Nitrogen sealing device for auxiliary material and control method for nitrogen sealing of auxiliary material

A technology of auxiliary raw materials and nitrogen sealing, applied in the direction of manufacturing converters, etc., can solve the problems of single control method of nitrogen sealing device, increase the production cost of enterprises, and cannot be adjusted in real time, so as to reduce the risk assessment results of hazardous sources, improve work efficiency, The effect of saving nitrogen usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

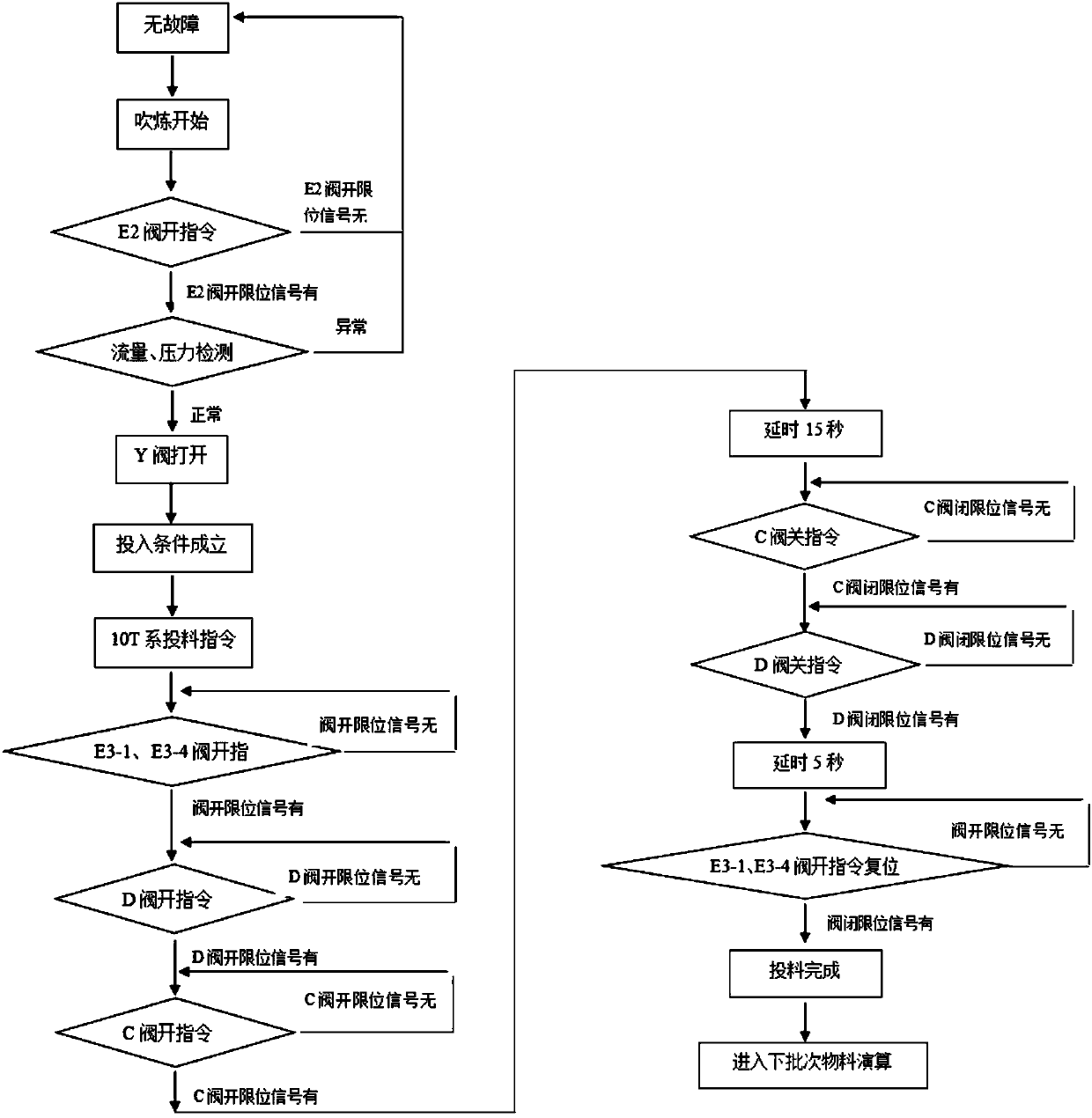

[0031] In order to make the content and advantages of the technical solution of the present invention more clear, the present invention will be further described below in conjunction with the accompanying drawings.

