel-based CO hydrogenation reaction catalyst and preparation method and application thereof

ActiveCN108816238BImprove hydrogenation activityImprove economyCatalyst activation/preparationLiquid hydrocarbon mixture productionPtru catalystHydrogenation reaction

The invention discloses a nickel-based CO hydrogenation reaction catalyst and its preparation method and application. The components of the nickel-based CO hydrogenation reaction catalyst include nickel oxide, aluminum oxide and additives, and the content of the nickel oxide accounts for The nickel-based CO hydrogenation reaction catalyst accounts for 55-90% of the total mass of the nickel-based CO hydrogenation reaction catalyst, and the content of the auxiliary agent accounts for 1-5% of the total mass of the nickel-based CO hydrogenation reaction catalyst; the particle size of the nickel oxide is 3-17nm. The nickel-based CO hydrogenation reaction catalyst is prepared by co-precipitation method, and the reactivity of the catalyst is improved by adding different kinds of additives, improving the way of adding additives, and improving the drying process, thereby greatly reducing methanation The reaction temperature of the reaction is high, and it can maintain high reactivity and stability under low temperature conditions, so the nickel-based CO hydrogenation reaction catalyst can be used to completely remove CO in hydrogen-rich gases under low temperature conditions.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

Process for unloading catalyst from petrochemical equipment

InactiveCN1140613CSave nitrogenReduce the cost of unloading agentPressurized chemical processHydrocarbon oil crackingOil phasePetrochemical

A process for unloading catalyst from petrochemical equipment features that before the catalyst is unloaded, it is immersed in oil phase compared from solvent and filming agent for 4-10 hr or cyclically contacted with said oil phase for 10-30 hr to generate a layer of film on the surface of catalyst, resulting in no generation of ash dust.

Owner:JIANGSU TIANPENG PETROCHEMICAL TECH CO LTD

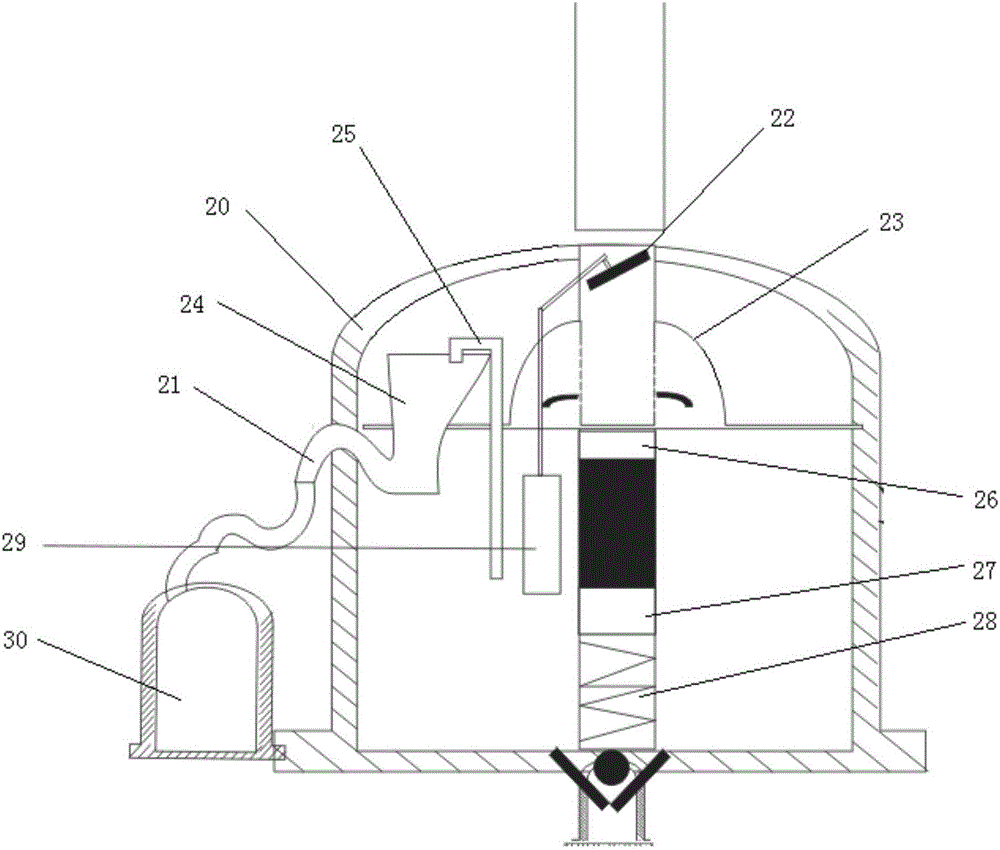

Full-automatic low-temperature storage equipment for stem cells

The invention discloses full-automatic low-temperature storage equipment for stem cells, and relates to the technical field of low-temperature storage. The full-automatic low-temperature stem cell storage equipment comprises a cooling device, the cooling device comprises a cooling shell, a placement device is arranged at the center of the interior of the cooling shell and comprises a placement shell, an upper end opening of the placement shell is flush with an upper end opening of the cooling shell, and the lower end of the placement shell is located above the lower end of the cooling shell; a bottom hole is formed in the middle of the lower end of the containing shell in a penetrating mode, side holes are formed in the left side wall and the right side wall of the middle of the containing shell in a penetrating mode, and a communicating device is arranged at the lower end of the interior of the cooling shell and comprises a bottom column. According to the full-automatic low-temperature storage equipment for the stem cells, a worker cannot be in contact with the temperature of nitrogen, so that test tubes filled with the stem cells can be safely taken out.

