A Cyclone Separator for Circulating Fluidized Bed Boiler with Inclined Air Inlet Section of Central Tube

A cyclone separator and circulating fluidized bed technology, which is applied in the directions of fluidized bed combustion equipment, fuel burning in a molten state, lighting and heating equipment, etc. The probability of cylinders, the effect of promoting separation, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

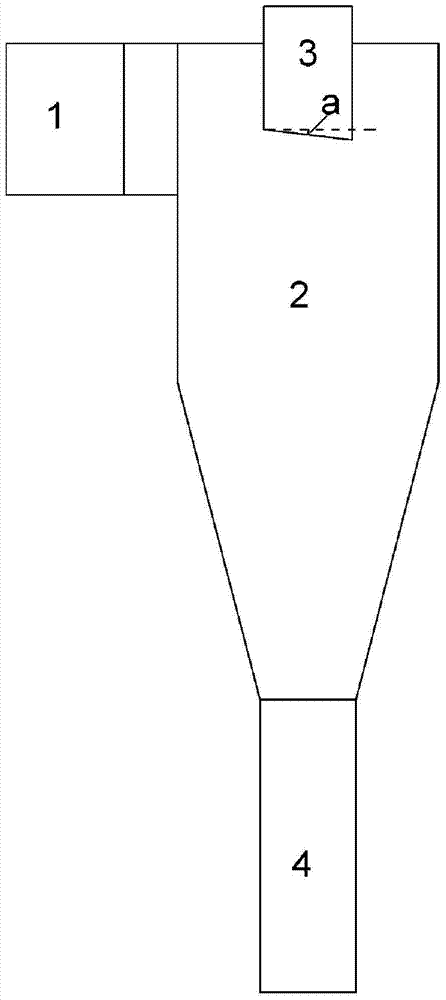

[0043] see figure 1 , figure 2 , a cyclone separator with an inclined central cylinder air inlet, comprising a tapered inlet flue 1, a cyclone separator body 2, a central cylinder 3, and a separator standpipe 4. Wherein, the tapered inlet flue 1 is connected to the side of the separator body 2, the lower part of the separator body 2 is connected to the upper part of the separator standpipe 4, and the central cylinder 3 is inserted into the separator body 2 from the upper part of the separator body 2.

