Post-processing method for polypropylene powder

A polypropylene powder and powder technology, applied in the petrochemical field, can solve problems such as reducing unit consumption, and achieve the effects of reducing unit consumption, reducing floor space, and simplifying process and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

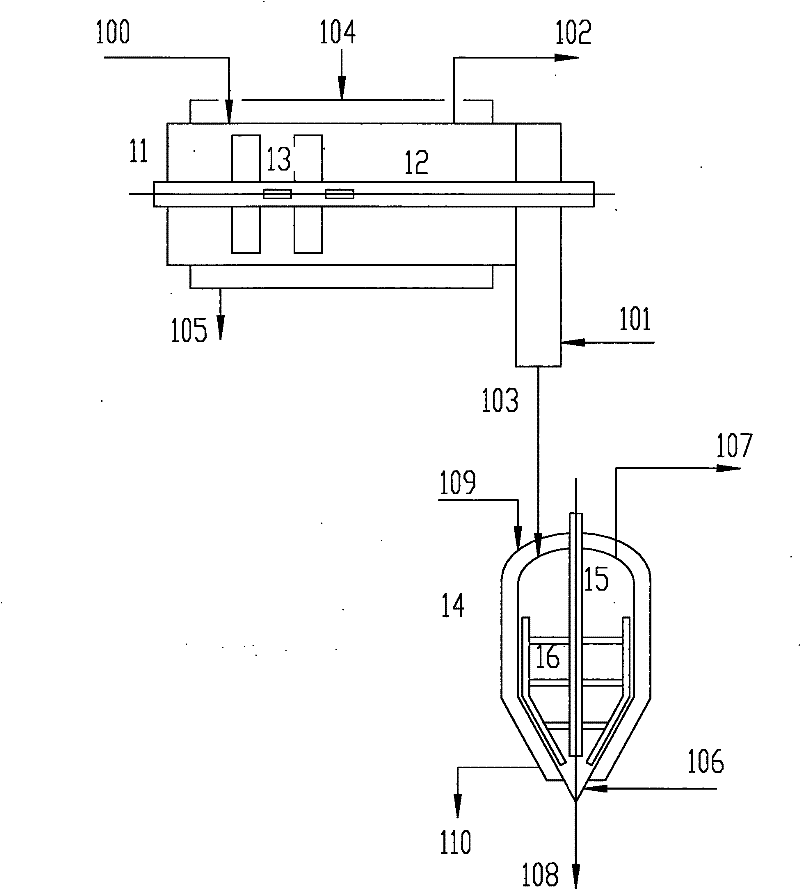

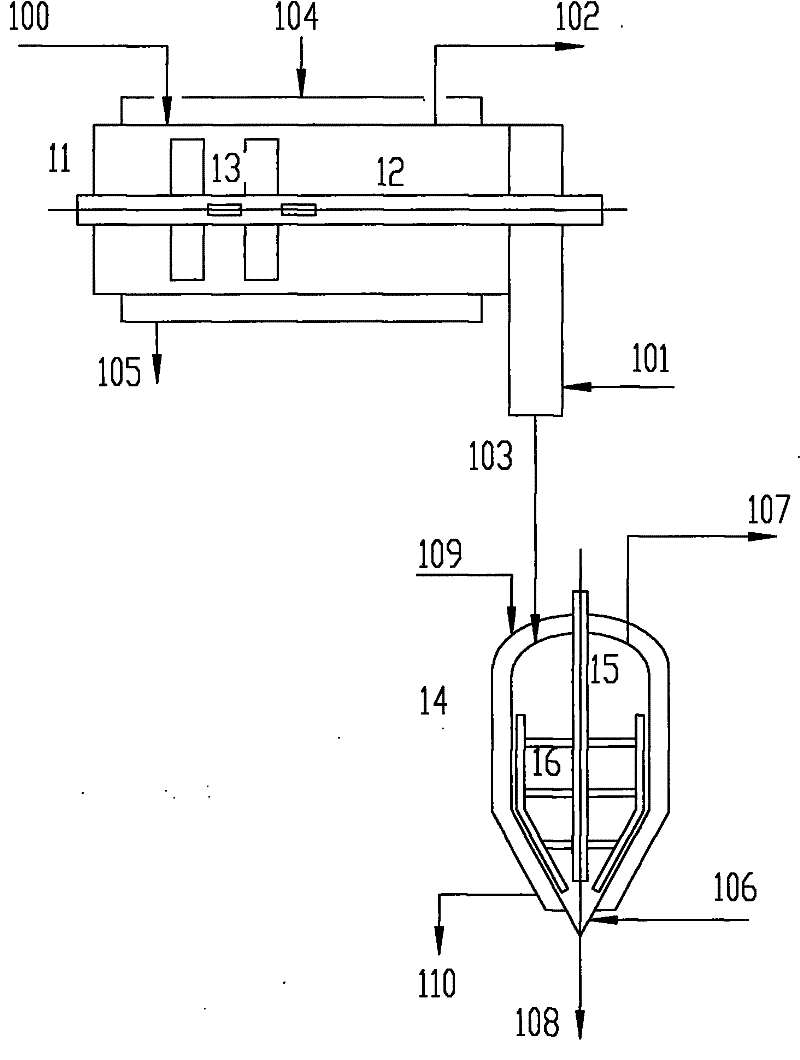

[0026] Embodiment 1: as attached figure 1 As shown, the steam dryer 11 is a powder material heater (paddle dryer) that feeds direct steam, the operating pressure is 0.006Mpag, and the heating area is 70 square meters. 12 is a stirring shaft, and 13 is a stirring paddle. After the gas / solid separation of the polymer leaving the polymerization tank, the polypropylene powder 100 entering the steam dryer 11 is 4000kg / hr, and the hydrocarbons carried are about 100kg / hr. The direct water vapor passed into the steam dryer 11 101 is 100kg / hr. The heating steam enters the jacket of 11 through 104, and the steam condensate leaves the jacket of 11 through 105. The inside of 12 and 13 can pass into heating steam, discharge steam condensate (not represented on the figure). The polypropylene powder is heated to 105°C in the steam dryer 11. Under the joint action of heating, stirring and water vapor replacement, hydrocarbons (volatile matter) escape from the powder and are recovered by 10...