Owner:久卫(北京)生物医药技术有限公司

Water removal device for oil storage tank

ActiveCN106742857BSafe and easy separationRelieve pressureTank wagonsNon-miscible liquid separationOil waterWater mass

The invention provides a water removing device for an oil storage tank. The water removing device comprises an oil tank filtering separator and a floating ball device, a crude oil inlet pipe is arranged on the bottom of a tank body, and the oil tank filtering separator is used for carrying out oil-water separation on water-contained oil entering the tank body of the oil tank filtering separator through the crude oil inlet pipe; and an inlet of the floating ball device is connected with a liquid outlet in the top of the filtering separator, and oil entering the floating ball device is drained through a siphon device. By means of the oil-water separation process in inner circulation of the water removing device, water is separated and concentrated in the lower tank body of the device after hydrone enters the oil tank from the outside and before the hydrone forms large-scale water mass.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA +2

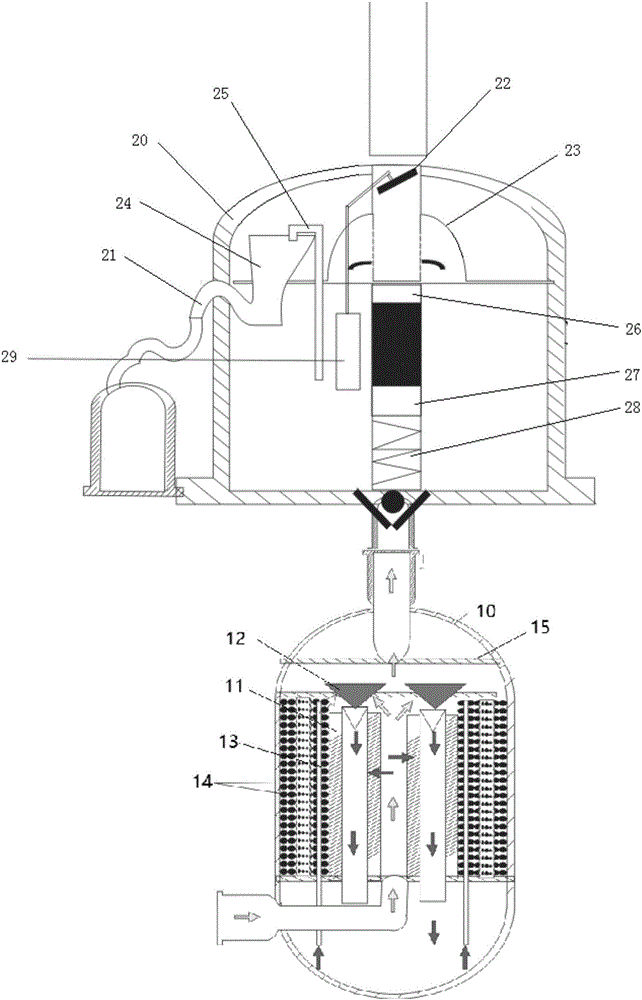

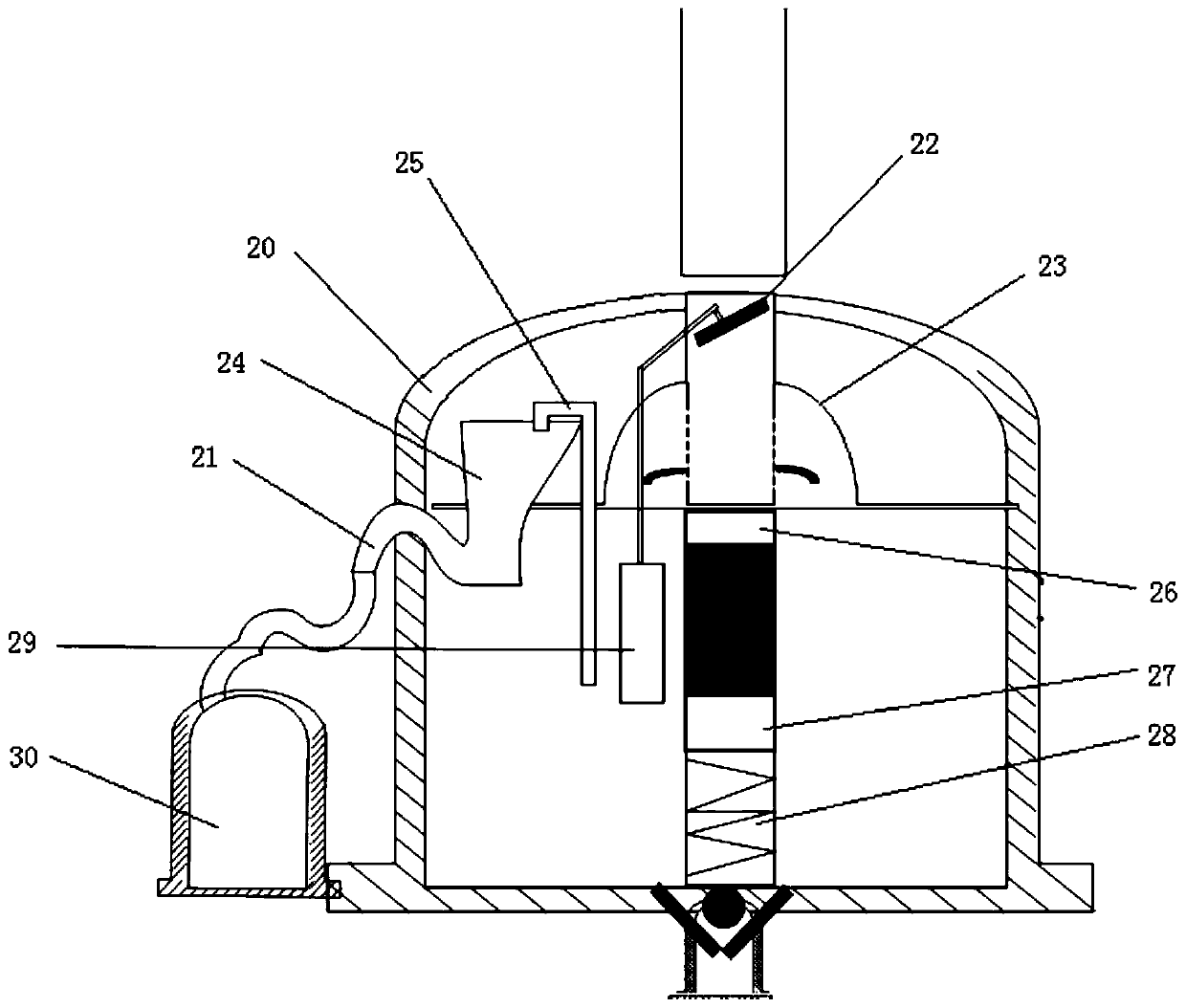