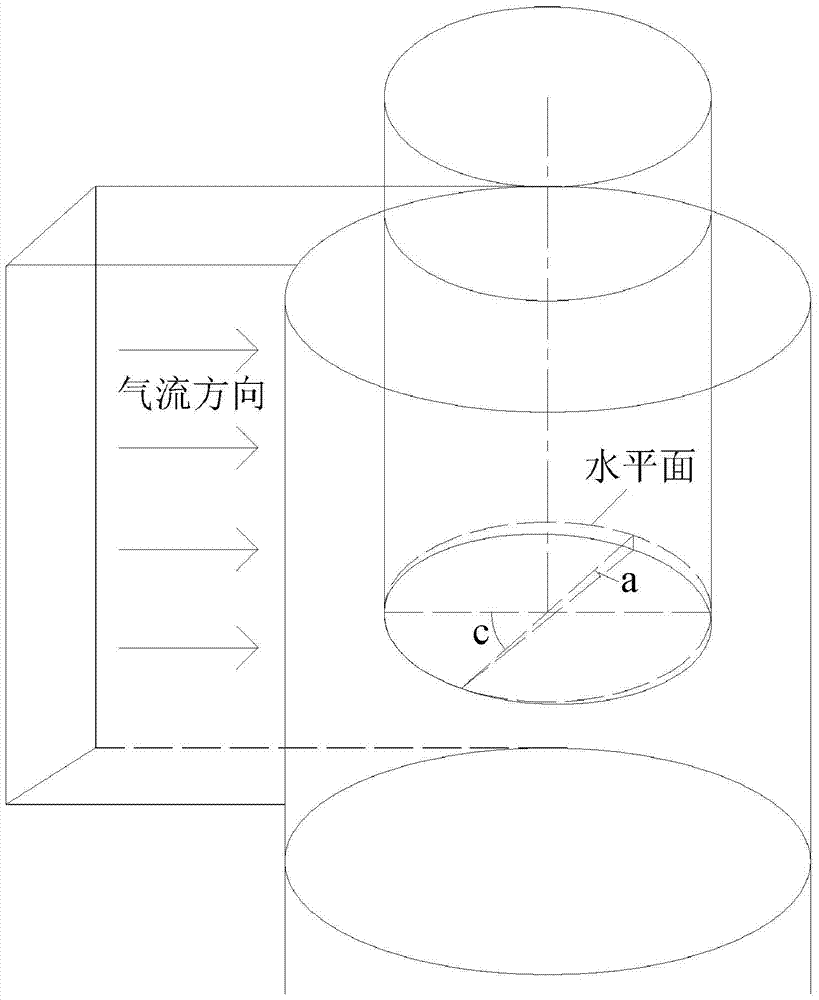

[0044] The angle a between the air inlet section of the central cylinder 3 and the horizontal plane is 10°. There is an included angle c of 30° between the vertical plane where the long axis of the air inlet section is located and the vertical plane where the airflow direction is located. The top of the central cylinder 3 is fixed in a free hanging manner, and can be freely matched and relatively slid with the cyclone separator body 2 . The outlet sectional area of the tap...

Embodiment 2

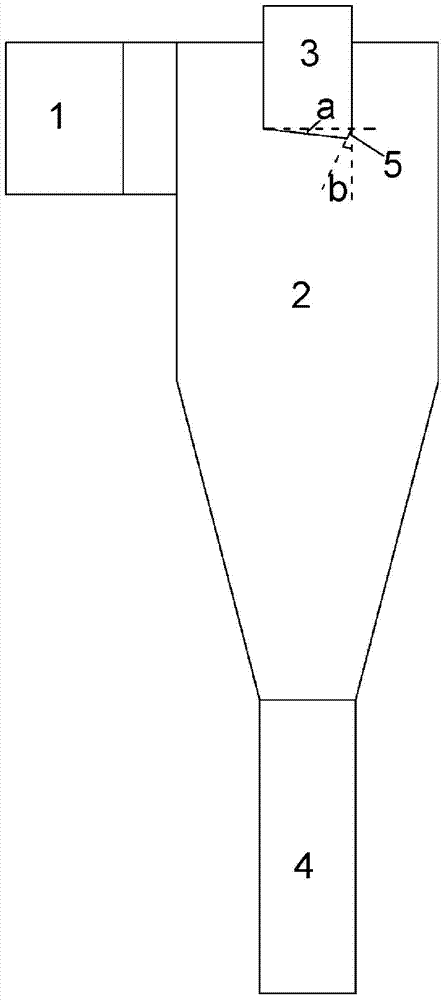

[0046] Such as figure 2 , image 3 As shown, a cyclone separator with an inclined air inlet of the central cylinder includes a tapered inlet flue 1 , a cyclone separator body 2 , a central cylinder 3 , and a separator standpipe 4 . Wherein, the tapered inlet flue 1 is connected to the side of the separator body 2, the lower part of the separator body 2 is connected to the upper part of the separator standpipe 4, and the central cylinder 3 is inserted into the separator body 2 from the upper part of the separator body 2.

[0047]The cross-section of the air inlet of the central cylinder 3 is in the form of closing, and the effect of reducing the cross-sectional area of the entrance of the central cylinder 3 is achieved by adding a closing cover plate 5 . The angle a between the air inlet section of the central cylinder 3 and the horizontal plane is 5°. There is an included angle b between the closing cover plate 5 and the vertical plane, which is 15°. The vertical plane w...

Embodiment 3

[0049] Such as figure 2 , Figure 4 As shown, a cyclone separator with an inclined air inlet of the central cylinder includes a tapered inlet flue 1 , a cyclone separator body 2 , a central cylinder 3 , and a separator standpipe 4 . Wherein, the tapered inlet flue 1 is connected to the side of the separator body 2, the lower part of the separator body 2 is connected to the upper part of the separator standpipe 4, and the central cylinder 3 is inserted into the separator body 2 from the upper part of the separator body 2.

[0050] The air inlet section of central tube 3 can be made up of an oblique plane and a horizontal plane, and the maximum length of the horizontal plane along the oblique direction is m is 50% of the diameter D of the central cylinder 3, and the height difference of the oblique plane in the vertical direction is n is 15% of the diameter D of the central cylinder 3 . The angle c between the vertical plane where the long axis of the air inlet section is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com