Biochar preparation device and method for single-phase depressurization with nitrogen filling in batch mode

A preparation device and biochar technology, applied in the field of environmental engineering, can solve the problems of large nitrogen consumption and nitrogen consumption, and achieve the effects of low cost, reduced consumption, simple operation and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

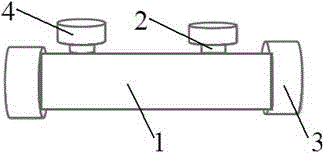

[0034] The structural representation of the biochar preparation device of this embodiment is as follows: figure 1 As shown, it includes a container 1, a protruding opening 2 provided on the top of the container, an end cap 3 and a cover 4 provided at both ends of the container; the container can be designed into different volumes and shapes, depending on the needs of the production scale. The cover 3 is opened, and the biomass raw material can be filled into the container 1 in batches or continuously. Afterwards, the end cover 3 is closed to make it tightly sealed and isolated from the outside air.

[0035] Nitrogen is charged from one of the protruding openings 2, and the air is discharged from the other protruding opening 2. The process of nitrogen filling lasts for more than a certain period of time, so that the air in the container can be fully discharged, and then the convex is closed with a cover 4. Cover the opening 2, put it in a heating device to raise the temperature...

Embodiment 2

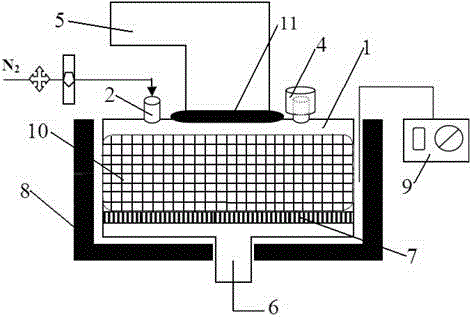

[0038]Take rice straw from the farms around Shanghai, crush it until the particle size is less than 2cm, put the material in a cylindrical iron container with a volume of 4L, and fill it with nitrogen gas from one of the protruding small holes with a diameter of 1cm. After filling the nitrogen gas for 10 minutes, measure the oxygen content in the container with a portable oxygen meter (CYS-1) to be 3%, and the system is in an oxygen-free environment. Put two small iron lids with a diameter of 1.3cm on the small holes, and place the container in a heating device at 18°C min -1 The temperature was raised to 350°C and 500°C respectively, and kept for 4h, then cooled to room temperature, the biochar was taken out, weighed, and the yield of biochar was calculated to be 48.9% and 35.1% at the two temperatures, respectively, and the product was not collected. to liquid bio-oil. And the biochar is black without ashing components, which proves that the carbonization is carried out i...

Embodiment 3

[0040] Take cow dung from a farm in Baoshan District, Shanghai, air-dry it, and crush it to a particle size of 1-3mm. Nitrogen was charged for 8 minutes. After the nitrogen was filled, the oxygen content in the container was measured with a portable oxygen meter (CYS-1) to be 4%, and the system was in a near anaerobic environment. Put two small iron lids with a diameter of 1.3cm on the small holes, and place the container in a heating device at 18°C min -1 The temperature was raised to 350°C and 500°C respectively, and kept for 2h, then cooled to room temperature, the biochar was taken out, weighed, and the yield of biochar was calculated to be 68.9% and 60.2% at the two temperatures, respectively, and the product was not collected. to liquid bio-oil. And the biochar is black without ashing components, which proves that the carbonization is carried out in an oxygen-free environment. According to the volume of the container, nitrogen gas is continuously passed 0.5L·min -1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com