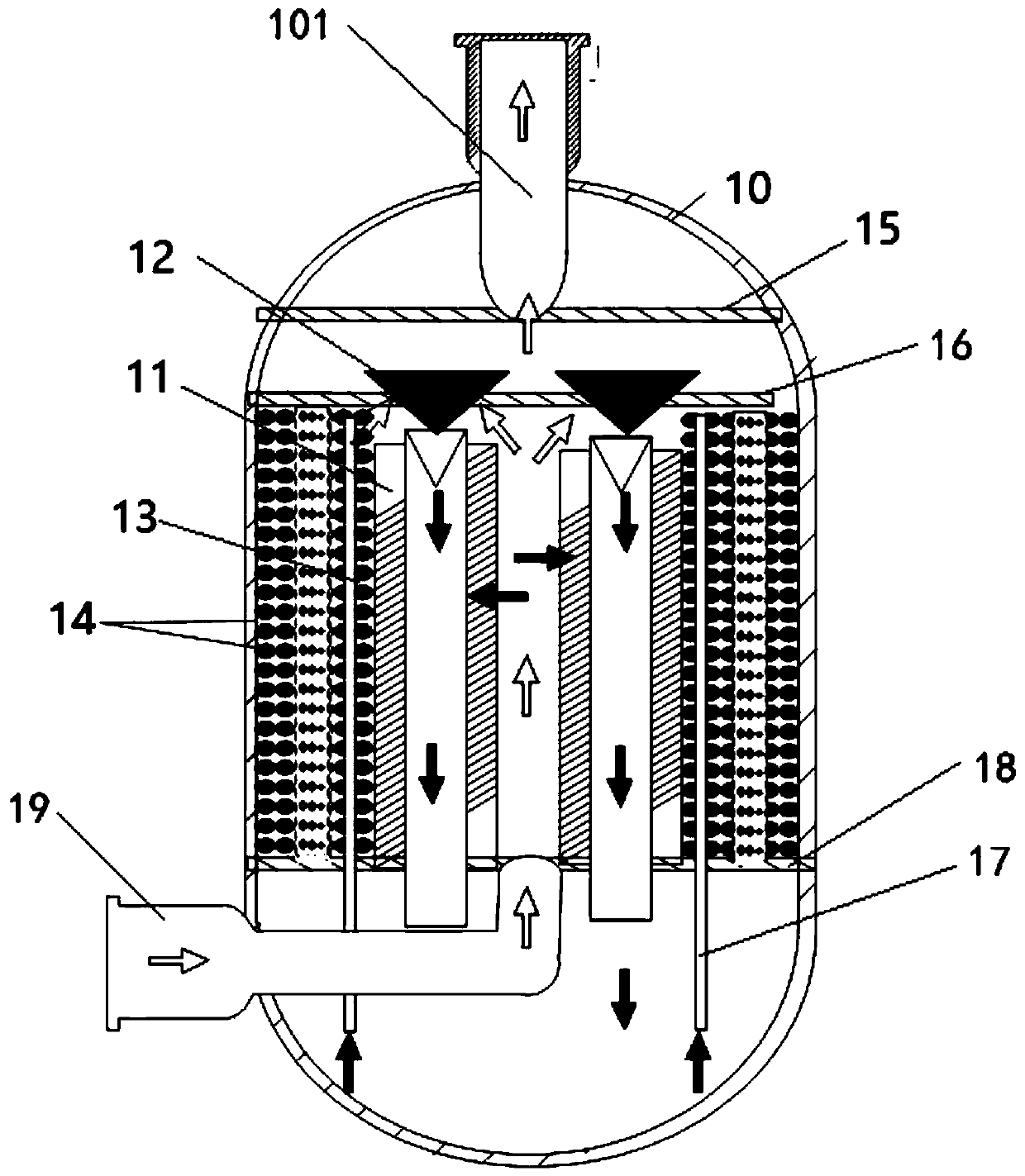

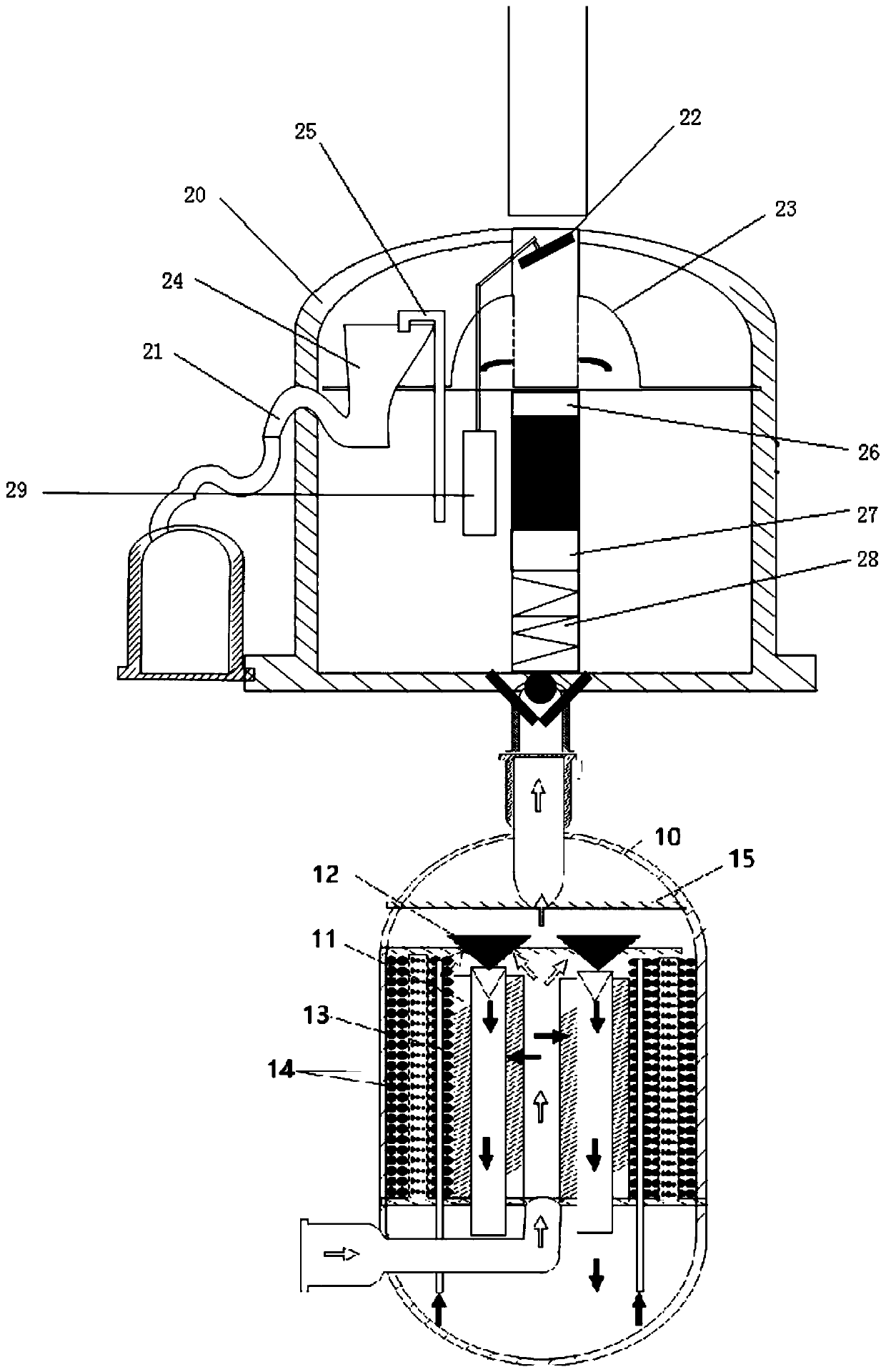

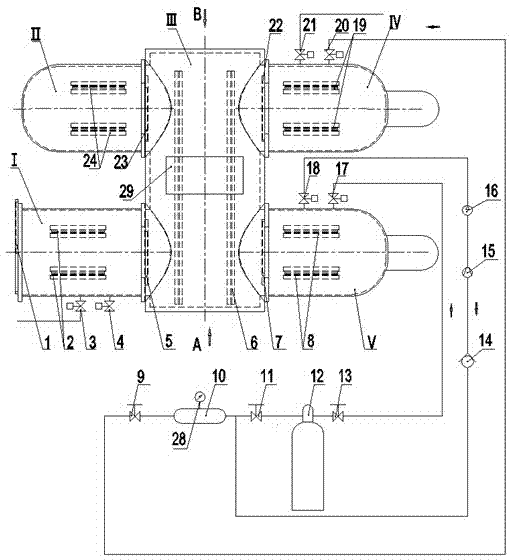

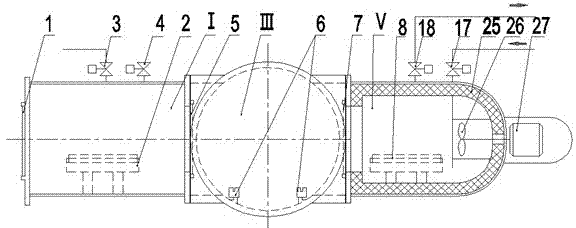

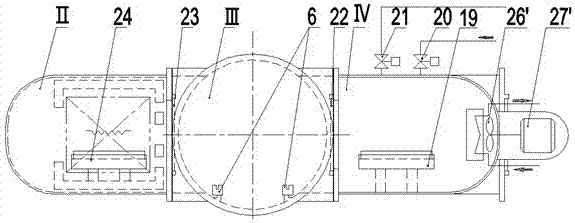

Vacuum heat treatment and subzero treatment integrated machine

The invention relates to a vacuum heat treatment and subzero treatment integrated machine and belongs to the field of metal heat treatment devices. The vacuum heat treatment and subzero treatment integrated machine is characterized in that four door openings are arranged on the left lateral face and the right lateral face of a middle corridor chamber in a two-to-two symmetrical mode and provided with unsealing and sealing doors which are respectively connected with a material loading and unloading chamber, a vacuum high-pressure gas quenching heating chamber, a vacuum high-pressure gas quenching cooling chamber and a subzero chamber. One unsealing and sealing door is arranged at the outer end of the material loading and unloading chamber, and a rail for enabling a material conveying cart to move is arranged in the middle corridor chamber. A first solenoid valve and a second solenoid valve are arranged on the outer wall of the material loading and unloading