Coloring and curing mechanism of optical fiber coloring machine

An optical fiber and curing furnace technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of wasting nitrogen, experts are handicapped, waste, etc., and achieve the effect of improving coloring speed, ensuring processing efficiency, and saving nitrogen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

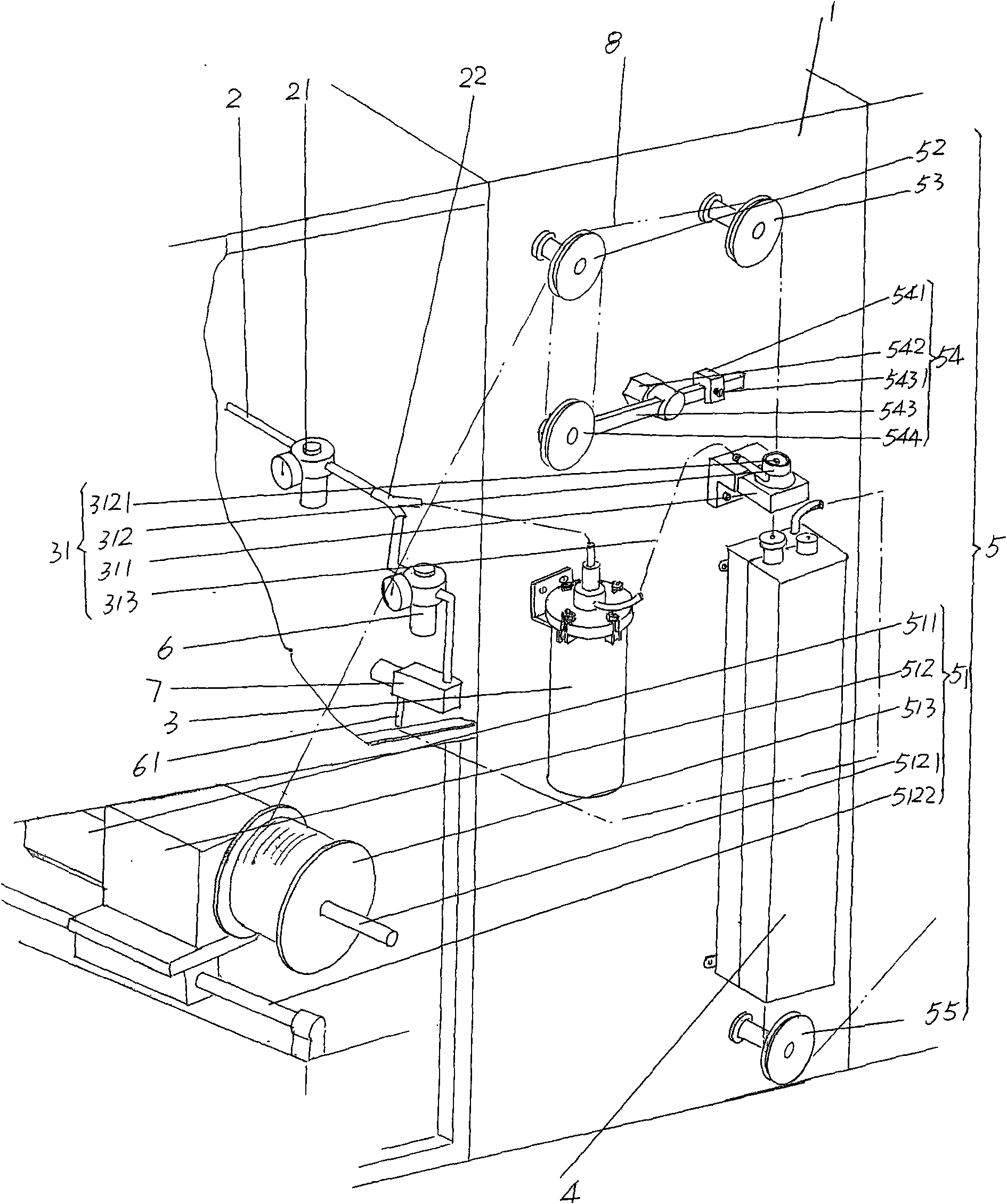

[0019] Please refer to the accompanying drawings, which shows a frame box 1 of an optical fiber coloring machine. The coloring and curing mechanism of the present invention uses the frame box 1 as a carrier, that is, is installed on the frame box 1 . The structure of the preferred coloring and curing mechanism is as follows: one end is connected with the nitrogen source and the other end is connected with the ink tank 3 and the curing furnace 4. The nitrogen inlet pipe 2 is laid on the frame box body 1, as shown in the accompanying drawings, in There is a first pressure regulating valve 21 connected to the pipeline of the nitrogen gas inlet pipe 2, and the first pressure regulating valve 21 can also be called a flow regulating valve (hereinafter the same). As a technical point of the present invention, a three-way interface 22 is fitted on the pipeline at one end of the gas outlet of the nitrogen gas inlet pipe 2 (also can be called the gas outlet side), and one of the interfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com