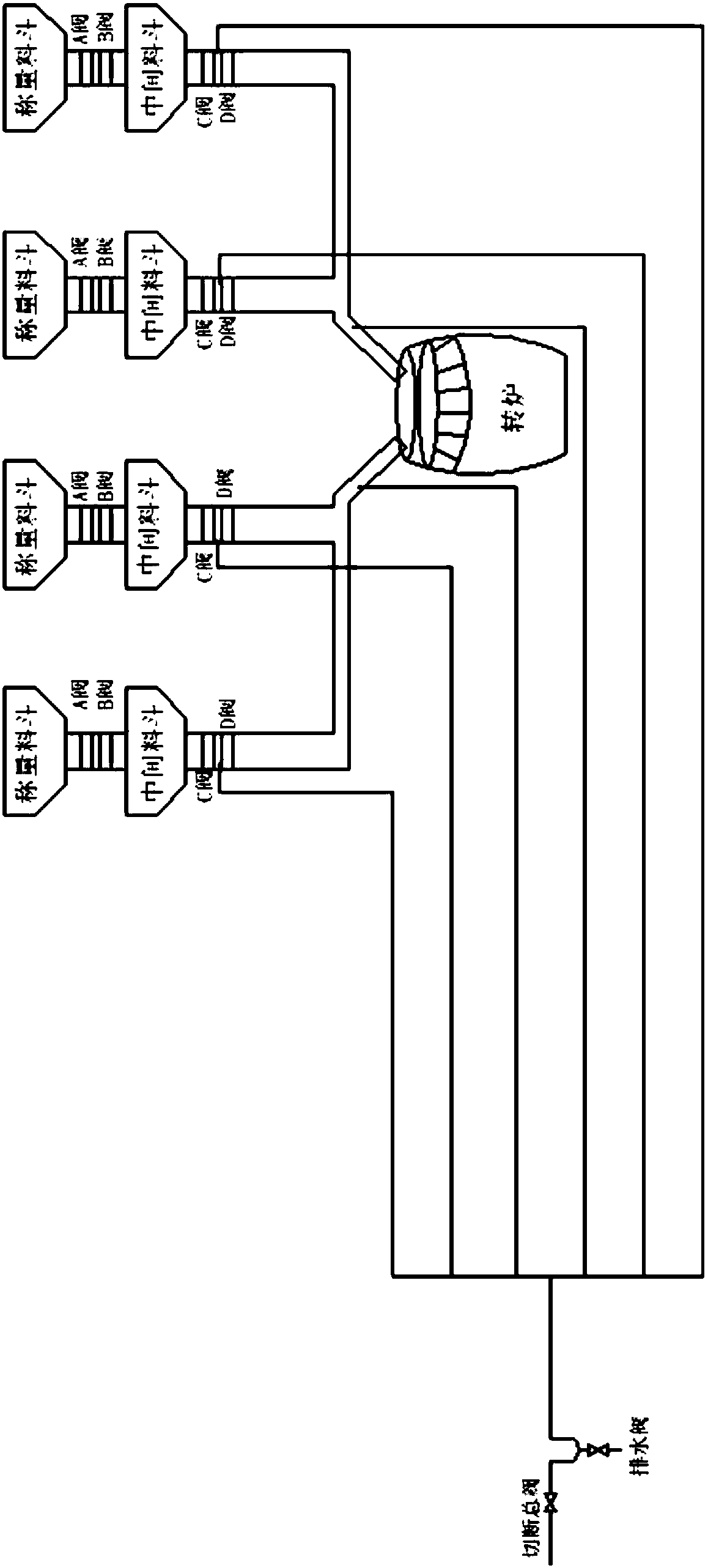

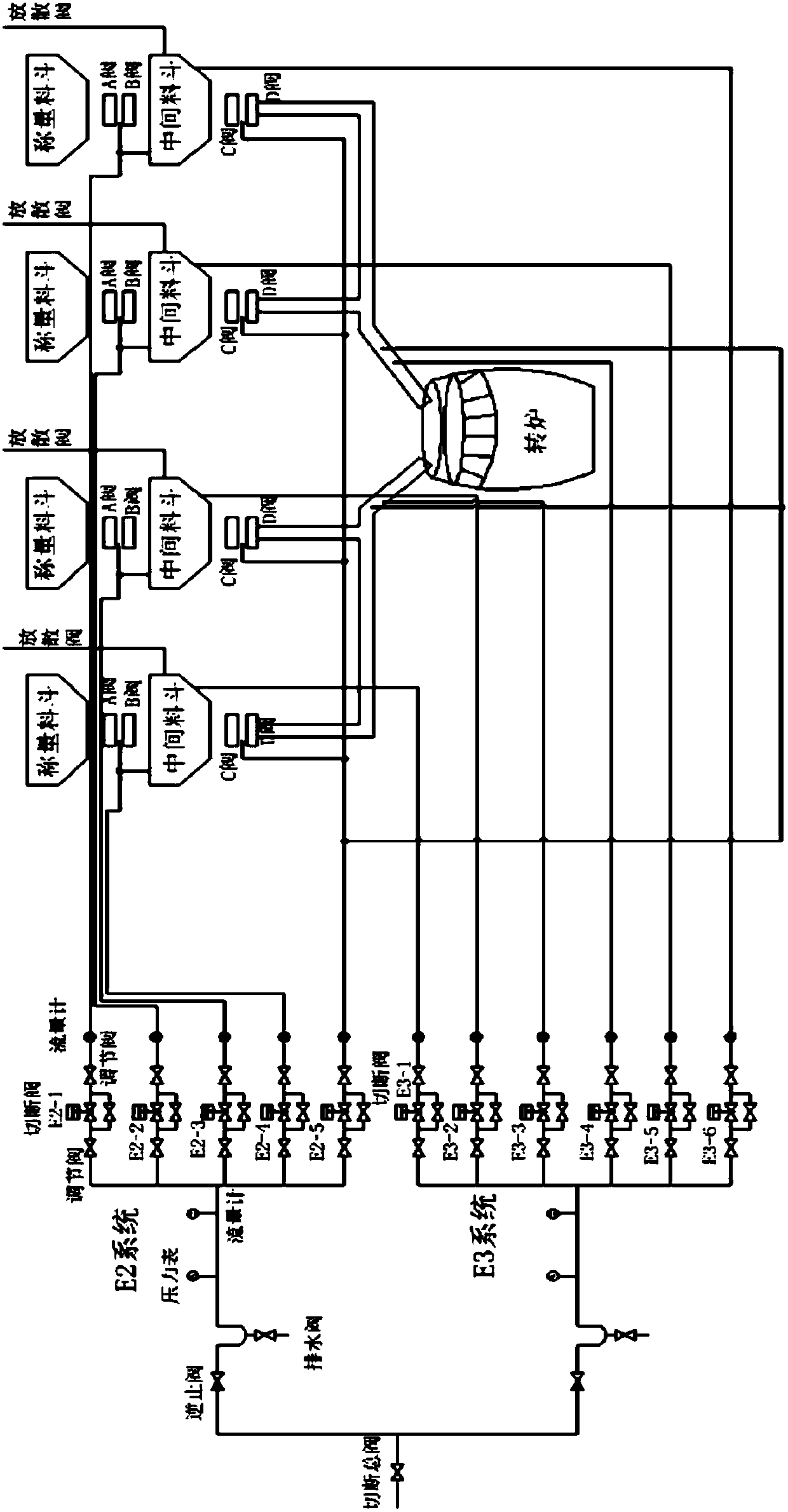

[0032] combine figure 2 , a nitrogen blanketing device for auxiliary raw materials, including a converter, 4 weighing hoppers, 4 intermediate hoppers, and a main intake pipe. The weighing hopper is connected to the middle hopper through the A valve and the B valve, the middle hopper is connected to the converter through the C valve and the D valve through the feeding pipe, and the intake main pipe is connected through the main cut-off valve. It also includes the anti-sound and explosion nitrogen sealing E2 system of the intermediate silo, the nitrogen sealing E3 system of the auxiliary raw material feeding pipeline, and the main cut-off valve is respectively connected with the anti-sound and explosion nitrogen sealing of the intermediate silo through the check va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com