chamber, a third solenoid valve and a fourth solenoid valve are arranged on the outer wall of the vacuum high-pressure gas quenching cooling chamber, and a fifth solenoid valve and a sixth solenoid valve are arranged on the outer wall of the subzero chamber. A gas storage tank is connected with a liquid nitrogen valve through a second stop valve, connected with the vacuum high-pressure gas quenching cooling chamber through a first stop valve and the third solenoid valve, and connected with the subzero chamber through a check valve, an air compressor, a sucking pump and the sixth solenoid valve. The vacuum heat treatment and subzero treatment integrated machine has the advantages of saving device investment, reducing material consumption and improving the production rate and product quality.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Biochar preparation device and method for single-phase depressurization with nitrogen filling in batch mode

ActiveCN103215054BReduce carry-onPlay the role of carbon sequestration and emission reductionBiofuelsIndirect heating destructive distillationContinuous flowNitrogen gas

Owner:安徽徽粮生物科技有限公司

Auxiliary Mold Adjustment System and Mold Adjustment Method for Vertical Squeeze Casting Machine

The invention discloses an auxiliary die adjusting system of a vertical type extrusion casting machine and relates to the technical field of casting machines. The auxiliary die adjusting system comprises a nitrogen gas cylinder and a tail board. Two sides of the tail board are respectively provided with one auxiliary die adjusting cylinder, piston rods of the auxiliary die adjusting cylinders are respectively connected with two sides of the tail board, each auxiliary die adjusting cylinder is divided into a front cavity and a rear cavity, the front cavities are communicated with a nitrogen gas cylinder pipe, the rear cavities are communicated with the atmosphere, and a high-pressure air valve is arranged on a pipe between the nitrogen gas cylinder and the front cavities. The auxiliary die adjusting system of the vertical type extrusion casting machine facilitates die adjustment, reduces abrasion of draglinks and threads of adjusting nuts and saves nitrogen gas.

Owner:SUZHOU SANJI FOUNDRY EQUIP

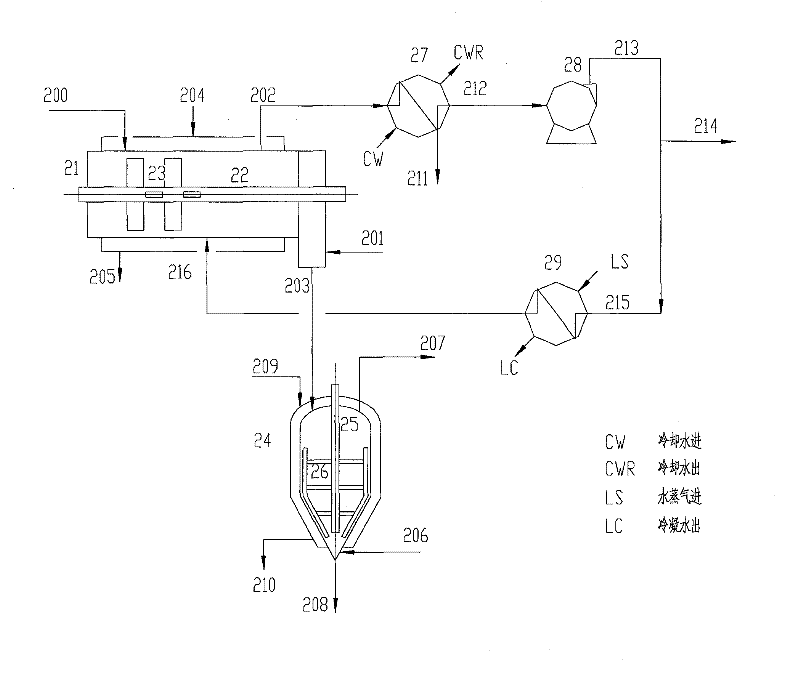

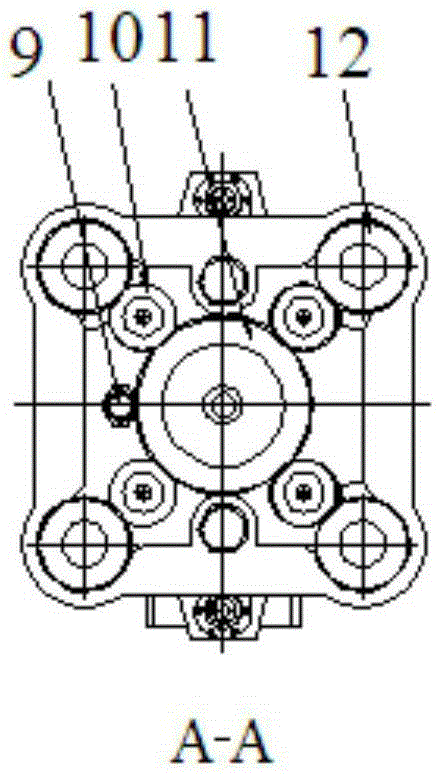

A Sulfur-tolerant Shift System for Coal-Making Gas that Can Improve the Cooling Efficiency of Shutdown and Start-up