Embodiment 2

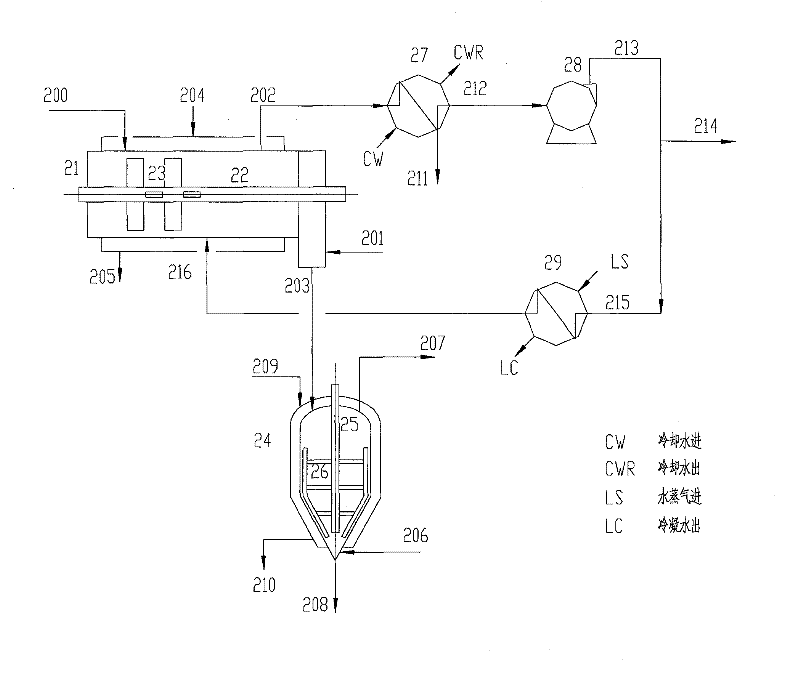

[0029] Embodiment 2: as attached figure 2 as shown,

[0030] The steam dryer 21 is a powder material heater (paddle dryer) that feeds direct steam, the operating pressure is 0.006Mpag, and the heating area is 70 square meters. 22 is a stirring shaft, and 23 is a stirring blade. After the gas / solid separation of the polymer leaving the polymerization tank, the polypropylene powder 200 entering the steam dryer 21 is 4000kg / hr, and the hydrocarbons carried are about 100kg / hr. The direct water vapor passed into the steam dryer 21 201 is 100kg / hr. The heating steam enters the jacket of 21 through 204 , and the steam condensate leaves the jacket of 21 through 205 . The inside of 22 and 23 can pass into heating steam, discharge steam condensate (not represented on the figure). The polypropylene powder is heated to 105° C. in the steam dryer 21 , and under the combined action of heating, stirring, and water vapor replacement, hydrocarbons (volatile matter) escape from the powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com