Method for processing methyl iodide-contained combustible gas discharged into torch system by carbonylation compounding device

A technology of a torch system and a treatment method, which is applied in the field of methyl iodide wastewater discharged from the torch of a carbonylation synthesis unit, and can solve problems such as strong toxicity of methyl iodide, low boiling point at normal pressure, and large nitrogen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

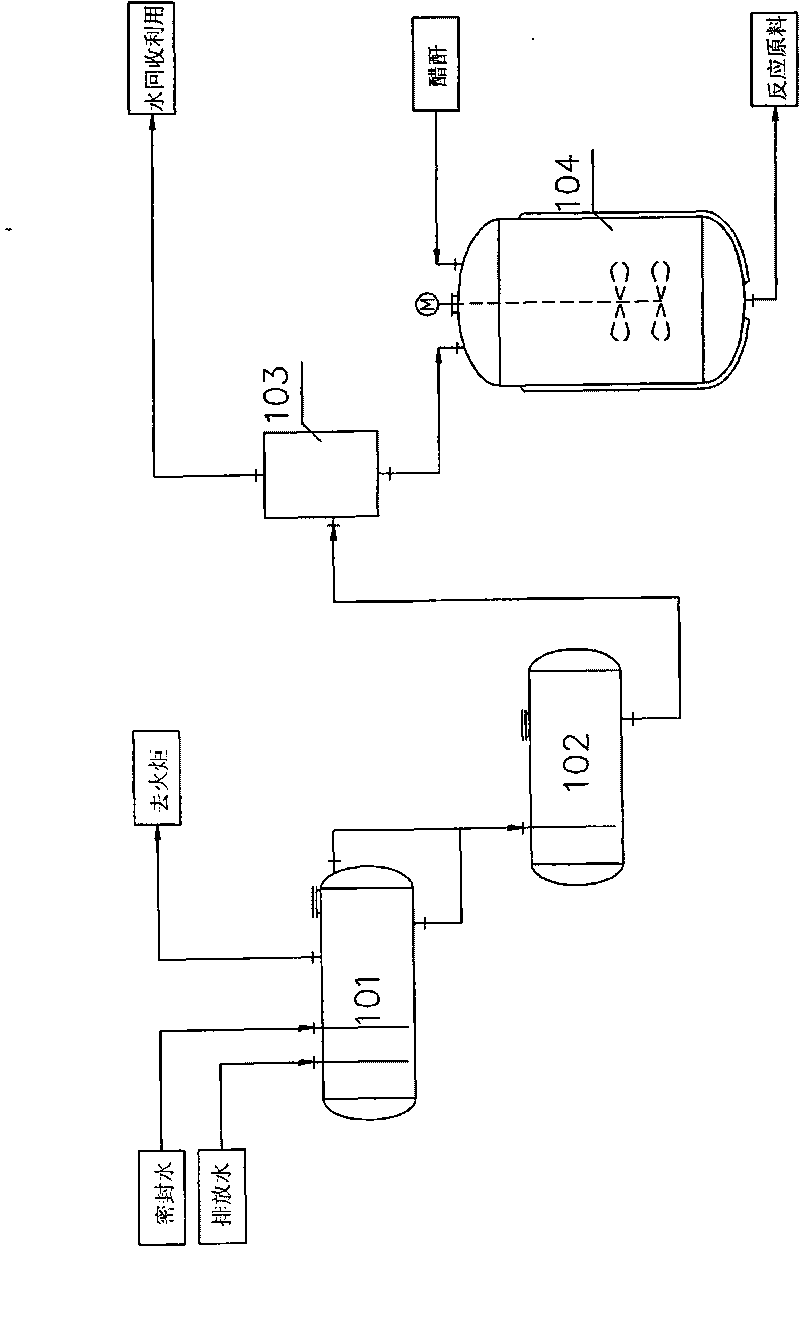

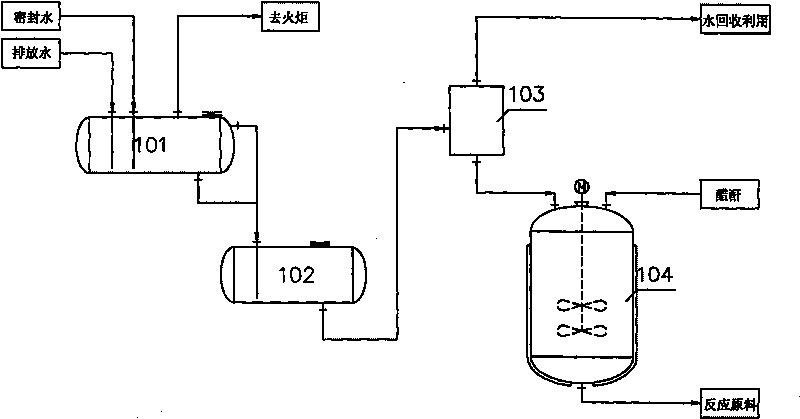

[0017] The treatment system for the combustible gas containing methyl iodide discharged into the flare system from the carbonylation synthesis unit is as follows: figure 1 Shown, comprise water sealing tank 101, sewage collection tank 102, membrane thickening device 103 and batching kettle 104, the sewage outlet of water sealing tank communicates with the inlet of sewage collecting tank, the outlet of sewage collecting tank communicates with the entrance of membrane concentrating device, The concentrated solution outlet of the membrane concentrating device communicates with the inlet of the reaction kettle. The water-sealed tank is also provided with a gas inlet and a gas outlet leading to the torch system; the reaction kettle is provided with an acetic anhydride inlet.

[0018] The amount of combustible gas containing methyl iodide discharged into the flare system from the carbonylation unit is 2500Nm 3 / h, which contains 0.04-0.2% mol of methyl iodide, 4.7-7.8% mol of methy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com