ActiveCN108862195BAccelerate and adjust the cooling rateEasy to replaceHydrogenHydrogen/synthetic gas productionGas compressorProcess engineering

The invention discloses a coal-made gas sulfur-resistant shift system capable of improving the cooling efficiency of shutdown and start-up, comprising a circulating gas compressor, an electric heater, a shift furnace, a shift gas final cooler and an ammonia washing tower connected in series by pipelines. A shutdown water cooling device is installed at the outlet of the circulating gas compressor, and the shutdown water cooling device is connected in parallel with the pipeline between the circulating gas compressor and the electric heater. During shutdown, the high-temperature gas from the circulating gas compressor enters the shutdown water cooling device to be cooled. Water cooling; a start-up cooling water cooling device is set at the entrance of the shift gas final cooler, and the start-up cooling water cooling device is connected in parallel with the pipeline between the shift furnace and the shift gas final cooler, and the high-temperature gas from the shift furnace enters the start-up operation. The cooling water in the water cooling device is cooled to the normal operating temperature of the shift gas final cooler or below, and then enters the shift gas final cooler to prevent the impact of the ultra-high temperature circulating gas on the shift gas final cooler.

Owner:CHINA PETROLEUM & CHEM CORP

Nitrogen saving system based on BTU reflow furnace and control method thereof

The invention discloses a nitrogen saving system based on a BTU reflow oven and a control method thereof, the nitrogen saving system comprises a PLC control module, a flow valve and a touch screen display, the flow valve is arranged on a nitrogen pipeline to regulate and control the flow of nitrogen, and the PLC control module is respectively connected with the flow valve and the touch screen display to control and regulate the flow valve. According to the nitrogen saving system based on the BTU reflow furnace and the control method of the nitrogen saving system, two nitrogen saving modes are set in the system, so that during normal production, the first nitrogen saving mode is automatically triggered, 25% of nitrogen can be saved, and when no circuit board exists in the BTU due to abnormal production, the second nitrogen saving mode is automatically triggered, and 50 amp can be saved; the nitrogen conveying accuracy and efficiency are improved, the cost is reduced, and energy is saved.

