Coal gas pulse dry-process recovery and purification system and method for medium-high pressure gasification furnace

A purification system and dry recovery technology, applied in combustible gas purification, combustible gas purification/transformation, gas dust removal, etc., can solve the problem of impossibility of pulse cleaning, achieve excellent dust removal and recovery effect, realize energy recovery and utilization, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

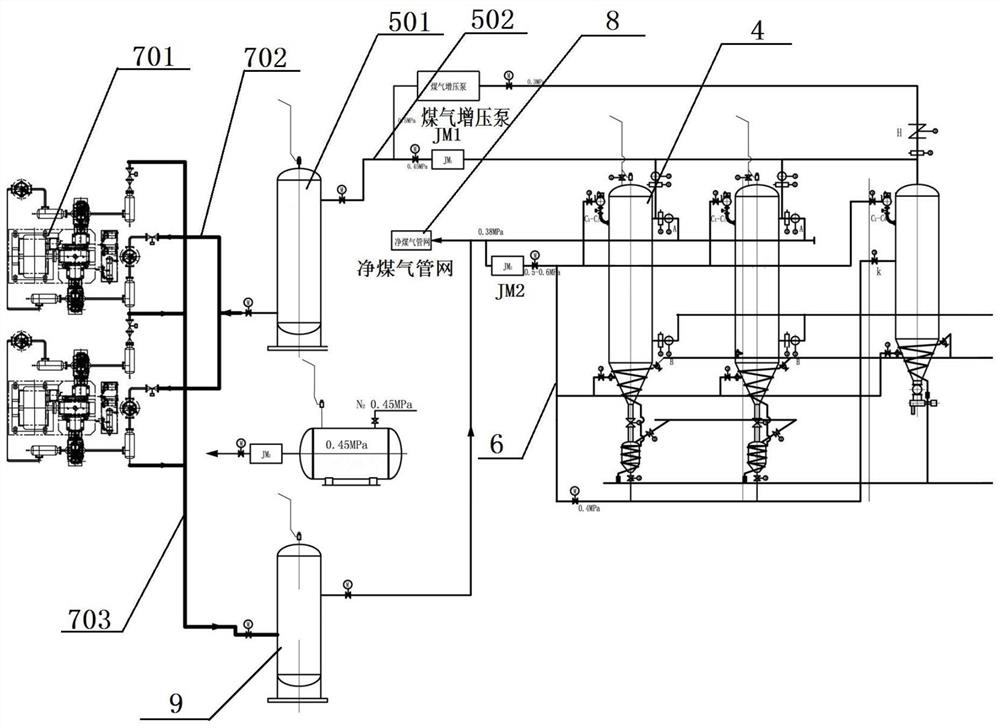

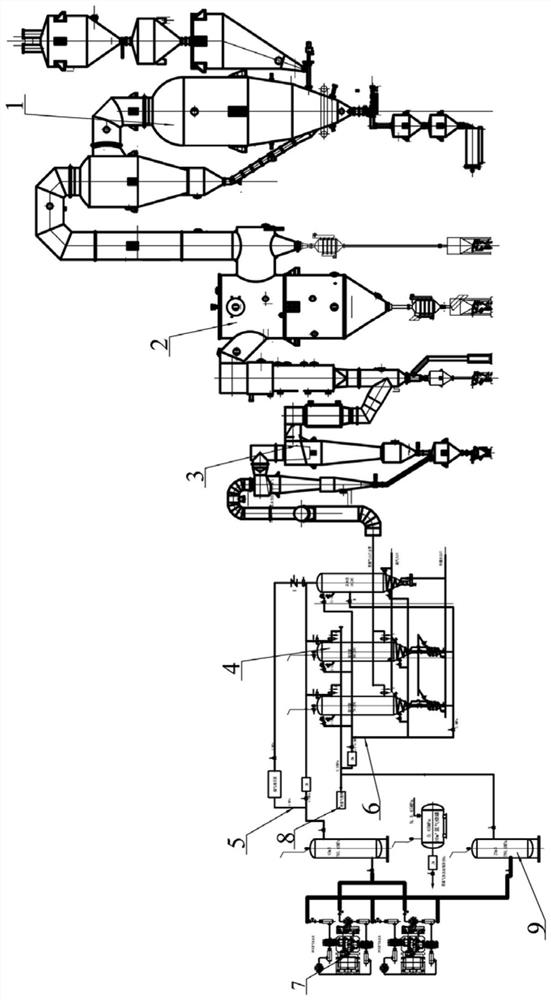

[0035] Figure 1-2 A schematic diagram of the overall structure according to an embodiment of the present invention is shown.

