Device for recovering Nd-Fe-B magnetic powder

A recovery device, NdFeB technology, applied in the field of NdFeB sintering molding process equipment, can solve the problems of easy oxidation of NdFeB magnetic powder, influence of magnetic properties, easy scrapping of products, etc., to achieve convenient and fast manual operation and prevent oxidation , the effect of saving nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

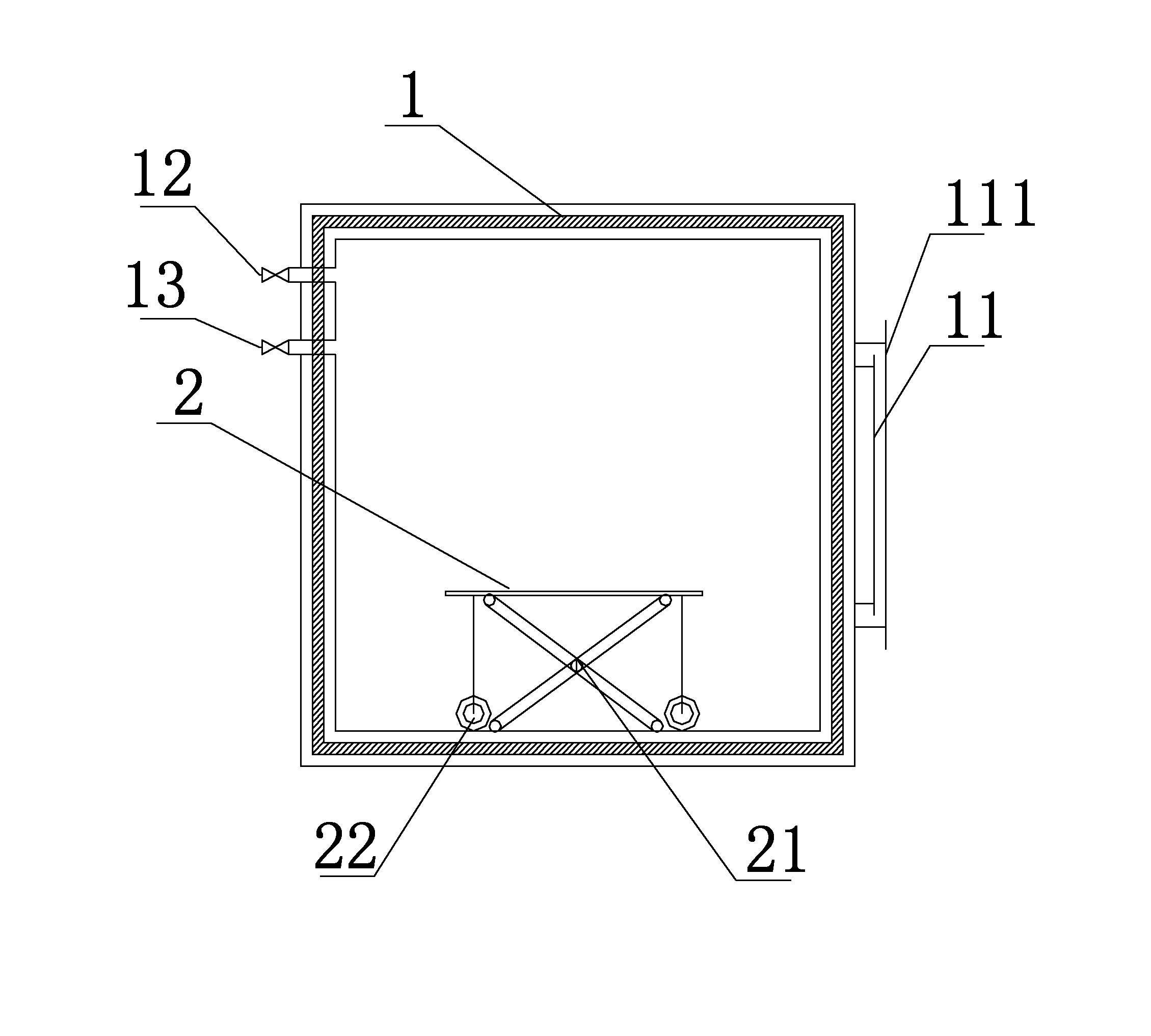

[0018] Please also refer to figure 1 , as shown in the figure, the embodiment of the recovery device of NdFeB magnetic powder of the present invention includes a vacuum box 1, an object stage 2 and a box support;

[0019] The vacuum box 1 is installed and fixed on the box body support, and the object table 2 is arranged in the vacuum box 1, and the oxygen isolation of the objects on the object table 2 is realized through the vacuum box 1, and the vacuum box 1 is provided with a material inlet and outlet Port 11, air inlet 12 and vacuum port 13, the inlet and outlet 11 is opened and closed through the airtight door 111, one end of the airtight door 111 is hinged with the vacuum box 1, and is opened and sealed through the hinge, the air inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com