Owner:FLEXTRONICS ELECTRONICS TECH SUZHOU

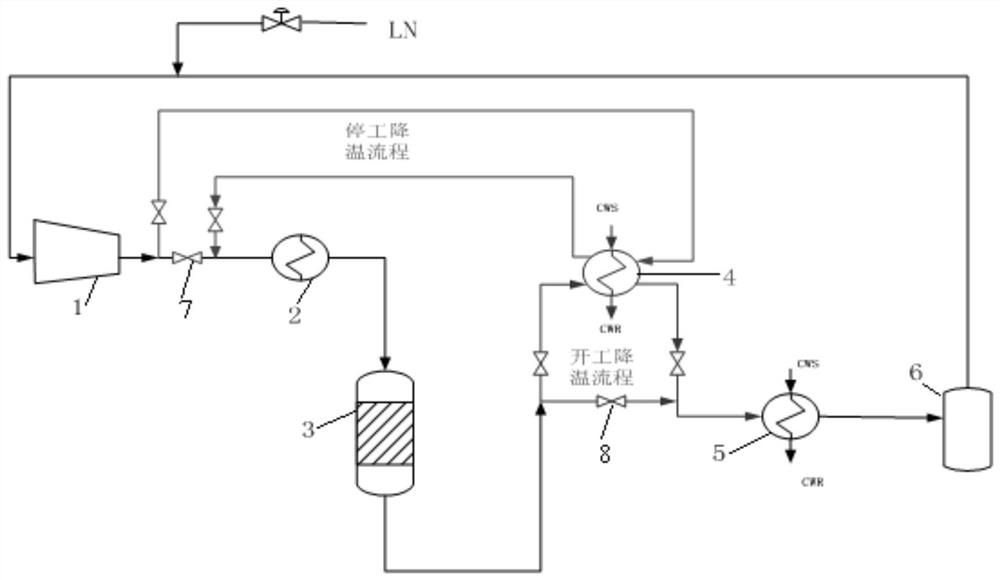

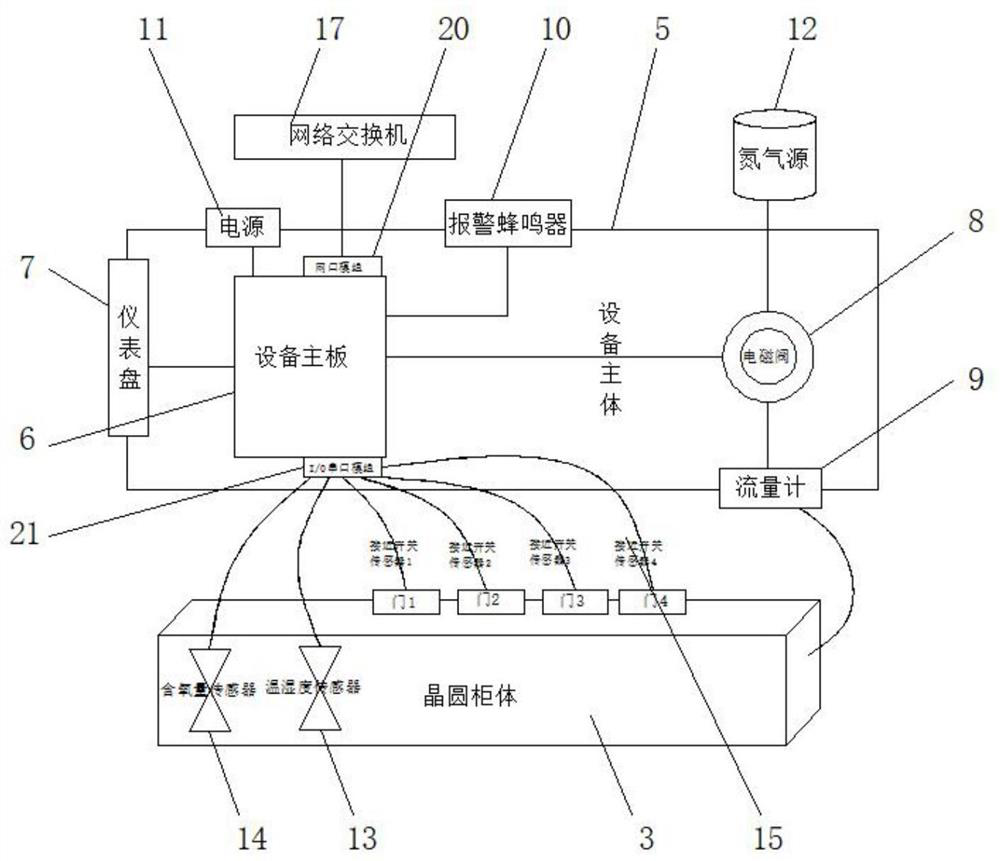

Semiconductor wafer storage environment intelligent control equipment

PendingCN112346502AEasy to detectEnsure safetySimultaneous control of multiple variablesThe InternetNitrogen gas

The invention discloses semiconductor wafer storage environment intelligent control equipment which comprises a server side, an operation side, a wafer cabinet body and control equipment installed onthe surface of the wafer cabinet body, the server side is connected with the operation side through the Internet, and the server side is connected with the control equipment through a cable. The control equipment comprises a shell, an equipment mainboard, an instrument panel, an electromagnetic valve, a flow meter, an alarm buzzer and a power supply, the input end of the electromagnetic valve is connected with a nitrogen source, the output end of the electromagnetic valve is communicated with the wafer cabinet body, and the flow meter is connected between the electromagnetic valve and the wafer cabinet body in series. The control equipment is further provided with a temperature and humidity sensor, an oxygen content sensor and a proximity switch sensor which are matched with data monitoring. The control equipment is arranged on the surface of the wafer cabinet body, so that various data in the wafer cabinet body can be conveniently and automatically detected, the problem of waste caused by continuously filling nitrogen into the wafer cabinet in the past is solved, and the wafer environment safety can be completely guaranteed under non-human factors.

