Double-layer flap valve blanking system

A flap valve, double-layer technology, applied in the direction of the lift valve, valve details, valve device, etc., can solve the problems of general sealing effect, easy wear of the flap, large gas consumption, etc., to reduce the maintenance workload and achieve good sealing effect , Improve the effect of gas recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

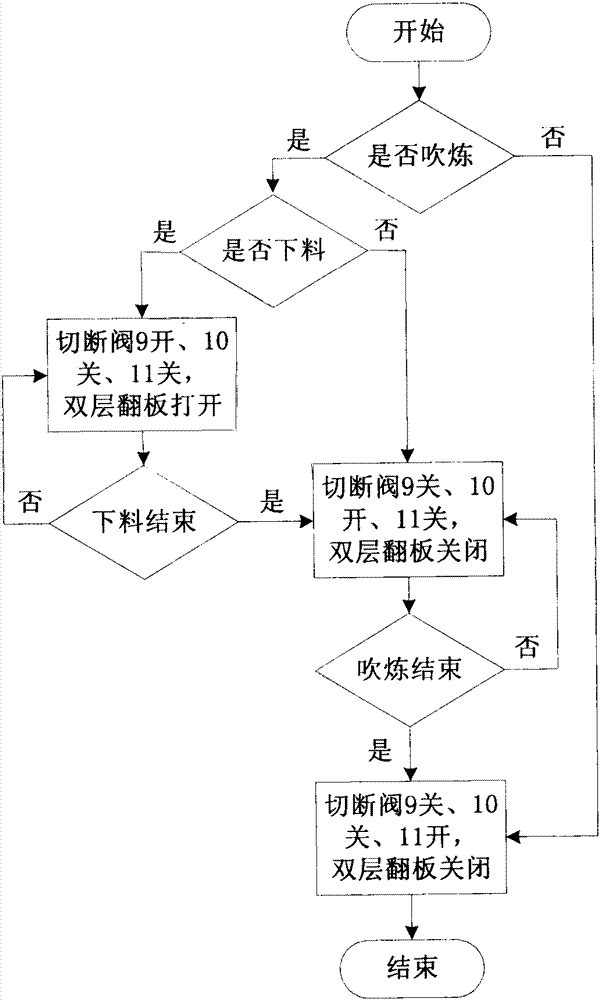

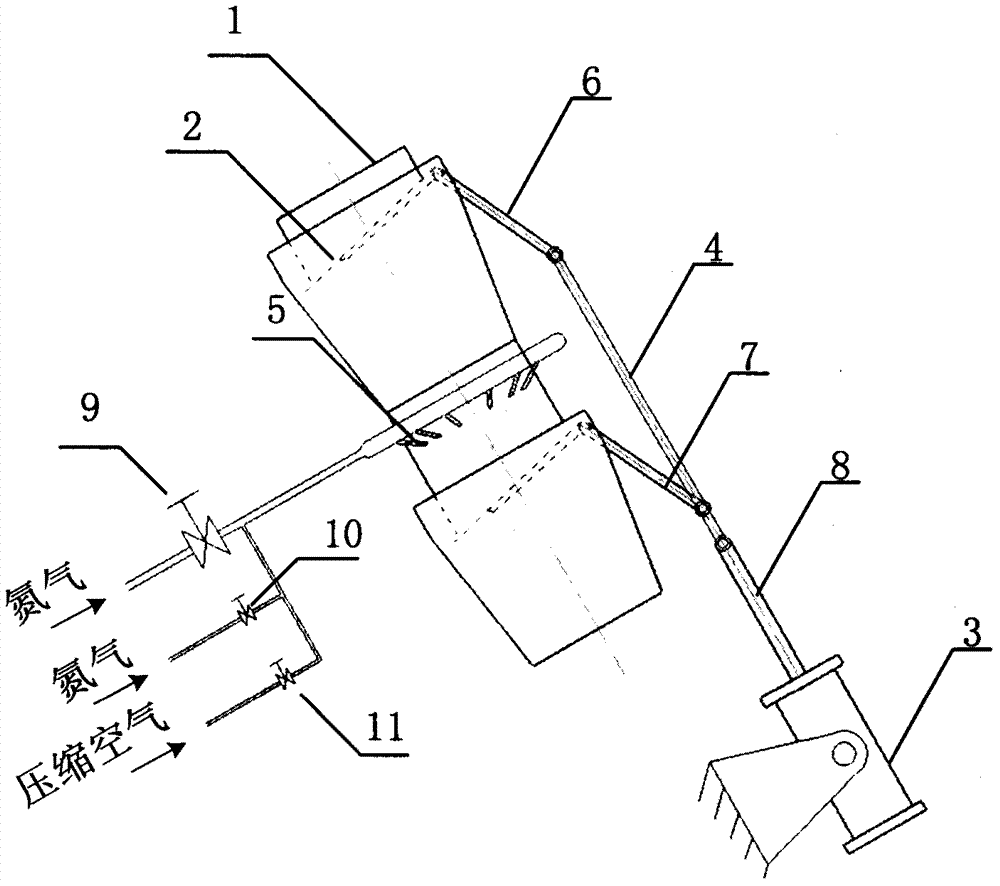

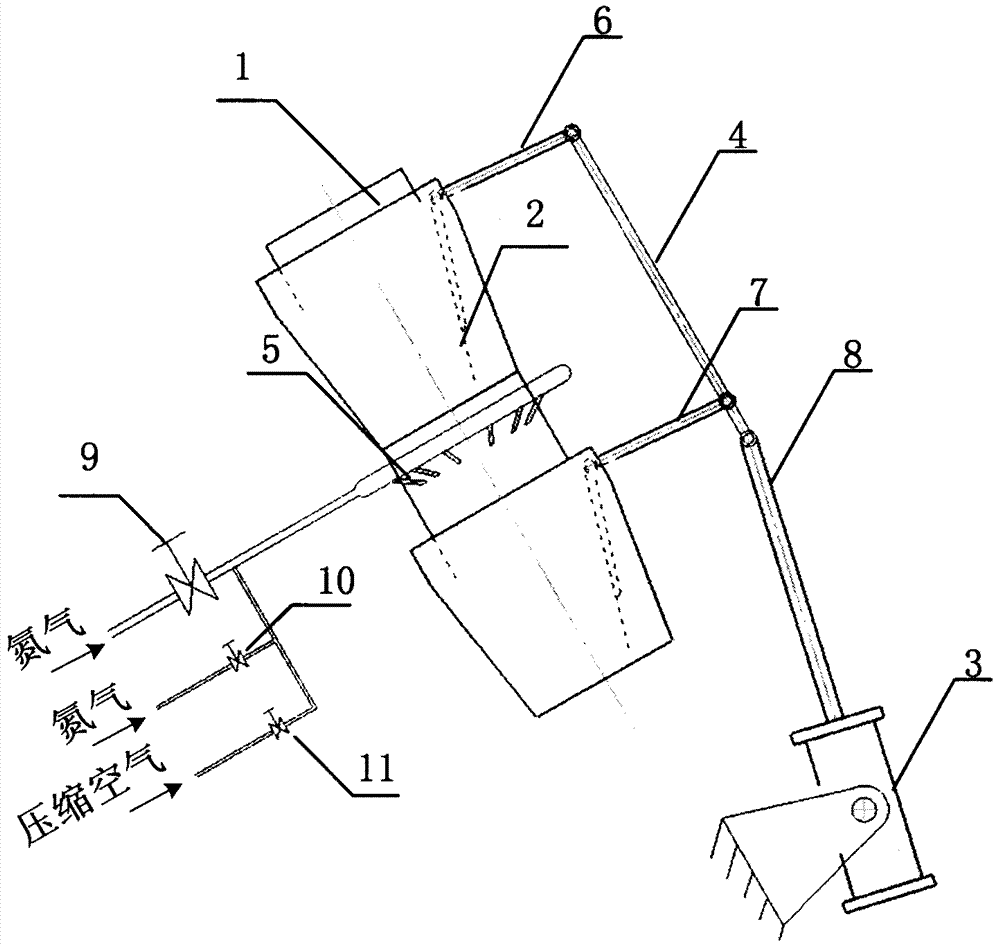

[0019] Example: such as figure 1 , 2 As shown, during the feeding process of the double-layer flap valve feeding system, the double-layer flap (2) is closed and opened, and the cut-off valves (9), (10), and (11) control the gas inflow. Combining the three modes of blowing blanking, blowing without blanking, and non-blowing in the steelmaking process, the cut-off valves (9), (10), (11) switches and double-layer flaps (2) are turned over by PLC control to realize A sealing method that matches the three patterns. to combine image 3 The PLC control flow chart of the double-layer flap valve feeding system illustrates the working process of the three modes.

[0020] In the stage of blowing and unloading, the system sends out a blanking signal, the PLC controls the opening of the shut-off valve (9), the shut-off valve (10) is closed, the shut-off valve (11) is closed, and the double-layer flap (2) is opened. After a delay of several seconds The purpose is to ensure that the mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com