Semiconductor wafer storage environment intelligent control equipment

A technology of intelligent control and control equipment, which is applied in the direction of control/adjustment system, non-electric variable control, and simultaneous control of multiple variables, etc. It can solve the problems of inconvenient staff management and difficult control of semiconductor wafer storage environment, etc. Achieve the effect of saving personnel costs, improving inspection efficiency, and facilitating inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

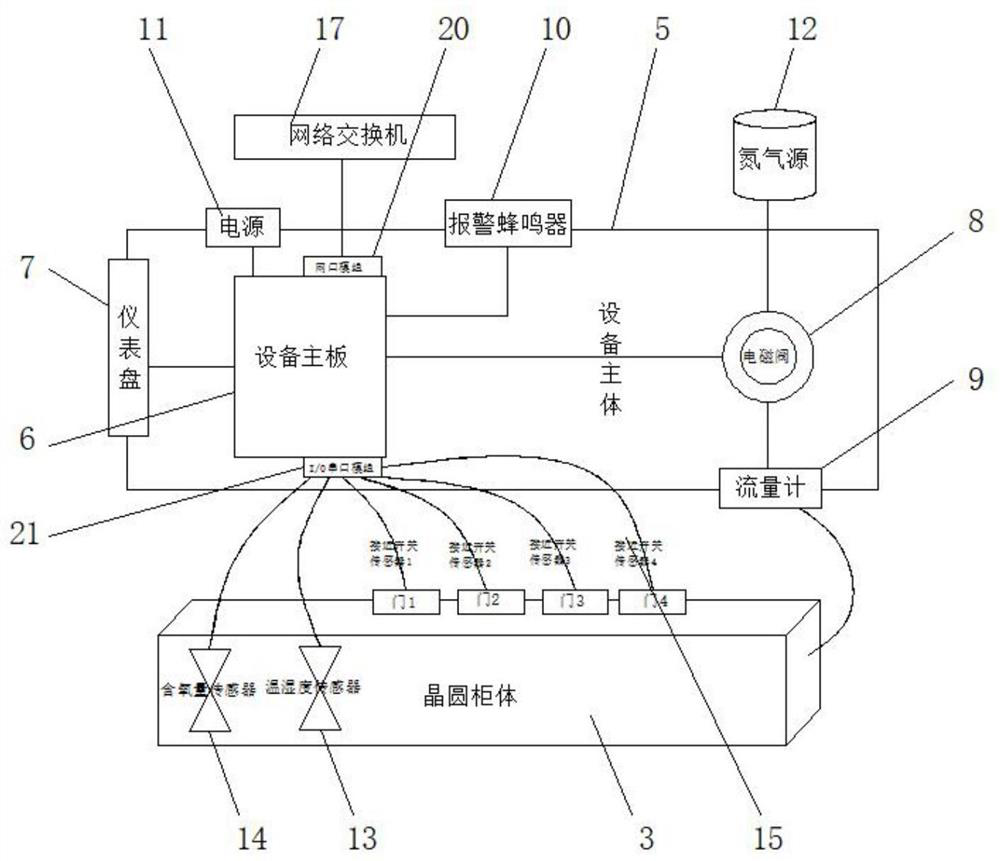

[0032]When the present invention is working, the control device 4 is fixedly connected to the surface of the wafer cabinet 3, the temperature and humidity sensor 13 and the oxygen content sensor 14 are fixedly installed inside the wafer cabinet 3, and the proximity switch sensor 15 is installed on the wafer cabinet 3. At the cabinet door of the round cabinet body 3, the cables of the temperature and humidity sensor 13, the oxygen content sensor 14 and the proximity switch sensor 15 are plugged and connected to the I / O serial port module on the surface of the equipment mainboard 6, and the input terminal of the solenoid valve 8 Connect with the nitrogen source, connect the output end of the flowmeter 9 with the wafer cabinet 3, and complete the installation of the control device 4. The power supply 11 supplies power to the control device 4. The prefabricated program is executed in the device main board 6 to control the wafer. The internal state of the cabinet 3 is monitored in r...

Embodiment 2

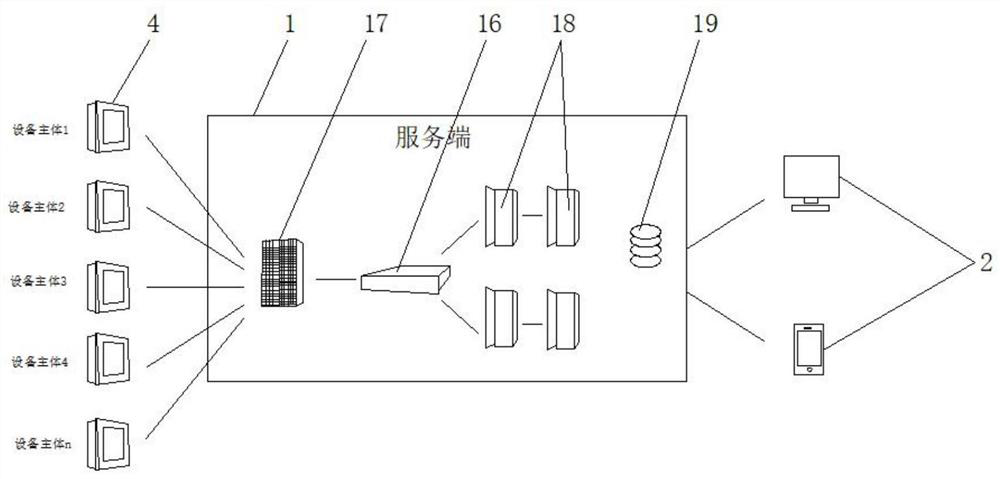

[0034] When the present invention controls a large number of wafer cabinets 3, a network cable is used to connect the network port module on the surface of the main board 6 of the device, and the other end is connected to the network switch 17 of the service end 1 in the factory, and each individual control device 4 passes through the socket The long-connection communication method uploads the monitoring data to the server 1, and the server 16 organizes and analyzes the data and stores them in the database 18. The factory equipment maintenance personnel can directly open the client 19 on the office computer to check the equipment status and remotely control it, which is greatly improved. Improve inspection efficiency and save personnel costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com