Owner:南京苏芯科技有限公司

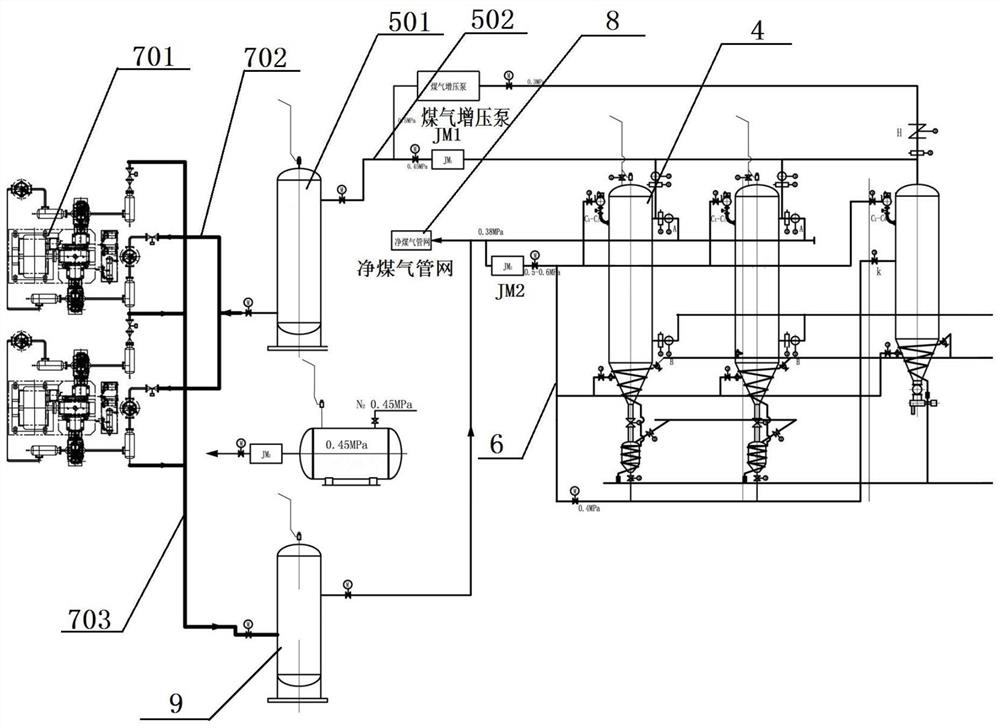

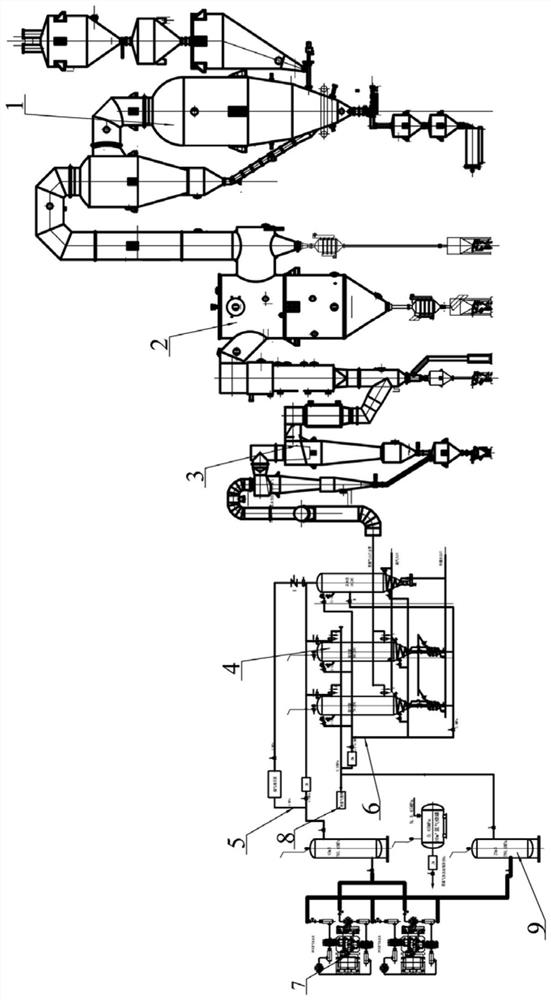

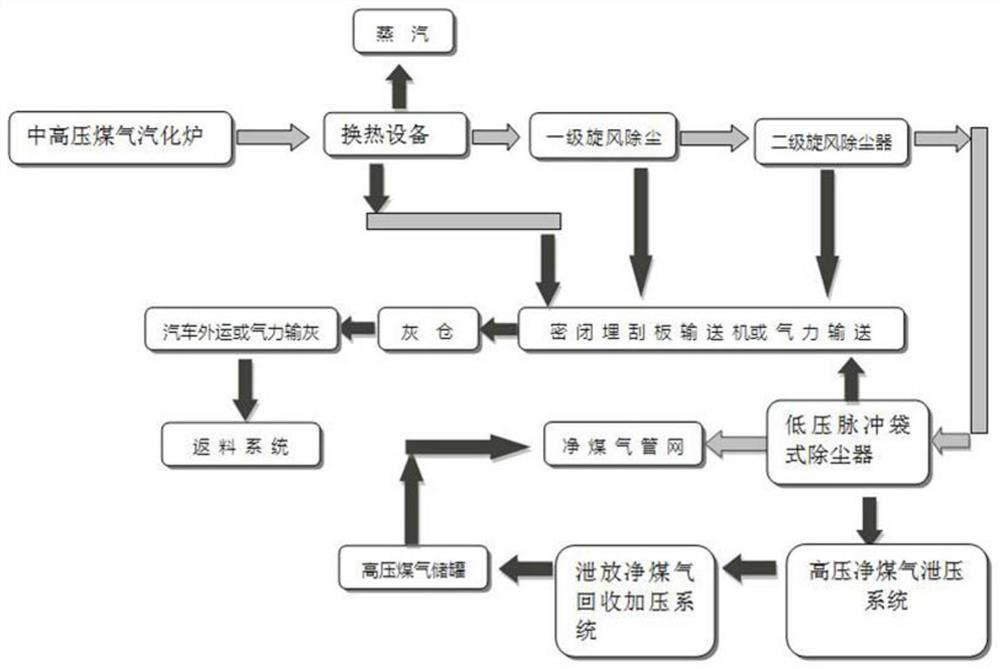

Coal gas pulse dry-process recovery and purification system and method for medium-high pressure gasification furnace

PendingCN114369478ASolve recycling difficultiesOvercome the technical problem that pulse cleaning cannot be usedGas dust removalThermodynamicsBaghouse

The invention relates to a pulse dry recovery and purification system and method for coal gas of a medium-high pressure gasification furnace, and the system comprises a medium-high pressure coal gas gasification furnace, heat exchange equipment, separation equipment, a dust removal system and a clean coal gas pipe network which are connected in sequence, and the dust removal system comprises a low-pressure pulse bag type dust remover and a depressurization clean coal gas reverse injection system; the low-pressure pulse bag type dust collector is used for filtering and purifying dust-containing coal gas into clean coal gas with the dust content of 5 mg / m < 3 > or below, and the depressurization clean coal gas reverse injection system is used for reducing the gas pressure in the low-pressure pulse bag type dust collector and then carrying out filter bag pulse dust collection; the depressurized clean gas reverse injection system comprises a high-pressure clean gas pressure relief system, a discharged clean gas recycling and pressurizing system, a high-pressure gas storage tank and a clean gas injection gas source pipeline with a pulse valve. The method has the advantages that the technical problem that pulse ash removal cannot be carried out on the medium-high pressure coal gas is solved, the problem that dry recovery of the coal gas of the medium-high pressure gasification furnace is difficult is solved, and the requirements of energy conservation, emission reduction and environmental protection policies are met.

Owner:HUANYU PURIFYING ENG EQUIP MFG DASHIQIAO CITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com