Industrial tail gas treatment multi-cycle adsorption tower

A technology of industrial tail gas and adsorption tower, applied in the direction of gas treatment, dispersed particle separation, membrane technology, etc., can solve problems such as fire hazards, air pollution, ammonia escape, etc., to improve flue gas treatment capacity, increase contact time, reduce The effect of footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

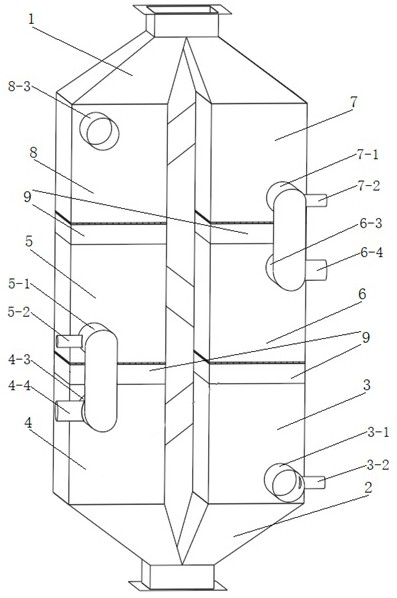

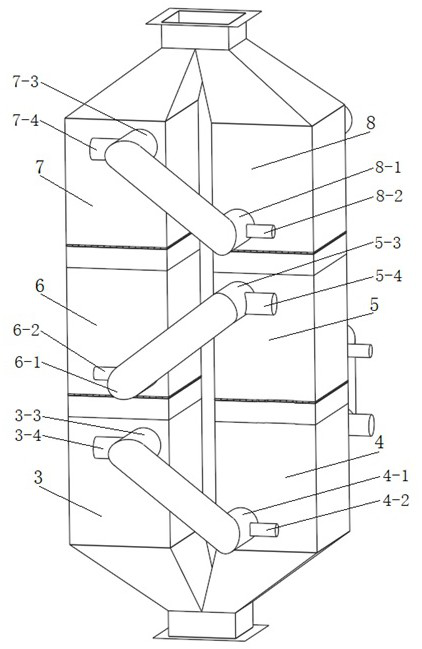

[0029] Such as figure 1 and figure 2 As shown, the industrial tail gas treatment multi-cycle adsorption tower of the present invention includes several tower bodies arranged side by side. In this embodiment, there are two tower bodies, and each tower body is sequentially provided with active coke feeding sections 1. The flue gas purification section and the active coke discharge section 2; there are three flue gas purification sections in each tower body, and the three flue gas purification sections are set up and down, and a transitional sealing section is provided between adjacent flue gas purification sections 9.

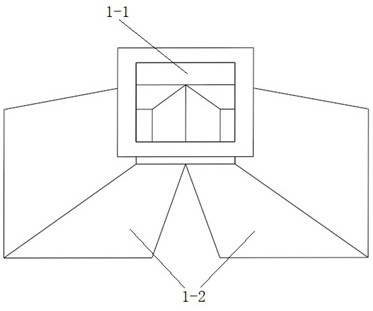

[0030] Such as image 3 As shown, the active coke feed section 1 is composed of the feed straight section 1-1 and the feed cone section 1-2, and the upper and lower ends of the feed cone section 1-2 are respectively connected with the feed straight section 1-1 and a flue gas The purification section, and the cross-section gradually increases from top to botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com