[0036] Such as Figure 1-2 As shown, the medium and high pressure gasification furnace gas pulse dry recovery and purification system provided by the embodiment of the present invention includes: a medium and high pressure gasification furnace 1, heat exchange equipment 2, separation equipment 3, dust removal system and clean gas pipeline network 8 connected in sequence , the dust removal system includes: a low-pressure pulse bag filter 4 and a depressurized clean gas back-injection system, the low-pressure pulse bag filter 4 is used to filter and purify the dusty gas to a dust content of 5 mg / m 3 The following clean gas, the depressurized clean gas reverse injection system is used to reduce the gas pressure in the low-pressure pulse bag filter 4 to perform filter bag pulse dust removal, and the inlet valve of the low-pressure pulse bag filter 4 is c...

Embodiment 2

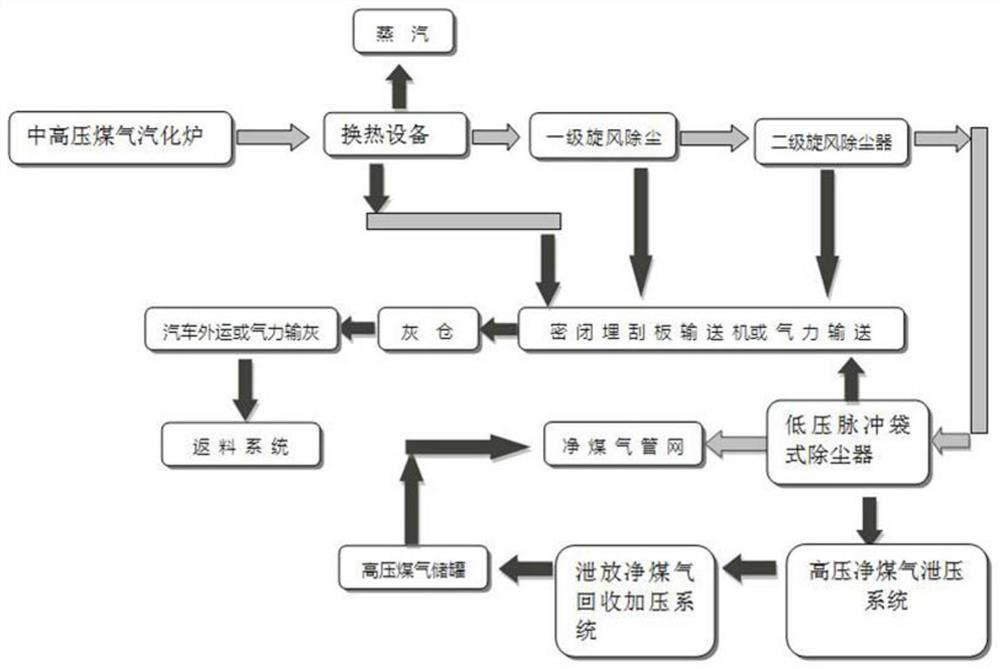

[0042] image 3 A flow chart of the overall structure according to the embodiment of the present invention is shown.

[0043] This embodiment provides a medium and high pressure vaporizer gas pulse dry recovery and purification method, which specifically includes the following steps:

[0044] Step S1: converting coal into gas by using a medium-high pressure gasification furnace 1;

[0045] Step S2: Use the heat exchange equipment 2 to exchange heat and cool down the high-temperature dusty gas generated by the gas vaporizer. The temperature of the gas after heat exchange by the heat exchange equipment 2 is about 250°C. Return to medium and high pressure gasification furnace 1;

[0046] Step S3: Utilize the separation device 3 to carry out rough dust removal:

[0047] Step S31: The dust-laden gas naturally settles down due to gravity, and the large-grained dust is cooled and recovered by the ash cooler, and then sent to the return system;

[0048] Step S32: The remaining gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com