A Sulfur-tolerant Shift System for Coal-Making Gas that Can Improve the Cooling Efficiency of Shutdown and Start-up

A technology for sulfur-resistant shift and gas generation, which is applied in hydrogen/syngas production, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of low cooling efficiency, large nitrogen consumption, affecting long-term operation of the device, etc. The effect of shock, saving nitrogen and avoiding damage to equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

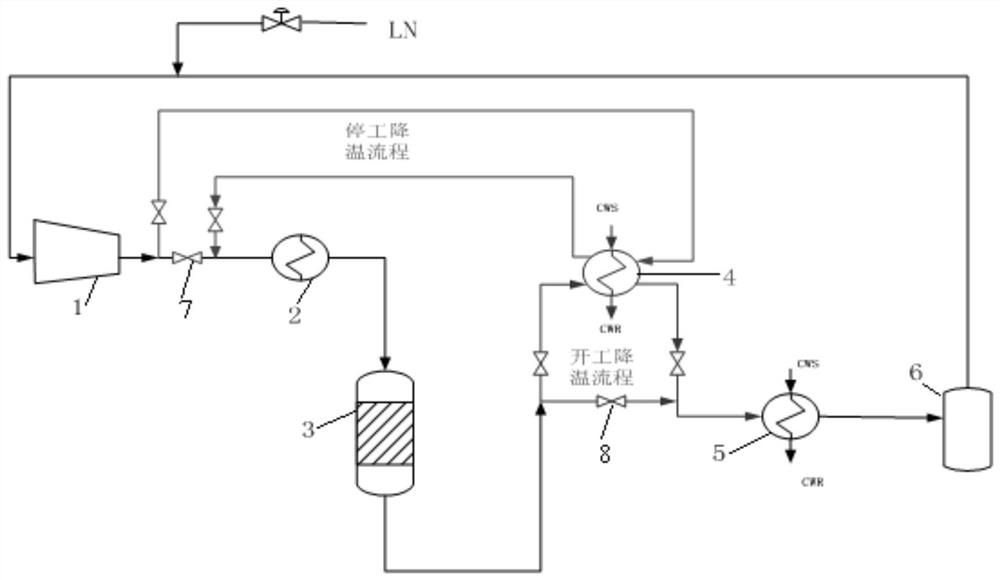

[0012] figure 1 It is an embodiment of the present invention that the coal gas-to-sulfur-resistant shift system that can improve the cooling efficiency of shutdown and start-up includes a circulating gas compressor 1, an electric heater 2, a shift furnace 3, a shift gas final Cooler 5 and ammonia washing tower 6. The top outlet of the ammonia washing tower 6 is connected with the air inlet of the circulating compressor 1 through a connecting pipeline, and the connecting pipeline is connected with the nitrogen delivery pipe. A first gas valve 7 is provided between the circulating gas compressor 1 and the electric heater 2 , and a second gas valve 8 is provided between the shift furnace 3 and the shift gas final cooler 5 . A shutdown water cooling device is installed at the outlet of the circulating gas compressor 1. The shutdown water cooling device is connected in parallel with the pipeline between the circulating gas compressor 1 and the electric heater 2. During shutdown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com